Professional Documents

Culture Documents

Guarding Against Contaminants

Uploaded by

gopiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guarding Against Contaminants

Uploaded by

gopiCopyright:

Available Formats

Guarding against contaminants

Analysing spent hydroprocessing catalyst underpins the development of guard

bed catalysts to counter contaminants

Michael SCHMIDT Haldor Topsoe A/S

Henrik Rasmussen Haldor Topsoe Inc

A

very important parameter

for the cycle length of a S Sulphur

Vanadium

hydroprocessing unit is

Nickel

the deactivation rate of the Aromatic rings S

installed catalyst. The deactiva- Naphthenic rings

tion of a hydrotreating catalyst

S S

can be coke induced and

contaminant induced. Coke

S

deposition is to a large extent S

controlled, but also dictated, by S

the unit operating regime

S

(temperature, hydrogen availa- S S

bility, residence time and partial S S

pressure of hydrogen). This will

normally cover most middle S S S

distillate units making ULSD or

S

lighter products. However, in S

S

units processing heavier feed-

S

stocks like vacuum gas oil

(VGO), heavy coker gas oil

(HCGO), deasphalted oil (DAO),

or even heavier cuts, the refinery Figure 1 Large porphyrin-like asphaltene molecule

normally faces a dual type deac-

tivation. The coking reactions here are even Topsoe researchers have within the past few

more significant because the feedstock is heavy years analysed and characterised a huge number

and contains lots of aromatic coke precursors in of spent catalysts retrieved from industrial

the high boiling fraction. But heavy feedstocks hydrotreater units operating on heavy feedstocks

will often also contain a significant amount of like VGO and HCGO. This characterisation work

heavy metals and other contaminants. In tries to understand how these contaminants are

particular, this includes nickel, vanadium, iron, deposited to help us develop more effective

silicon, arsenic, phosphorus, calcium and guard bed catalysts.

sodium. These contaminants are present in

processed feedstocks at ppm or even ppb levels, Contaminants to deal with

but the effect is significant. Following a non-re- In general, the heavier the hydrocarbon cut the

versible pathway, heavy metals will be deposited higher the content of contaminants. In a feed

on active catalyst following different mecha- stream such as VGO, DAO and HCGO, metals

nisms. The outcome is that activity is lost contamination is therefore mainly an issue for

permanently and will thus not even be regained FCC pretreaters, hydrocracker pretreaters and

during catalyst regeneration. lube units.

www.digitalrefining.com/article/1001244 Catalysis 2016 1

Vanadium and nickel are mainly found in Phosphorus species are rarely found in typical

large, porphyrin-like structures (asphaltenes) in crudes; however, some opportunity crudes (and,

crude oil (see Figure 1). Generally, the metallic in particular, renewable feeds) often contain

species of the crude are concentrated in the resid significant amounts of phosphorus. Furthermore,

portion, but some organometallic species are phosphorus containing anti-corrosion additives

present in the lower boiling ranges with a boiling can be found in diesel and VGO fractions.

point above 660°F (350°C). Phosphorus compounds are decomposed in the

Introduction of feeds containing vanadium, hydrotreater, and the phosphates react with the

nickel or iron (such as atmospheric tower alumina support (much like silicon), forming very

bottoms) into VGO hydrotreating could have stable aluminium phosphates. Accumulated

severe consequences in terms of cycle length. amounts of phosphates will reduce accessibility to

The relatively high space velocity of these units the active sites of hydrotreating catalysts and

(compared to resid hydrotreating) could result in lower the activity accordingly. Phosphorus

metal migration into the active, main bed cata- compounds are often found to originate from

lyst. To overcome this problem, a highly active injection of corrosion inhibitors in the form of

demetallation catalyst with a high metal pick-up thiophosphorus compounds like thiophosphate

capacity must be installed on top of the main esters, thiophosphites and tributyl phosphate.

catalyst bed. Topsoe has commercialised Handling of organic phosphorus compounds

specially designed VGO demet catalysts desig- in the VGO being fed to FCC pretreaters or

nated TK-453 and TK-455 MultiTrap. hydrocracker pretreaters is a major challenge in

