Professional Documents

Culture Documents

Deswik. Drill & Blast - Ugdb

Deswik. Drill & Blast - Ugdb

Uploaded by

Johnny Pachecoc0 ratings0% found this document useful (0 votes)

221 views204 pagesPV deswik

Original Title

DESWIK. DRILL & BLAST -UGDB

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPV deswik

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

221 views204 pagesDeswik. Drill & Blast - Ugdb

Deswik. Drill & Blast - Ugdb

Uploaded by

Johnny PachecocPV deswik

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 204

L Deswik

Delivering mining efficiency

Training Tutorial

C00

000

0°20

Deswik.UGDB

Underground Drill & Blast

Underground Metals

Module ID: 4.07

Duration: 1 day

Poe

COPYRIGHT

Copyright aver this clocument and any accompanying modlels or data is reserved by Deswik Wlining Consultants

(Australia) Pty Ltd ("Deswik"). This dacument is only to be used by the Client under Lhe Lerms outlined herein, It

may not he distributed, reproduced or circulated in any way. It may not be edited! or amended! in any way, unless

expressly agreed ro by Deswik, Products and registered lagas referred to in this document are ti

respective owners and these trademarks are hereby acknowledged,

emarks of their

CONFIDENTIALITY

This tutorial is subject to Deswik Standard Terms and Conditions which detail the confidentiality obligations of

both Deswik and the Client. The Client should treat this tutorial and any accompanying documents, models or

data as confidential at all times,

VERSION CONTROL

Asummaty of the revision history of thi

document follows:

version | Bulle Date Comments

Number | Number | — Modified

40 | 40 | Sept2013 Release

ar [4a Sept 2015 Update branding, images and text

50 | 2o161 | oct 2016 Update in tre with sofware changes andversion control

2 (Page

cea

1. Introduction ae 7

2. Learning Objectives 8

3. Setup samen seg 9

3.1. Required Documents z 9

4. Getting Started 10

4.1. Title Block Template . . feo a 10

4.1.1. Format the Template 4

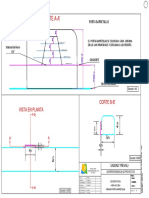

5. Design a Winze Long Section 16

5.1. Create the initial Hole Placements a

5.2, Set the Drillhole Diameter 25

5.3. Generate Reamer Holes . 26

6. Drill and Blast Module 32

6.1, Load the Drill and Blast Module 32

6.1.1 Automatic Loading 33

6.2, Deswik UGDB Navigation 35

7. Ring Design Project Setup 37

7.1, Create a New Project

7.2. Design Line Setup 38

7.3, Select Stope Drive Solids 39

7.4, Standoff 40

7.5, Rig Configurations 4

7.5.1. Drill ig Properties 43

7.5.2 Carousel Properties 43

7.8.3 Drill Bits Configuration

7.5.4 Dump Convention 45

7.5.5 Dip Convention 47

7.5.6 Plotting and Pivots 50

7.6. Primer Rules 51

7.7. Explosives Database ...

‘8. Views and Annotations 54

8.1, View Options

8.2. Hole Annotations ..

9. Winze Long Section Placement 57

410. Ring Placement eee wo 68

10.1. Manual Ring Placement .. . 68

10.1.1 Manually Select Ring Position _ 69

10.1.2 Distance along Reference Line ...... _ 70

10.2, Automatic Ring Placements R

10.2.1 Ring Naming Settings

10.2.2 Placing Options .....

10.2.3 Dump and Azimuth Settings ..

11, Automatic Hole Placement and Charging .

11.1, Ring Selection 80

11.2, Automatic Hole Placement Setup ..... 81

11.3. Pivot Configuration ...... ce 82

11.4. Drillholes .. oo 84

11.4.1. Automatic Hole Configuration... be 84

11.4.2 Automatic Fan Holes . eeseeneeee BG

11.4.3 Fan Hole Constraints . 87

11.4.3.1 Complete the Automatic Hole Placements, . 88

14.5. Automatic Charging ..........0.. - se 7

12, Manual Hole Placement and Charging sslnomaninetaton fowler 102

12.1, Manual Drilhole Placement 102

12.2, Mantaal Charging, ...ccssesscessssonseeessnsseeenee . 105

13. Primer Locations

14. Copy Holes a at

15. Modify Drill Holes ....

4 | Page

15.1. Change Hole Position 4

15.2. Rename Holes

16. Hole Delays .. cossceeetesesseseesetttnsensssesettessen IVT

17. Blast Solids and Interrogation .. ee . N22

17.1, Blast Solid Results 124

17.1.1 interrogation Results .... 126

18. Survey Export 129

19. Plotting .... 133

19.1, Ring Plan Piot .. 133

19.1.1 Ring Plan Viewport - 137

19.1.2 Plotting Tables 138

19.1.3 Update the Title Block ....... cn 141

19.2. Ring Section Plot . 143

19.3. Long Section Plot .. 148

TIA, WiN2€ PIO esc ee eseeeeeettennsnneeenensenneneneeeennen a . wa 152

19.5. Breakthrough Plan 155

20. Appendix A - 159

20.1. APPENDIX A-1, Shared Files . seca eesssesnnsneeee 159

20.2. APPENDIX A-2. Related Configurations 2160

20.2.1 Apply the Related Configuration .......cccccesssssseensnsssssseneesrensneae 162

20.2.2 Remaining Ring Placement 68

20.2.3 Loading Related Configuration a 69

20.2.4 Remaining Configuration Setup oe son 170

20.3. APPENDIX 3, Dumped Drill Rings a . n

20.3.1 Incremental Dump Rings an eee ~ 176

20.4. APPENDIX A. Curved Pivot Lines ......... 79

20.5. APPENDIX A'S, IREDES Export 7 182

20.6. APPENDIX A.6, Automatic Parallel Hole Placement 183

20.6.1 Parallel Holes at Constant Distance . 83

20.6.2 Parallel Hole by Evenly Spaced Holes .. Ie.

20.7. APPENDIX A-7. Annotations

188

20.7.1 Development Labels,

20.7.2 Collar and Toe Markers 196

20.7.3 Intrusion Labels ... 198

20.7.4 Delay Schematic

21. Support 203

21.1, Help Files 203

21.2, Client Portal 203

21.2.1 Client Portal Access, 203

21.3. Support Contacts . 204

6 | Pag

INTRODUCTION

Fast, efficient dri and blast designs for underground mining methods

‘This tutorial includes inst

design and plot ring

ictions and inf

mation on the Des

for atypical underground stoping op

k.UGDB module in Deswik,CAD, You can then

You can then apply these concepts to other underground drilland blast design projects.

cat

course. A thorough knowledge of drill and blast pr

of Deswik.CAD as covered in the

user should be familiar with the bosic oper

factory tr

es is also ed,

71 P%

age

2. LEARNING OBJECTIVES

This tutorial provides an opportunity to design and plot ring designs for a single stope,

At the conclusion of this tutorial, the participant should be able to:

+ Create title blocks for use in platting

nly winze sections

gate the Deswik.UGDB tool

+ Create initial ring design configurations

+ Create and modify rig configurations

+ Setup and apply primer rules

+ Define the explosives database

+ Apply different ring views

+ Design ring placements

+ Design and char

Copy and edit rings

+ Setup blast dela

+ Create and interro last solids

+ Export survey and IREDES data

+ Design various plotting views

+ Design dumping rings

8 | Page

3. SETUP

This module includes the training data folder: 4.07 Deswik.UGDB for UGM Datasets v5.0.

Deore foidertosave te les tatyou generate during this ttt

3.1, REQUIRED DOCUMENTS.

The documents required to complete this tutorial are:

4.07 Deswik.UGDB for UGM Tutorial v5.0 Printed document

4.07 Deswik. UGDB for UGM Data Sets v5.0 Electronic folder

4.07 Deswik.UGDB_A3 Plot Landscape Deswik,CAd file

4.07 Deswik.UGDB_Dumps Deswik.CAO file

4,07 Deswik. UGDB Parallel Holes Deswik.CAD file

4.07 Deswik. UGDB_Related Configurations Deswik.CAD file

4.07 Deswik.UGDB_Orebody

4.07 Deswik UGDB_Main Project Deswik. CAD fle

|

|

| Datamine Block Model file

|

Deswik Logo *PNG file

4,07 Deswik.UGDB for UGM Completed Electronic folder

4.07 Deswik UGDB_Plot A3 Landscape Complete Deswik.CAD file

4.07 Deswik. UGDB_Dumps Complete Deswik.CAD file

4.07 Deswik UGDB. Project Complete Deswik.CAD file

4.07 Deswik, UGDB_ Parallel Holes Complete

4.07 Deswik.UGDB_Winze Model Complete Deswik.CAD file

4.07 Deswik.UGDB_Related Configurations Complete Deswik.CAD file

4.07 Deswik. UGDB_Survey Exports

tronic folde

4.07 Training Project Hales.csv *.csv report file

4.07 Training Project Ring.csv *.csv report file

4.07 Training Project. xt *.dxf survey file

9 | Page

4. GETTING STARTED

on the underground drill and blast module in

training tutorial includes am

sik, CAD,

of theory and prac

@ Atitle block is for print layouts, to define information about the drawings, including.

+ drowing title

+ drow

Q Deswik.CAD has t

CAProgramData\Deswik\Tirleblacks f

ocks designed t

standard paper sizes, are in the

p

4.1, TITLE BLOCK TEMPLATE

This tutorial includes an A3 sized Deswik.CAD file as a template to design the title block.

GQ Pease compete the folowing exercise

Navigate to the data sets folder and select the 4.07 Deswik.UGDB Plot A3 Landscape file

10 | Page

bites

Variable Properties

Agar avi

igntoviewsize °

unerype eyiaver

Liner ypescate

Linetweight LW_BMLAYER +

OuiquAnyie a

2, Click Draw | Text | Block Text to display the Draw BLock Text dialog box

3, Enter: ID in the Tag field, and select <> in the Value list.

4, Replace [Att Name] with [Ring] to ensure the ring ID attributes read from the plane definition,

Teg

FValoe: _<>

ral Charge Meter: | 4 Charge meter <>

Ring Azimuth: la azimuth <>

text value to limit the number of decimal places.

Q Add [0.0]

YQ The completed text shot

resemble the following image:

Ring ID: ID

Total Drill M Drill m Perce S010

| Total Charge Meter: Charge meter mmole emo mies

Re Ma eet) Ree uee vay

Q The atibutes avaiable to ye used within atte block

Field Crea

wath Ring placement (plan view

Burde Burden from displayed ring

sles Number of holes in 1

amelers All diameters of holes within ring

Dil he designed length of all holes

tal Drill he drill depth of all holes including mult-pass holes

13 | Page

cer

charg Total charge length of the ing

Ring tnlvidual ring 10

Configuration Name of dil and blast project

Primers Total number of primers used in ring

Explosive Amount ‘otal explosive amount expected in ring,

Position XYZ coordinates of the ing

Look Direction Direction the rigis facing

Comments Any comments attached to the ring by the use

Repeat the process to create the Following text in the lower-right comer

Interactive Text Height Block Text Tag Corresponding Block Value

Ring Design Training

Layout Name 4 Layout name <<>

Document 4 Document -

Date 4 Date <

Seale 4 scale -

Q _ Me competed ex shoul resemble the following image

Ring Design Training Dear

Siento

Layout Name:Layout name Document: Document

¢ following interactive Lext (height = 4) n the lower-lelt coun

Ganon Signed

nsert a Document Path block text under the borcler (Heigl

file path of the plot displays.

3 and Value = <>), so the

To complete the Lemplate, click Insert | Image from File, to inset a company logo.

Select the Deswik Logo file in the data sets folder

Follow the prampts, and snap the image to the upper-left corner of the template,

@ The con

lete tem s the following

ick Tools | Blocks | Write Title Block File, to save as a temnplat

low the prompts, select everything, and then snap the origin point

nthe TiiLe BLock dialog box, enter Ring Section Plane in the Name fielc

Click OK to save the template in the default Titleblocks folde

Close the 4.07 Deswik,UGDB Plot A3 Landscape ‘ile

left corn

ofthe

DESIGN A WINZE LONG SECTION

‘The winze section for Deswik,UGDB is defined by a winze block file with a certain pattern and attributes,

Create the attributes that define a winze section block ie

ZA, Pease compete the folowing exercise

1. Open anew Deswik.CAD file,

2. Right-click on the base layer, and select Attribute in the lst

3. Add the following attribute settings:

rae Tivpe [Dafa Value [Dapiay [eroup [rompt [values Unt [ami To ust [Descrpton [roma

JWinze ‘String TRUE a oO oO

oto stm a o a

[Diameter Double: a go

Jowmetewunts sting u Q a

[Reamer ‘sting FALSE w Oo a

Jowine suing Tau [ a

opr rom ‘nyto copy properties 4 || & [2 |>= |x

ox ance

|. Click File | Save, and name the Deswik.CAD file: Winze Model

QD) Adeserption foreach atubute inthe flowing table

The contents of the block file is for a winze section. The default value for this,

aLiibute ws always set TRUE for a wince block

HoleIo This attribute identities the holes with a unique numbe

Diameter ple diameter in the selected unit

Diameter Units Hole diameter unit (mm ar inch)

Reamer (clentifies the hole as a veamer hole, soit cloes not get charged

Outline Outline allows the winze boundary polyline to display in ring design.

Ignore Define the entities to ignore when you design the wanze section

16 | Page

5.1, CREATE THE INITIAL HOLE PLACEMENTS

Generate the initial hole placements,

ZG Please complete the following exercise:

1

2

Glick Draw | Circle | Center, Radius, to start drawing the hole

Follow the prompt, and click anywhere in the Model Space to place the circle, then enter 0.0445 as the radius,

Click Modify | Translate to display the TRawstate dialog box.

Select the circle, and enter the fallowing settings:

17 | Page

Entity selection

Visible entities

© Selected Entities - 1

Active layer - 0

Specified layers: a

All Entities - 1

Direction and distance

Distance: 1000/5

Set; [Slope

‘Azimuth:

180.000/5

Dip: 0.00/54

Delta

vx: 0.00013;

by 1.0003] | Pic

0.00013)

attribute

5, Select the four circles and translate them with the following settings:

Entity selection

‘© Visible entities

@ Selected Entities - 4

© Selected Layer

© Active layer - 0

© Specified layers:| 0

Oallentives -4

Base value of

Increment: if}

2B] Cibelete originals

Translate lose

19 | Page

Select the

nd delete it

7. Click Draw | Polyline a

QJ use Format | sop Mode | Center tosnap the

J digitize a polyline in the direction as shown in the following image,

the poiyline.

21 | Page

9, Click Modify | Attributes | Set from Direction, 2

attributes,

er the fallow

12 settings to generate the HolelD

22 | Page

Attributes From Direction, 2

Define direction by

© bigttzing

© Bxisting polyline

Entities to apply attributes to

© Visible entities

© Selected entities - 11

| OSelected layer - 0

© Active layer - 0

| © specified layers:

| Oallentities - 12

© Intersection only

Extend start: [Do Not Extend

Extend end: [Do Not Extend v}{ soo

Group entities by

‘Attributes

tame: [ile

Prete: |

ace value: [1

inorement: | 1.0054} 1 wethin group

10. Click OK, and then click the polyline to set the HoleID attributes on the circles.

23 | Page

5.2. SET THE DRILLHOLE DIAMETER

Set the diameter of the drillnoles,

G Please complete the following exercise:

Select the 11 drillhole circles, and then enter the following attribute values;

+ Diameter = 89

+ DiameterUnits = mm

Selected Entities

Fixed Properties,

TypeName CIRCLE

Layer 0

Minimum{ayz} {0.335 j -2.891 ; 0.000}

Maximum(xyz} {2.424 ; 0.198 ; 0.000}

Dettatiy2} {2.089 ; 3.089 ; 0.000}

Area 0.068

Length 3.076

The diameter attributes are to calculate drill meters. The number of passes needed for each aril diameter is

defined in the rig configuration.

25 | Page

5.3. GENERATE REAMER HOLES

Generate the four reamer holes

GY Pease compete the fotowing exercise

1. Change the Pen Color anc Line Type to the folowing setting

Pen Color MI ~ Pen Width: 0 Line Type: aASHoTO +

(D_ onie tons Bo, cick Restore | Show Geneva to display the Drawing Defats toolbar

Draw construction lines to connect the starting hole (HoleID = 6) with the holes at 45°, 135°, 275° and 315)

azimutl

Snap to the

center ofthe

circles,

27

Draw | Circle

Pen Color

Center, Radius

Line Type t

S_ Select Snap to Intersection, and then draw the reamer holes at each of the intersections with 20.106 m.

fers for display and

i bits configura

Select the four reamer holes and update the following attribute values:

+ Diameter 6.

+ DiameterUnits = Inch

+ Reamer = TRUE

Firbutes

Diameter

DiameterUnts

Holetd

Ignore

Outline

Reamer

Wine

7. Enter a unique HolelD for each reamer hole as shown below:

me aware

Delete the red and white construction lines

29 | Page

Dr Je arouy vd ensure the Outline te val

Tools | Blocks | Write Bl

File and save thy ve C:\ProgramData\Deswik\Blocks\Default

e TrainingWinze

Q Chopter Review

Before proceeding to the next chapter, review the list of subjects fram the chapter. The acquired skills and

knowledge should include the ability to:

Bias focus

Open atitle block template file, Title Block Template on page 10

Complete the template with text labels and values, then save as atitle | Format the Template on page 11

block file,

Define the winze design attributes. Design a Winze Long Section on page

16

Create the holes and assign ID attributes. Create the initial Hole Placements on

page 17

Define the drillhole diameter. Set the Drilhole Diameter on page 25

Design the reamer holes and assign ID attributes. Generate Reamer Holes on page 26

Qty te theres covered these oso sino processes

31 | Page

Peer eT e) 18}

Review the development design and geology data to complete the training,

Z Peose complete te fooingeverase:

Open the 4.07 Deswik.UGDB Main Project.

The Deswik.CAD project includes the reference lines, stope solids, development drives, and intrusion (standoff)

solids

e The layer tree should look similar to the following image:

“LID SURVEY

1D TOPOGRAPHY

Fa TOPO_oTm

4 COD AS our (s1RNcs)

LIP 186 Levev

Op tes evel

COB 50 ever

IB too Lever

AB oveve.

0 LEVEL

CID sore 190

COB As But (ors)

+ OB besicw une

COB Riso

«+ Cp stanoorrs

ID INTRUSION SoD

|+ [1B DeveLopment FUNNEL Sous:

|, iB 150 LEVEL

AAD 130 LEVEL

ID store soup

HB iencoeseon

6.1. LOAD THE DRILL AND BLAST MODULE

Deswik, UGB 1uns asa plugin Lo Deswik.CAD, You can load it from the main menu, oF alternatively set it to load

when you open Deswik.CAD.

ZX Peswik.UG0B req

using the module

ives its own license. This means you must load « valid license for Deswik.UGOB before

32 | Pa

6.1.1 AUTOMATIC LOADING

Set the Deswik.UGDB plugin to open each time Deswik.CAD opens.

FG Please complete the following exercise:

1. Glick Tools | Plugin Manager to display the PLUGIN MANAGER,

‘Add arow to the grid to open Windows Explorer.

Select the C:\Program Files\Deswik\Deswik Suite\Deswik.UGDB.all fie.

Select the Load on application startup check box

Select the Restore plugin dock position check box,

Click {Load to open the Deswik.UGDB module.

2 Agreen atrow displays next to the plugin name.

oy aAeE

foe [| [Pm

oad ood

33 | Page

Q) then you open Besik.cAD, the Deswsik.UGbD winaloxe wit oa inthe defoutk position (docked as a tob with

the Layer Contiol window).

esoukustie

Select Active Contigraton

Show Edtor

Settings Wart

i Dotabaca

Framer Or Booster eulos

‘ploswes Oatahase

plore Roles

trite

You ran also lod the Deswik.UGDE module wi the main mena. Click Tooks | Duilland Blast | Bese UGDR

(Underground),

34 | Page:

6.2. DESWIK.UGDB NAVIGATION

‘You can access the Deswik.UGDB options via the main panel, by expanding the menu tabs.

Deswik.uc08 ox

Select Active Configuration

‘Show Eitor

‘Show Wee Edtor

‘Add Winee Section

(mp current winze Setons

Annotation Settings

| oxonucoe Cr

od Many of the options are not available, until you start the design,

35 | Page

You eat alse dick Show Edit

Destens dialog box.

| maton Pes

i |

| ' il

| FEE |

L |

Taco]

A Toadd a new ring design, you must use the editor,

36 | Page:

7. RING DESIGN PROJECT SETUP

‘Assign hole placements to the ring designs. You can access the design rings, winze sections, and create plots via

the RING Destcns dialog box.

7.1, CREATE A NEW PROJECT

The Ring Options tab allows the user to change the view of the ring before you place pivot points and holes. It

also allows the user to change physical aspects of the ring such as position, dump and azimuth,

F Please complete the following exercise:

1, Inthe Deswik, UGDB window, click Show Editor to open RING DEsiGns dialog box.

2. Click” to add anew design called TRAINING.

Q The SETTINGS WIZARD displays, and the RING DESIGNS dialog box is hidden.

Settings wizard

‘This wizard guides yu through the steps needed forthe mal

setup of the rings coniguration.

‘Once configured, al ofthese options can be edted wa the |

Sertings tb.

You can ext the wizar at any ime by chching Cancel or by

amply closing the fr

Copy settings fom: | che :

‘ck Nxt to continue

3, Click Next (o proceed to the Desian Lave screen,

37 | Page

7.2. DESIGN LINE SETUP

The design line for this exercise is the centertine of the working drive. I is not necessary to have the design line

inside of the development drive solid.

{tis important to remember that the design ine elevation is where the survey planes are cut. Draw the design

line at the same RL. as the dump pivot point, on the dri ig for the stope. For example, draw the design line at

the floor of the drill drive, and then translate the line to the height ofthe drill rig pivot point.

Design tine

Generate or select a design ine for rig reference.

Design tne output layer:

[RINGOESTGNYTRARUNG PESTON INE

Method of creation:

(os Diaitize on design layer

{aa Copy selected ]

[$a copy from another layer |

L cud |

Q There are three easy ways to create a design line:

+ Digitize on design layer - use this option to digitize a centerline on the DESIGN LINE layer

+ Copy selected - use this option to copy the design line to the DESIGN LINE layer.

+ Copy from another layer - use this option to pick a layer in Deswik.CAD that contains the design tine poly

line entity,

For this tutorial, setup a design centerline with the Copy from another layer option,

38 | Page

GQ rease complete the fotowing exerese:

1. Click Copy from another layer, and then select the DESIGN LINE\RL150 layer,

a0

2 D survey

4 BD Toroceamy

Ff 070.07

4D ASeuer(stRNas)

195 LEVEL,

‘os Level

‘50 Level

sno tevel

‘Ho vevet

so uevet

‘STOPE 130

D Aseutr comms)

p DESIGN UNE

“4B STANDOFES

BD wrusion sou

4B bevevorucnt Tune soups

‘180 Level,

B out

BD store sou

4 ef RINGDESIGN

2 @ TRANG

2. Confirm the selection, and then click

7.3. SELECT STOPE DRIVE SOLIDS

itis not essential to load a stope solid layer into a ring design project. You can design service or utility holes

without having a stope solid layer as a boundary.

39 | Page

Pease comple efeoing execs

1.

2,

3

4

Inthe SToPe SOLIDS AN DEVELOPAENT soLIDs screen, add a row to the Stope solid layers and filters gr.

ciickL Jin the Layer field, and then select the STOPE SOLID layer:

ioe sok ant deve set

Set ter ica he i al be ed refer te rds.

‘ape ayaa ee

ids [Tier nee RW Avelan

Dew devant eaves and Me

ives terme meets car ath ne Type een neat [amatin |

| | Cae

‘Add two rows to the Drive or development solid layers and filters gric,

Select the Following layers:

+ DEVELOPMENT TUNNEL SOLIDS\150 LEVEL

+ DEVELOPMENT TUNNEL SOLIOS\130 LEVEL

eeacepenc nee censHOIFAL Fhe» Cendgment—Y y yw

Ce MLOMENT TINE SASL aeirn> Oewdyment ION, Hosa

KU LO proceed to the STANDOFES AND RIG SELECTION screen,

7.4, STANDOFFS

The standoff function lets the user add any wireframes that represent geological structures, voids or filled stopes

to the ring design. You can also setup a separation distance from the toe of the blast holes and the wireframes,

For this tutorial, there is an intrusion to the southeast of the stope. You will add a standoff distance of one meter

40 | Page

G Please complete the following exercise:

1. Inthe Standoffs to be observed field click!" to display the SranooFes dialog box.

2. Create a new standoff setting with the following settings:

aver (iia en) [ona ReeOa loere |Twpe[uscamionee [Oar Te

smoorrsmmisowsou 1 isn 0,255,255 HokhOpmd Sd

3. Click Close to return to the Serrinas WIZARD.

The standoff

distance

Geoteowoifyra contouatons: | adatsbae |

‘create or modify primer rules: |[E} Primerruies |

cromarnedty nba | eee dabie_|

7.5. RIG CONFIGURATIONS

You can set the configuration of the drill rig to the actual dimensions of the rig that wil be driling in the stope.

A If the rig configuration is not accurate, driflholes will not be accurate, resulting in poor drill and blast

outcomes.

Q Mere are exo dit confguration tons

+ Prefoaded rig profiles that you can select.

+ You can create a new profile with the rig database function,

The dimensions of the preloacied rig profiles are generic tis therefore necessary to check the rig dimensions

with your manufacture before using any of them in operation.

For this tutorial, you will create a new dril rig configuration,

41 | Page

the following exer

G Pose

1 ClckiRig databasesto display the Ric ConFicunarions dialog box

2. Create a DESWIK DRILL RIG configuration.

Q)_ Me mew ri profie wile ovale inte ig selection menu

pe jinx

Oven) a etd

|

| ae can [SaaS

| cxaentoge [aT

| Metra prot het vor 000

| ett er] 500 8500

aah vee [a a> ow sow

Bee

(EP heh vet frm oor 13800 135.00 |

| woe

| saaiegn! a1)

| eum

Cac resis © ede |

ees

etwas 1 |

pent 8 |

| ——|

|

a

moe

3, Select Metric (meters) unit system fo)

LX the

used for reporting and other fi

this rig configuration,

nit configuration (Imperial or Metric) cor lds any. You can define the units

is the units for the Lengt

ds in the project in Deswik.CAD project settings,

42 | Page

7.5.1 DRILL RIG PROPERTIES

Drill rig properties control the pivot height limits as well as the maximum driling distance.

