Professional Documents

Culture Documents

Mantall HZ Series Diesel Articulated Booms Operating Manual

Mantall HZ Series Diesel Articulated Booms Operating Manual

Uploaded by

ศักดิ์อิเล็กทรอนิกส์ ทุกชนิด0 ratings0% found this document useful (0 votes)

30 views29 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views29 pagesMantall HZ Series Diesel Articulated Booms Operating Manual

Mantall HZ Series Diesel Articulated Booms Operating Manual

Uploaded by

ศักดิ์อิเล็กทรอนิกส์ ทุกชนิดCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 29

HZ Series Diesel Articulated Booms

Operating Manual

Company name: Mantall Heavy Industry Co., Ltd.

Tel: 0513-83830000

Fax: 0513-83905178

Company address: No.62, Binhai Avenue, Binhai

Industry park, Qidong Economic Area,

Nantong city, Jiangsu province, China,

Operating manual

7

Important

Read, understand and obey these sefety rules and

‘operating instuctions before operating this machine

Oniy trained and authorized personnal shall be

Dermitted to operate tis machine. This manuel should

be considered a permanent part of your machine ond

should remain with the machine at all times I you

have any questions, call Manta

Contents

Page

Safety ..

Technical parameters.

Assembly size chart.

Electrical schematics

Hydraulic schematics ...

Operating Instructions

‘Transport Instructions ...

Maintenance

Contact us:

ite: _wwwanantall,com

sales@mantall.com

HZ160RT

Operating manual

Safety Rules

Danger

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

E You leam and practice the principles of safe

‘machine operation contained in this operator's

manual

1 Avoid hazardous situations.

Know and understand the safety rules

bofore

going on to the next section.

2 Always perform a pre-operati

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

@ You read, understand and obey:

Manufacturer's instructions and safety

rules—safety and operator's manuals

and machine decals

employer's safety rules and worksite

regulations

applicable governmental regulations

You are properly trained to safely operate the

machine.

‘SAFETY RULES

HZ160RT

‘Operating manual

Electrocution Hazards

This machine is not electrically insulated and will

ot provide protection from contact with or

proximity to electrical current.

Maintain safe distances from electrical power lines

‘and apparatus in accordance with applicable

governmental regulations and the following chart.

inimum Safe

‘Approach Distance

Feet Meters

Voltage

Phase to Phas

0=300v

300V — SOKV , 34

SKV=2MKV. gs

200 SKY PO

350KV—500KV SS SSOS*~S~S~SCS~S

‘SOOKV — 750KV 10.7

TSOKV—1,000KV.—=~SOS~*~«

Allow for platform movement, electrical ine sway or

sag and beware of strong or gusty winds,

Keep away from the machine if it contacts

energized power lines. Personnel on the ground or

in the platform must not touch or operate the

machine until energized power lines are shut off

‘Do not use the machine as a ground for welding.

Tip-over Hazards

Occupants and equipment shall not exceed the

maximum platform capacity.

Maximum platform capacity 280 kg

Maximum occupants

Mase

Do not raise or extend the boom unless the

machine is on a firm, level surface.

Do not depend on the tit alarm as a level indicator.

The tit alarm sounds in the platform only when the

machine is on a severe slope.

Ifthe tit alarm sounds:

Do not extend, rotate or raise the boom above

horizontal. Move the machine to a firm, level

surface before raising the platform. Ifthe tit alarm

‘sounds when the platform is raised, use extreme

caution to retract the boom and lower the platform.

Do not rotate the boom while lowering. Move the

machine to a firm, level surface before raising the

platform.

Do not use the platform controls to free a platform

that is caught, snagged or otherwise prevented

from normal motion by an adjacent structure. All

Personnel must be removed from the platform

before attempting to free the platform using the

ground controls.

Do not alter or disable the limit switeh(es).

HZ160RT

Operating manual

Do not operate the machine in strong or gusty

‘winds. Do not increase the surface area of the

Platform or the load. Increasing the area exposed

to the wind will decrease machine stability.

Use extreme care and slow speeds while driving

the machine in stowed position across uneven

terrain, debris, unstable or slippery surfaces and

near holes and drop-offs.

Do not drive the machine on or near uneven

terrain, unstable surfaces or other hazardous

conditions with the boom raised or extended.

Do not push off or pull toward any object outside

ofthe platform,

oo7N

400 N

Maximum allowable side force

“Maximum allowable sideforce MON

%s

Do not alter or disable

machine components

that in any way affect

safety and stability.

