Professional Documents

Culture Documents

Tips-For-D1 - 1 Testing

Uploaded by

Charlie MillerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tips-For-D1 - 1 Testing

Uploaded by

Charlie MillerCopyright:

Available Formats

Tips for Passing Structural Welding Test

Here’s a list of 9 top tips that will help you pass your 3G Structural Welding Test (using a 7018 rod)

1. Most structural welding tests require a 22.5 degree bevel (also known as a 45 degree included angle)

on the two plates you will be joining together, with a 1/4 inch gap between the two pieces, and 1/4 inch

backing plate. 1/4 inch gap is pretty wide, but this is so you’re able to lay the 1/8 inch rod into the bevel

section between the two pieces. You need to make sure your gap is wide

enough to avoid excessive burn into the side walls of the bevel, or down into the backing plate.

2. Use a grinder to remove the mill scale from the welding area of subject materials, grinding down to

clean shiny metal on both sides of weld bevels and the backing plate. This is not technically a test

requirement, but a good idea because it’s the ideal field practice, and evaluators are looking for that kind

of behavior and attention to detail.

3. Plan ahead for placing your tie-ins. You don’t want to put your tie-ins on your root bend. Ideally, you

want to place them just a touch off-center.

4. The angle and height of the plate when you’re welding is important. Make sure you don’t put the plate

up to high relative to your physical height, it just makes the process that much harder. Evaluators expect

you to position the test plate straight up-and-down, but you can usually get away with up to a 5 degrees

angle. You don’t, however, want to angle the plate toward you (that’s almost like welding overhead), but

you should be able to get away with angling the plate about 5 degrees away from you, which will make

the rising angle a touch easier to handle as your weld travels upward.

5. Body position is important, because the more confortable you feel, the easier the process. The

consumable rod will become shorter as you weld, and you need to be comfortable with the body motion

necessary to adapt to this shrinking action. It’s best to use something to prop up the rod as you weld. If

don’t have any suitable object handy, you can prop up the rod with your finger as your weld travels

upward. Take a few dry runs to make sure you’re comfortable with the movements necessary to execute

the weld.

6. Expose the tip of your 7018 rod, especially if you’re going to restart a rod that’s already been used.

7018 rods don’t restart well, as they tend to form a slag cover over the end of the rod. With a file, you can

remove the slag coating and create a better starting surface.

7. You want your root pass to make contact with each side of the beveled edge, to ensure the weld

adequately penetrates the side walls and backing plate, and creates solid weld.

8. When you clean the weld with a file or slag hammer, you don’t want to peck at the weld bead, because

you’ll end up with divots, dents and dings. Instead, use the file and slag hammer to rake down each side

the of the weld bead to clean up the weld and remove slag.

9. Use a grinder to clean up the weld bead, especially at start points and where you tie-in to other welds. It

is rare that a grinder can not be used. However, the welder must be careful not to grind into the bevels and

change the joint geometry if this occurs the welder may be welding outside the parameters of the WPS and

the test would no longer be valid.

You might also like

- Top Tips For Passing STDocument1 pageTop Tips For Passing STtuna61No ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Pivot Replacement: ChecklistDocument7 pagesPivot Replacement: Checklistottershaw57No ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- DIY Bolt GuideDocument48 pagesDIY Bolt Guidelmkkilo3No ratings yet

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyFrom EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyRating: 5 out of 5 stars5/5 (4)

- Workshop Hints Pivot Replacement: ChecklistDocument8 pagesWorkshop Hints Pivot Replacement: Checklistottershaw57No ratings yet

- DIY Angle Grinder Pipe SanderDocument14 pagesDIY Angle Grinder Pipe SanderEdmar DL100% (1)

- Mashop Theory and PracticeDocument38 pagesMashop Theory and PracticeCel Caren MakidatoNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Comon Hand ToolsDocument15 pagesComon Hand Toolsचौकीदार गोपाल भार्गवNo ratings yet

- A Treatise on Staff Making and Pivoting Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialFrom EverandA Treatise on Staff Making and Pivoting Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialNo ratings yet

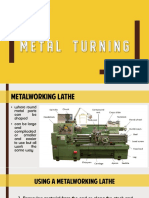

- Lathe Facing Operation Reduces Cylindrical Workpiece LengthDocument32 pagesLathe Facing Operation Reduces Cylindrical Workpiece Lengthusmaniqbal15No ratings yet

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerFrom EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerRating: 4 out of 5 stars4/5 (1)

- Drilling of A Work Piece Held in A ViseDocument8 pagesDrilling of A Work Piece Held in A ViseFaisal RafiqueNo ratings yet

- Bladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesFrom EverandBladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesRating: 4.5 out of 5 stars4.5/5 (3)

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- Ultimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildFrom EverandUltimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildNo ratings yet

- Installing the Instrument Panel and Engine CowlingDocument34 pagesInstalling the Instrument Panel and Engine Cowlingviorelu99No ratings yet

- Soldering: A Concise Guide to Joining Metal PartsDocument41 pagesSoldering: A Concise Guide to Joining Metal Partsメルヴリッ クズルエタNo ratings yet