G Please complete the following exercise:

Enter the following Drill rig properties:

‘rl ig properties

Default pivot heiht: | ae

Minimum pivot height: [ 2I2

‘Maximum pivot height: | 2s

Maxhale length from pot to toe: [

Gasstom pivot ine Edit pivot ine

Ep wot heights - vertical from floor

orto ent | DB

Q For further details regarding the property fields, refer to the help files.

7.5.2 CAROUSEL PROPERTIES

‘The Carousel properties section defines the dimension of the carousel

[ZY Pease compete te flung exercise

Enter the following Carousel properties:

Corousel properties

Length:

Left width: 0.5/2]

ght wth: os:

Feed distance: 12/2]

Q For further details regarding Carousel properties, refer to the help files.

43 | Page

[753 DRILL BITS CONFIGURATION

The Dill bits configuration section defines the drill bit options and the number of passes needed to achieve each

drilthole diameter,

Griese comple she fowing exer:

Enter the following Orill bits configuration settings:

rl bits configuration

ease [Unie [Sunbat of Poses 4

© om \

bi 2

Pl ee

Q For further details regarding the Drill bit configurations, refer to the help jiles.

44 ( Page

7.5.4 DUMP CONVENTION

Dump convention cantrals the boom front to back rotation limits as shown below.

[ Pump convention [Op convention | oti | Pots |

0.00

45.00 45.00

Rig -> 90.00 90.00

135.00" 135,00

18000

zeropodtion: | Tap >

| Rig Side View |

45 | Page

complete the foto

GZ Plea:

Enter the following Oump convention settings:

ig exercise,

45,00 45,00

Rig -> 90.00 90.00

135.00 135,00

180.00

Zeropostion: |Top

© 4p 180 O30

|:@ clockwise

iit from

Unit to:

Q For further details on the dump convention fields, refer to the help files.

46 | Page

7.5.5 DIP CONVENTION

‘The Dip convention section controls the carousel rotation limits as shown below.

[Rig Front View

| Dip Convension

[Bewsnain oe one [eta [ho]

0.00

45.00 45.00

-90.00 90.00

135,00 135.00

180.00

zero padton: [top |

[© wo x0

[@ reais © coamterdodose

Uri fa: | |:

Unt: | a5):

Classify 35 uphole from: | Og

lassify ac uphole to: o>

47 | Page

GZ Please complete the fol

Enter the following Dip convention settings:

0.00

315.00, 45.00 :

270.00 90.00

7500 "135.00

180.00

2opodton: | Ta |

Oh 10 © 30

|@ codoise © canter

Ua om:

Litt:

cay shoe om: |

say anh to: |

Q For further details on the dip convention fields, refer to the help files.

48 | Page

eg The diagram below is an example of setting up a down-hole rig, with a dip angle limited from 45° to 315 * in

a clockwise direction.

EXAMPLE - DO NOT USE SETTINGS

0.00

315.00 45.00

270.00 90.00

225.00 135.00

180.00

ZeroPoston | Top

© + 180 @ x0

| © clockntse © Antidocvise

ware aE]

Unt To: es

| Cassfy 26 Up Hole Fr

‘lassfy as Up Hole! To:

A This is on example only, please do not use these settings for this training module,

49 | Page

‘The Plotting section controls the dump and dip settings. The Pivot section controls the rig pivot point offsets,

® ‘No changes are required for either plotting or pivots.

ump convention | ipeonventon | Potting | Pots

‘copy from: | >]

Dump

(F) Use relative mining coordinates

[F090 (show sgne Format: (0.00

[ome conerton [op eonvenion [Poi | Prot |

© Use standard pivot offsets . 8)

© Use custom pivot offset

© Use relative mining coordinates

Prefixes and suffixes

; “

0.00 \ |

45,00 45.00

135.00 135.00

160.00 |

\ |

oe ‘or this training tutorial)

Use relative mining codes

0-90 | Show sons Format: 0.00

Prefixes and suffixes

0.00

315,00 45.00 ||

270.00 90.00

225.00 135.00

180.00

no changes are require

to plotting or pivots.

50 | Page

G Please complete the following exercise:

1, Glek{QX)to return to the SerTINes WizaRD,

2, Select the DESWIK DRILL RIG profile in the Drill rig ist,

Standoffs to be observed:

1

Drilig: | DESWIK ORILL RIG

Greate or modify rig configurations: | Rig databace

cree ott: [mre

‘Create or modify explosives: \M e Explosives database

7.6. PRIMER RULES

Primer rules let the user develop primer-placing rules for the drill and blast project. A project can have many sets

of rules letting users copy rule sets from project to project.

[Please complete the following exercise:

1._ Inthe STANDOFES AND Ais SELECTION screen, cick/Primer rules to display the PRIMER oR BoosTeR RULE

CONFIGURATIONS dialog box.

2. Create a TRAINING rule.

3. Inthe Type field, select Primer.

4, Enter the following settings in the Placement rules grid

: ne eimanlangh [Motmmtent [Ostane Type [Oelawe raion [OetaneFron | acto length

1 Abele

as 2 Fracton OF

— Forall holes beaween 1 ond 30 meters a primer wil be placed 2 meters from the charge toe.

CD Forathotes benveen 15 and 30meters a primer willasobe placed at ol ofthe charge length

5. Click’OK to return to the SETTINGS WizarD.

51 | Page

7.7. EXPLOSIVES DATABASE

‘The explosive database defines the explosive types and densities used inthe ring design. Ths allows the user to

utlize several different types of explosives within a design

© Ar example is using a fow impact explosive fr the perimeter of the blast design to reduce over break in that

area. The database also allows the user to define stemming requirements and entical radius for each type of

explosive.

GQ Preosecomplte ne otowing exer:

1. Click Explosive database to open the ExeLosives DaraBast dialog box,

2. Enter the following database settings:

rae [Dany Gk) [chro Cer [alas [Cola Stewng [Te Stmatiowee) [Toe Stamina) |

seo 08 mR 255,0,0 1 18 ° °

» omen 1.25 mass, 12,0 ts 2 °

|[FoeStemninaiie) [Toe Senn) Prine oorteriade [Upele ae panson (0) [Downe Gasnanson 30 |

° 1.5 mas

° 1s meas

Lo

Dons cotutated using tonnes, or pounds forimperial projects,

3. ClickOK to return to the SerTiNes Wizaro, and then click Next

4, Click Finish to exit the wizard and return to the RING DesiGNs dialog box.

5. Save the project (you can leave the RING Desicns dialog box open for the next exercise)

52 | Page

Q Chapter Review

Before proceeding to the next chapter, review the lst of subjects from the chapter. The acquired skills and

knowledge should include the ability to:

Aire See

Open the design project

Load the Deswik.UGOB plugin,

‘An overview of the navigation pathways.

‘An overview of the ring design options.

Create a new project via the show editor.

Specify the design centerline.

‘Specify the stope solids.

Setup the standoffs,

Create a dri rig profile.

Specify the primer rules.

Setup an explosives database settings.

Q Apply the theories covered in these topics to similar processes.

| Dri and Blast Module on page 32

Load the Drill and Blast Module on

page 32

Deswik. UGDB Navigation on page

35

Ring Design Project Setup on page

37

| Create a New Projet on page 37

| Design Line Setup on page 38

| Select Stope Drive Solids on page

|39

standoffs on page 40

| Rig Configurations on page 41

Primer Rules on page 51

Explosives Database on page 52

53 | Page

Ee VAUD OL ULES

With Views and Plots, you can access various views, and setup and store created plot

G Please cot

Rina Desians dialog box, click the Views and plots tab,

[Rina deintione | views and plots | Settings

We

fi: (@ shaded eed 7 Sronbces

Long: | Shaded 0 Siced (lreverse | @ Animate

tongsecindp:|_90|:] Rockdevizota | 50:

eel ano aide vetia:| 0:

dries

show te ctor oe annotations

| Show colar ncator Color maker

Cp holes Toe marker

Prins play options: [OM Symbol Clr [Orage], 0.29) |=

Booster day option: [OM Symbols (ob (Geen, 0.20) :

Pro 10 text hag iE

Pots

update | Ei Inpart ots | P- Show ot tor

54 | Pag

8.1, VIEW OPTIONS

The long section view has a default value of 90° that you can edit

@

Wik, UGDB has four vi

g options.

55 | Page

8.2, HOLE ANNOTATIONS

You can define where annotations display, relative to the end of ahole.

Q Please complete the following exercise:

1, Inthe Drillholes section, click Hole annotations to display the PoINTs ANNOTATION dialog box.

1g points annotation settings:

a |

The Hole 1D annotation is offset from the end of the hole by 1 meter along the Xand ¥ axis, while the

Delay annotation is not offset from the end of the hole. You can edit these properties via the SHOW

Eoiron

56 | Page

WINZE LONG SECTION PLACEMENT

You design winze patterns before mapping them in the drill and blast project. You can then select the diffe

patterns for a project.

F Please complete the following exercise:

nt

1. Click the Ring definitions tab, and then cick Winze long sections to display the Winze Sections dialog box

2. Click” to create a new winze long design, and display the Apo winze SECTION dialog box.

3. Select Training Winze in the Winze pattern list

Wine patter: | Traininglnze (ee

(Ci Perpenciadar to holes

4. Click Elin the Position field, to select a winze section position,

5, Set the location of the winze section front about 2.5m from the front of the stope as shown below,

57 | Page

5. Click

58 | Page

vthe Working Drive

ct the top development drive as the working drive

ndow to select the working drive if there are muttiple poly

8. cickl*'lin the Origin field, to se

59 | Page

60 | Page

10, In the Hole rotation and length section, click Pick to digitize the section as shown in the folowing imag

cd winze,

11. Select Dip in the Integer restriction list to adjust the rotation to awhole number

joles rotation and length

D 158

tend

Integer restriction: [Dg :

a srousel intersection with walls when placing hok

61 | Page

13, Enter the following Charging setting

Ghargng

Explosive:

Collar stemming

Maxinuam charge length

Prime or booster rue:

lick Update to charge the winze section

62 | Page

fmulsion

TRAINING

Update

edt

The slot ring function will create slot rings associated with the winze. The number of rings specified will

space the rings across the winze.

15. Inthe Slot rings section, enter the following settings:

oO The Ring name prefix will give the slot rings an individual name.

16. Click Updateto place the slot rings, and then clck|Confirm to set the direction.

Confirm Look Orection PR

Please confirm the look direction for the ring.

‘Thisis the drection the rg wl face when diingholes.

‘The direction wd be used for left and right dp conventions.

17. Click Close to return to the RiNG DESIGN dialog box,

63 | Page

hole blind winze desi

Q_ Ihe final section view of the

21, Click Clase to create the up-hole winze.

22, Inthe RING DESIGNS dialog box, select all the COS holes, and then click Re-Slice to re-cut the sections,

Te sai nase aie i

‘ vod tates 1308 : or

’ seem 123028 - wo :ca

a) \ amen a8 ani 0 ae

bm

Click No to adjust the holes, and then click

65 | Page

66 | Paye

Q Chapter Review

Before proceeding to the next chapter, review the list of subjects from the chapter. The acquired skills and

knowledge should include the ability to:

tes focu

Define the available view options. View Options on page 55

Configure the annotation properti Hole Annotations on page S6

Create the winze long section, Winze Long Section Placement on page 57

Q Apply the theories covered in these topics to similar processes.

67 | Page

SHEA Ve

Placing the ring slices defines the plane and direction far the dritholes.

Deswik.UGDB offers bath manual and automatic ring placement with options to define the burden, ring dump,

azimuth and the naming conventions ofthe ring slice.

10.1. MANUAL RING PLACEMENT

You can manually place a ring slice on the design centerline.

Pease complet the floning exerese

1. Open the Rin DEsian dialog box.

2. To place rings manually on the design line, click Manual ta display the DEFINE RING SECTIONS | MANUAL dialog,

box.

Sohn me XYZ [Ah amp ies destiny in Reusing

OPE ost oose

OF & cose a)

Oath oss sas

Dt boxes vos

004 ows wos 0

of 8 oss ans

ee

Sores rare = Mts

2. Inthetop ecto ee Rig name | Rad Dump | Oto sees dnp ange

pak wisi

| aos |

Dump: Oo: |

The dump angle calculates from the horizontal plane and the dump angle range, The current rig

configuration will mit the angle range.

68 | Page

10.1.1 MANUALLY SELECT RING POSITION

The ring position can be set graphically on the screen or at set distances from a current ring slice,

G Please com

In the Position section, select the Select on screen option, and then click Pick

© select on sree Pek

Distance along reference ne

erpendiclar distance

2. Select a location on the design line near the front of the stope as per the following image:

Select Azimuth | Relative to design line

‘ath

69 | Page

The azimuth of the ring can be adjusted using either static azimuth true azimuth} ot relative to design

line (always perpendicular to the design line), You can also select the ring slice azimuth interactively with

the Pick option

4, Clck)Placeto position Ring 1at the temporary green ring plane.

10.1.2. DISTANCE ALONG REFERENCE LINE

Place arring at a specific distance, measured along the design line, from a selected ring in the direction indicated by

the red direction arrows,

[ZA reose compete te lioning evercse:

1. Select the Distance along reference line option, and then select the COS6 ring with a distance of 2.5

meters,

eer [semornsee7__][ Be

© Distance along reference line: a a5

© Pospendtatr stance: [eos Tet osha

[tevemmarectn_]

2. Click Reverse Direction|to change the direction of the red arrows on the design line.

This action does not change the actual direction of the design line. Itis specific to the placement of rings

only

70 | Page

3._ Click Place to position Ring 2, and then click Place again to position Ring 3.

71 | Page

10.2, AUTOMATIC RING PLACEMENTS

10.2.1 RING NAMING SETTINGS

You can setup ring names for automatic ring placements.

ZF Please complete the following exercise:

Enter the following Ring naming and view settings:

ing umber starts | 4

Ring number increment:

Ring name formats

ste sods type

ripe: [Devs riwsn, Sone |r]

73 | Page

10.2.2 PLACING OPTIONS

You can setup automatic placement settings,

Please complete the.

Select the Placing options tab.

2

In the Ring position settings section, cick|"“/in the Start point field.

3. Follow the prompts, and pick a starting position about 2.5 n

eters away

Ring 3 as shown below:

ute °S” key on the keyboud

Complete the Ring position settings:

Ring positon stings

25

Start point: |6244,526:9691. 320: 152

Offset fom start point: °

pont

| Specify maximum distance

ihe Number of rings.

5. Click(Preview to check the position of the ring slices,

ice locations, move onto the Dump and azimuth tab,

75 | Page

the sing position si

an f

@ “9 1g to select the Specify maximum distance.

evenly dlisniburte sings from a position atthe rear of the stope

‘Start point: | 6244,526:9891,320: 152.

Coffe fom sat pont: |

sons ofrra: |

(7) adr a tart pont

|W) Specify maximum distance

Finish pint: [0,000:0.000:0.000

|W) Evenly distribute rings with Distance’ as maximum

(Ad tat cing

A\, Please ensure the Specify maximum distance check box s cleared, before you proceed

76 | Poge

[10.2.3 DUMP AND AZIMUTH SETTINGS

‘The dump and azimuth settings control the dump angle of the ring slice, with Stati, Relative to design line, and

Incremental options. For this tutorial, the dump angles will be zero, and the azimuth will be relative to the design

line,

oO Refer to APPENDIX A-3. Dumped Drill Rings on page 171 for information on the ring slice dump function and

how its opplied.

G Please complete the following exercise:

1. Select the Dump and azimuth tab.

2. Enter the following Dump settings to set the ring slice at a vertical position.

[Rnonening ad view [Aesraoptins | Owed acmum |

Dram: [i El

a

© state:

O Relative to design ine

O Incremental

3. Enter the following Azimuth setting, to set the ring plane perpendicular to the design line,

‘Raimuth

O state: OBIE

© Relative to design tne

4, Click'OK to place the rings on the di

face in the correct direction,

ensure the new

5, Inthe CONFIRM Look DiREcTION dialog box, click/Revers

6. Click'Confirm.

77 | Page

7. Inthe RiNc DESIGN dialog box, click Save and Close.

eg Chapter Review

Before proceeding to the next chapter, review the list of subjects from the chapter. The acquired skils and

knowledge should include the ability to:

tes ous

Manually create ring placements Manual Ring Placement on page 68

Automatically create ring placements ‘Automatic Ring Placements on page 72

Q Apply the theories covered in these topics to similar processes.

79 | Page

11. AUTOMATIC HOLE PLACEMENT AND CHARGING

Deswik.CAD offers twa hole placement methods, automatic and manual

Automatic hole placement uses a wizard to input the design parameters required to place the holes on the ring,

11.1, RING SELECTION

Now the rings have been generated, they can be selected to access options such as hole placements and charging

GZ} Pease complete te folening eerie

1. In Deswik.UGDB, click Show editor to open the RING DESIGNS dialog box.

2. Inthe Ring Definitions ab, select the R1 row,

3. Click’ to open the Eom RING dialog box.

[teu [None omits [owne [Pes [Burden Next Ring [Burden Previous in|

Us? cos 2058

fact om

dt cos

[deb cosa

ama.sie

awo.st8

aw0.si8

| d.2 & coss mn.si8

BP & cose 20 58

PoP AR 6,233.15 9,904.969 152.75 60.518

Ua? a Re sie

Cle costa

lat bee oosis

ek Rs eosi8

De aR cose

Ut aw oo.si8

orp

Copy bales |#.- Rename Charge || Rewove charge || A Reset oder

Q You can also double-click a row to open the Ett RING diclog box.

80 | Page

11.2, AUTOMATIC HOLE PLACEMENT SETUP.

‘Automatic hole placement allows multiple holes to be generated by specifying hole pattern type, toe spacing, and

other hole placement constraints.

e The selected ring name displays on the bottom of the Eoit Rinc dialog box.

|

|

kay tine

exvalayesto dete E

even cant

ty tg. || ely aos

ates

> Upicaes | Aa lope des | mpart ees) + |

Pe adhe ke | Hermon

81 | Page

11.3, PIVOT CONFIGURATION

Pivat points are the carousel ratation, center paint positions insicle the working drive

Z Please complete t

nthe Epi! Rin dialog box, select the Pivots tab,

following exercise:

2. Enter the following settings:

[argeptone PCO | Oe | Gaxae ae | Canis

t> [other Tonigit oftet [Psat Hight [Pvc igh ec) tambo rhea

1 07 > 7 3 1s 295

Det i Wa

£ fH jpn ra fo

moveunsnd | 6) sat Gh savetote [9 toadfom te

Q_Thephot points dsployin te Model space

i 2

Click Save to file, and save Ihe pivat configuration as 2.0 X RLO.7

guvcition saves (0 the C:\ProgramData\ Deswik \RingDesign\RigConfigurations\ Pivots fold

D. rochange the postion the pet points grophicaly, select the raw and then click

the Modei Space.

to edit the position in

A The offset clistance and pivot height ore limited by the rig configuration used and the size of the working drive.

83 | Page

11.4, DRILLHOLES

The AUTOMATIC HOLES PLACEMENT wizago will step you through the inputs required to generate the hole placements

including naming configurations, various spacing options, and fan-hole placements.

ana AUTOMATIC HOLE CONFIGURATION

Define settings to autamatically place drillholes on a selected ring.

GQ Pease compete the folowing exercise:

1, Inthe Ei Rive dialog box, select the Drillholes tab.

Click|Automatidto open the wizard, and then click(Next}to continue.

Enter the following Hole configuration settings, and then click Next,

Hote configuration

‘Chose the common popes ties and naning convention.

Clear the

Prefix field

Properties lenin

84 | Page

4. Enter the following Start position and pattern settings, and then click Next,

‘Stat postion anu pattern

Choote the start poston and the type of pattern that you want to use to place dle.

lUse Pick to select a dip|

angle for the first hole,

from the pivot point.

| © Paral lespatter

| combined patera

Q You can enter an angle in the Dip field, or use the[Pick button to select a position in the Model Space, and

then change the dip angle to a whole number.

@ Ifthe starting hole already exists in the ring plane, select the Existing hole option. Then either use the

Hole 1D list to select the start, or click Pick to select the startin the Model Space,

85 | Page

a

11.4.2 AUTOMATIC FAN HOLES

The automatic fan hole placement is designed to generate holes by the separation of dip, toe (collar) spacing or by

evening hole angles.

FG Please complete the following exercise:

Enter the following Fan hole settings, and then click (Next)

Fan oles

Seat read prance fn es

ost dec: [@ Godse 6) Cantrdodie

db at fa potion

Overainteann | Svinte dp ane

0 constant de: |

| Cmte tives (__41-]

© const:

Frat do: LE] [ret Be |

lo | [=}| rt |

(O Maximum nner of les: Ise the Pick butot

toselecta

maximum dip.

© Moxinum

) | Gnd

86 | Page

11.4.3 FAN HOLE CONSTRAINTS

Specify constraints for the holes.

ZF Please complete the following exercise:

Enter the following Fan hole constraints, and then click (Next.

Fan hole constraints

Specify constraints Gf any) forthe hoes

2) cree minim color spacing:

0) rare mininumn toe spacing:

Glerare mimuan dp separation:

Strategy ifconstrans are not met by a hele:

© Ploce a hoes

O Place roboles

© Place hoes up to fest nvald ole

(© Hove inva eto dosest posse poston and contin:

87 | Page

11.4.3.1, COMPLETE THE AUTOMATIC HOLE PLACEMENTS

You can now complete the AUTOMATIC HOLE PLACEMENT Wz

ZA, Pose complete te fotos

Click Finish to run the wizard

© the Pott holes display in the Mode Space, andthe detaisdspay the ditt gra

@ if there ave errors with the hole constraints, a message box will eppear t

Repeat the process to complete the hole placements for ring RA, using Pivot 2.

In the Edt RING dialog box, lick Automatic Lo open the wizardl again

Hole configuration

Enter the next

letter for your

pattern,

‘Sibetatcontact: |

‘subi at contact roles): |

Start position and pattern

‘Start postion and patter

(Choose the start postion and the typeof pate that you want to use to place dies

| atin start potion

| - Use the Pick button

O©erwioaie —@newhole | to select the dip.

Hoke: [ FE] ms fe

re: (2 FF] [PB] be @ Fanta pate

| © Para des pattern

| ow: [ wl] (me GH || |

| toemene {3 |

i (Waste ot start position |

AX _Hthemew hole positon displays in red, the hole poston is invalid or too close to an existing hot

89 | Page

Fan ie

Spey ered praetor fan ks.

Design direction: | @ Codavise ©) Counterdadkwise |

pte td pnt

retreat Sane ofhdes teen dp ane |

(O carson de: Tl

nab oe:

| conint oe aa a l 13

| Fre ice [ 95] ak

(Ocoman L al = kl |

Ovemnnmbsrettaie [212] Click Pick to

© Hom [ select the final

hole angle. =

Fan hole constraints

Fanhote contsirtn

‘Spay cncrants ta forthe ks.

(Wenane miso ole space: oul:

nate minim toe spac:

/]ereiemininam dp separbon: [

Staley consratts ae mat wetby aie:

| @ face a eles

}© eco des

© Ac es esta ke

© Hove iv et dnest posible patna conte

5, ClickiNext}and then clickiFinisti to complete the hole placements

90 | Page

ole placement for RI should

Q tnt Eom Rive ato

6. Inthe Epir Rincs dialog box, ¢

Repeat the process to pl

In the RING Desions dial le-lick the COS2 ring detinition,

In the Ebir Rings dialog, box, select the Pivots tal

91 | Page

10, Click{Load from file, and then select the 2.0 xRLO.7 pivots file.

[ovo [oat [rte ami tat ainr owas e a [otc wl

est ontario Lod ev a|

rotenone

11. Click the Driltholes tab, and then click Automatic to open the wizard.

a

Hole Configuration

i

ee ate rttorectecate] fetter,

i

z

i

92 | Page

Fae star postin || Pate ope

[rma Greene ||

Elna) ||

| | (mab) al © rane ptm

~ aimee | gma

oe: [ 42] =] (mex I | ©) Combed pattern

Teepe [

|) Add hole at start position

Le Fan Holes

93 | Page

evan dp separation:

Stategy if constants are not met by ale

hoe

sble positon and continue

12. Enter the Pivot 2 drillhole settings for ring COS2:

Hole Configuration

— SSS =a oe

Stbdil at contact of]

Subdlat contact thes): | 82)

Ctameter: :

‘num hole length: [ 3] Increnwent: ie

TD) tonore carousel intersection with drive

Start Position

© Biistinghole © New hole

Hole 1D:

Pot: [2

De:

Toe spacing?

(7 Ad hole at start position

© Fan holes pattern

© Paral holes pattern

compres pattern

95 | Page

| Synunberofhales at even dp ance

|

Fedde os [1

([imter tes: [11]

Fan Hole Constraints

ienare menue smc:

Di crare miu oe space: [

rare minum separcion: [

Strategy f consrants are not metby ale:

© Place athates

© Pace notes

© Place es up to festival he

@ Move vail hae to dosest posable positon and continue

13. Clee ea, and then ck lnisito complete the hole placements

96 | Page

mae dalt

a

14, Save and clos

the Err Rin dialog box

11.5. AUTOMATIC CHARGING

You can charge the drilholes either manually or automatically

Bere

1. Open the Eon Rincs dialog box for the R1 sing,

2. Select the Charge holes tab, and ensure the Display influence radius check box is

97 | Page

4. Enter the following CHarce Hotes | AuroMmaric settings:

Ifrequired, edit the toe

stemming, critical radius,

and minimum collar to best|

suit the design.

QQ rhe caticotrauis can beser1001 meteor charging nnn vein operations.

5. ClickiProcess, select hole A as thelead charge hole, and then right-click to run the command,

98 | Page

82 drillholes.

process to charge the CC

@ Use

55 RI with hole 1as the leat

99 | Page

7. Save and clase both dialog boxes, and then save the project

Q Chapter Review

Before proceeding to the next chapter, review the list of subjects from the chapter. The acquired skills and

knowledge should include the ability to:

Bm eeu

Select the rings to place and charge Ring Selection on page 80

Select the hole to run the auto rules Automatic Hole Placement Setup on page 81

Load a saved Pivot setup into the auto rules Pivot Configuration on page 82 Oo

Load and run the Auto Hole Setup wizard Drillholes on page 84 -

‘Automatically charge the created holes ‘Automatic Charging on page 97

Q _ plyite theories covered in these topics to similar processes,

101 | Page

SPL eae ee eee SILC

Use the manual hole placement method to select the hole positions in the Mode! Space.

12.1. MANUAL DRILLHOLE PLACEMENT

The Drillholes tab contains settings to configure the following

+ Thedrilhole 1D

+ Attached pivot point

«+ Charging status

+ Editable hole dip angle

+ Length and hole diameter

Gj Pease complete ve fowing exercise

1. Select the COSI ring, and open the Eotr Rin dialog box.

2. Click the Ring options tab, and enter the following settings:

2 ae [ores [Cnt [ omer

eget

prope: | Moy

ay ota

alessio dy

Po Updtebe ||P Abts dn | ie EEE a

Po abba e-ink wee

3. Select the Pivots tab, and load the 2.0 x RLO.7 rule,

4, Select the Drillholes tab, and then click Manual to open the EDIT RING | DRILLHOLES | MaNuAL dialog box.

5. Confirm that Pivot 4 selects and the Diameter is set to 89 mm.

"le ropetles

Next het: [ car

Method Fram chosen pivot FI

pt FL aa 1 |= |=]

Pivots tlerances | 0.057]

ameter: [29m

Q If required, click Pici\to choose the required pivot point.

6. Enter the following Placing Options settings:

Placing options

‘ube at contact (BT holes):[

Toe spacing: |

Cola spacing

Fixed holelength:

nena hole lent: |

7 tonore carousel intersection with drive:

Integer revit: | =

redileardec[|

103 | Page

e holes, are hole iD, h

jotations that

p angle. The toe spacing di

le len

yon the scree re placing th

when you

@ mea

dj

plays as a white circle, except when the toe spacing is closer than desi

he circle will turn red but you can still place driltho

When the carousel position is not suitable, the carousel will turn red ani

disable

the hole placing function will

9. Repeat the pracess to digitize the holes for pivot point 2 as per the following image:

12.2. MANUAL CHARGING

Charge the holes from the previous exercise

1. Select the Ring options tab, ar

at the Shadow | COS 2 clieck box

Inthe Charge holes tab, ensure the Display influence radius check box is clear

3. Click Manual to display the EDIT RING| CHARGE Hoves | Manual dialog box

105 | Page

4. Select Emulsion in the Explosive lst, ond ig settings:

Explosives

cose: Gnaton

Primer or booster rufe to run: | TRAINING

tc rads:

Charge collar adjustment

Adjustment type: [Select on screen

5. lek Sialto start charging

6. Follow the prompts and select the H1 hole

QD Aevetewmeppen wine nas oft acne at spe eater

408 | Page

should match the following image:

ing auitomatic charging,

efer to Automat nd Chorgi

1g on poge 80,

QD) Perdew regar

107 | Page

13. PRIMER LOCATIONS

This chapter will cover configuring the primer locations and applying them to the COSI ring You will repeat the

process to apply the primers to the R1 ring,

(Q) Peose complete te folowing execs

1. Inthe Eoir Rive COS 1 dialog box, select the Charge holes tab.

2. Click Primers or boosters to edit the Primer OR BOOSTER RULE CONFIGURATIONS.

3. Add anew row to the Placement rules grid.

4. Enter the following settings to lacate the primers in the middle of the charged length,

eaves -

[ [tse [terghiNeanre [Wma lang |vinimimienth [Dita Tye [Ontnceration [Oetneston [Facing

i 1 2 Rote 2

[|= 15 30 Fracton OF os

ple

15 5 Abit 1

5. Click Run these Rules to apply the new primer rule.

108 | P

6. Repeat the

o run the primer rules on the R1 ring,

7. Click OKto c

PRIMER OR BOOSTER RULE CONFIGURATION

109 | Page

Q Cropter Review

Before proceeding to the next chapter, review the list of subjects from the chapter. The acquired skills and.

knowledge should include the ability to:

Bima

Se

‘Manually create the driliholes ‘Manual Drillhole Placement on page 102

Manually charge the drilholes, ‘Manual Charging on page 105

Configure the primers Primer Locations on page 108

Q ‘Apply the theories covered in these topics to similar processes.

110 | Page

14. COPY HOLES

Copy holes and their related charge to single or muiple ring designs.

For this tutorial, copy the COS1 drilholes and charges to the COS3, COS4, COS5, and COS6 designs.

Following this, copy the drillholes and related charges for ring R1 to the remaining holes.

ZY Please complete the following exercise:

1. Inthe Rie Désicns dialog box, click Copy Holes to display the Cory Hotes dialog box.

ing [ard Previous Re

70.518 14 1000;c0s2 2658: R1

20518

20518

20510

20.518

cose

6o.s18

costa

so.510

cosis |

Moy ese Drecton ||P Manual |/ Pes Automanc

Charge | Remove digs | OY Reset order

111 | Page

2. Enter the following Cory Hoes settings a

copy to:

(cor

|) cose

iv) Coss,

i¥| cos4

“Delete esting pivots and doles

(lenable mapping of new pivots to exstng pivots on rng)

ieee nesta

‘Choose 2 contact point to keep the length snk to orignal

© choose the first cantact point

Asthe stope shope changes, the copied holes shay nat suit the tng slice that the holes are copied to,

ake sine you check the ou(purs on eich of the viags cal edit when ceqiuaed,

112 | Page

3. Repeat the process to copy the Ri drilholes and charges to the remaining holes.

[Enable mapping of new pivats to existing pivots on Hing

[| Adjust hole toes to new stope sices.

© choose a contact pant to keep the length sar to original

© chooee the frst contact point

113 | Page

Kiera) tees (0

here are several options to edit the drill holes via the Eo1T RING dialog box, including a Bulk Edit option.

Do Manual || Automatic

Yo Bukedt |[sm Rename a || Sort

The fallowing section will detail how to move the toe, collar, or pivot point of a hole, You can also rename all the

holes for a selected ring.

15.1. CHANGE HOLE POSITION

In this optional exercise, you can select a hole, and then move the toe, collar, and pivot point.

ZA recomplete the cptonatererse

1. Inthe RING Destans dialog box, double-click the COS1 ring to open the Edit Ring (COS 1) dialog box.

iick the Drillholes tab, and then in the Model Space select a hole.

When you select a hole, the toe, collar, and pivot point grips display. Note, the background color of the

{following image is white for display purpose only.

«

Inthis example 4

Hn ssthe ]

fal 1H12

fe 6

3, Tomove any part of the hole, select the relevant grip in the Model Space, anc thi

Wve it Lo.a new position,

114 | Page

Q This process is the same as moving any entity in the Model Space,

4. Repeat the process to move the hole back to the original position,

15.2. RENAME HOLES

You can rename all the holes on a ring at the same time.

Fj Please complete the following exercise:

1. Inthe Edit Ring COSt dialog box, select the Drillholes tab,

2. Click Rename all to display the ReNaME ALL HOLES dialog box,

3. Enter the following settin,

[@ cower © Counterdackse |

Selectreference hole and process |

D_Tese stings wilename the hoes ote sme fermata the Rt ving

4, Click Select reference hole and proc

5. Follow the prompt, and select H1 as the reference hole,

115 | Page

Allof the hole 1D’s on the COS! ring

6. Click Save and closetto exit the Eorr RING dialog box

aI e) a) aw NA)

Setup blast delays for each ring with a 25 ms delay between each hole, In this section, you will create an

alternating pattern for R2, and a sequential pattem for R3.

Please complete the following exercise:

1. Inthe Rinne Desiens dialog box, double-click ring R2 to open the EDIT RING [R2] dialog box,

2. Select the Charge Holes tab, and ensure the Display influence radius check box is clear,

3. Select all holes in Ring 2, and then click Delays to open the BULK Eorr dialag box,

4, Enter the following settings, and then click Select reference hole and process,

[Movin | seocno [ Naming | Oars |

Intl delay: of: | me

Delay increment: 5] | me

Manual ordering

Clock D Countesdockwise |

Style;

(2 seavent © Alena decton

Select reference hole and process

low the prompt, and select hole A as the reference hole.

117 | Page

Q@ mera

6. Save and close the BULK EoIr and Ebr RiNG dialog boxes,

7. Open the Eoit RING (R3] dialog box, and repeat the process to set the hole delays with the following settings:

Hots | sono [naming | Oars |

vet doy: | 500] } ma

119 | Page

Stating at hole A the

blast elays are setin

louise and

120|

Q Chapter Review

Before proceeding to the next chapter, review the list of subjects from the chapter. The acquired skills and

knowledge should include the ability to:

Copy holes from one ring to another Copy Holes on page 111

Move the toe, cola, or pivot point of ahole CChange Hole Position on page 114

Renamealiholesinaring Rename Holes on page 115

Setup blast delay patterns Hole Delays on page 117 a

Q Apply the theories covered in these topics to similar processes.

121 | Page

ee W PM serra)

with the Blast solids and interrogation function, you can create blast solids and interrogate the solids against

a block mode!

Blast solids are created using one of the following three methods:

+ Create a solid for each ring with the exception of the first ring in the sequence,

+ Group rings together to represent the blasts.

+ Create blast solids as a single solid for all rings.

