Professional Documents

Culture Documents

Linde BPV Reparation

Linde BPV Reparation

Uploaded by

Arko RoosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linde BPV Reparation

Linde BPV Reparation

Uploaded by

Arko RoosCopyright:

Available Formats

Bulletin No.

PRESSURE CUT-OFF FOR LINDE BPV PUMPS BPV 000

03.89/001/06

Page 1 / 5

BPV..HF with Pressure Cut-off BPV..EH with Pressure Cut-off

PURPOSE

The purpose of the "PRESSURE CUT-OFF" is to prevent large amounts of oil from bleeding over a

relief valve, which reduces overheating of the main loop in a closed loop application. The "PRESSURE

CUT-OFF" reduces the control pressure of the pump so that the pump can stroke back towards neutral at

a pre- determined maximum system pressure. Adjusting screws I and II are used to set the system

pressure when the "PRESSURE CUT-OFF" becomes functional. Adjusting screw III determines the

minimum pump flow going over the relief valve by establishing a minimum control pressure felt in the

pump servo control once the "PRESSURE CUT-OFF" is active.

P = System Pressure

P1 = System Pressure at Maximum Flow

P2 = System Pressure at Minimum Flow

C = Control Pressure

C1 = Control Pressure at Minumum Flow

Linde Hydraulics Corporation, P.O. Box 82, Canfield, Ohio 44406

PRESSURE CUT-OFF FOR LINDE BPV PUMPS Bulletin No.

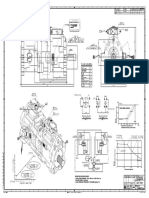

SCHEMATICS BPV 000

03.89/001/06

Page 2 / 5

BPV...HF with Pressue Cut-off

BPV...EH with Pressue Cut-off

Linde Hydraulics Corporation, P.O. Box 82, Canfield, Ohio 44406

PRESSURE CUT-OFF FOR LINDE BPV PUMPS Bulletin No.

TUBING DIAGRAM BPV 000

03.89/001/06

Page 3 / 5

Linde Hydraulics Corporation, P.O. Box 82, Canfield, Ohio 44406

PRESSURE CUT-OFF FOR LINDE BPV PUMPS Bulletin No.

ADJUSTMENT PROCEDURES BPV 000

03.89/001/06

Page 4 / 5

Port identification and adjustment locations:

1. INSTALL 1.0mm ORIFICES

A. For "HF" control: One in each control pressure line.

B. For "EH" control: One in control cover (see parts book).

2. PRE-ADJUSTMENTS

A. Check for proper adjustment of Rb, hydraulic neutral, high pressure R/V settings and

plumbing of BPV.

B. To insure the proper function of the pressure cut-off valve, control presssure at Y & Z

should be limited to a maximum of 21 bar (305 psi).

C. Mount pressure gauges to monitor system pressure and the control pressure downstream

of the control orifices.

D. Turn in adjustment screws I and II until the ends of the screws are flush with the lock nut.

This will block the pressure cut-off valve.

E. Adjustment screw III should be turned all the way out, but not removed.

3. PRELIMINARY READINGS

A. With the discharge of the pump blocked (closed lines, blocked motor or cylinder),

very slowly increase the control pressure to the pump. As control pressure increases

the pump's discharge pressure will also increase. Continue raising control pressure until

the discharge pressure stablizes and remains constant.

B. Note the constant discharge pressure and the corresponding control pressure to reach it

for each direction of pump swash.

C. To each control pressure reading, add 0.3 bar or 4.4 psi.

Linde Hydraulics Corporation, P.O. Box 82, Canfield, Ohio 44406

PRESSURE CUT-OFF FOR LINDE BPV PUMPS Bulletin No.

ADJUSTMENT PROCEDURES BPV 000

03.89/001/06

Page 5 / 5

4. FINAL ADJUSTMENTS

A. Loosen adjustment screws I and II all the way out, but do

not remove them.

B. With the discharge of the pump still blocked, slowly introduce full control pressure to the

pump, ie pump control valve in a fully open position. (The control pressure during this

step should be below the control reading observed in step 38. If not, repeat steps

1 thru 4B).

C. With full control on the pump, turn in the corresponding adjustment screw I or II (see chart

below for relationship of adjustment screws to ports) until the calculated control pressure

(step 3C) is registered on the appropriate control pressure gauge and lock adjustment

screw with lock nut. Repeat procedure for opposite direction of pump swash, setting the

appropriate control pressure reading from step 3C.

D. Turn in adjustment screw III until the control pressure rises another 0.1 + 0.1 bar (1.5 +

1.5 psi) and lock with lock nut.

5. INCIDENTALS

A. Since oil will be bleeding over the main relief valves during this procedure, watch the oil

temperature in the main loop.

B. Any change in hardware, control pressure supply or system configuration after the initial

adjustments are made, will probably alter the performance of the pressure cut-off valve. In

this event, readjustment is necessary to retune the pressure cut-off valve to accommodate

the change.

C. The "Pressure Cut-Off" valve can be used only in combination with "HF" and "EH"

controlled BPV pumps.

6. RELATIONSHIP OF ADJUSTMENT SCREWS TO PORTS

Control Port or Solenoid System Pressure Port Corresponding

on BPV Pump on Pressure Cut-off valve Adjustment Screw

Z B I

Y A II

Linde Hydraulics Corporation, P.O. Box 82, Canfield, Ohio 44406

You might also like

- Manual Training Hydraulic System Caterpillar Backhoe LoadersDocument23 pagesManual Training Hydraulic System Caterpillar Backhoe Loaderseulogio89% (19)

- Manual Oficina PDFDocument20 pagesManual Oficina PDFFelipe Douglas da Silva100% (1)

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- BMW E60 Climate Control DescriptionDocument20 pagesBMW E60 Climate Control DescriptionAndrew Denny100% (5)

- Tesla Roadster Ebook 1 BlueprintsDocument13 pagesTesla Roadster Ebook 1 BlueprintsTECH TUBENo ratings yet

- Motor MCR 15207-RDocument24 pagesMotor MCR 15207-RDavid AltarribaNo ratings yet

- Sundstrand Series 42 Pump Technical Info PDFDocument52 pagesSundstrand Series 42 Pump Technical Info PDFAngelo AlmeidaNo ratings yet

- Variable Pumps For Closed Loop Operation Type Hv-02Document36 pagesVariable Pumps For Closed Loop Operation Type Hv-02Eric CNo ratings yet

- Hitch Control Valves EHR5-OC, EHR5-LS, EHR24-EM2, EHR24-EHS: FeaturesDocument30 pagesHitch Control Valves EHR5-OC, EHR5-LS, EHR24-EM2, EHR24-EHS: Featuresmetin metinNo ratings yet

- LINDE R-02 Hydraulic Motors For Open and Closed OperationDocument44 pagesLINDE R-02 Hydraulic Motors For Open and Closed OperationRomanko100% (1)

- Minidiag 2: Diagnostic Unit User GuideDocument58 pagesMinidiag 2: Diagnostic Unit User Guidevitor santos100% (3)

- Re93010-01-B - 2009-05 A8voDocument52 pagesRe93010-01-B - 2009-05 A8vothierrylindo100% (10)

- Reverse Type PistonDocument9 pagesReverse Type PistonMirequip Mirequip100% (1)

- Mobile Division: Service Parts ListDocument52 pagesMobile Division: Service Parts ListSamy Sam100% (1)

- 90 Series Variable Pumps and Motors Repair Manual PDFDocument54 pages90 Series Variable Pumps and Motors Repair Manual PDFsssydorenko100% (3)

- Danfoss H1P 069-H1P 250 Axial Piston Single Pumps Service ManualDocument68 pagesDanfoss H1P 069-H1P 250 Axial Piston Single Pumps Service ManualJustinNo ratings yet

- Handok Hydraulic - Co: Flow Rate ControlDocument1 pageHandok Hydraulic - Co: Flow Rate Controlanon_485665212No ratings yet

- Axial Piston Pump Bosch Rexroth A10VG PDFDocument60 pagesAxial Piston Pump Bosch Rexroth A10VG PDFjuan100% (11)

- Axial Piston Variable Double Pump A22VG Series 40: RE 93221/05.2014, Bosch Rexroth AGDocument26 pagesAxial Piston Variable Double Pump A22VG Series 40: RE 93221/05.2014, Bosch Rexroth AGjulioNo ratings yet

