Professional Documents

Culture Documents

Tugas 6 J. Erwin R. Tambunan

Uploaded by

JAGAR ERWIN RIZNANDO TAMBUNANCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tugas 6 J. Erwin R. Tambunan

Uploaded by

JAGAR ERWIN RIZNANDO TAMBUNANCopyright:

Available Formats

TUGAS 6 JAGAR ERWIN RIZNANDO TAMBUNAN

MANAJEMEN PERAWATAN PESAWAT UDARA 23622029

HW6 AE5046: MATERIAL MANAGEMENT

1. The following spares are kept in inventory at a plant. Their annual use rate and

unit price are shown in the following table. Classify them as class A, B or C

items. Then suggest a policy for controlling each class.

SPARE ANNUAL

COST PER

PART USE

UNIT

NUMBER (UNITS)

S01 5000 17

S02 17000 51

S03 6000 17

S04 4000 75

S05 11000 200

S06 60000 9

S07 12000 60

S08 28000 50

S09 4000 18

S10 3000 25

2. In the average demand during lead time of a certain type of pump is 120 and the

standard deviation is 12. If the expected out of stock of the pump is 2%,

determine the re-order level so that the expectation can be realized.

Jawab :

1. - Menghitung Proyeksi Dollar Usage Annual ($)

Projected Dollar Usage Annual ($) = Annual Usage x Unit Cost

- Mengurutkan seluruh data dalam urutan menurun dari Annual $ Value.

- Menghitung Cumulative Dollar Usage dengan menjumlahkan Annunal $ Value.

- Menghitung Cumulative Percent of Total (%)

Cumulative Percent of Total (%) = Items Value ÷ Cumulative Annual $ Value

- Menghitung Cumulative Percent of Item

Cumulative Percent of Item = Sum of Cumulative Percent of Total (%) item wise

- Mengkalsifikasikan Cumulative Percent of Item:

A CLASS 10-20% OF TOTAL ITEMS BUT ACCOUNT FOR 60-80% OF THE TOTAL COST

B CLASS 20-30% OF TOTAL ITEMS BUT ACCOUNT FOR 60-80% OF THE TOTAL COST

C CLASS 60-80% OF TOTAL ITEMS BUT ACCOUNT FOR 10-20% OF THE TOTAL COST

TUGAS 6 JAGAR ERWIN RIZNANDO TAMBUNAN

MANAJEMEN PERAWATAN PESAWAT UDARA 23622029

SPARE PROJECTED PERCENTAGE

ANNUAL COST PER

PART DOLLAR USAGE OF TOTAL $ CUMULATIVE CLASS

USE (UNITS) UNIT

NUMBER ANNUAL ($) VALUE

S05 11,000 200 2,200,000 34.59% 35% A

S08 28,000 50 1,400,000 22.01% 57% A

S02 17,000 51 867,000 13.63% 70% A

S07 12,000 60 720,000 11.32% 82% B

S06 60,000 9 540,000 8.49% 90% B

S04 4,000 75 300,000 4.72% 95% B

S03 6,000 17 102,000 1.60% 96% C

S01 5,000 17 85,000 1.34% 98% C

S10 3,000 25 75,000 1.18% 99% C

S09 4,000 18 72,000 1.13% 100% C

TOTAL = 6,361,000

Item-item ini bisa dikendalikan seperti di bawah:

"Item Kelas A" harus memiliki kontrol yang sangat ketat dan catatan yang

akurat, penghitungan inventaris setiap dua minggu atau bulan.

"Item Kelas B" harus memiliki kontrol yang tidak terlalu ketat dan catatan

yang baik, penghitungan inventaris setiap kuartal.

"Item Kelas C" harus memiliki kontrol sesederhana mungkin dan catatan

minimal, jumlah inventaris setiap 6 bulan atau hitungan tahunan.

2. Diketahui : Expected demand during lead time = 𝜇 = 120

Standard deviation = 𝜎 = 12

Let R = Mean demand + Safety stock

Sehingga Safety stock = 𝑅 – 𝜇

𝑅−μ

𝑍= σ

Nilai Z didapatkan dari standarized normal tables

𝑍 = 2.326 for 98%

𝑅 − 120

2.326 =

12

Safety Stock = 𝑅 – 𝜇 = 147.912 – 120 = 27.912 ≈ 28

Re-order Level, R = 120 + 28 = 148

You might also like

- Visual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsFrom EverandVisual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsNo ratings yet

- PC Ch. 11 Techniques of Capital BudgetingDocument22 pagesPC Ch. 11 Techniques of Capital BudgetingVinod Mathews100% (2)

- Athletic Knit: A Case Study On Inventory ControlDocument9 pagesAthletic Knit: A Case Study On Inventory ControlAnagha Bhatkar100% (1)

- Business Plan On HIRING A MAIDDocument21 pagesBusiness Plan On HIRING A MAIDharsha100% (1)

- List of SAP Status CodesDocument19 pagesList of SAP Status Codesmajid D71% (7)

- Debt Collector Disclosure StatementDocument8 pagesDebt Collector Disclosure StatementGreg WilderNo ratings yet

- RAD Project PlanDocument9 pagesRAD Project PlannasoonyNo ratings yet

- Corporation Law DigestsDocument18 pagesCorporation Law DigestsDonnNo ratings yet

- Workplace Housekeeping: Training Slides OnDocument42 pagesWorkplace Housekeeping: Training Slides Onamit yadavNo ratings yet

- Athletic Knit: A Case Study On Inventory ControlDocument9 pagesAthletic Knit: A Case Study On Inventory ControlAnagha BhatkarNo ratings yet

- Inventory Valuation TutorialDocument4 pagesInventory Valuation TutorialSalma HazemNo ratings yet

- Corporate SustainabilityDocument17 pagesCorporate SustainabilityShiloh Williams0% (1)

- Assignment 2-Feb2023Document18 pagesAssignment 2-Feb2023NURUL HANISNo ratings yet

- 2021 - Topic Specific Assignment 4 - Inventory - Module 9Document6 pages2021 - Topic Specific Assignment 4 - Inventory - Module 9Tham NguyenNo ratings yet

- Chapter Four Material ManagementDocument58 pagesChapter Four Material ManagementbelaynehNo ratings yet

- EE HW3 SolutionDocument5 pagesEE HW3 SolutionLê Trường ThịnhNo ratings yet

- POM C12 Inventory ManagementDocument10 pagesPOM C12 Inventory ManagementLouis PatNo ratings yet

- CH 10 Spare Parts ProvisiongDocument20 pagesCH 10 Spare Parts ProvisiongTewodros DereseNo ratings yet

- Chapter Four - Inventory ManagementDocument13 pagesChapter Four - Inventory ManagementJahirul Islam ShovonNo ratings yet

- Engineering Economy Homework 3: Student Name: Student IDDocument4 pagesEngineering Economy Homework 3: Student Name: Student IDMinh TríNo ratings yet

- FM Assaignment Second SemisterDocument9 pagesFM Assaignment Second SemisterMotuma Abebe100% (1)

- Inventory ControlDocument56 pagesInventory ControlRahat AhammedNo ratings yet

- ABC Analysis Questions With AnswersDocument25 pagesABC Analysis Questions With AnswerslokendraNo ratings yet

- Exam 2 ReviewDocument53 pagesExam 2 ReviewNkeih FidelisNo ratings yet

- BPB31103 Production & Operations Management ch5Document76 pagesBPB31103 Production & Operations Management ch5Anis TajuldinNo ratings yet

- Inventory Management AnalysisDocument13 pagesInventory Management AnalysisMd Ashraful Al AsifNo ratings yet

- ABC AnalysisDocument1 pageABC AnalysismedrekNo ratings yet

- CBE 5 Module 5 TrueDocument8 pagesCBE 5 Module 5 TrueChristian John Resabal BiolNo ratings yet

- Please See Below Answer On Next Page: Homework By: Hardeep Singh (5411453)Document4 pagesPlease See Below Answer On Next Page: Homework By: Hardeep Singh (5411453)Hardeep SinghNo ratings yet

- Banking - Prof. Rafael Schiozer - Exercícios de Aula - Aulas 5 A 9 - SoluçõesDocument5 pagesBanking - Prof. Rafael Schiozer - Exercícios de Aula - Aulas 5 A 9 - SoluçõesCaioGamaNo ratings yet