Do not replace items

critical to machine

stability with items of

different weight or

specification

SAFETY RULES

Do not modify or alter an aerial work platform

Mounting attachments for holding tools or other

materials onto the platform, toeboards or guard rail

system can increase the weight in the platform and

the surface area of the platform or the load.

Do not place or attach overhanging loads to any

part of this machine.

Do not place ladders or scaffolds in the platform or

against any part of this machine.

Do not use the machine on a mo\

surface or vehicle.

19 or mobile

Be'sure all tires are iri good condition, air-flled tires

are properly inflated and lug nuts are properly

tightened,

SAFETY RULES

HZ16ORT

‘Operating manual

SS SEE

Do not use the machine as a crane.

Do not push the machine or other objects with the

boom,

Do not contact adjacent structures with the boom.

Do not tie the boom or platform to adjacent

structures.

Do not place loads outside the platform perimeter.

Fall Hazards Occupants must wear a

safely belt or hamess in

accordance with

governmental regulations.

‘tach the lanyard tothe

anchor provided in the

platform.

Itis recommended that operators wear an approved

hard hat when operating the machine.

Do not sit, stand orclimb on the platform guard

‘ails. Maintain a firm footing on the platform floor

atall times.

Do not climb down from the platform when

raised.

Keep the platform floor clear of debris.

Lower the platform entry mid-rail or close the

entry gate before operating,

Bodily Injury Hazard

Do not operate the machine with a hydraulic oll or

air leak. An air leak or hydraulic leak can

penetrate and/or burn skin

Always operate the machine in a well-ventilated

area to avoid carbon monoxide poisoning.

Collision Hazards

mame

Be aware of boom position when rotating the

tumtable.

Check the work area for overhead obstructions or

other possible hazards.

Be aware of limited sight

distance and blind spots

when driving or operating

Be aware of crushing hazard when grasping the

platform guard rail

Observe and use color-coded direction arrows

on the platform controls and drive chassis for

rive and steer functions.

HZ60RT

Operating manual

Do not lower the boom unless the area below is

lear of personnel and obstructions.

Limit travel speed according to condition of ground

surface, congestion, slope, location of personnel,

and any other factors which may cause-cettiston.

‘De not operate a boom in the path of anyserane

unless the controls of the crane have beerwlacked

‘out and/or precautions have been taken to-prevent

any potential collision.

No stunt driving or horseplay while operating @

machine,

Explosion and Fire Hazards

Do not start the engine if you smell or detect fiquid

petroleum gas (LPG), gasoline, diesel fuel.or other

explosive substances.

-Bomot refuel'the machine with the engine running.

‘Refuel the machine and-charge the battery only in

‘ap open, well-ventilated area away from sparks,

flames and lighted tobacco.

-Domot operate the machine in hazardous locations

or locations where potentially flammable or

explosive gases or particles may be present.

SAFETY RULES

Damaged Machine Hazaras

Do not use a damaged or meltunctioning machine.

Conduct a thorough pre-operation inspection of the

machine and test all functions before each work.

shift. Immediately tag and remove from service a

damaged or malfunctioning machine.

Be sure all maintenance has been performed as

specified in this manual and the Genie Z-45/25 &

Genie Z-45/25J Service Manual

Be sure all decals are in place and legible.

Be sure operator's, safety and responsibilities

manuals are complete, legible and in the storage

container located on the platform.

Battery Safety

Burn Hazards

Batteries contain acid. Always wear protective

clothing and eyewear when working with

batteries.

Avoid spilling or contacting battery acid.

Neutralize battery acid Spills with baking soda |

and water.

Explosion Hazard

Keep sparks, flames and lighted tobacco away

from batteries. Batteries emit explosive gas.

Electrocution Hazard

Avoid contact with electrical terminals.

Component Damage Hazards

Do not use any battery or charger greater than

12V to jumpstart the engine

Do not use the machine as a ground for welding,

Be sure the hydraulic shutoff valves (located by

hydraulic tank) are open before starting the

engine.

SAFETY RULES

HZ160RT

Operating: manual

Decal Legend

Maniall product decals use symbols, color coding

and signal words to identify the folowing:

peg

Caution

Caution

Note:

‘Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—used to indicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

presence of a potentially

hazardous situation which, if not

‘avoided, could result in death or

serious injury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentially hazardous situation

which, if not avoided, may cause

minor or moderate injury. )

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

HZ160RT

Technical Parameters

platfora height max

vorking height nax

vorking Tadius max

Across height nax

platfera: specifications (steel)—Length

Width

Width

Height

7 HZAGORT

Operating manual

Assembly Size Chart

8 HZ160RT

Operating manual

Nameplate

Decals

Warning!

When the oil of this machine is below

this level, Please refill the HM46 high

anti-wear hydraulic oil.

9 HZI6ORT

Operating manual

ene ceeeeene a eee?

enone

doc te patom wronhe pater sg Onan

ah aly senna css ar cawn ee

Premiorentrcke aa

see cna ga a

Bo foe ui urea hw sed sts

aerneemineonpecrene cee

pas

nti wpm ah

fer coo

eee

Se ipa eeotetreton

eesipan eer ceernencos

Seemann memnincy

Eos km en ge cn ao crn

fea Se eneaves esate

10

A WARNING

CRUSHING HAZARD

* Do not stand under a raised

platform or boom or between a

rotating platform and the boom.

* Keep all body parts away from

‘any moving components,

Failure to follow these

instruction could result in

death or serious injury.

A DANGER

ELECTROCUTION HARZARD

This machine is not insulated.

+ Maintain a clearance of at

least. 10FT. (3M) between any part

of machine or load and any

electrical lines or apparatus.

* Failure to follow instructions

will result in death or serious

injury,

FRG HY fea a

aR BEY BATH Fi

axmamnomiene

SLATE DHE RAPE»

x BAT EH SHER

PES.

fi fe

ALBA

A RECE BLABY OER FDR SE

LH ARORA eZ li] BPRS AC/10

FRIES

RANE LM THES SE”

RTH.

HZ160RT

Explosion/fire Harzard

‘tdo Not Use Starting Fluid.

This Unit Is Equipped With

An Air Intake Heater Or Glow Plugs

Failuer To Follow Instructions Could

Result In Death Or Serious Injury.

TERGIBTE Bek fe

‘VARhADR, kee

ARTOMABLAAB,

SRORRSER, TREE

EHCHR.

HZ160RT

Electrical

schematics

en

HESMOR-G19

24NB

HZ160RT

Onerating manual

a

f=

ie

i

ie

1,

{

y

ag

As

2 ay

2 7

°

m~ :

iy 200)

= a

5 5

4 i

= °

. OF

14

HZIGORT.

Operating manual

Hydraulic schematics

te HZ160RT

Precautions when use

Control handle switch

time is slow and

‘normal operate and use)

Handle Schematic

upper control module power off

relatively quickly and the lower part of

the motor drive has large-capacity

capacitor after its installation,

non-synchronized shutdown, so pls

wait five seconds once pressed the

‘emergency stop switch. Then you can

(because the

0 off

resulting in

HZ160RT

Left and right

tum button of

‘control handle

Platform

speakers

Control lever joystick

is responsible for

walking and lifting

operation

Control handle pressure

switch. Before doing

anything must first

press. the switch, then

‘operating the handle

16

HZIGORT

fing, walking

mode

select switch

Walking Toggle switeh: Toggle switch:

options: options: lift mode: walking mode

Jow-speed high-speed

mode

Operating manual

ee EE TEP

Battery use precautions

For your normal use, pls |.before each

uuse;, 2. work runs every 20h, routinely

check the battery bolts fastening; 3 use

after work, please tighten if loose in

case.

PEPPER TE , AROSE ARETE ONO ER IRR

LEEGEMS 2ERORRE 367 8RIN

601-040

7

HZ160RT.

‘Operating manual

a

Need to raise butter at the following place:

Filling butter between the

spring and the spring of

the cylindrical column

(two places)

Refueling cycle: 80h /

time

Filling butter between

Steering column and steering

copper sleeve on the steering

wheel (two places)

Refueling cycle: 80h / time

Filling butter in butter mouth

on the upper cover of chassis

steering (two places)

Refueling cycle: 100h / time

Spare parts list

18 HZ160RT.

Device name: Aerial work platform HZ160RT Device no:

T

tem no. | Spare Name/Model | ltemnumber | Quantity | Notes

4 PFM020024-020 axle | 0311208036 7

sleeve

FI = dle |

2 PFM020024-025 axle 0311208037 4

sleeve.

3 PFM020024-045 axle 0311208038 1

sleeve

x cj

i PFM025030-035 axle 0311208039 2

sleeve

5 PFM030036-050 axle 0311208040 ri

sleeve

r i

6 PFM035041-030 axle 0311208041 2

sleeve

7 PFM035041-050 axle 0311208042 6

sleeve

3 7

8 PFM060070-045 axle 0311208043 2

sleeve

9 'WCR-35-26 Rubber Feet 0511208352 6

10 D4V-8112ZLimit switch 051005J055. 3

1 (G065411 Air filter cover 05112QB065001 a

412 065411 Air filter outer 0511208065002 1 i.

cylinder #

13. G065411 Air filter elbow 05112QB065003 1

14 3050 Clamps 0511208358 4

15 6080 Clamps 0511208357 2

Lister: Wang jiafeng Reviewer: Tian zhihong

19

HZ160RT

Operating manual

Operating Instructions

Do Not Operate Unless:

You lear and practice the principles of safe

‘machine operation contained in this

operator's manual,

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection,

3 Always perform function tests prior to use.

Fundamentals

% The Operating Instructions section provides

instructions for each aspect of machine operation,

Itis the operator's responsibilty to follow all the

‘safely rules and instructions in the operator's,

safety and responsibilities manuals,

Using the machine for anything other than lifting

personnel and tools to an aerial work site is

unsafe and dangerous.

Only trained and authorized personnel should be

permitted to operate a machine. If more than one

operator is expected to use a machine at different

times in the same work shift, they must all be

Qualified operators and are all expected to follow

all safety rules and instructions in the operator's,

safety and responsibilities manuals. That means

‘every new operator should perform a

re-operation inspection, function tests, and a

workplace inspection before using the machine,

Starting the Engine

1 At the ground controls, turn the key switch to

the desired position,

2.Be sure both ground and platform control red

Emergency Stop buttons are pulled out fo the

on position.

3-Gasoline/LPG models: Choose fuel by moving

the fuel select switch to the desired position.

4Move the engine start toggle

‘switch to either side. If the engine

fails to start or dies, the restart

delay will disable the start switch

for 3 seconds.

If the engine fails to start after 15 seconds of

cranking, determine the cause and repair any

malfunction. Wait 60 seconds before trying to start

again.

All models: In extreme cold conditions, 20°F / -6°C

and below, warm the engine for 5 minutes 1o

prevent hydraulic system damage.

Gasoline/LPG models: In extreme cold conditions,

20°F /-6°C and below, the machine should be

started on gasoline, then switched to LPG.

Emergency Stop

Push in either ground or platform red Emergency

‘Stop button to the off position to stop all functions

and tirn the engine off.

Repair any function that operates when the red

Emergency Stop button is pushed in. Selecting and

‘operating the ground controls will override the

platform red Emergency Stop bution.

OPERATING INSTRUCTIONS.

: HZ160RT

20

Operating manual

Auxiliary Controls

Use auxiliary power if the primary power source

(engine) fails

1 Turn the key switch to ground or platform

contro

2 Pull out the red Emergency Stop button to the

‘on position.

3 Move the lift/drive select switch to the lift

position when operating the auxiliary controls

from the platform.

4 Press down the foot switch when operating the

auniliary controls from the platform

5 Simultaneously hold auxiliary power switch on

‘and activate the desired function.

‘The drive and steer functions will not operate with

auxiliary power.

Operation from Ground

1 Turn the key switch to ground control.

2 Pull out the red Emergency Stop button to

the on position.

3 Gasoline/LPG models: Choose fuel by moving

the fuel select switch to the desired position.

4 Start the engine.

To Position Platform

1 Hold the function enable switch to either side.

2 Move the appropriate toggle switch according to

the markings on the control panel

3.Drive and steer functions are not available from,

the ground controls.

Machines equipped with Platform Level Control

Disable Function: The platform level toggle switch

will not operate when the primary boom is raised

past the drive speed limit switch

Operation from Platform

1 Turn the key switch to platform control.

2 Pull out both ground and platform red

Emergency Stop buttons to the on position.

3 GasolinelLPG models: Choose fuel by moving

the fuel select switch to the desired position.

4 Start the engine. Do not press down the foot

‘switch when starting the engine.

To Position Platform

1 Move the liftdrive select switch to the lift

position (if equipped),

2 Press down the foot switch.

3 Slowly move the appropriate function control

handle ortoggle switch according to the

markings on the control panel.

Machines equipped with Platform Level Control

Disable Function: The platform level toggle

switch will: not operate when the primary boom is

raised past the drive speed limit switch.

To Steer

1 Move the liftidrive select switch to the drive

position (if equipped).

2 Press down the foot switch.

3 Slowly move the control handle in the direction

indicated by blue or yellow triangles

OR press the thumb rocker switch located on

top of the drive control handle.

Use the color-coded direction arrows on the

platform controls and the drive chassis to

identify the direction the wheels will turn

OPERATING INSTRUCTIONS

2

HZI6ORT

Operating manual

1 Move the liftirive select switch to the drive

position (if equipped).

2 Press down the foot switch.

3 Increase speed: Slowly move the drive control

handle off center,

Decrease speed: Slowly move the drive control

handle toward center.

‘Stop: Return the drive control handle to center or

release the foot switch,

Use the color-coded direction arrows on the

platform controls and the drive chassis to identify

the direction the machine will travel.

Machine travel speed is restricted when the booms

are raised,

Drive Enable

LLight on indicates that the boom has moved just

past either non-steer wheel and the drive function

has been interrupted.

To drive, hold the drive enable switch to either side

and slowly move the drive control handle off center.

Be aware that the machine may move in the

opposite direction that the drive and steer controls

are moved.

Always use the color-coded direction arrows on the

platform controls and the drive chassis to identity

the direction the machine will travel.

Generator

To operate the generator, move the generator

toggle switch to the generator position. The engine

will continue to run but no drive or platform

functions will operate.

Plug a power too! into the power to platform GFCI

outlet.

To resume machine functions, move the generator

toggle switch to machine functions position. All

functions will operate.

Drive Speed Select

* Machine on incline symbol: Low range operation

for inclines

+ Machine on level surface symbol: High range

‘operation for maximum drive speed

Engine Idle Select (rpm)

Select the engine idle speed (rpm) using the

symbols on the control panel.

zl-le

” Rabbit and foot switch symbol: foot switch activated

high idle

«Turtle symbol: low idle

Rabbit symbol: high idle

Check Engine Light (if equipped)

Light on and engine stopped: Tag the machine and

remove from service

Light on and engine stil running: Contact service

personnel within 24 hours.

Stopping the Engine

Push in the red Emergency Stop button and turn

the key switch to the off position.

After Each Use

1 Select a safe parking location—firm level

‘surface, clear of obstruction and traffic.

2 Retract and lower the boom to the stowed

position

3 Rotate the turntable so that the boom is between

the non-steer whools

4 Turn the key switch to the off position and

remove the key to secure from unauthorized

use.

5 Chock the wheels.

22

HZ160RT

Operating manual

Transport Instructions

Observe and Obey:

‘The transport vehicle must be parked on a level

surface,

‘The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.Be sure the vehicle capacity, loading surfaces

and chains or straps are sufficient to withstand

machine weight. See the serial plate for the

machine weight.

Be sure the turntable is secured with the

tumtable rotation lock before transporting. Be

sure to unlock the turntable for operation.

Securing to Truck or Trailer for

Transit

‘Always chock the machine wheels in preparation

for transport.

Use the tie points on the drive chassis for

anchoring down to the transport surface.

Use the rotator guard under the platform to secure

the boom from side-to-side movement. Do not use

excessive downward force when securing the boom

section.

Use chains or straps of ample load capacity.

‘Tum the key switch to the off position and remove

the key before transporting,

Inspect the entire machine for loose or unsecured

items.

Transport

Free-wheel Configuration for

Winching

‘Chock the wheels to prevent the machine from

rolling,

Release the non-steer wheel brakes by turing

‘over the drive hub disconnect caps (see below).

Be sure the winch line is properly secured to the

drive chassis tie points and the path is clear of all

obstructions.

Reverse the procedures described to re-engage the

brakes.

Note: Towing the Genie Z-45/25 or the Z-45/25J is,

not recommended. If the machine must be towed,

do not exceed 2 mph / 3.2 km/h.

Disengage

Position

23

HZ160RT

Operating manual

aaaanann I Inamammmmmammmmeseremaimmamermetseemeeetemeeeemeeast

Before operating the machine, pls read, understand and comply with the relevant

safety regulations and operating instructions.

Normal storage does not require preparation. But need carrying out regular

maintenance. If you want long-term storage, need the following conservation

measures:

Storage

Clean the surface of the paint. If there is damage to the paint surface, pls repainted.

After the platform bar completely lowered, check the hydraulic oil level. Unscrew the

reservoir cap and dipstick; oil level can be seen on the dipstick. If necessary, add

hydraulic oil

Battery

Remove the battery and place in an alternate

location.

26 HZ160RT

Operating manual

Maintenance

Observe and Obey:

‘Only routine maintenance items specified in this

‘manual shall be performed by the operator.

