0% found this document useful (0 votes)

328 views1 pageRoot Cause Analysis Report Summary

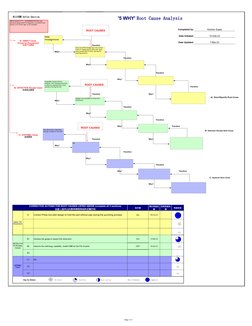

This document outlines a root cause analysis for a failed FAI of a leg extrusion band where the actual dimension was 13.72mm instead of the required 13.05±0.5mm. The direct cause was a hole misalignment due to an incorrect press tool pilot design that caused play in the part during punching. The detection cause was that the small variation was not captured during FAI because the part was checked with DVC instead of a gauge. The systemic cause was that gauges were not available to check the dimension even though it was included in the SQP.

Uploaded by

RAJESH SHARMACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

328 views1 pageRoot Cause Analysis Report Summary

This document outlines a root cause analysis for a failed FAI of a leg extrusion band where the actual dimension was 13.72mm instead of the required 13.05±0.5mm. The direct cause was a hole misalignment due to an incorrect press tool pilot design that caused play in the part during punching. The detection cause was that the small variation was not captured during FAI because the part was checked with DVC instead of a gauge. The systemic cause was that gauges were not available to check the dimension even though it was included in the SQP.

Uploaded by

RAJESH SHARMACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd