Professional Documents

Culture Documents

ME8694-Hydraulics and Pneumatics QP - by WWW - LearnEngineering.in

Uploaded by

prethiprathi18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME8694-Hydraulics and Pneumatics QP - by WWW - LearnEngineering.in

Uploaded by

prethiprathi18Copyright:

Available Formats

For More Visit : www.LearnEngineering.

in

SRMVALLIAMMAI ENGINEERING COLLEGE

(An Autonomous Institution)

SRM Nagar, Kattankulathur– 603 203

DEPARTMENT OF MECHANICAL ENGINEERING

QUESTIONBANK

.in

ng

eri

g ine

En

VII SEMESTER

arn

ME-8694- HYDRAULICS AND PNEUMATICS

Le

Regulation – 2017

Academic Year 2019 – 20

w.

ww

Prepared by

Mr.G. Ananth, Assistant Professor (Sel. Gr) /MECHANICAL ENGINEERING

Mr.R. Srinivasan, Assistant Professor (Sr. Gr)/MECHANICAL ENGINEERING

Mr.P.Vijayan, Assistant Professor (O.G) /MECHANICAL ENGINEERING

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

SRM VALLIAMMAI ENGINEERING COLLEGE

(An Autonomous Institution)

SRM Nagar, Kattankulathur – 603 203.

DEPARTMENT OF MECHANICAL ENGINEERING

QUESTION BANK

UNIT-I FLUID POWER PRINICIPLES AND HYDRAULIC PUMPS

Introduction to Fluid power – Advantages and Applications – Fluid power systems – Types of fluids -

Properties of fluids and selection – Basics of Hydraulics – Pascal’s Law – Principles of flow -

.in

Friction loss – Work, Power and Torque Problems, Sources of Hydraulic power : Pumping Theory –

Pump Classification – Construction, Working, Design, Advantages, Disadvantages,

Performance, Selection criteria of Linear and Rotary – Fixed and Variable displacement pumps –

ng

Problems.

PART A

eri

1 Describe fluid power. BT1 Remembering

2 List out the advantages and disadvantages of fluid power systems. BT1 Remembering

ine

3 Define Pascal law. BT1 Remembering

4 Why are the hydraulic system is preferred for heavy work than

BT2 Understanding

pneumatic system

g

5 Describe the primary functions of a fluid in the fluid power systems.

En

BT1 Remembering

6 Discuss the properties of hydraulic fluids which is used in the fluid

BT3 Applying

power systems.

arn

7 Name the basic component which is employed in the hydraulic systems. BT3 Applying

8 State the effect of temperature on viscosity of fluids in the fluid power

BT1 Remembering

Le

systems.

9 Define demulsibility. BT1 Remembering

w.

10 Define neutralization number of hydraulic fluids. BT1 Remembering

11 State the pumping theory. BT2 Understanding

ww

12 Define pump. BT1 Remembering

13 List any four hydraulic fluids that are commonly used in fluid power

BT1 Remembering

systems

14 Why water is not used as hydraulic fluid in fluid power systems BT2 Understanding

15 Differentiate fixed and variable displacement pump. BT3 Applying

16 Describe the term volumetric efficiency and mechanical efficiency. BT2 Understanding

17 List the losses in the fluid power systems. BT1 Remembering

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

18 Describe work and power of fluid power systems. BT1 Remembering

19 Write the Darcy’s equation and explain the uses of Darcy’s equation. BT2 Understanding

20 What is positive displacement pump? Why are they called so? BT2 Understanding

PART B

1 State Pascal's law and Explain in details about the application of

BT1 Remembering

Pascal's law with neatsketch.

2 Discuss the following,

(i) Draw and name the graphic symbols used for pump and motor. (6) BT4 Analyzing

.in

(ii) Draw and name the graphic symbols used for cylinder and flow

control valves. (7) BT4 Analyzing

ng

3 Explain with neat sketch about working principle of basic hydraulic

BT2 Understanding

system and pneumatic system

4 Discuss the following

(i) eri

Various types of hydraulic fluids used in the hydraulic

BT4 Analyzing

ine

systems. (5)

BT4 Analyzing

(ii) Properties of hydraulic fluids. (8)

g

5 Explain the following BT2 Understanding

En

(i) Fluid power system based on control system. (7)

(ii) Fluid power system based on type of control. (6) BT2 Understanding

6 Explain in details about the various losses in hydraulic fluid power

arn

BT2 Understanding

systems.

7 (i) Explain the pumping theory with suitable sketch. (6) BT2 Understanding

Le

(ii) Explain the working of Lobe pump with suitable sketch. (7) BT2 Understanding

8 Explain the working principle of following pumps with neat sketch

w.

(i) Lobe pump (7) BT2 Understanding

(ii) Screw pump (6) BT2 Understanding

ww

9 (i) Explain the external gear pump with suitable sketch.(6) BT1 Remembering

(ii) Explain the working of internal gear pump with suitable sketch. (7) BT1 Remembering

10 Discuss the following

(i) Balanced vane pump. (6) BT3 Applying

(ii) Unbalanced vane pump. (7) BT3 Applying

11 Explain the construction and working principle of in-line axial piston

BT2 Understanding

pump with suitable sketch.

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

12 Explain the construction and working principle of bend axis axial piston

BT2 Understanding

pump with suitable sketch.

13 Describe the working principle of radial piston pump with suitable

BT1 Remembering

sketch.

14 Explain the performance characteristics of pump with suitable sketch

BT2 Understanding

and specific term associated with performance.

PART C

1 Design the hydraulic circuit and explain with neat sketch for the

BT6 Creating

.in

application of hand operated hydraulic jack.

2 Write short notes about the various application of hydraulic systems

BT1 Remembering

ng

with suitable example.

3 A pump has displacement of 8.19 cm3. It delivers 75.8 x 10-3m3/min at

eri

1000 rpm at 67 bars. If the prime mover input torque is 100 Nm. Find

BT5 Evaluating

(i) Overall and volumetric efficiency.

ine

(ii) Theoretical torque required to operate the pump.

4 List and explain the design criteria of Linear and Rotary pump in the

BT4 Analyzing

hydraulic systems.

g

En

arn

Le

w.

ww

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

UNIT II HYDRAULIC ACTUATORS AND CONTROL COMPONENTS

Hydraulic Actuators: Cylinders – Types and construction, Application, Hydraulic cushioning –

Hydraulic motors - Control Components: Direction Control, Flow control and pressure control valves

– Types, Construction and Operation – Servo and Proportional valves – Applications – Accessories:

Reservoirs, Pressure Switches – Applications –Fluid Power ANSI Symbols – Problems.

PART A

1 Describe actuator. BT2 Understanding

2 Classify the various types of actuator. BT2 Understanding

.in

3 Discuss about telescoping cylinder. BT2 Understanding

4 Name the types of cylinder mountings. BT1 Remembering

ng

5 What is the function of hydraulic motor and how does it differ from the

BT1 Remembering

hydraulic pump?

6

7

Describe the term cylinder cushioning.

eri

What is a semi-rotary actuator? List the application of semi -rotary

BT1 Remembering

ine

BT2 Understanding

actuator.

8 What are the advantages of double acting cylinder over a single acting

BT2 Understanding

g

cylinder?

En

9 What is the function of seals in the hydraulic system and list the type of

BT2 Understanding

seals used in the systems?

arn

10 Draw the ANSI symbol for bidirectional fixed displacement

BT4 Analyzing

unidirectional motor and variable displacement bidirectional motor.

11 Describe the three important parameters should controlled the hydraulic

Le

BT1 Remembering

system.

12 Draw the symbols for a pressure relief valve and pressure reducing

w.

BT4 Analyzing

valve

13 Describe the purpose of Shuttle valve and mention types of control

ww

BT1 Remembering

valve based on their function.

14 Draw the ANSI symbol for Pilot operated check valves and shuttle

BT4 Analyzing

valves.

15 What is the function of sequence valve and pressure reducing valve? BT2 Understanding

16 Discuss the function of pressure control valve BT2 Understanding

17 What are flow control valves? Why are they referred as speed-control

BT2 Understanding

valves?

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

18 List out the various types of pressure control valve. BT1 Remembering

19 Describe the function of check valves. BT1 Remembering

20 What is solenoid valve and how does it actuatethe spool of a DC valve? BT1 Remembering

PART B

1 Explain the working principle following types of cylinders

i) Single acting cylinder (5) BT2 Understanding

ii)Cylinder Cushioning (8) BT2 Understanding

2 Explain the construction and working of following with neat sketch

.in

(i) Gear motor (7) BT2 Understanding

(ii) Double acting cylinder (6) BT2 Understanding

ng

3 With neat sketch explain the construction of Telescopic cylinder and

BT3 Applying

state its applicationwith example.

eri

4 Explain with neat sketch about the construction and working principle

BT4 Analyzing

of vane motor and state its applications.

ine

5 Explain the following with neat sketch

(i) Poppet valve. (6) BT2 Understanding

(ii) Pilot operated check valve. (7) BT2 Understanding

g

6 Explain the following

En

(i) 4/3- Direction Control Valve (7) BT2 Understanding

(ii) 3/2-DirectionControlValve (6) BT2 Understanding

arn

7 Explain with neat sketch about different types of flow control valve

BT4 Analyzing

used in the hydraulic systems.