D The create single Blase Solid option, includes seaings clean up rings

1. Inthe RING DesI6Ns dialog box, click Blast solids oF interrogation,

[ee tr |

Veranda | sets |

EE Wns seire 5 wanes

|

f

| | |stauer — |ttome | 2 [Amity [Ome [isles [ude Next ing [Burden Previous ing

| Piast cost 20.518

| [028 os ose

| []ose cos peste

| 0.6 cose ane

[064 os 20

DP & cose 2nsi0

| Fo+an ose

| we was

8 ose

ka ose

| bs ws

| ke ose

87 wos

£ Epp px

aI ‘tote

Copy hoke ||P Rene 0) eset order

122 | Page

2, Select the Blast solids creation tab, and enter the following settings:

‘last sakds creation | glast polygon creation |

© Connect toes © tint toe spacing to: |

Overtrea: | os[2]

Estrude rings: None [=] [advance

© Fastringin fring sequence: [COS2 El

O createsnleblastsotts (051)

© customs sods oun fat Configured

of:

®O The COS2 ring will not have the associated blast solids, as this is the first ring fired in the sequence.

3, Select the Blast polygon creation tab, and enter the following settings:

CColars to connect

© brit cotars

© Charge cotars:

© Dei toes

| charge toes

HeeGaseeanae

ooooooo0o000o0)

4, Click Pic follow the prompt, and select the stope shape in the Model Space.

123 | Page

n=”

(Blescice hes) Unherged hoes

5. Enter the following Block model configuration settings:

‘lock model configuration

Process interr09at00

Model + Wiitimms EMINE\07 Dewi UGDO_Orebody.dm| || lp Refresh

Density field: [56 7]

Q ‘Map the Model field to the 4.07 Deswik.UGDB_Orebody.dm Block Model in the datasets folder.

6. Click Process to create the blast sofids,

Deswike

Process Completed. Blast solids ae created under

RINGDESIGNATRAINING\BLASTSOLIDS

17.1, BLAST SOLID RESULTS

View the results of the blast solids and interrogation process, Apply a legend to identify each ting and the

associated volume.

GZ Pes compete he otowng exerci

1, Isolate the RINGDESIGN\TRAINING\BLASTSOLIDS layer.

2. Set the view to shaded mode, and reset the transparency of the solids to 0%.

3. Createa Blast Solids legend based on the Ring attribute,

4,

‘Apply the legend to the blast solids, and then use the Modify | Color and Line Type from Legend com

mand to embed the colors.

5. Make the INTRUSION SOLID, 150 LEVEL, and 130 LEVEL layers visible,

124 | Page

le the following image:

should resemble the f

Q The result

125 | Page

17.4.1 INTERROGATION RESULTS

You can view the results of the interrogation via a plane definition.

Zi Please complete the following exercise:

1. Isolate the R1 layer, and then make all the R1 child layers visible,

2. Onthe locked PLANEDEFINITIONS layer, right-click and select Modify Plane Definition,

4 C@ rncoesion ]

2 Cod Traninis |

(leg cesionne

PLANEDEFNITONS

°

cost

cosz

oss

cose

coss

ty vveveres

3. Inthe PLANE Detiniion dialog box, click the Advanced Options tab,

126 | Page

Scroll down to the bottom of the static attributes list to view the interrogation results. Any anomalies may

‘mean an error occurred within the interrogation.

Static attrbites | Caladated attributes | Linked entities |

costes

Burden 2693: cost

Hoes 16

/Sampletole

Diameters 89mm

bet 1623028

Hrotal ot 1623028

charge 95.5306

ring RL

[Config uration TRAINING

Ungassed chargeLenoth 95.5306

Primers 6

Explosive Amount 5404

[Position {6233.1153:9884,8692:152.3753)

Positions 6233.1153

Position 9084.8692

Positionz 1523753

Drawbell False

JLookDirection ‘EAST

Comments

Rig DDESWIK DRILL RIG

Pe 0.1256

|Daill Factor 33.3234

1224.55026224089

Q You can right-click and unlock the plane definitions to modify any of the ring attributes

127 | Page

oO

4. Select one of the blast solils, and review the attribute results,

ates *

aa 17.961

au 5.221

Bbstsolds R3:R4

RESCAT 1.392

Reg Ra

s6 3.200

Tonnes, 675.9658

5. Save and Close}the Rina Desias dialog box.

128 | Page

18. SURVEY EXPORT

You can export survey lines in CSV and DXF format with laser line offset distances.

GZ Please compete the towing exercise

1

Create a new folder: 4.07 Survey Export Data in the same directory as the training data

2.

In the Deswik.UGDB window, click 6. Process Rings Configuration | Export Survey Data,

Deshi UGB

Select Active Configu

(reams

arvmate Holes

Generate Delay Schematic

| 7.

129 | Page

130 | Page

ig settings

Cl enerate pivot markers

7 enerate laser ines

Laver ne tance Bai]

7 oenerate navigation les

Confoue

(Zl export OXF fle

OXF fle name: +8 444.07 Survey Export OatalTraining Project. dt |

porte data CY the

3) rane: |\¥.07 Survey por OatlTaring Project Hole. |

Exporting data CSV fle

CSV fle name; [4.07 Survey Export Datalahing Projecting <5 |)

hoes configured

ain the laser ines,

jer the Survey Expo

QD) The Survey Export layer wi

each ring containing all the holes.

131 | Page

Q “Hover Review

Before proceeding to the next chapter, review the lst of subjects from the chapter. The acquired skills and

knowledge should include the ability to:

Et oes

Generate blast solids representing the ring design Blast Solids and interrogation on page 122

Review the bast solids oh Blast Sold Results on page 124 -

Reviewthe interrogation results Interrogation Results on page 126.

Export survey lines to .DXF and .CSV formats ~ | Survey Export on page 129 ==

Q “Pei the theories covered in these topics to similar processes.

132 | Page

19. PLOTTING

Deswik.CAD comes with several templates to assist in plotting the plans,

ZX, Some operations may have template plot fle stored ona shared network. Copy these les fram the network,

«ind save them in €:Programbata Deswik\Titleblocks folder. From there you can eal tothe project

requirements without editing the shared template,

Q_Youcam ats select tile bocks ram asi ofthe Program Bata fer,

The Ring Section Layout has three different view types for a single configuration using different viewports. The

available plot types are:

+ Section view

+ Plan view

+ Long view

19.1, RING PLAN PLOT

The first plot you will generate isa ring plan configuration,

133 | Page

Zi Please complete the following exercise:

1. Glick Show Editor to open the RING Desicns dialog box.

2, Select the Views and plots tab, and then click/Show plots editor

Vem

Pon: |G Shaded 0 sued A Stow beles

long: | shoded 0 sed reverse inate

Long section dp: ‘ng guide orznta: zi

Angraneste:| 1 | Reggie vert |

Cloostars rosthats sve: [25] =]

ontrles

Dison teietatr

(Di stew ctr cate

Bohies

rer kay pte: [OM Syl (Car A255, =285, 165, 0-0, 02)

Boost day os on Sb (Cr [A-25, 0, 6-12, 0, 0.2)

Pot teat het

Pte

(O_ ume [>]

3. Inthe PLor Conricurarions dialog box, click!” land create a Training - Ring Plan plot.

4, Select Plan as the Plot type, and then click?" !to createa new layout

Edt oyut [

© section

Pot type: | @ Plan

tong

Caneel

134 | Page

5. Enter the following Insert Lavour settings:

Name: [Franing Ring Pan

ae |

Pagesize: [a3 ane

venta

Nominating a printer at this stage is not important, as you will nt print the plot in this course, Map the

printer to any printer with A3 page siz.

6. Click(OK{to return to the SELECT LAYOUTS FOR PLOTS dialog box,

@ The new layout also displays in the Model Space.

135 | Page

Pet: eadian >)

(splay options: Cob makers, Toe markers

seve [ee]

| [levee [Sone Laver [ine Tree

caren dene: [|

Restrict plane defistons for pening: |

a

henge evn

[create

&

scales [Rstamabe

du |x)

136 | Page

[rsa RING PLAN VIEWPORT

Now you can insert the ring plan viewport

G Pease compe the folowing errs

1. clealreate nen, and create a Training -Ring Plan viewport layer

2. Fellow the prompts, and insert a viewport tothe extents ofthe layout

Inserta viewport

hat fils the layout]

area,

137 | Page

3. Set the scale as 1:250,

Layout: TRAINING - RNG PLAN Change layout

Pot ype: PLAN

| Wewport: TRAIMING -RING PLANTRAINING -RINGPLAN

Pot: Ringplin +

(pay opton: Cor mats, Toe markers - Changes to the scale

call

| tevels | Totes | are automatically

|

JlevelName |Poline Layers Une Type | Hatch 2roted tothe

|

Carentan define: | 4)

Restle defitions fr etn:

The display options fora ring plan defautt to collar and toe markers, The following options are also

available via the Display options list above.

Standoff dices from design

[1 tndkude Winze Sections in tables

19.1.2 PLOTTING TABLES

The PLOT CONFIGURATIONS | TABLE EDITOR has several table options including;

+ Display information for the types of holes (up holes and down holes)

+ Display a number of holes per plot

+ Report out information on any attributes associated with a hole

+ Add formula rows to report calculated values