Professional Documents

Culture Documents

Astm A514 A514m 14

Astm A514 A514m 14

Uploaded by

Mohamed AboelkhierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A514 A514m 14

Astm A514 A514m 14

Uploaded by

Mohamed AboelkhierCopyright:

Available Formats

Designation: A514/A514M − 14

Standard Specification for

High-Yield-Strength, Quenched and Tempered Alloy Steel

Plate, Suitable for Welding1

This standard is issued under the fixed designation A514/A514M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 4. Materials and Manufacture

1.1 This specification covers quenched and tempered alloy 4.1 The steel shall be killed and conform to the require-

steel plates of structural quality in thicknesses of 6 in. [150 ments for fine austenitic grain size in Specification A6/A6M.

mm] and under intended primarily for use in welded bridges

and other structures. 5. Heat Treatment

NOTE 1—All grades are not available in a maximum thickness of 6 in.

5.1 Except as allowed by 5.2, plates shall be heat treated to

[150 mm]. See Table 1 for thicknesses available in each grade. conform to the tensile and hardness requirements given in

Table 2 by heating to not less than 1650°F [900°C], quenching

1.2 If the steel is to be welded, it is presupposed that a

in water or oil, and tempering at not less than 1150°F [620°C].

welding procedure suitable for the grade of steel and intended

The heat-treatment temperatures shall be reported in the test

use or service will be utilized. See Appendix X 3 of Specifi-

report.

cation A6/A6M for information on weldability.

5.2 Plates ordered without the heat treatment specified in

1.3 The values stated in either inch-pound units or SI units

5.1 shall be stress relieved by the manufacturer, and subsequent

are to be regarded separately as standard. Within the text, the

heat treatment of the plates to conform to 5.1 shall be the

SI units are shown in brackets. The values stated in each

responsibility of the purchaser.

system are not exact equivalents; therefore, each system is to

be used independently of the other, without combining values 6. Chemical Composition

in any way.

6.1 The heat analysis shall conform to the requirements

2. Referenced Documents given in Table 1.

2.1 ASTM Standards:2 6.2 The product analysis shall conform to the requirements

A6/A6M Specification for General Requirements for Rolled given in Table 1, subject to the product analysis tolerances in

Structural Steel Bars, Plates, Shapes, and Sheet Piling Specification A6/A6M.

A370 Test Methods and Definitions for Mechanical Testing 7. Mechanical Properties

of Steel Products

7.1 Tension Test—The plates as represented by the tension

3. General Requirements for Delivery test specimens shall conform to the tensile requirements given

in Table 2.

3.1 Plates furnished under this specification shall conform

to the applicable requirements of the current edition of Speci- 7.2 Hardness Test—For plates 3⁄8 in. [10 mm] and under in

fication A6/A6M unless a conflict exists in which case this thickness, a Brinell hardness test may be used instead of

specification shall prevail. tension testing each plate, in which case a tension test shall be

made from a corner of each of two plates per lot. A lot shall

consist of plates from the same heat, thickness, prior condition,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, and scheduled heat treatment and shall not exceed 15 tons [15

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Mg] in weight [mass]. A Brinell hardness test shall be made on

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock and Ships.

Current edition approved May 1, 2014. Published May 2014. Originally

each plate not tension tested and the results shall conform to

approved in 1964. Last previous edition approved in 2013 as A514/A514M – 13. the hardness requirements given in Table 2.

DOI: 10.1520/A0514_A0514M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8. Number of Tests

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 8.1 Except as allowed by 7.2, one tension test shall be taken

the ASTM website. from a corner of each plate as heat treated.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A514/A514M − 14

TABLE 1 Chemical Requirements (Heat Analysis)

NOTE 1—Where “. . .” appears in this table, there is no requirement.