Le

8 Explain with neat sketch about the following

(i) Meter-in (7) BT3 Applying

w.

(ii) Meter-out (6) BT3 Applying

9 Explain with neat sketch about spring loaded pressure relief valve and

BT4 Analyzing

ww

pressure reducing valve.

10 Explain with neat sketch about compound pressure relief valve. BT2 Understanding

11 Explain with neat sketch about the following

(i) Unloading valve (6) BT3 Applying

(ii) Sequence valve (7) BT3 Applying

12 Explain the construction and working principle of rotary spool valve

BT2 Understanding

used in the hydraulic systems.

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

13 (i) Explain the working principle of Mechanical hydraulic servo

valve. (7) BT2 Understanding

(ii) Explain the flapper servo valve with neat sketch. (6) BT2 Understanding

14 Discuss the following

(i) Proportional pressure relief valve. (7) BT2 Understanding

(ii) Proportional pressure reducing valve. (6) BT2 Understanding

PART C

1 Design the hydraulic drilling circuit using sequence valve and explain with

BT6 Creating

neat sketch.

.in

2 Explain and design the hydraulic circuit by using pressure reducing valve for

BT6 Creating

the weld and clamp unit to weld the Engineering materials.

ng

3 Explain with suitable sketch and mention the various possible location of

BT4 Analyzing

filters in the hydraulic circuit systems.

4

symbol of all the components in the hydraulic systems. eri

List the components used in the hydraulic systems and sketch the ANSI

BT3 Applying

g ine

En

arn

Le

w.

ww

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

UNITIII - HYDRAULIC CIRCUITS AND SYSTEMS

Accumulators, Intensifiers, Industrial hydraulic circuits – Regenerative, Pump Unloading, Double-

Pump, Pressure Intensifier, Air-over oil, Sequence, Reciprocation, Synchronization, Fail-Safe, Speed

Control, Hydrostatic transmission, Electro hydraulic circuits, Mechanical hydraulic servo systems.

PART A

1 Draw the different types of accumulator symbols. BT2 Understanding

2 Discuss the functions of accumulators. BT4 Analyzing

3 What is meant by sizing of accumulator? BT1 Remembering

4 What is the function of pressure intensifier? BT1 Remembering

.in

5 Define the term “capacity of accumulator” BT1 Remembering

6 What type of gases used in a gas loaded accumulator? Why oxygen not

ng

BT1 Remembering

used for this purpose?

7 Why are non-separator type gas loaded accumulator not preferred in

eri

BT2 Understanding

hydraulic systems?

8 What condition in a hydraulic system would require an intensifier? BT2 Understanding

ine

9 List any four applications of intensifier. BT1 Remembering

10 Draw fluid power symbol for pressure intensifier and gas loaded type

BT4 Analyzing

g

accumulator.

En

11 Define the term intensifier ratio. BT1 Remembering

12 What are the factors to be considered while designing any fluid power

BT2 Understanding

arn

system?

13 Why extension stroke faster than the retraction stroke in the

BT2 Understanding

regenerative circuit?

Le

14 What is the purpose of using fail safe circuit in any hydraulic system? BT2 Understanding

15 What is meant by servo control system BT2 Understanding

w.

16 Define the term lap and null with respect to servo valves. BT1 Remembering

17 Mention any four applications hydro-mechanical servo valves. BT1 Remembering

ww

18 What is the purpose of air over oil intensifier circuit? BT2 Understanding

19 Describe the hydraulic accumulator and its type. BT2 Understanding

20 What are electrohydraulic servo valves? How do they differ from

BT4 Analyzing

mechanical servo valves?

PART B

1 With a neat sketch, explain the construction and working of a piston

BT4 Analyzing

type accumulator and diaphragm type accumulator?

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

2 Explain the construction and working of the following

(i) Dead weight accumulator. (7) BT2 Understanding

(ii) Spring loaded accumulator. (6) BT2 Understanding

3 Design and explain the working of a sequencing circuit. BT6 Creating

4 Explain the construction and working of pilot operated sequence valve. BT4 Analyzing

5 Draw and explain the Counterbalance circuit used in the hydraulic

BT3 Applying

circuit.