Scheduled maintenance inspections shall be

‘completed by qualified service technicians,

according to the manufacturer's specifications

and the requirements specified in the

responsibilities manual.

Maintenance Symbols Legend

The following symbols have been

Note:

used in this manual to help

communicate the intent of the

instructions. When one or more of

the symbols appear at the

beginning of a maintenance

procedure, it conveys the meaning

below.

procedure,

Indicates that a cold engine is required

before performing this procedure,

Check the Engine Oil Level

Maintaining the proper engine oil level is essential

to good engine performance and service life.

Operating the machine with an improper oil level

can damage engine components.

Note: Check the oil level with the

Check the oil dipstick. Add oil as needed.

Result: The oil level should be wit

© safety place.

ce a ae

the

Gil viscosity requirements

Below 15.5°C

23°00 32°C

‘Above -23°C.

‘Above -4'C

Use oils meeting API classification SH or SG.

Units ship with 10-40 CCISG.

Indicates that tools will be required to perform this procedure.

Indicates that new parts will be required to perform this

25

HZL60RT

Operating manual

a

Engine 31. 1011F

ae

below15.5'C(synthetic)

-23T to 20

Above -20°C

Engine oll should have properties of API classification

CCISE, CDISE, SFICC or SFICD grades,

Units ship with 10-40 Ccisc.

Perkins Engine 104-22

Oil viscosity requirements

Below 155°C

BT to 2T

Above -23°C_

Above 40

Engine olf should have properties of API classification —

CCISE, CDISE, SFICC or SFICD grades.

Units ship with 10-40 CcIsG.

MAINTENANCE.

Check the Hydraulic Oil Level

Maintaining the hydraulic ol at the proper level is

essential to machine operation. improper hydraulic

oil levels can damage hydraulic components. Daily

checks allow the inspector to identify changes in oll

level that might indicate the presence of hydraulic

system problems.

1 Be sure that the boom is in the stowed position,

then visually inspect the sight gauge located on

the side of the hydraulic oll tank.

Result: The hydraulic oll lovel should be within

the top 2 inches / 5 om of the sight gauge.

2.Add oll as needed,

Hydraulic oll specifications

Hydraulic oll ype Dexron Daxron equivalent

28

HZ16ORT

Operating manual

MAINTENANCE

Check the Batteries

Proper battery condition is essential to good engine

performance and operational safety. Improper fluid

levels or damaged cables and connections can

result in engine component damage and hazardous

Check the Engine Coolant Level

Maintaining the engine coolant at the proper level

is essential to engine service life. Improper coolant

level will affect the engine's cooling capability and conditions. Electrocution hazard. Contact with

‘damage engine components. Daily checks will rst eborinveleMRL ts thay, caduie I

allow the inspector to identify changes in coolant Warming: cath or serious injury, Remove all

level that might indicate cooling system problems. seat finan Wathen apeio\hek iain!

Warning: "9 es

Burn hazard. Beware of hot

engine parts and coolant. Contact

with hot engine parts and/or coolant

‘may cause severe burns.

1 Check the fluid level in the coolant recovery

Caution:

Bodily injury hazard. Batteries contain

acid. Avoid spilling or contacting battery

‘acid. Neutralize battery acid spills with

baking soda and water.

Put on protective clothing and eye wear.

Be sure that the battery cable connections are

tight and free of corrosion,

Be sure that the battery hold-down bracket is.

secure.

Remove the battery vent caps.

Check the battery acid level. needed,

tank. Add fluid as needed.

Result: The fluid level should be at the Fut mark.

Do not remove the radiator cap.

Note:

‘Adding terminal.protectors and a

corrosion preventative sealant

will help eliminate corrosion on

the battery terminals and cables.

Note:

27 HZ160RT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

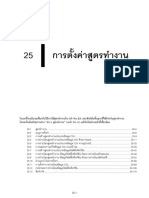

- การตั้งค่าสูตรทำงานDocument122 pagesการตั้งค่าสูตรทำงานศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- HDF 2415 DDocument2 pagesHDF 2415 Dศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- Visio-ลายไฟกล่อง CHMPIONDocument2 pagesVisio-ลายไฟกล่อง CHMPIONศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- Mantall HZ 160RT Self-Propelled Articulating Boom Spare Parts Instruction ManualDocument30 pagesMantall HZ 160RT Self-Propelled Articulating Boom Spare Parts Instruction Manualศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- Zoomlion ZCC1100H Parts Manual - Compressed 3Document19 pagesZoomlion ZCC1100H Parts Manual - Compressed 3ศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet