Professional Documents

Culture Documents

Yageo LR FMP 1

Uploaded by

nanodocl5099Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yageo LR FMP 1

Uploaded by

nanodocl5099Copyright:

Available Formats

Through-hole resistors

High Power &

Metal Film Resistors Flame-Proof Type

Ultra Miniature Style [ FMP Series ]

FEATURES

Power Rating 1/2W, 1W, 2W, 3W

Resistance Tolerance ±1%, ±5%

T.C.R. ±100ppm/°C

Flameproof Multi-layer Coating Meets UL-94V-0

Flameproof Feature Meets Overload Test UL-1412

INTRODUCTION DERATING CURVE

The FMP Series Metal Film High Power For resistors operated in ambient temperatures above 70°C, power rating must be derated

Resistors are manufactured using a vacuum in accordance with the curve below.

sputtering system to deposit multiple layers of

Rated Load (%) 70 155 °C

mixed metal alloys and passivative materials 100

onto a carefully treated high grade ceramic 80

substrate. After a helical groove has been cut

60

in the resistive layer, tinned connecting leads of

40

electrolytic copper are welded to the end-caps.

20

The resistors are coated with layers of pink

color lacquer. 20 40 60 80 100 120 140 160 Ambient Temperature (°C)

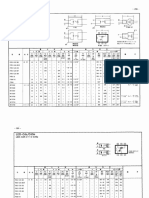

DIMENSIONS Unit: mm

STYLE DIMENSION

Ultra Miniature L øD H ød

FMP-50 3.4±0.3 1.9±0.2 28±2.0 0.45±0.05

ød

FMP100 6.3±0.5 2.4±0.2 28±2.0 0.55±0.05

H L øD

FMP200 9.0±0.5 3.9±0.3 26±2.0 0.55±0.05

FMP3WS 11.5±1.0 4.5±0.5 35±2.0 0.8±0.05

FMP300 15.5±1.0 5.0±0.5 33±2.0 0.8±0.05

Downloaded from Arrow.com.

15

Note:

ELECTRICAL CHARACTERISTICS

STYLE FMP-50 FMP100 FMP200 FMP3WS FMP300

Power Rating at 70°C 1/2W 1W 2W 3W

Maximum Working Voltage 200V 350V 500V 750V

Maximum Overload Voltage 400V 600V 700V 1,000V

Voltage Proof on Insulation 300V 500V

Resistance Range 1Ω - 4M7Ω & for E24 & E96 series value

Operating Temp. Range -55°C to +155°C

Temperature Coefficient ±100ppm/°C , ±50ppm/°C (FMP-50 & FMP100 types, R ≥ 10RΩ)

Note: Special value is available on request

ENVIRONMENTAL CHARACTERISTICS

PERFORMANCE TEST TEST METHOD APPRAISE

Short Time Overload IEC 60115-1 4.13 2.5 times RCWV for 5 sec. (Not more than maximum Overload Voltage) ±1.0%+0.05Ω

Voltage Proof on Insulation IEC 60115-1 4.7 In V-Block for 60 sec., test voltage as above table No Breakdown

Temperature Coefficient IEC 60115-1 4.8 Between -55°C to +155°C By type

Insulation Resistance IEC 60115-1 4.6 in V-block for 60 Sec. >1,000MΩ

Solderability IEC 60115-1 4.17 245±5°C for 3±0.5 Sec. 95% Min. coverage

No deterioration of

Solvent Resistance of Marking IEC 60115-1 4.30 IPA for 5±0.5 Min. with ultrasonic

coatings and markings

Robustness of Terminations IEC 60115-1 4.16 Direct load for 10 Sec. in the direction of the terminal leads ≥2.5kg (24.5N)

Periodic-pulse Overload IEC 60115-1 4.39 4 times RCWV 10,000 cycles (1 Sec. on, 25 Sec. off) ±1.0%+0.05Ω

Damp Heat Steady State IEC 60115-1 4.24 40±2°C, 90-95% RH for 56 days, loaded with 0.1 times RCWV ±2.0%+0.05Ω

Endurance at 70°C IEC 60115-1 4.25 70±2°C at RCWV (or Umax., Whichever less) for 1,000 Hr. (1.5Hr.on, 0.5Hr. Off) ±2.0%+0.05Ω

Temperature Cycling IEC 60115-1 4.19 -55°C Room Temp. +155°C Room Temp. (5 cycles) ±1.0%+0.05Ω

Resistance to Soldering Heat IEC 60115-1 4.18 260±3°C for 10±1 Sec., immersed to a point 3±0.5mm from the body ±0.25%+0.05Ω

No evidence of flaming

Accidental Overload Test IEC 60115-1 4.26 4 times RCWV for 1 Min.

or arcing

Note: RCWV(Rated Continuous Working Voltage) = Power Rating x Resistance Value or Max. working voltage listed above, whichever less. Revision: 2020

Downloaded from Arrow.com.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kbu8 SerDocument3 pagesKbu8 SerPablo RiscoNo ratings yet

- Express 5-25, 5-50 (1)Document8 pagesExpress 5-25, 5-50 (1)nanodocl5099No ratings yet

- MSP430C11x1, MSP430F11x1A Mixed Signal Microcontroller: DescriptionDocument47 pagesMSP430C11x1, MSP430F11x1A Mixed Signal Microcontroller: DescriptionasdfghjNo ratings yet

- st100, st200_seriesDocument29 pagesst100, st200_seriesnanodocl5099No ratings yet

- www_xenons_cn_x6090-small-flatbed-printer-p00237p1_htmlDocument4 pageswww_xenons_cn_x6090-small-flatbed-printer-p00237p1_htmlnanodocl50990% (1)

- 5t-31 4miniaturebayonetbaseDocument1 page5t-31 4miniaturebayonetbaseDIPAK SINGHANo ratings yet

- EX330_UMDocument20 pagesEX330_UMnanodocl5099No ratings yet

- fx90_delay_operation_manualDocument2 pagesfx90_delay_operation_manualnanodocl5099No ratings yet

- 1987IbanezPowerSeriesDocument5 pages1987IbanezPowerSeriesnanodocl5099No ratings yet

- Express 5-25, 5-50 (1)Document8 pagesExpress 5-25, 5-50 (1)nanodocl5099No ratings yet

- hfe_marantz_cd-50_serviceDocument28 pageshfe_marantz_cd-50_servicenanodocl5099No ratings yet

- brofil 6040-b21Document2 pagesbrofil 6040-b21nanodocl5099No ratings yet

- LOA - TemplateEurope 1 1 (3)Document1 pageLOA - TemplateEurope 1 1 (3)nanodocl5099No ratings yet

- TI LM319 DATASHEET - RETROAMPLISDocument27 pagesTI LM319 DATASHEET - RETROAMPLISnanodocl5099No ratings yet

- Vox Cambridge 30Document1 pageVox Cambridge 30nanodocl5099No ratings yet

- mn3003Document5 pagesmn3003nanodocl5099No ratings yet

- ST p14nf12 PDFDocument15 pagesST p14nf12 PDFwertingoNo ratings yet

- Samsung KSK117 Datasheet - RetroamplisDocument5 pagesSamsung KSK117 Datasheet - Retroamplisnanodocl5099No ratings yet

- NEC EC2 RELAY DATASHEET - RETROAMPLISDocument8 pagesNEC EC2 RELAY DATASHEET - RETROAMPLISnanodocl5099No ratings yet

- XJW01 LCR Bridge ManualDocument24 pagesXJW01 LCR Bridge Manualnanodocl5099No ratings yet

- Moririca MCD735 optoDocument2 pagesMoririca MCD735 optonanodocl5099No ratings yet

- 2N3390 2N3391 2N3391A 2N3392 2N3393: NPN General Purpose AmplifierDocument7 pages2N3390 2N3391 2N3391A 2N3392 2N3393: NPN General Purpose Amplifiercarlos16702014No ratings yet

- High Voltage, Solid State Relay OptocouplerDocument4 pagesHigh Voltage, Solid State Relay OptocouplerTony LingNo ratings yet

- 2N5950 PDFDocument3 pages2N5950 PDFnanodocl5099No ratings yet

- 2sa970-2sc2240 CdilDocument5 pages2sa970-2sc2240 Cdilnanodocl5099No ratings yet

- 2sa1837-Kta1837 Datasheet - RetroamplisDocument2 pages2sa1837-Kta1837 Datasheet - Retroamplisnanodocl5099No ratings yet

- 1x40 Pin AngledDocument1 page1x40 Pin Anglednanodocl5099No ratings yet

- 2n5087 CDIL Datasheet - RetroamplisDocument5 pages2n5087 CDIL Datasheet - Retroamplisnanodocl50990% (1)

- 2n5462 National Semiconductor PDFDocument1 page2n5462 National Semiconductor PDFnanodocl5099No ratings yet