- Low-Angle and Standard Block PlanesDocument8 pagesLow-Angle and Standard Block Planesrao1307100% (1)

- 4 Foot PVC Propeller: (Including New Blade Revisions)Document14 pages4 Foot PVC Propeller: (Including New Blade Revisions)eu1mister6002No ratings yet

- BandsawDocument11 pagesBandsawTrung Quoc LeNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- Benchcrafted Tail Vise Installation GuideDocument22 pagesBenchcrafted Tail Vise Installation GuideIulian MihaiNo ratings yet

- A Rotary Sine Bar For The LatheDocument2 pagesA Rotary Sine Bar For The LatheTheodor EikeNo ratings yet

- Building Firearms - HoffmanDocument81 pagesBuilding Firearms - HoffmanWilliam Owers100% (2)

- Slim Ballpoint Pen Hardware Kit: Preparing The Material BlanksDocument4 pagesSlim Ballpoint Pen Hardware Kit: Preparing The Material BlanksLachaud YvonNo ratings yet

- AK-47 Souptonuts 5Document7 pagesAK-47 Souptonuts 5tshirley47100% (3)

- Figure #2: The Parts For The Drilling Jig After Cutting To SizeDocument7 pagesFigure #2: The Parts For The Drilling Jig After Cutting To SizejacquesmayolNo ratings yet

- ConradDocument10 pagesConradEthiel TelescopiumNo ratings yet

- Machine and Building - Gc¡c¡¡rcafetv Off: Lab Safety 19O SnellDocument4 pagesMachine and Building - Gc¡c¡¡rcafetv Off: Lab Safety 19O SnellTHOMAS PUGHNo ratings yet

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDocument25 pagesWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockKovačević Darko100% (1)

- Riveting Basics: A Step-by-Step Guide to Riveting ProjectsDocument17 pagesRiveting Basics: A Step-by-Step Guide to Riveting ProjectsTanu RdNo ratings yet

- Guia VeritasDocument10 pagesGuia VeritasNatalia DiazNo ratings yet

- Construction of A Longworth ChuckDocument10 pagesConstruction of A Longworth ChuckshopsmithmodNo ratings yet

- Pipe Welding Guide: Essential Tips & TechniquesDocument8 pagesPipe Welding Guide: Essential Tips & TechniquesviptoneytNo ratings yet

- Rivet Tool Setup GuideDocument4 pagesRivet Tool Setup GuideDale WadeNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCristian Silva100% (1)

- Safe Grinder Use and Drill Safety TipsDocument13 pagesSafe Grinder Use and Drill Safety TipsEJ CastroNo ratings yet

- General DrillingDocument3 pagesGeneral DrillingAndrew GoslingNo ratings yet

- Bowl Basics 1Document5 pagesBowl Basics 1api-522254901No ratings yet

- Threading Operations of Lathe SystemDocument37 pagesThreading Operations of Lathe SystemResshille Ann T. SalleyNo ratings yet

- 4 Handy Table Saw Jigs Unlock Potential With Simple DIY ProjectsDocument11 pages4 Handy Table Saw Jigs Unlock Potential With Simple DIY Projectsmargalaz100% (1)

- Dovetail Guide User ManualDocument9 pagesDovetail Guide User ManualAnonymous 9zL9MblM3HNo ratings yet

- Testing Lathe For AccuracyDocument4 pagesTesting Lathe For AccuracyArnieTNo ratings yet

- BandsawDocument11 pagesBandsawVincent jaramillaNo ratings yet

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDocument25 pagesWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockJosé OrdoñezNo ratings yet

- Compact Metal Bender Manual PDFDocument64 pagesCompact Metal Bender Manual PDFarnoldodiel55% (11)

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Chapter 2 Different Types of FixturesDocument20 pagesChapter 2 Different Types of FixturesaragawNo ratings yet

- Teknologi Dan Rekayasa Cold ChiselsDocument21 pagesTeknologi Dan Rekayasa Cold ChiselsSinggih PNo ratings yet

- Sharpening Drill BitsDocument12 pagesSharpening Drill Bitsaabb_1my3724100% (2)

- 60 Marks: Fill The Gaps in The Sentences Using These VerbsDocument4 pages60 Marks: Fill The Gaps in The Sentences Using These VerbsAndrea AnidoNo ratings yet

- Dead Drop DeviceDocument7 pagesDead Drop DeviceAgino MottoNo ratings yet

- Ez Engine Build InstructionsDocument24 pagesEz Engine Build InstructionsAnonymous T7zEN6iLHNo ratings yet

- Bending ShapesDocument4 pagesBending ShapesramjoceNo ratings yet

- Arc Welding BasicsDocument61 pagesArc Welding BasicsHemaNo ratings yet

- Wood Crate Building Guide - Ana WhiteDocument22 pagesWood Crate Building Guide - Ana WhiteCharlie MillerNo ratings yet

- Adjustable 4 Corner Framing Clamp PlanDocument8 pagesAdjustable 4 Corner Framing Clamp PlanCharlie MillerNo ratings yet

