Professional Documents

Culture Documents

R410 Line Sizing

R410 Line Sizing

Uploaded by

Richard LIpa0 ratings0% found this document useful (0 votes)

13 views3 pagesOriginal Title

R410 line sizing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesR410 Line Sizing

R410 Line Sizing

Uploaded by

Richard LIpaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

Graphic 3

oer) EyEy

E

R410A

Graphic 1

@. cane

Discharge tube - horizontal ine

24

EL JUNIFLAIR™

Graphic 2

Discharge tube - vertical line

® Liat

S

‘S

WAX

\\

VW

\\\

\

TA

.|\

WW

8

25

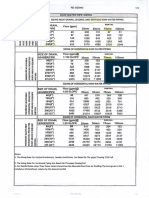

Conforming to the Standards EN 14276-1 and EN 14276-2 the minimum recommended thickness for the gas supply pipe

where bends are made for the air cooled units with R410A refrigerant, must be equal othe values presentin the attached

table below, The value "R' refers tothe minimum allowed radius of the bend,

External diameter] Radius of the bend | Thickness

De (mm) + [mm] Umm]

28 100) 12

22 66 4 o a

18 27 1

16 26 1

12 20 1

Line sizing R07

¥ ¥

.

¥

fp egrets

EXAMPLE - Choosing the diameter of the discharge tube

with R407C refrigerant

Conditioner selected: TDARO721A

Cooling capacity per circuit: 24 Kw

Discharge line: vertical

Equivalent length of the line: 20 m

1) Graphic 2:

Operating at 100% (2 compressors - cooling capacity per

circult = 24KW)

possible diameters:

20mm DPIL= 1,8 Kpalm

‘@mm DP/L= 3,0 Kpaim

1mm DP/L= 6,0 Kpaim

26

‘14mm _DPIL= 11,5 Kpalm

Operating at 50% (1 compressor - cooling capacity per

circuit = 12 KW): possible diameters:

7 Kpaim

2) Graphic 3:

Operating at 100% (2 compressors)

Diameter 16mm 6,0Kpalm Allowed Diameter 14mm

11,5 Kpaim Not allowed

‘The advised diameteris 16mm

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HRC BAR BOOK - DFC 19 Final Print FileDocument9 pagesHRC BAR BOOK - DFC 19 Final Print FileRichard LIpaNo ratings yet

- IIEE CBL With CommentsDocument22 pagesIIEE CBL With CommentsRichard LIpaNo ratings yet

- DS Soakaway Sizing Calculations 06182018Document11 pagesDS Soakaway Sizing Calculations 06182018Richard LIpaNo ratings yet

- Lux CalculationDocument1 pageLux CalculationRichard LIpaNo ratings yet

- Swimming Pool Design PresentationDocument55 pagesSwimming Pool Design PresentationRichard LIpaNo ratings yet

- Roof Drain SizingDocument1 pageRoof Drain SizingRichard LIpaNo ratings yet