Chemical Composition, %

Grade A Grade B Grade E Grade F Grade H Grade P Grade Q Grade S

Maximum Thickness, in. [mm]

Element 11⁄4 [32] 11⁄4 [32] 6 [150] 21⁄2 [65] 2 [50] 6 [150] 6 [150] 21⁄2 [65]

Carbon 0.15–0.21 0.12–0.21 0.12–0.20 0.10–0.20 0.12–0.21 0.12–0.21 0.14–0.21 0.11–0.21

Manganese 0.80–1.10 0.70–1.00 0.40–0.70 0.60–1.00 0.95–1.30 0.45–0.70 0.95–1.30 1.10–1.50

Phosphorus, max 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030

Sulfur, max 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.020

Silicon 0.40–0.80 0.20–0.35 0.20–0.40 0.15–0.35 0.20–0.35 0.20–0.35 0.15–0.35 0.15–0.45

Nickel ... ... ... 0.70–1.00 0.30–0.70 1.20–1.50 1.20–1.50 ...

Chromium 0.50–0.80 0.40–0.65 1.40–2.00 0.40–0.65 0.40–0.65 0.85–1.20 1.00–1.50 ...

Molybdenum 0.18–0.28 0.15–0.25 0.40–0.60 0.40–0.60 0.20–0.30 0.45–0.60 0.40–0.60 0.10–0.60

A

Vanadium ... 0.03–0.08 0.03–0.08 0.03–0.08 ... 0.03–0.08 0.06

B

Titanium ... 0.01–0.10 0.01–0.10 ... ... ... ...

Zirconium 0.05–0.15C ... ... ... ... ... ... ...

Copper ... ... ... 0.15–0.50 ... ... ... ...

Boron 0.0025 max 0.0005–0.005 0.001–0.005 0.0005–0.006 0.0005–0.005 0.001–0.005 ... 0.001–0.005

Columbium, max ... ... ... ... ... ... ... 0.06

A

May be substituted for part or all of titanium content on a one for one basis.

B

Titanium may be present in levels up to 0.06 % to protect the boron additions.

C

Zirconium may be replaced by cerium. When cerium is added, the cerium/sulfur ratio should be approximately 1.5 to 1, based upon heat analysis.

TABLE 2 Tensile and Hardness Requirements

NOTE 1— See the Orientation and Preparation subsections in the Tension Tests section of Specification A6/A6M.

NOTE 2—Where “. . .’’ appears in this table there is no requirement.

Thickness, in. [mm] Tensile Strength, Yield Strength, minA , Elongation in 2 Reduction Brinell

ksi [MPa] ksi [MPa] in. [50 mm], of Area, Hardness

minBCD , % minBC , % NumberE

To 3⁄4 [20], incl 110 to 130 [760 to 895] 100 [690] 18 40F 235 to 293 HBW

Over 3⁄4 [20] to 21⁄2 [65], incl 110 to 130 [760 to 895] 100 [690] 18 40F , 50G ...

Over 21⁄2 [65] to 6 [150], incl 100 to 130 [690 to 895] 90 [620] 16 50G ...

A

Measured at 0.2 % offset or 0.5 % extension under load as described in the Determination of Tensile Properties section of Test Methods and Definitions A370.

B

Elongation and reduction of area need not be determined for floor plates.

C

For plates tested in the transverse direction, the elongation requirement is reduced by two percentage points and the reduction of area minimum requirement is reduced

by five percentage points. See elongation requirement adjustments in the Tension Tests section of Specification A6/A6M.

D

If measured on the Fig. 3 (Test Methods and Definitions A370) 11⁄2-in. [40-mm] wide tension test specimen, the elongation is determined in a 2-in. [50-mm] gage length

that includes the fracture and shows the greatest elongation.

E

See 7.2.

F

If measured on the Fig. 3 (Test Methods and Definitions A370) 11⁄2-in. [40-mm] wide tension test specimen.

G

If measured on the Fig. 4 (Test Methods and Definitions A370) 1⁄2-in. [12.5-mm] round tension test specimen.

9. Retest test specimens from separate pieces, such pieces shall be full

9.1 Plates that were subjected to Brinell hardness testing thickness, and shall be similarly and simultaneously heat

and failed to conform the specified hardness requirements may treated with the plate. All such separate pieces shall be of such

be subjected, at the manufacturer’s option, to tension testing a size that the prepared test specimens are free of any variation

and shall be accepted if the results conform to the tensile in properties due to edge effects.

requirements given in Table 2. 10.2 If specified in the purchase order, the test pieces shall

9.2 The manufacturer may re-heat treat plates that fail to be subjected to additional thermal treatments intended to

meet the mechanical property requirements of this specifica- simulate thermal treatments that subsequently might be done

tion. All mechanical property tests shall be repeated after such by the fabricator.

heat treatment.

11. Keywords

10. Test Specimens

10.1 If possible, all test specimens shall be cut from the 11.1 alloy; bridges; high-yield-strength; plates; quenched;

plate in its heat-treated condition. If it is necessary to prepare steel; structural steel; tempered; welded construction

Copyright by ASTM Int'l (all rights reserved); 2

A514/A514M − 14

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the purchase order or contract.

Standardized supplementary requirements for use at the option of the purchaser are listed in

Specification A6/A6M. Those that are considered suitable for use with this specification are listed by

title:

S5. Charpy V-Notch Impact Test S8. Ultrasonic Examination

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A514/A514M – 13) that may impact the use of this standard. (Approved May 1, 2014.)

(1) Modified titanium range for Grade B in Table 1.

Committee A01 has identified the location of selected changes to this standard since the last issue

(A514/A514M – 05 (2009)) that may impact the use of this standard. (Approved Oct. 15, 2013.)

(1) Revised Table 1 to modify phosphorus and sulfur limits.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 3

You might also like

- Strength of Materials: Theory and ExamplesFrom EverandStrength of Materials: Theory and ExamplesRating: 4 out of 5 stars4/5 (14)

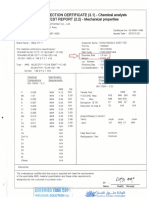

- MTC For Esab 1.60mm Dia. Flux Cored Welding WireDocument1 pageMTC For Esab 1.60mm Dia. Flux Cored Welding Wireaahil ahmad100% (1)

- Bioquimica-Del AguaDocument40 pagesBioquimica-Del AguaNicolas75% (4)

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsFrom EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Saw Flux Wire CombinationDocument1 pageSaw Flux Wire Combinationaahil ahmadNo ratings yet

- Saw Flux Wire CombinationDocument1 pageSaw Flux Wire Combinationaahil ahmadNo ratings yet

- Stroke - Physiotherapy Treatment Approaches - Physiopedia PDFDocument25 pagesStroke - Physiotherapy Treatment Approaches - Physiopedia PDFBeta100% (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

- Thermodynamic Degradation Science: Physics of Failure, Accelerated Testing, Fatigue, and Reliability ApplicationsFrom EverandThermodynamic Degradation Science: Physics of Failure, Accelerated Testing, Fatigue, and Reliability ApplicationsNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Coating-Failure-Defects 3Document10 pagesCoating-Failure-Defects 3aahil ahmadNo ratings yet

- Coating-Failure-Defects 2 PDFDocument10 pagesCoating-Failure-Defects 2 PDFaahil ahmadNo ratings yet

- Coating-Failure-Defects 2 PDFDocument10 pagesCoating-Failure-Defects 2 PDFaahil ahmadNo ratings yet

- Coating Failures and Defects: A Comprehensive Field GuideDocument10 pagesCoating Failures and Defects: A Comprehensive Field Guideaahil ahmadNo ratings yet

- 3rd Class Gusse Ka Anth NotesDocument5 pages3rd Class Gusse Ka Anth Notesaahil ahmad100% (1)

- Stud Welding MTCDocument3 pagesStud Welding MTCaahil ahmadNo ratings yet

- ASTM A385 - 2011 (Scallop, Notch Cutting)Document9 pagesASTM A385 - 2011 (Scallop, Notch Cutting)aahil ahmadNo ratings yet

- Part1 PDFDocument22 pagesPart1 PDFaahil ahmadNo ratings yet

- PART2Document14 pagesPART2aahil ahmadNo ratings yet

- Computer KraamamDocument166 pagesComputer Kraamamaahil ahmadNo ratings yet

- PlumsDocument17 pagesPlumsM.P. SeenivasanNo ratings yet

- Características Anatómicas y Fisiológicas Del Recien NacidoDocument25 pagesCaracterísticas Anatómicas y Fisiológicas Del Recien NacidoZoila Salazar Chavez50% (2)

- Motorola APX2500 Specification Sheet ENGDocument4 pagesMotorola APX2500 Specification Sheet ENGAdrian McGannNo ratings yet

- 1.6 Actividades de Repaso-Equipo 3Document8 pages1.6 Actividades de Repaso-Equipo 3Música para dormir y másNo ratings yet

- Product Catalogue Launcher and ReceiverDocument49 pagesProduct Catalogue Launcher and Receiverraja syahNo ratings yet

- Fletamento MaritimoDocument88 pagesFletamento MaritimoKelly Cordova100% (1)

- General Physics 1 CGDocument311 pagesGeneral Physics 1 CGCristine Quizano50% (2)

- Mapa Mental - Informe de Sostenibilidad ALPINA.Document1 pageMapa Mental - Informe de Sostenibilidad ALPINA.Rafael David Baron PoloNo ratings yet

- DK Did You Know SpaceDocument146 pagesDK Did You Know SpaceDiego Zambrano100% (6)

- Guia de Redacción - Proyecto de InvestigaciónDocument9 pagesGuia de Redacción - Proyecto de InvestigaciónMajo RodríguezNo ratings yet

- Guia Da Brincadeira: Espaços, Estratégias e Atividades para Dinamizar Os Recreios EscolaresDocument54 pagesGuia Da Brincadeira: Espaços, Estratégias e Atividades para Dinamizar Os Recreios EscolaresADRC CulturalNo ratings yet

- Lime and Dolomite For The Steel IndustryDocument8 pagesLime and Dolomite For The Steel IndustrychmsarfrazNo ratings yet

- Determinación Del Peso Especifico de Un Suelo Arcilloso Mediante El Metodo de La ParafinaDocument5 pagesDeterminación Del Peso Especifico de Un Suelo Arcilloso Mediante El Metodo de La ParafinaACOSTANo ratings yet

- ClinaDocument12 pagesClinaKatty Olanda Cornejo ChaconNo ratings yet

- A Process and Control Simulator For Large Scale Cryogenic PlantsDocument10 pagesA Process and Control Simulator For Large Scale Cryogenic PlantsLasse AhrendsenNo ratings yet

- Poblaciones Originarias de LimaDocument13 pagesPoblaciones Originarias de LimaLuis Bazan MazuelosNo ratings yet

- Terawins Video Display Controller Selection GuideDocument1 pageTerawins Video Display Controller Selection GuideSonic SabacNo ratings yet

- GM VialdiDocument6 pagesGM VialdiAlexander GallardoNo ratings yet

- Le Suivi Des Comptes Clients Et FournisseursDocument5 pagesLe Suivi Des Comptes Clients Et FournisseursmedkoNo ratings yet

- Dosage MultiDocument7 pagesDosage Multifarida71No ratings yet

- Protocolo Alimentar - João Victor - Fase1Document10 pagesProtocolo Alimentar - João Victor - Fase12nnqrffsc6No ratings yet

- Higiene Alimentaria y Plan General de EmergenciaDocument79 pagesHigiene Alimentaria y Plan General de EmergenciaEd Torres GtzNo ratings yet

- Mason Connie - Valiente Corazon de LeonDocument234 pagesMason Connie - Valiente Corazon de Leon1312295841No ratings yet

- 1 - Lectura - Cartilla de Lectura Fonética en Español (Enseñar A Leer)Document67 pages1 - Lectura - Cartilla de Lectura Fonética en Español (Enseñar A Leer)mirshalizNo ratings yet

- Ensayo Sobre Bibliografia de Steve Jobs - Diaz AndresDocument19 pagesEnsayo Sobre Bibliografia de Steve Jobs - Diaz AndresCristal TorresNo ratings yet

- 1 Wire Instruction ManulalDocument6 pages1 Wire Instruction ManulalhdnutzNo ratings yet

- Metodología para La Socialización Sobre La Implementación, Descripción y Caracterización de La Política de Prevención y Control de La Contaminación Del AireDocument15 pagesMetodología para La Socialización Sobre La Implementación, Descripción y Caracterización de La Política de Prevención y Control de La Contaminación Del AireAndrés Morales SedanoNo ratings yet

- Resumen EjesDocument5 pagesResumen EjesIlseSarahiMartinezNo ratings yet