- Gen-26883h Filler Metal Databook Us 2016 PDFDocument434 pagesGen-26883h Filler Metal Databook Us 2016 PDFMahendravarman ChinnasamyNo ratings yet

- ESAB Filler Book - 2015Document505 pagesESAB Filler Book - 2015Charlie MillerNo ratings yet

- Wood Turners HandbookDocument222 pagesWood Turners HandbookCharlie MillerNo ratings yet

- Braze Materials Guide: Sulzer MetcoDocument16 pagesBraze Materials Guide: Sulzer Metcojohn davidsNo ratings yet

- Request Form For MELISA Metal Allergy Testing: Instructions For Sample Taking Referred byDocument1 pageRequest Form For MELISA Metal Allergy Testing: Instructions For Sample Taking Referred byMárk KöllnerNo ratings yet

- Zeron 100-Data SheetDocument8 pagesZeron 100-Data SheetAfronie Cepoz D'nextNo ratings yet

- BS 1560 PDFDocument54 pagesBS 1560 PDFvaibhav100% (3)

- Datasheet For Steel Grades Structure Steel 45MnDocument2 pagesDatasheet For Steel Grades Structure Steel 45MnJhon ChitNo ratings yet

- Flomatic Price-List-2022Document40 pagesFlomatic Price-List-2022Esteban Barboza RiveraNo ratings yet

- Heat-Treatment - Basics: G S MahobiaDocument59 pagesHeat-Treatment - Basics: G S MahobiaElangoNo ratings yet

- SA-517 Grades for Pressure Vessel SteelDocument2 pagesSA-517 Grades for Pressure Vessel SteelsepackltdaNo ratings yet

- Chemical Resistance Guide: Chemical Resin Type Specific Gravity Rating Fitting Material Gasket Material Bolt MaterialDocument1 pageChemical Resistance Guide: Chemical Resin Type Specific Gravity Rating Fitting Material Gasket Material Bolt MaterialGokul VenugopalNo ratings yet

- LBC Fence Main & Addendum Contract Boq & Report ProgressDocument4 pagesLBC Fence Main & Addendum Contract Boq & Report ProgressRoge MingNo ratings yet

- Enginnering Tables - Part2Document14 pagesEnginnering Tables - Part2RRSNo ratings yet

- TUBE, UNS S31600/S31609, SMLS, AnnealedDocument2 pagesTUBE, UNS S31600/S31609, SMLS, AnnealedTuấn Dương QuốcNo ratings yet

- ISO 3506 stainless steel designation system breakdownDocument3 pagesISO 3506 stainless steel designation system breakdownPaulo Henrique NascimentoNo ratings yet

- Bohler CatalogDocument308 pagesBohler CatalogPerumal GovindanNo ratings yet

- Boost Metallurgy Knowledge for Boiler MaterialsDocument41 pagesBoost Metallurgy Knowledge for Boiler MaterialsLakshmi Narayan100% (2)

- Precidur HLB 17 / 17Mnb3: Boron-Alloyed Case Hardening SteelDocument3 pagesPrecidur HLB 17 / 17Mnb3: Boron-Alloyed Case Hardening Steelo_l_0No ratings yet

- ProductCatalog PDFDocument251 pagesProductCatalog PDFJorge VigoNo ratings yet

- Battery Recycling Datasheet: AccurecDocument1 pageBattery Recycling Datasheet: AccurecMacarena DiazNo ratings yet

- Welding 3&4 REV21Document40 pagesWelding 3&4 REV21Muhd Shabeeb ANo ratings yet

- Lecture-4-Intro. To Melting Furnaces-Lecture NotesDocument43 pagesLecture-4-Intro. To Melting Furnaces-Lecture NotesManchi MaheetNo ratings yet

- List of Indian Standard Specifications on Dimensional MetrologyDocument2 pagesList of Indian Standard Specifications on Dimensional MetrologyRavichandran DNo ratings yet

- "Rapid Repair" Machinable Sealing & Filling Compound: Trust Corium FORDocument2 pages"Rapid Repair" Machinable Sealing & Filling Compound: Trust Corium FORFraz AhmadNo ratings yet

- Lenox Catalog 2017Document52 pagesLenox Catalog 2017LuizEduardoBragaNo ratings yet

- M6-M20 Bolt and Nut Making Machine - HuaruiDocument25 pagesM6-M20 Bolt and Nut Making Machine - HuaruiparhamadkNo ratings yet

- Steel Specifications PDFDocument2 pagesSteel Specifications PDFdeniNo ratings yet

- Industrial Automation: Operating Principle Ferrite CoreDocument5 pagesIndustrial Automation: Operating Principle Ferrite Coreabd salamNo ratings yet

- Technical Data PDFDocument41 pagesTechnical Data PDFrachitmailNo ratings yet

- SubmittalDocument45 pagesSubmittalsydneyaus2005No ratings yet

- Stainless and Electrical Steels - Machinability-RatingDocument1 pageStainless and Electrical Steels - Machinability-RatinggoggerNo ratings yet

- CatalogueDocument3 pagesCatalogueGrayloupNo ratings yet