- QM3345Document5 pagesQM3345Ngọc AnhNo ratings yet

- Solution Manual Engineering Economy 16th Edition William G. Sullivan, Elin M. Wicks, C. Patrick KoellingDocument15 pagesSolution Manual Engineering Economy 16th Edition William G. Sullivan, Elin M. Wicks, C. Patrick KoellingTrí NhânNo ratings yet

- 2nd Session Data Table What If AnalysisDocument6 pages2nd Session Data Table What If AnalysisAditya SinghNo ratings yet

- Inventory ControlDocument15 pagesInventory ControlNor Akramin MohamadNo ratings yet

- Elite, S.A. de C.V.: Balance GeneralDocument6 pagesElite, S.A. de C.V.: Balance GeneralGuadalupe e ZamoraNo ratings yet

- Romario N Austin IA MODULE 3Document4 pagesRomario N Austin IA MODULE 3Ben BrownNo ratings yet

- Inventory AnalysisDocument3 pagesInventory Analysisapi-3747057100% (3)

- X-Value Y-Value or Observed Cost Y-Value or Predicted CostDocument8 pagesX-Value Y-Value or Observed Cost Y-Value or Predicted CostIlpram YTNo ratings yet

- X-Value Y-Value or Observed Cost Y-Value or Predicted CostDocument8 pagesX-Value Y-Value or Observed Cost Y-Value or Predicted Costmiranti dNo ratings yet

- Week3 SolutionDocument3 pagesWeek3 SolutionRiski -No ratings yet

- Assignment 1 BAN 100 Edwin CastilloDocument11 pagesAssignment 1 BAN 100 Edwin CastilloEdwin CastilloNo ratings yet

- Depreciation Table MOFDocument3 pagesDepreciation Table MOFTerra HannaNo ratings yet

- Inventory ManagementDocument29 pagesInventory ManagementSyeda Samia SultanaNo ratings yet

- Chapter 12Document14 pagesChapter 12Naimmul FahimNo ratings yet

- Inventory Classification-ABC AnalysisDocument24 pagesInventory Classification-ABC AnalysisHritik DilawariNo ratings yet

- Assignment: Name: Faizan MoazzamDocument6 pagesAssignment: Name: Faizan MoazzamFaizan MoazzamNo ratings yet

- EndTerm Quiz 1 May 102022Document2 pagesEndTerm Quiz 1 May 102022Kyokyo TokimiNo ratings yet

- Costing Homework SolutionsDocument97 pagesCosting Homework SolutionsKunal BhansaliNo ratings yet

- Jerremy AcebuDocument9 pagesJerremy AcebuacebujerremyNo ratings yet

- OM Lab CH 12Document43 pagesOM Lab CH 12FLAVIAN BIMAHNo ratings yet

- Proyecto MoocDocument3 pagesProyecto MoocHector GodoyNo ratings yet

- WRD720S-2022 - Engineering Feasibility Econ - Examples 1 - 4 & Solutions RevDocument11 pagesWRD720S-2022 - Engineering Feasibility Econ - Examples 1 - 4 & Solutions RevMeg TNo ratings yet

- Inventory ManagementDocument43 pagesInventory Managementdharmendra kumarNo ratings yet

- Assignment 01-Fin421Document11 pagesAssignment 01-Fin421i CrYNo ratings yet

- Abc Method 555Document78 pagesAbc Method 555mohamed saidNo ratings yet

- Inventory ManagementDocument76 pagesInventory ManagementAnshul NataniNo ratings yet

- Problem Solving 6 - SoDocument8 pagesProblem Solving 6 - SoJoseph Maximus SoteloNo ratings yet

- BSFIN - Your Final OutputsDocument6 pagesBSFIN - Your Final OutputsPaul Jures DulfoNo ratings yet

- Assignment 1 Kelompok 3Document15 pagesAssignment 1 Kelompok 3iyanNo ratings yet

- FINC3014 Topic 8 SolutionsDocument5 pagesFINC3014 Topic 8 Solutionssuitup100No ratings yet

- Investment CriteriaDocument15 pagesInvestment CriteriaGOWTHAM K KNo ratings yet