6 Design and explain the working of a regenerative circuit. BT6 Creating

.in

7 Explain the working principle of pressure intensifier, with neat diagram. BT4 Analyzing

8 Draw and explain the Air-over-oil circuit used in the hydraulic circuit.

BT3 Applying

ng

9 Describe a hydraulic circuit for synchronizing two cylinder with flow

BT2 Understanding

eri

control valves.

10 Design the accumulator circuit for the application of hydraulic shock

BT6 Creating

ine

absorber and Emergency power source in the hydraulic circuit.

11 Discuss the construction and working of a Mechanical hydraulic servo

BT3 Applying

system with a diagram.

g

12 Develop a circuit having 4/3 DCV regenerative neutral used to control

En

BT6 Creating

double acting cylinder

13 Design the intensifier circuit for the application of punching press in the

arn

BT6 Creating

hydraulic circuit.

14 Design and explain the working of Electro hydraulic circuit. BT6 Creating

Le

PART C

1 A double acting cylinder is hooked up in a regenerative circuit for

drilling application. The relief valve is set at 75 bar. The piston diameter

w.

is 140mm and rod diameter is 100 mm. If the pump flow is 80 1/min. BT5 Evaluating

find the cylinder speed and load carrying capacity for various position

ww

of direction control valve.

2 Design the accumulator circuit for the application of leakage

BT6 Creating

compensator and auxiliary power source in the hydraulic circuit.

3 Create a failsafe control circuit using emergency cut off value and two-

BT6 Creating

hand safety control circuit.

4 Design the accumulator circuit for the application of hydraulic shock

BT6 Creating

absorber and Emergency power source in the hydraulic circuit.

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

UNIT IV PNEUMATIC AND ELECTRO PNEUMATIC SYSTEMS

Properties of air – Perfect Gas Laws – Compressor – Filters, Regulator, Lubricator, Muffler, Air

control Valves, Quick Exhaust Valves, Pneumatic actuators, Design of Pneumatic circuit – Cascade

method – Electro Pneumatic System – Elements – Ladder diagram – Problems, Introduction to

fluidics and pneumatic logic circuits.

PART A

1 Give the standard graphical symbol for FRL unit. BT3 Applying

2 Discuss the function of an air filter BT2 Understanding

3 Point out the purpose of a Pressure regulator. BT2 Understanding

.in

4 Point out the purpose of a quick Exhaust Valve. BT5 Evaluating

5 Sketch the graphical symbol of pneumatic regulator. BT1 Remembering

ng

6 Discuss the function at reservoir in a pneumatic system BT1 Remembering

7 How are logic circuits classified? BT3 Applying

8

9

List the purpose of an Air lubricant.

eri

What are the factors affecting the selection of filter?

BT4

BT4

Analyzing

Analyzing

ine

10 Define ladder diagram. BT1 Remembering

11 What is the best type of lubricant for the pneumatic system? BT3 Applying

g

12 Mention the few applications of air cylinder. BT2 Understanding

En

13 List the components present in PLC.

14 Conclude that why should a lubricator be used in a pneumatic system? BT4 Analyzing

arn

15 Discuss the need of lubricator unit in the pneumatic system. BT1 Remembering

16 Name the various types of filters used in the pneumatic system. BT2 Understanding

17 Give the truth table for fluidic AND/NAND gate. BT4 Analyzing

Le

18 Define fluidics BT1 Remembering

19 Define Programmable Logic Control (PLC). BT1 Remembering

w.

20 Illustrate about cascade method. BT4 Analyzing

ww

PART B

1 Define compressor. Explain the working principle of piston type

BT1 Remembering

compressor and screw type compressor with neat sketch.

2 With a neat sketch of the pneumatic filter and explain its construction

BT3 Applying

and working of cartridge filter.

3 With a neat sketch of the pneumatic Regulator and explain its

BT4 Analyzing

construction and working.

10

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

4 Explain the construction and working principle of Muffler with neat

BT4 Analyzing

sketch.

5 Sketch the graphical symbol and Explain the construction and working

BT3 Applying

principle of FRL Unit with neat sketch.

6 Explain the construction and working of following pneumatic control

components

1) check valve

BT4 Analyzing

2) Shuttle valve

.in

3) Sequence valve

4) Flow control valve

ng

7 Explain the construction and operation of quick exhaust valve with neat

BT2 Understanding

sketch.

eri

8 Describe pneumatic actuators andexplain the types of linear actuators

BT1 Remembering

with neat sketch.

ine

9 Discuss the construction and operation of the basic fluidic devices. BT2 Understanding

10 Draw the circuit of control of air cylinder using Flip-Flop and explain it. BT3 Applying

11 Explain the ladder logic diagram with a suitable example. BT4 Analyzing

g

12 Design a pneumatic circuit for the following sequence using cascade

En

method A+B+B-A- where the + cylinder extraction and - cylinder BT5 Evaluating

retraction.

arn

13 Explain the construction and operation of rotary actuators with neat

BT2 Understanding

sketch.