- SI 10203 Advacements HPV 02 E 09.03 CDocument4 pagesSI 10203 Advacements HPV 02 E 09.03 Cdouble microNo ratings yet

- Linde HPR 02 DatasheetDocument48 pagesLinde HPR 02 Datasheetdavor1414100% (1)

- A8V - Variable Displacement Double PumpDocument10 pagesA8V - Variable Displacement Double Pumpviktormario100% (1)

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- Wr430gb00b BMP Cat Discl EngDocument12 pagesWr430gb00b BMP Cat Discl EngY.EbadiNo ratings yet

- Furukawa HD712 PartsListDocument4 pagesFurukawa HD712 PartsListY.Ebadi100% (2)

- MAN-BW L16-24 (ЧН 16 - 24) (Инстр. по экспл.) + PDFDocument544 pagesMAN-BW L16-24 (ЧН 16 - 24) (Инстр. по экспл.) + PDFAndrey83% (6)

- Axial Piston Compact Unit A10CODocument8 pagesAxial Piston Compact Unit A10COJohn SimmondsNo ratings yet

- A10VSODocument40 pagesA10VSOJulio Carrero100% (1)

- Electro-Hydraulic Control System DFE1x For Axial Piston Variable Pumps A4VSO and A4VBO Series 1x and 3xDocument32 pagesElectro-Hydraulic Control System DFE1x For Axial Piston Variable Pumps A4VSO and A4VBO Series 1x and 3xPrasantaKumarMallika100% (1)

- E PUPI TM019 E HPR Conversion ManualDocument32 pagesE PUPI TM019 E HPR Conversion ManualxxshNo ratings yet

- SM-SPV SMF20-E 695379A - Englisch PDFDocument46 pagesSM-SPV SMF20-E 695379A - Englisch PDFJayRellvic Guy-abNo ratings yet

- Spec Pump Hd2-4000Document24 pagesSpec Pump Hd2-4000SAKDA MAPRADITKUL100% (2)

- A4VG - Data Sheet - Serie 40Document68 pagesA4VG - Data Sheet - Serie 40Aurimas Bendinskas100% (1)

- OMEW Repair InstructionsDocument16 pagesOMEW Repair Instructionsjose manuel barroso pantojaNo ratings yet

- 135-En Telehandler Mobile06Document9 pages135-En Telehandler Mobile06xxshNo ratings yet

- Mib VC TNR SVM TpiDocument6 pagesMib VC TNR SVM TpiTkroNo ratings yet

- Technical Training Presentations - 564-574 ForwardersDocument152 pagesTechnical Training Presentations - 564-574 ForwardersSantos Condori MurilloNo ratings yet

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Document25 pagesA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaNo ratings yet

- Poclain Piston MotorDocument40 pagesPoclain Piston MotoredascribdNo ratings yet

- 135 3500-3500B MotoresDocument131 pages135 3500-3500B MotoresMARCOS100% (3)

- Aa4v56 Series 1 Service Parts ListDocument36 pagesAa4v56 Series 1 Service Parts Listhamza HamzaNo ratings yet

- 1600 SERIES: Gear Pumps and MotorsDocument16 pages1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- Workshop Manual: Training CenterDocument9 pagesWorkshop Manual: Training CenterStas100% (1)

- Bomba Linde BPV 100 Parte 2Document1 pageBomba Linde BPV 100 Parte 2Mary Betcel100% (2)

- Load-Sensing Control Block in Sandwich Plate Design SB23-EHS1Document32 pagesLoad-Sensing Control Block in Sandwich Plate Design SB23-EHS1ВладиславГолышев100% (1)

- A10VO Regulator Teory PDFDocument45 pagesA10VO Regulator Teory PDFmohammad100% (2)

- Load Sense and Pressure Compensator Control Adjustment For HPR-02 PumpDocument5 pagesLoad Sense and Pressure Compensator Control Adjustment For HPR-02 Pumpsatria adiNo ratings yet

- Brompton Bicycle - Owner'S Manual: Downloaded From Manuals Search EngineDocument31 pagesBrompton Bicycle - Owner'S Manual: Downloaded From Manuals Search EnginegwskripNo ratings yet