- Annual Worth Analysis: Principles of Engineering Economic Analysis, 5th EditionDocument28 pagesAnnual Worth Analysis: Principles of Engineering Economic Analysis, 5th EditionnorahNo ratings yet

- Abm 2 (Week 2)Document4 pagesAbm 2 (Week 2)testing padasNo ratings yet

- Operations Management PS4Document9 pagesOperations Management PS4Vishal BhagiaNo ratings yet

- Replacement Breakeven AnalysisDocument8 pagesReplacement Breakeven AnalysisZoloft Zithromax ProzacNo ratings yet

- ABC Analysis FinalDocument3 pagesABC Analysis FinalJoyal GeorgeNo ratings yet

- Business Basics Test: Please Complete This Puzzle by Finding The Hidden WordsDocument1 pageBusiness Basics Test: Please Complete This Puzzle by Finding The Hidden WordsCavene ScottNo ratings yet

- Start A New Challenge - FXIFYDocument1 pageStart A New Challenge - FXIFYSähïl GäjëräNo ratings yet

- Mid Term Exam 1 - Fall 2018-799Document3 pagesMid Term Exam 1 - Fall 2018-799abdirahmanNo ratings yet

- B2B E-Marketplace Adoption in Agriculture: Zheng XiaopingDocument8 pagesB2B E-Marketplace Adoption in Agriculture: Zheng XiaopingNikhil MalhotraNo ratings yet

- Ibs Bukit Pasir, BP 1 31/03/22Document5 pagesIbs Bukit Pasir, BP 1 31/03/22Design ZeroNo ratings yet

- Politica de Dezvoltare Regională În RomâniaDocument34 pagesPolitica de Dezvoltare Regională În RomânialaNo ratings yet

- ABS Summary TextDocument12 pagesABS Summary TextjesusmemNo ratings yet

- Lilly Ghalichi, Lilly Lashes Sued For 10 Million DollarsDocument33 pagesLilly Ghalichi, Lilly Lashes Sued For 10 Million DollarsAll Glam Everything100% (1)

- Ilo Convetion 133Document12 pagesIlo Convetion 133Vicmel DiazNo ratings yet

- Helmet Jan19 PDFDocument31 pagesHelmet Jan19 PDFLokeshNo ratings yet

- 19.lewin, David. Human Resources Management in The 21st CenturyDocument12 pages19.lewin, David. Human Resources Management in The 21st CenturymiudorinaNo ratings yet

- BM 201 AssignmentDocument12 pagesBM 201 AssignmentMukul SuryawanshiNo ratings yet

- Braytron Catalogue 2019 PDFDocument174 pagesBraytron Catalogue 2019 PDFLiviu Cioroianu0% (1)

- Point 03 07 2023Document89 pagesPoint 03 07 2023Raouia El OuaiNo ratings yet

- Vishal Mega Mart Survey Atl BTLDocument2 pagesVishal Mega Mart Survey Atl BTLShuvajit BiswasNo ratings yet

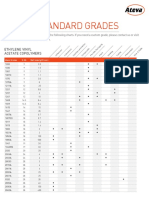

- !!!EVA 019 AtevaOverviewGradesSheet TS EN 0416 PDFDocument2 pages!!!EVA 019 AtevaOverviewGradesSheet TS EN 0416 PDFSlava75No ratings yet

- Ashishgupta3554 ResumeDocument1 pageAshishgupta3554 ResumeAshish GuptaNo ratings yet

- Issue 7: October 1998Document68 pagesIssue 7: October 1998Iin Mochamad SolihinNo ratings yet

- Leadership Development at Hindustan Unilever Limited FinalDocument10 pagesLeadership Development at Hindustan Unilever Limited FinaldurdenNo ratings yet

- TOA Reviewer (UE) - Bank Reconcilation PDFDocument1 pageTOA Reviewer (UE) - Bank Reconcilation PDFjhallylipmaNo ratings yet

- Governance, Risk and Dataveillance in The War On TerrorDocument25 pagesGovernance, Risk and Dataveillance in The War On Terroreliasox123No ratings yet

- Appendix V-Honda CSR 003Document11 pagesAppendix V-Honda CSR 003SowdayyaNo ratings yet