Le

14 Design a pneumatic circuit using cascade method for the sequence A+

BT5 Evaluating

A- B+ B- and explain its working principle.

w.

PART C

1 Give the empirical rules for sizing the compressor. BT5 Evaluating

ww

2 Define coanda effect. Discuss how this effect useful to develop a mono-

BT5 Evaluating

stable and bi-stable- flip flop device

3 (i) Design a pneumatic cascade circuit for the following BT6 Creating

sequence of operation: A+ B+B-C+C-A- . (10)

BT6 Creating

(ii) Also develop the travel-step diagram for the above sequence

of operation. (5)

4 Explain the various approaches for entering the program into the PLC. BT4 Analyzing

11

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

UNIT V TROUBLE SHOOTING AND APPLICATIONS

Installation, Selection, Maintenance, Trouble Shooting and Remedies in Hydraulic and Pneumatic

systems, Design of hydraulic circuits for Drilling, Planning, Shaping, Surface grinding, Press and

Forklift applications. Design of Pneumatic circuits for Pick and Place applications and tool handling in

CNC Machine tools – Low cost Automation – Hydraulic and Pneumatic power packs.

PART A

1 What are the basic requirements for trouble free life of fluid power

BT1 Remembering

systems?

.in

2 List any two common faults in hydraulic system. BT2 Understanding

3 Name any two faults that can be found in pneumatic systems. BT4 Analyzing

ng

4 How a hydraulic system breaks down? BT2 Understanding

5 List any two selection criteria of hydraulic systems BT3 Applying

6

7

Distinguish between hydraulic and pneumatic systems.

What is the purpose of tree branching chart? eri BT1

BT4

Remembering

Analyzing

ine

8 List four causes of hydraulic system break down. BT3 Applying

9 Describe a power pack. BT1 Remembering

g

10 List any four pump faults. BT1 Remembering

En

11 Name two causes of relief valve faults. BT2 Understanding

12 What does the term troubleshooting refer? BT4 Analyzing

arn

13 If a pump is delivering insufficient or no oil, what are all the possible

BT2 Understanding

causes and also give remedies for them

14 List any four causes for pump making more noise. BT3 Applying

Le

15 What will you do to reduce or prevent excessive heating of oil in

BT1 Remembering

hydraulic system?

w.

16 List any two types of that can be found in each of the components of

BT4 Analyzing

FRL unit.

ww

17 What is meant by interlock contacts? BT3 Applying

18 Mention any two roles of pneumatic systems in low cost automation BT1 Remembering

19 What are the parable causes and remedies for the problem of leakage of

BT2 Understanding

compressed air in pneumatic system?

20 What is a power pack? What are the important components of a

BT3 Applying

hydraulic power Pack?

12

For More Visit : www.LearnEngineering.in

For More Visit : www.LearnEngineering.in

PART B

1 Design and draw a circuit using the hydraulic components for the

BT6 Creating

Shaping operation.

2 Design and draw a circuit using the hydraulic components for the

BT6 Creating

Drilling operation.

3 Design a circuit using the hydraulic components for the Press

BT6 Creating

operation.

4 Tabulate the various faults, probable causes and also the remedial

actions for the following hydraulic system components:

BT5 Evaluating

a. Pump b. DC valve

.in

c. Hydraulic motors d. Hydraulic cylinders

5 Enlist the various faults, probable causes and also the remedial actions

ng

for the following pneumatic system components:

BT5 Evaluating

a. Compressor b. FRL unit

b. Air cylinder d. Pipelines and hoses

eri

6 Explain in detail about how the failure and trouble shooting is carried

BT3 Applying

out in hydraulic system.

ine

7 Explain in detail about Various selection criteria for pneumatic

BT1 Remembering

components

8 What is the tree branching in pneumatic fault finding system? BT6 Creating

g

9 List out any seven types of faults that can be found in pneumatic

En

BT1 Remembering

system. Also write the remedial actions for the faults.

10 What is the tree branching in hydraulic fault finding system? BT6 Creating

arn

11 Explain in detail about how the failure and trouble shooting is carried

BT4 Analyzing

out in pneumatic system.

12 How tools are handled in a CNC machine illustrate with neat sketches

Le

BT1 Remembering

13 What are hydraulic and pneumatic power packs BT6 Creating

14 List down the features of low cost automation

w.

BT4 Analyzing

PART C

1 Design and develop a pneumatic system to pick and place objects.

ww

BT6 Creating

2 Design and develop the tool handling system in a CNC machine BT6 Creating

3 Narrate a case study of low cost automation. BT6 Creating

4 Draw and explain a pneumatic circuit to actuate a shaping machine ram.

Incorporate the following features in the circuit.

i. Rapid tool approach BT3 Applying

ii. Slow cutting and

iii. Rapid tool retraction/ return.

13

For More Visit : www.LearnEngineering.in

You might also like

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsFrom EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsRating: 4 out of 5 stars4/5 (5)

- EI6002-Power Plant InstrumentationDocument7 pagesEI6002-Power Plant Instrumentationgdreddy25No ratings yet

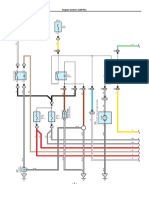

- Toyota 2AR-FE Wiring DiagramDocument19 pagesToyota 2AR-FE Wiring DiagramTomyNo ratings yet

- ME6021-Hydraulics and Pneumatics PDFDocument9 pagesME6021-Hydraulics and Pneumatics PDFelabalajiNo ratings yet

- ME6021-Hydraulics and PneumaticsDocument9 pagesME6021-Hydraulics and PneumaticsDharmalingam Ramasamy100% (1)

- HP Question Bank PDFDocument8 pagesHP Question Bank PDFdurgapriyaNo ratings yet

- ME8694 Hydraulics and Pneumatics QBDocument11 pagesME8694 Hydraulics and Pneumatics QBKarthi KeyanNo ratings yet

- Design of Hydraulic and Pneumatic SystemsDocument11 pagesDesign of Hydraulic and Pneumatic SystemsBoopathi Kalai100% (1)

- Design of Hydraulic and Pneumatic Systems - QPDocument11 pagesDesign of Hydraulic and Pneumatic Systems - QPKarthik SubramaniNo ratings yet

- ME8791-Mechatronics-Question Bank - by WWW - LearnEngineering.inDocument12 pagesME8791-Mechatronics-Question Bank - by WWW - LearnEngineering.inManoj Kumar.SNo ratings yet

- ME8791 MechatronicsDocument12 pagesME8791 MechatronicsAnkitNo ratings yet

- EI8552-Industrial Instrumentation-IIDocument13 pagesEI8552-Industrial Instrumentation-IIARUNKUMAR MNo ratings yet

- Power Plant Engineering Question BankDocument17 pagesPower Plant Engineering Question BankVidyarthiplus IndiaNo ratings yet

- Mechatronics and AutomationDocument21 pagesMechatronics and AutomationVignesh kumar GNo ratings yet

- Design of Hydraulic and Pneumatic Systems Digital MaterialDocument138 pagesDesign of Hydraulic and Pneumatic Systems Digital Materialla masiaNo ratings yet

- Valliammai Engineering College Question Bank on Power Electronics for Renewable Energy SystemsDocument10 pagesValliammai Engineering College Question Bank on Power Electronics for Renewable Energy SystemsraghavNo ratings yet

- Me8073 Unconventional Machining ProcessesDocument16 pagesMe8073 Unconventional Machining ProcessesVenkadesh Arumugam (Esaikaathalan)No ratings yet

- EE6009-Power Electronics For Renewable Energy SystemsDocument10 pagesEE6009-Power Electronics For Renewable Energy SystemsMani RNo ratings yet

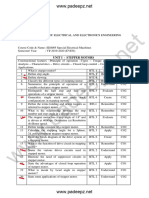

- EE8005-Special Electrical Machines QP - by WWW - LearnEngineering.inDocument13 pagesEE8005-Special Electrical Machines QP - by WWW - LearnEngineering.inpriya dharshiniNo ratings yet

- Restructred Power SystemDocument14 pagesRestructred Power SystemKURAKULA VIMAL KUMARNo ratings yet

- HP Question Paper 2023Document3 pagesHP Question Paper 2023Monika BNo ratings yet

- Ei2303 II 2 Nov Dec 2014 QPDocument11 pagesEi2303 II 2 Nov Dec 2014 QPKirthikaNo ratings yet

- EE8702-Power System Operation and Control - by WWW - Learnengineering.inDocument20 pagesEE8702-Power System Operation and Control - by WWW - Learnengineering.inhari vigneshNo ratings yet

- EE8072-MEMS and Nano ScienceDocument10 pagesEE8072-MEMS and Nano ScienceMs.Ezhilarasi ICE DepartmentNo ratings yet

- 2 D Transformations 2Document12 pages2 D Transformations 2Scilviya. WNo ratings yet

- Computer Aided Design of Electrical ApparatusDocument12 pagesComputer Aided Design of Electrical Apparatusraj selvarajNo ratings yet

- All Unit Important Question Without Answer - Kinematics of MachineryDocument22 pagesAll Unit Important Question Without Answer - Kinematics of MachineryGanapathy TNo ratings yet

- IC8451-Control SystemsDocument21 pagesIC8451-Control Systemsusha raniNo ratings yet

- Power ElectronicsDocument10 pagesPower ElectronicsAish KrishNo ratings yet

- SRM Valliammai Engineering College Question Bank on Unconventional Machining ProcessesDocument11 pagesSRM Valliammai Engineering College Question Bank on Unconventional Machining ProcessesBollu SatyanarayanaNo ratings yet

- Mems and Nano ScienceDocument10 pagesMems and Nano ScienceDr. Gopinath SNo ratings yet

- Protection Anmd SwitchgearDocument15 pagesProtection Anmd Switchgearraj selvarajNo ratings yet

- Control Systems Engineering Question BankDocument19 pagesControl Systems Engineering Question BankSelvaraj ParamasivanNo ratings yet

- EE6009-Power Electronics For Renewable Energy SystemsDocument10 pagesEE6009-Power Electronics For Renewable Energy SystemsManjuKarthick100% (1)

- Restructred Power System PDFDocument13 pagesRestructred Power System PDFLakshmi ZaharaNo ratings yet

- ME8391 IQ 03 - by LearnEngineering - inDocument24 pagesME8391 IQ 03 - by LearnEngineering - inelabalajiNo ratings yet

- 1st ASSIGNMENT - FPEDocument1 page1st ASSIGNMENT - FPEsujay uiNo ratings yet

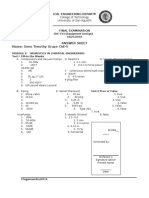

- Roll No.: PART-A (10 X 2 20 Marks)Document2 pagesRoll No.: PART-A (10 X 2 20 Marks)TamilselviNo ratings yet

- S.No Questions Level Competence: Bethlahem Institute of EngineeringDocument8 pagesS.No Questions Level Competence: Bethlahem Institute of EngineeringNIKASH maniNo ratings yet

- SRM Valliammai Engineering College Question Bank on Advanced I.C. EnginesDocument21 pagesSRM Valliammai Engineering College Question Bank on Advanced I.C. EnginesajitsssNo ratings yet

- EE8005 Special Electrical Machines IMPORTANT QUESTIONDocument13 pagesEE8005 Special Electrical Machines IMPORTANT QUESTIONDHANESH R 18EC026100% (1)

- Hirasugar Institute of Technology, Nidasoshi: 1. AssignmentDocument2 pagesHirasugar Institute of Technology, Nidasoshi: 1. AssignmentChetan KarigarNo ratings yet

- EE8005 Iq Special Electrical MachinesDocument12 pagesEE8005 Iq Special Electrical MachinesVishnuNo ratings yet

- ST5203 Experimental TechniquesDocument8 pagesST5203 Experimental TechniquesDharmaraaj RajalinggamNo ratings yet

- ME F242 IC EnginesDocument4 pagesME F242 IC EnginesHIMANSHU SHARMANo ratings yet

- Kinematics of MachineryDocument22 pagesKinematics of MachineryPati Sai VenkatNo ratings yet

- Valliammai Enginering College Department of Mechanical EngineeringDocument6 pagesValliammai Enginering College Department of Mechanical EngineeringMani KandanNo ratings yet

- Important Questions For UCMPDocument12 pagesImportant Questions For UCMPSai KethavarapuNo ratings yet

- BIoE Hydraulics ExamDocument4 pagesBIoE Hydraulics ExamCOMMANDER ALANNo ratings yet

- Kinematics of MachineryDocument32 pagesKinematics of Machineryprempragupta123No ratings yet

- AHPMEDocument1 pageAHPMEStephen JacsiNo ratings yet

- EE6703 Special Electrical MachinesDocument12 pagesEE6703 Special Electrical MachinesSuganthiNo ratings yet

- 1903604 Water Supply and Waste Water EngineeringDocument15 pages1903604 Water Supply and Waste Water EngineeringI MixNo ratings yet

- Ei6002 Power Plant Instrumentation Question Bank PDFDocument11 pagesEi6002 Power Plant Instrumentation Question Bank PDFLokesh Gopinath100% (1)