- A10V Series 31 Eng DataDocument32 pagesA10V Series 31 Eng DataMARCO HernándezNo ratings yet

- Sauer90 ServiceManual PDFDocument72 pagesSauer90 ServiceManual PDFeng13100% (7)

- A11vo - Re 92 500 - PDFDocument60 pagesA11vo - Re 92 500 - PDFSyed Azhar Hussain50% (2)

- Eaton 420 PartsDocument16 pagesEaton 420 PartsF Labio Alex100% (1)

- PVB PVBQ A10vso PVHDocument38 pagesPVB PVBQ A10vso PVHWilliam ValenciaNo ratings yet

- 6.8 - Sauer Danfoss - Serie 90Document48 pages6.8 - Sauer Danfoss - Serie 90Maximiliano DreyerNo ratings yet

- A10VG Bomba HidraulicaDocument1 pageA10VG Bomba HidraulicaRicardo&Priscila GilNo ratings yet

- Rieju MRT 50 (ENGLISH) Workshop ManualDocument75 pagesRieju MRT 50 (ENGLISH) Workshop Manualavista12350% (2)

- Sauer Bomba S90Document65 pagesSauer Bomba S90hambaallah99100% (1)

- Defecte Motor DieselDocument305 pagesDefecte Motor DieselGoranka Bulatovic Ilic100% (5)

- Instructions For Installation, Use and Maintenance: Keto 2000-Series Single Grip Harvesters 51 100 150 500 800 1000Document37 pagesInstructions For Installation, Use and Maintenance: Keto 2000-Series Single Grip Harvesters 51 100 150 500 800 1000pascukinta100% (1)

- A4vsg Us-Version. Ra92100Document72 pagesA4vsg Us-Version. Ra92100Eduardo CramerNo ratings yet

- Bit Weight ChartDocument1 pageBit Weight ChartY.EbadiNo ratings yet

- Rexroth A4VGDocument68 pagesRexroth A4VGÁgoston Imre50% (2)

- Hurricane B7-41/1000: Product ReferenceDocument8 pagesHurricane B7-41/1000: Product ReferenceY.EbadiNo ratings yet

- A10vso 71 DFR - 31r-Ppa12noo r910942635 Parts ListDocument15 pagesA10vso 71 DFR - 31r-Ppa12noo r910942635 Parts ListAgus YulfizarNo ratings yet

- Linde (BPV) Model Codes For B Series Closed Loop PumpsDocument2 pagesLinde (BPV) Model Codes For B Series Closed Loop Pumpsحري فوكو ني100% (2)

- H1 115-130-147-165 Pumps Repair Instructions - 520L0874 - Rev AC - April 2008Document48 pagesH1 115-130-147-165 Pumps Repair Instructions - 520L0874 - Rev AC - April 2008Jose Manuel Barroso Pantoja100% (1)

- A10VO 52 Series Re-A92703Document68 pagesA10VO 52 Series Re-A92703Agus YulfizarNo ratings yet

- Moteurs Hydrauliques: Hydraulic MotorsDocument10 pagesMoteurs Hydrauliques: Hydraulic MotorsИгорь Терещенко0% (1)

- Mobile Division: Service Parts ListDocument20 pagesMobile Division: Service Parts Listwag008No ratings yet

- Tractor Hydraulics in Line With The TrendDocument10 pagesTractor Hydraulics in Line With The TrendNelson PaicoNo ratings yet

- Revista Danfoss PDFDocument32 pagesRevista Danfoss PDFjhonnymlfNo ratings yet

- Bul 947015aDocument14 pagesBul 947015asssydorenkoNo ratings yet

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoNo ratings yet

- LF 230 Core Drill 4Document2 pagesLF 230 Core Drill 4Y.EbadiNo ratings yet

- 02450-Final 06 01 2017Document14 pages02450-Final 06 01 2017Y.EbadiNo ratings yet

- Model 175 Wireline Steering Tool SystemDocument2 pagesModel 175 Wireline Steering Tool SystemY.EbadiNo ratings yet

- Interim Guidelines For Horizontal Directional Drilling (HDD) Under Union Pacific Railroad Right-Of-WayDocument2 pagesInterim Guidelines For Horizontal Directional Drilling (HDD) Under Union Pacific Railroad Right-Of-WayY.EbadiNo ratings yet

- RSC09ver2 Specification For Horizontal Directional DrillingDocument8 pagesRSC09ver2 Specification For Horizontal Directional DrillingY.EbadiNo ratings yet

- Directional Boring - 201207191627015877Document8 pagesDirectional Boring - 201207191627015877Y.EbadiNo ratings yet

- b4 41 BoosterDocument2 pagesb4 41 BoosterY.EbadiNo ratings yet

- Hurricane Booster B18Document2 pagesHurricane Booster B18Y.EbadiNo ratings yet

- 3-4-1-2935 0791 31 - L - tcm795-1697585Document2 pages3-4-1-2935 0791 31 - L - tcm795-1697585Y.EbadiNo ratings yet

- DSB 2 Technical-DataDocument2 pagesDSB 2 Technical-DataY.EbadiNo ratings yet

- 3-4-2-2935 0795 31 - L - tcm795-1697591Document2 pages3-4-2-2935 0795 31 - L - tcm795-1697591Y.EbadiNo ratings yet

- Changes To Unintended Lift Movement: Risk Topic March 2016Document3 pagesChanges To Unintended Lift Movement: Risk Topic March 2016bugseNo ratings yet

- Refuse Disposal PDFDocument9 pagesRefuse Disposal PDFNtando MoyoNo ratings yet

- What Are The Applications of Suntak PCBDocument7 pagesWhat Are The Applications of Suntak PCBjackNo ratings yet

- Hyundai D 9 and DA 9 Series 35 50 SpecificationsDocument16 pagesHyundai D 9 and DA 9 Series 35 50 SpecificationsMetal FastrackNo ratings yet

- A/C System Precautions: Please Read This FirstDocument3 pagesA/C System Precautions: Please Read This FirstRonald FernandezNo ratings yet

- T110C Jupiter Z FenderDocument1 pageT110C Jupiter Z FenderDidik safdaliNo ratings yet

- Check SheetDocument6 pagesCheck SheetSyarif HidayatNo ratings yet

- RTA-19 - Oil Supply Monitoring For Geislinger Torsional Vibration DamperDocument5 pagesRTA-19 - Oil Supply Monitoring For Geislinger Torsional Vibration Damperdhilip87No ratings yet

- Arme Desarme Balancines C7Document3 pagesArme Desarme Balancines C7Alex Consuegra MedinaNo ratings yet

- Eco-Friendly Brake-Pad PDFDocument9 pagesEco-Friendly Brake-Pad PDFAndreea UrsacheNo ratings yet

- Employer List ChennaiDocument11 pagesEmployer List ChennaiKathirasan RamalingamNo ratings yet

- IC Engine (L1)Document8 pagesIC Engine (L1)abasNo ratings yet

- Triumph Tiger 1200 AccessoriesDocument24 pagesTriumph Tiger 1200 AccessoriesRodrigo FischNo ratings yet

- Targa Top Installation 911 - 65 93Document8 pagesTarga Top Installation 911 - 65 93Ulrik HjalberNo ratings yet

- Chassis LubricationDocument142 pagesChassis LubricationKen ThungNo ratings yet

- Baja Rule Book Updates & DVP Format - Padmesh Sewda (Compatibility Mode)Document28 pagesBaja Rule Book Updates & DVP Format - Padmesh Sewda (Compatibility Mode)Shrikant KhatingNo ratings yet

- Automobile Internship ReportDocument141 pagesAutomobile Internship Reportsathiya rNo ratings yet

- BearingsDocument2 pagesBearingstotol90No ratings yet

- P025A-Fuel Pump Control Circuit Open: 2013 - DS - RAM 1500 PICKUP - 4.7L MAGNUM V8Document4 pagesP025A-Fuel Pump Control Circuit Open: 2013 - DS - RAM 1500 PICKUP - 4.7L MAGNUM V8Willie AustineNo ratings yet

- Equipment Received DetailsDocument1 pageEquipment Received DetailsSubhadipSamanta OfficialNo ratings yet

- Hybrid Battery System Diagnostic Trouble Code ChartDocument5 pagesHybrid Battery System Diagnostic Trouble Code ChartAdamNo ratings yet