- DCA Model ME8792 - PPEDocument3 pagesDCA Model ME8792 - PPESolomon DurairajNo ratings yet

- Syed Ammal Engineering College Power Plant Engineering Question BankDocument16 pagesSyed Ammal Engineering College Power Plant Engineering Question BankNizam MANo ratings yet

- Department of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ADocument15 pagesDepartment of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ABhagavathi ShankarNo ratings yet

- FMM Question Bank 2Document22 pagesFMM Question Bank 2Vishnu VaradhanNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Introduction to Bond Graphs and their ApplicationsFrom EverandIntroduction to Bond Graphs and their ApplicationsRating: 5 out of 5 stars5/5 (1)

- Alfa Laval Unique Mixproof ValveDocument12 pagesAlfa Laval Unique Mixproof ValveThiago FioreseNo ratings yet

- PIPING INTERVIEW QUESTIONSDocument7 pagesPIPING INTERVIEW QUESTIONSChandra Asiah WNo ratings yet

- CST06 Capacity Improvement of A Large, Two Stage Diaphragm CompressorDocument19 pagesCST06 Capacity Improvement of A Large, Two Stage Diaphragm CompressorGustavoNo ratings yet

- ElectroluxDocument3 pagesElectroluxSyed Noman AhmedNo ratings yet

- Diaphragm Seal Filling GuideDocument14 pagesDiaphragm Seal Filling GuideKrishnaraj DhavalaNo ratings yet

- Pumps CalculationDocument16 pagesPumps CalculationEkundayo JohnNo ratings yet

- Atmospheric PollutionDocument19 pagesAtmospheric PollutionFaraz100% (1)

- Supercritical TechnologyDocument24 pagesSupercritical TechnologyBv RaoNo ratings yet

- Acv Automatic Control Valves PDFDocument20 pagesAcv Automatic Control Valves PDFabdallah391No ratings yet

- Oxy-Fuel Welding and CuttingDocument14 pagesOxy-Fuel Welding and CuttingImran Hanif LubisNo ratings yet

- Improving Dust Collection in a Sand Reclamation PlantDocument48 pagesImproving Dust Collection in a Sand Reclamation Plantananda narayananNo ratings yet

- Operation & Maintenance Manual For 17 KG/HR Biomass Gasifier System For Cooking ApplicationDocument18 pagesOperation & Maintenance Manual For 17 KG/HR Biomass Gasifier System For Cooking ApplicationAdhavan ThamizhanNo ratings yet

- Alarm Check Valve - MECHDocument5 pagesAlarm Check Valve - MECHGabriel TapiaNo ratings yet

- Cge567 2Document7 pagesCge567 2Fareast KeizerNo ratings yet

- Forced convection over cylinders and spheresDocument17 pagesForced convection over cylinders and spheresananth2012No ratings yet

- Kinetic TheoryDocument11 pagesKinetic TheoryKM_147No ratings yet

- H06034Document2 pagesH06034kirankirkNo ratings yet

- Zonal Two Equation K-W Turbulence Models For Aerodynamic FlowsDocument22 pagesZonal Two Equation K-W Turbulence Models For Aerodynamic FlowsEnricNo ratings yet

- RAC 6 SemDocument6 pagesRAC 6 SemAmrinder Singh SangheraNo ratings yet

- Euroloop Calibrations B.VDocument3 pagesEuroloop Calibrations B.VmohamedNo ratings yet

- Assignment 2Document4 pagesAssignment 2C.MeiarajNo ratings yet

- AHP Important QuestionsDocument22 pagesAHP Important QuestionsaadhithyarajasekaranNo ratings yet

- The Tanker Chartering MarketDocument118 pagesThe Tanker Chartering MarketAlex Tanase100% (3)

- InstructionDocument4 pagesInstructionHtunn Thu Thu UNo ratings yet

- Brochure - Modelo 3300 PressureDocument4 pagesBrochure - Modelo 3300 PressureLisa GarciaNo ratings yet

- Mindray-Wato-Ex-65 - Service ManualDocument322 pagesMindray-Wato-Ex-65 - Service Manualichraq nouarNo ratings yet

- Refrigeration and Air-Conditioning SystemDocument30 pagesRefrigeration and Air-Conditioning Systemkeval patel100% (3)

- Vendor DataDocument6 pagesVendor DatasubudhiprasannaNo ratings yet

- ChE 533 Equipment Design Final ExamDocument4 pagesChE 533 Equipment Design Final ExamGene Squal GrupeNo ratings yet