The large molecules containing these metals some refineries. The phosphorus quickly deacti-

require catalyst shapes with a high surface to vates the conventional catalyst and reduces cycle

volume ratio to remove these metals efficiently. length dramatically. Topsoe has developed

Iron will mainly deposit on the catalyst surface, specific guard bed catalysts, TK-31 and TK-455

whereas nickel and vanadium will deposit inside MultiTrap, to effectively protect the main cata-

the catalyst pore structure due to the very large lyst. These guard catalysts, with proprietary

average pore sizes of TK-453 and TK-455. properties and composition, will be able to

Arsenic is a true catalyst poison as it will prolong the cycle length of the unit.

chemically react with active catalytic sites, for The main source of sodium in a FCC or hydro-

instance transforming the catalyst’s nickel and cracker pretreat feed is normally poorly desalted

cobalt into NiAs or CoAs. Poisoned sites will not crudes. This type of inorganic sodium will not

be reactivated during regeneration, and even easily enter the catalyst’s pore system. Sodium

small amounts on the catalyst will affect catalyst will therefore tend to deposit around the exterior

activity in a critical way. Fortunately, the of the catalyst, forming a solid crust between

concentration of arsenic is in the ppb range and catalyst pellets, which will harm activity and

can be effectively dealt with by utilising Topsoe’s cause pressure drop issues.

high capacity arsenic traps TK-49 as an extru- We should not forget to mention inorganic

date, and TK-45 and TK-41 in a ring shape. iron, which is a very common contaminant. Iron

Silicon found in oil fractions originates from rust originates from corrosion of upstream

Si-containing anti-foam additives used in coker equipment and may consist of everything from

units, as well as from the use of chemicals intro- large flakes to the smallest particle tank rust.

duced during oil transport and tertiary oil Large particle rust is known to be easily trapped

recovery. Silicon reacts with the surface of the in filters, scale catchers and high void catalytic

catalyst and forms a silica gel, hindering access materials. However, 5-10 micron inorganic iron

to the active catalytic sites and thereby deacti- particles are very hard to handle as they will

vating the catalyst. Silicon penetrates into the pass feed filters and, without a proper graded

pore system of the catalysts, and deactivation is bed system, enter the catalyst bed. Inorganic

proportional to the concentration of silicon on iron will also preferentially deposit in the outer

the catalyst. surface of the catalyst, unless a very large pore

Haldor Topsoe’s TK-400 series catalysts for demet catalyst is utilised as a guard catalyst, and

naphtha and TK-453 for heavier fractions provide will eventually lead to increasing pressure drop.

the highest silicon pick-up on a volume basis. To handle inorganic iron, Haldor Topsoe intro-

2 Catalysis 2016 www.digitalrefining.com/article/1001244

duced themacroporous Demetallisation functionality

particulate trap TK-25 TopTrap (HDM) in a gas oil hydrotreater

a number of years ago and it has is a function of pressure, temper-

proven to be a leading trap ature, residence time (LHSV),

material. catalyst and feed. The catalyst

The company recently system selected is a key factor in

launched an improved particu- determining the cycle length. It

late trap, designated TK-26 is not only important to install

TopTrap, with an optimised the proper HDM catalysts but

daisy shape with three axial also a main bed catalyst that has

holes to provide about 20x Figure 2 Macroporous particulate both a high capacity and toler-

higher pick-up capacity as trap TK-26 TopTrap ance for metals.

compared to TK-25 TopTrap. The metal capacity of a hydro-

TK-26 TopTrap is designed with a 61% particle treating catalyst is mainly determined by the

void fraction as well as a large internal pore catalyst’s porosity. However, the rate of metal

volume and macro pores Larger sized inorganic removal is a catalytic reaction and is therefore

contaminants deposit in the spaces between very much dependent on catalyst activity and

traps; fines or smaller sized materials enter the reactor operating temperature. Based on experi-

pore system and are trapped within the structure ence, it is advisable to have reactor temperatures

of the particle itself (see Figure 2). Theinternal above 600°F (315°C) to ensure that enough

particle void of TK-25 TopTrap is 25%, so that the demetallisation takes place. The severity of the

total void in this product is greater than 85%. feed is also an important factor. The actual metal

More exotic metals like calcium, zinc and pick-up for a catalyst is dependent on all of the

magnesium are also observed in some units. above factors.

These can all originate from different additives Haldor Topsoe’s demet catalysts show very

but are also occasionally found in porphyrin high metals pick-ups, with as much as 40 wt% of

structures in crude. These contaminants are nickel plus vanadium pick-up in FCC pre-treat

quite common in units upgrading spent lube oils service and over 20 wt% each of both silicon and

to new base lubes stocks and can be a challenge. phosphorus. This high level of capacity of demet

They are harmful to the main bed catalyst catalyst will protect the main bed catalyst and

because they tend to stick to the surface of the allow for longer run lengths.

catalyst, thereby preventing access to the pore Our main bed catalysts, BRIM and HyBRIM,

system. Table 1 summarises the mechanisms of show a high level of both capacity and tolerance

contamination. for metals. In FCC pre-treat services, these cata-

The importance of utilising specialised graded lysts have shown as much as 25 wt% of nickel,

bed catalysts and guard catalysts designed to vanadium and iron. Designed with an optimum

handle these many poisons with different depo- combination of pore diameter, pore volume and

sition mechanism cannot be overstated. The ‘one surface area, the catalysts have also shown pick-

size fits all‘ approach will simply not provide the ups as high as 20 wt% of silicon and phosphorus.

refiner with an optimised cata-

lyst loading for proper Contaminants overview

protection of the main bed cata-

lyst and the cycle length will be Contaminant Ni/V Fe As Fe Si P Na

Origin Crude Crude Crude Corrosion Additives Additives Salt

reduced. Haldor Topsoe has Typical VGO feed 1-5 1-3 50-250 0-3 0-3 0-2 0-2

fine-tuned its catalyst portfolio concentration wtppm wtppm wtppb wtppm wtppm wtppm wtppm

Contamination Precipitation Precipitation Titrating Reducing Absorbed Coating

to provide proper main bed mechanism on as sulphides.as sulphides. active void to catalyst of

protection by constantly adding main bed Pore mouth Pore mouth sites resulting surface area. catalyst

new and improved graded bed catalyst plugging plugging forming in pressure Co-reaction exterior

arsenides. drop with P

products. This is illustrated in Real poisoning

Figure 3, which expresses 23 Severity + + +++ + +(+) +++ ++

graded bed products as a func-

tion of size vs catalytic activity. Table 1

www.digitalrefining.com/article/1001244 Catalysis 2016 3

hydrotreating units every year,

Products and we analyse the contents after

11/2in TK-15 the cycle to continuously opti-

mise the catalyst formulation for

5/ in

8 TK-10 maximum pick-up of the

1/ in TK-26 contaminants mentioned here.

2

TopTrap

Our research laboratories are

Size

3/ in equipped with a wide range of

16 TK-30 TK-709 TK-710 TK-45

1/ in

analytical tools for characteris-

TK-30 TK-335 TK-437 TK-337 TK-41 TK-831

8

ing spent catalysts. ICP-MS,

1/ in QL

10

TK-455

TK-31 TK-339 Multi- TK-341 TK-743 TK-453

X-ray fluorescence, X-ray

Trap diffraction and state-of-the-art

1/ in QL TK-340 TK-49 microscopy are within the range

15

of possibilities.

Activity The first thing in the toolbox

is always to characterise the

Figure 3 Haldor Topsoe’s graded bed products spent catalyst using a precise

bulk analysis method. An exact

Retrieving spent catalyst samples quantification of what is present in the sample is

It is essential to have access to relevant and required. The most efficient method to apply for

representative spent catalyst samples if a detailed this purpose is

understanding of contamination type, degree and inductive coupled plasma mass spectrometry

profile is to be obtained. Because the contamina- (ICP-MS).

tion process is difficult to simulate in a realistic Scanning electron microscope (SEM) and elec-

manner in lab-scale pilot units, almost all devel- tron micro probe analyser (EMPA) are tools

opment work for making new, improved guard used to determine the chemical composition in

catalysts relies on retrieving industrially aged localised areas of solid materials. The method is

spent catalysts. One option is to sample catalyst ideal for a combination of structural and chemi-

while the industrial reactor is being unloaded. cal information. An electron beam interacts with

This obviously gives valuable information about the sample and produces electrons both for

the contamination profile and illuminates how imaging and characteristic X-rays. Both the

well certain contaminants migrate through the energy and the wave length of the X-rays can be

different catalyst layers. The best way to get good detected.

samples is to unload the catalyst by vacuuming.

However, if the catalyst is being dumped through The strength of canisters and spent catalyst

a bottom dump chute it is not possible to identify analyses

the exact position of the catalyst that is being Topsoe installed canisters in a hydrotreater

sampled. The catalyst unloaded by gravity designed to process and upgrade spent lube oils

through a dump tube will funnel out like grains to base oils and group 2+ lubes. Spent lube oil

emptying from a silo. Alternatively, we recom- contains large amounts of contaminants and

mend using Petroval’s sampling method called additives, such as zinc, magnesium, calcium and,

Probacat, which will drill down through the bed in particular, phosphorus and silicon. All of these

and a set of perfect core samples of the bed is contaminants deposit on catalysts, causing signifi-

collected. cant loss of activity. Two canisters were installed

The other option is to have catalyst test baskets in the top of the reactor with catalysts having

or canisters installed in a known location within different properties (pore volume, pore size,

the reactor during the entire cycle. The canister surface area and active metal content). Besides

will hold several catalysts in different compart- the canisters, catalyst samples were also obtained

ments, and each catalyst within the canister is from the unloading of the three reactors. Some of

exposed to practically the same type and amount the unloaded catalyst samples had been in opera-

of contaminants. In collaboration with clients, tion for one cycle and other samples had been in

Topsoe installs 10-20 test canisters in various the reactor for two cycles.

4 Catalysis 2016 www.digitalrefining.com/article/1001244

Analysis by ICP-MS

The spent catalysts unloaded Largest pore size Large pore size

Si

Pick-up (fresh catalyst basis)

Highest pore volume High pore volume

from the reactors were analysed P Low activity Medium activity

using ICP-MS in order to quan-

tify the bulk amounts of

phosphorus and silicon in Medium pore size

particular. This analysis Medium pore volume

High activity

confirmed that the catalysts

indeed were heavily contami-

nated. The numbers also

confirmed the theory that cata-

lysts with a high pore volume

and large open pores could trap TK-562 Brim TK-455 MultiTrap TK-743

most phosphorus and silicon.

Figures 4 and 5 illustrate how Figure 4 Bulk analyses for phosphorus and silicon: canister test (ICP-MS)

three different catalysts from

the canister picked up different

Unit B reactor results: spent lube HDT

amounts of phosphorus and sili- Gradient from top to bottom

con, reflecting the difference in

Reactor top Reactor bottom

porosity and activity.

Pick-up (fresh catalyst basis)

Si

2 cycles

Analysis by SEM and EDS P

Now it was time to apply the

1 cycle

SEM technique to map and

quantify exactly where the 1 cycle

contaminants were present.

Figures 6 to 8 show the quantita-

tive cross-section analyses of

TK-562 BRIM, TK-831 and

TK-743 using the SEM/EDS

technique. These catalysts were

all grabbed from different loca- TK-831,1/8in R TK-743,1/10in QL TK-562,1/16in TL

tions in the reactor and represent

a bulk catalyst, a graded bed Figure 5 Bulk analyses for Si and P: samples from the catalyst bed (ICP-MS)

catalyst and an effective HDM

catalyst. Hence, the last two mentioned have the within the catalyst pellet than was the case for

biggest pore systems and the largest pores. TK-562 BRIM. The crust itself is again very rich

A firm crust of phosphorus is seen on the in phosphorus, silicon and the other

surface of the main bed catalyst pellet. The phos- contaminants.

phorus content in the crust exceeds 15 wt% and The data shows a good correlation between the

silicon is around 10 wt%. In fact, the crust catalyst’s porosity and pore size and its ability to

appears to be a complex matrix of the impurities allow phosphorus and silicon compounds to

of the spent lube oil as it also contains high enter the catalyst pore system. This data as well

amounts of calcium, magnesium and zinc. The as dozens of other similar canister studies has

two measurements made within the catalyst pellet enabled Haldor Topsoe to generate optimised

show a steep drop in the phosphorus content, catalysts designed to pick up the specific poisons

whereas silicon is fairly constant at all points. causing issues in each individual hydrotreating

Looking at the TK-831 and TK-743 samples, unit, resulting in a better performance and cycle

there is a significant difference. While they also length. The graded bed system needs to be

have a crust layer surrounding them, the crust is designed for each unit to effectively eliminate

thinner and, more importantly, the phosphorus unit constraints.

species are found in much higher concentrations

www.digitalrefining.com/article/1001244 Catalysis 2016 5

OK NaK MgK AsL AlK SiK PK MoL SK CaK VK FeK CoK NiK ZnK

1 41.6 3.6 1.4 0.9 <0.5 6.0 15.7 <0.5 6.2 14.9 0.0 1.4 <0.5 0.0 7.0

2 39.9 3.7 1.3 1.0 <0.5 1.3 24.5 <0.5 2.3 17.1 0.0 1.2 <0.5 0.0 6.1

3 44.2 2.7 1.1 0.6 <0.5 10.2 16.9 <0.5 4.9 11.7 0.0 0.9 0.5 0.0 5.5

Catalyst

4 44.2 2.2 1.5 <0.5 <0.5 9.7 16.5 <0.5 4.6 12.4 0.0 1.2 0.6 0.0 6.0

5 51.2 2.9 1.0 <0.5 <0.5 10.2 15.5 <0.5 2.4 12.6 0.0 1.0 <0.5 0.0 1.8

6 46.6 1.3 <0.5 <0.5 14.7 8.9 9.8 4.3 5.0 5.0 0.0 0.6 1.3 0.0 1.0

Crust

7 44.6 <0.5 <0.5 <0.5 24.0 10.5 5.0 5.9 6.7 <0.5 0.0 0.2 2.0 0.0 0.6

Catalyst 8 42.6 <0.5 <0.5 <0.5 26.7 10.0 2.5 6.3 7.7 <0.5 0.0 0.2 2.4 0.0 0.6

wt%

Figure 6 EDS analysis of a cross-section of TK-562 BRIM

OK NaK MgK AsL AlK SiK PK MoL SK CaK VK FeK CoK NiK ZnK

1 33.0 2.8 1.0 0.9 0.7 10.9 23.4 3.7 0.7 25.7 0.0 2.3 0.0 0.5 5.9

Catalyst 2 51.7 5.2 1.0 <0.5 <0.5 3.5 18.0 <0.5 2.2 8.9 0.0 0.7 0.0 0.6 2.4

3 30.5 0.8 <0.5 <0.5 23.5 4.1 14.4 0.7 3.0 <0.5 0.0 <0.5 0.0 1.4 <0.5

Crust 4 42.2 <0.5 <0.5 <0.5 26.1 4.7 18.3 2.7 2.5 <0.5 0.0 <0.5 0.0 1.3 0.7

5 44.4 <0.5 <0.5 <0.5 27.4 5.2 14.9 2.1 2.4 <0.5 0.0 <0.5 0.0 1.5 0.6

6 52.9 <0.5 <0.5 <0.5 24.0 5.8 11.5 1.6 1.8 <0.5 0.0 <0.5 0.0 1.1 <0.5

Catalyst

wt%

Figure 7 EDS analysis of a cross-section of TK-831 (ring shape)

OK NaK MgK AsL AlK SiK PK MoL SK CaK VK FeK CoK NiK ZnK

1 33.7 3,7 1.0 0.0 0.7 5.2 14.9 0.0 8.6 14.5 0.5 1.2 0.0 0.5 14.2

Catalyst 2 48.0 4.4 0.9 0.5 2.3 4.9 12.8 0.0 6.6 10.8 <0.5 0.7 0.0 <0.5 7.3

3 47.7 1.5 <0.5 <0.5 21.4 4.3 10.5 2.7 5.0 2.7 <0.5 0.6 0.0 1.7 0.8

Crust 4 51.2 <0.5 <0.5 <0.5 25.3 4.0 8.4 3.6 4.3 <0.5 <0.5 <0.5 0.0 1.8 <0.5

5 48.7 <0.5 <0.5 <0.5 29.3 4.5 7.3 2.7 4.2 <0.5 <0.5 <0.5 0.0 1.8 0.6

6 46.0 <0.5 <0.5 <0.5 32.9 5.1 6.4 3.2 4.0 <0.5 <0.5 <0.5 0.0 1.5 <0.5

Catalyst wt%

Figure 8 EDS analysis of a cross-section of TK-743 (HDM catalyst)

Michael T Schmidt is Product Manager with Haldor Topsoe,

responsible for the development and quality of Topsoe’s FCC LINKS

pretreat and hydrocracking pretreat catalysts. He holds a degree

in chemical engineering from the Technical University of Denmark. More articles from: Haldor Topsoe

Henrik Rasmussen is Vice President of Catalyst and Technology

More articles from the following categories:

with Haldor Topsoe, responsible for the catalyst and license

Catalysts & Additives Fluid Catalytic Cracking

technology business for the US, Canada, and the Caribbean. He

Precious Metals Recovery

holds a degree in chemical engineering from the University of

Copenhagen.

6 Catalysis 2016 www.digitalrefining.com/article/1001244

You might also like

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- A System of Instruction in the Practical Use of the BlowpipeFrom EverandA System of Instruction in the Practical Use of the BlowpipeNo ratings yet

- KatalisatorDocument6 pagesKatalisatorchoco chpsNo ratings yet

- Topsoe Coker Naphtha Hydroprocessing CatalystsDocument6 pagesTopsoe Coker Naphtha Hydroprocessing CatalystsrafaelNo ratings yet

- (2016) Kohli, K. Deactivation of Hydrotreating Catalyst by Metals in Resin and Asphaltene Parts of Heavy Oil and ResiduesDocument10 pages(2016) Kohli, K. Deactivation of Hydrotreating Catalyst by Metals in Resin and Asphaltene Parts of Heavy Oil and ResiduesSarahEkaPutriDarlismawantyaniNo ratings yet

- Catalyst Used in Fluid Catalytic Cracking (FCC) Unit As A Support of NiMoP Catalyst For Light Cycle Oil HydroprocessingDocument11 pagesCatalyst Used in Fluid Catalytic Cracking (FCC) Unit As A Support of NiMoP Catalyst For Light Cycle Oil HydroprocessingJuan Diego Pabon CastilloNo ratings yet

- TOPSOE Seminar - Catalysts and Reactions PDFDocument132 pagesTOPSOE Seminar - Catalysts and Reactions PDFAhmad Nakash100% (3)

- Chapter 1 Introduction 2007Document4 pagesChapter 1 Introduction 2007Paravastu VinuthaNo ratings yet

- Hydrometallurgy: Jochen PetersenDocument7 pagesHydrometallurgy: Jochen PetersenAlex Paolo Paz AldayNo ratings yet

- 1A - Haldor Topsoe - Pressure - Drop - ControlDocument8 pages1A - Haldor Topsoe - Pressure - Drop - ControlAlNo ratings yet

- MOST Process Catalitic Removal of SOx and H2S From Refinery Tail GasDocument6 pagesMOST Process Catalitic Removal of SOx and H2S From Refinery Tail Gasrai rodriguezNo ratings yet

- WSN 3 (2015) 99-111Document13 pagesWSN 3 (2015) 99-111Husnain ArshadNo ratings yet

- Sgs Min Tp2003 07 Copper Extraction at Elevated Feed ConcentrateDocument10 pagesSgs Min Tp2003 07 Copper Extraction at Elevated Feed ConcentrateJose Eduardo Osuna AraizaNo ratings yet

- 58 60 Pmrapr89Document3 pages58 60 Pmrapr89Glorie Mae BurerosNo ratings yet

- On The Use of Acid-Base-Supported CatalyDocument19 pagesOn The Use of Acid-Base-Supported CatalyVishal GoswamiNo ratings yet

- ABB VisbreakingDocument72 pagesABB Visbreakingmihaileditoiu2010No ratings yet

- 1 s2.0 S0010938X18307078 MainDocument10 pages1 s2.0 S0010938X18307078 MainRuma ChandraNo ratings yet

- By Product in Ammonia Plant PDFDocument12 pagesBy Product in Ammonia Plant PDFMd. Imran HossainNo ratings yet

- Catalytic Cracking: Cat Products Become Feed To Other Units, Such As Alkylation andDocument13 pagesCatalytic Cracking: Cat Products Become Feed To Other Units, Such As Alkylation andPriscilaPrzNo ratings yet

- 1 s2.0 S0021951711002685 MainDocument8 pages1 s2.0 S0021951711002685 MainRita ZKNo ratings yet

- Leaching NotesDocument13 pagesLeaching NotesB ShankarNo ratings yet

- (Initial Line Up & Process Description) : BY: M. SALEEM CHOHAN (Trainee Engineer) NRL# 11542Document17 pages(Initial Line Up & Process Description) : BY: M. SALEEM CHOHAN (Trainee Engineer) NRL# 11542Saleem Chohan100% (2)

- Scientific & Technical ReportDocument12 pagesScientific & Technical ReportVenkatesan DevendranNo ratings yet

- Catalysis TodayDocument12 pagesCatalysis Todayamirhosein saqafiNo ratings yet

- Guard Bed CatalystsDocument7 pagesGuard Bed CatalystsargachoNo ratings yet

- Single Step Calcium Sulfate Scale Removal at HighDocument18 pagesSingle Step Calcium Sulfate Scale Removal at Highmarco.cedilloNo ratings yet

- Fluid Catalytic CrackingDocument20 pagesFluid Catalytic CrackingSandeep KumarNo ratings yet

- Catalyst, And: DeactivationDocument24 pagesCatalyst, And: Deactivationyussra amerNo ratings yet

- CH414 PRE (Hydrocracking)Document22 pagesCH414 PRE (Hydrocracking)Ali Daniyal AwanNo ratings yet

- Recycling of Precious Metal CatalystsDocument3 pagesRecycling of Precious Metal CatalystsSarangNo ratings yet

- Catalytic Hydrotreating of Heavy Gasoil PDFDocument9 pagesCatalytic Hydrotreating of Heavy Gasoil PDFVishal GoswamiNo ratings yet

- How Does A Recovery Boiler Become Plugged?: TAPPI Journal November 1986Document6 pagesHow Does A Recovery Boiler Become Plugged?: TAPPI Journal November 1986Mario MeloNo ratings yet

- Book Reviews: The Desulfurization of Heavy Oils and Residua, 2nd Edition. by James G. Speight, Marcel Dekker: New YorkDocument1 pageBook Reviews: The Desulfurization of Heavy Oils and Residua, 2nd Edition. by James G. Speight, Marcel Dekker: New YorkVishal GoswamiNo ratings yet

- Recycling of Precious Metal Catalysts: January 2004Document4 pagesRecycling of Precious Metal Catalysts: January 2004nurlianaNo ratings yet

- NHT OperationsDocument61 pagesNHT OperationsIrfan Shahzad75% (4)

- Role of Iron in CESL ProcessDocument16 pagesRole of Iron in CESL Processkittens1234No ratings yet

- Hydrotreating - UOP - A Honeywell CompanyDocument59 pagesHydrotreating - UOP - A Honeywell CompanySamNo ratings yet

- Topsoe Novel Coker NaphthaDocument13 pagesTopsoe Novel Coker NaphthaGarry DavidNo ratings yet

- 3 Coking ProcessesDocument26 pages3 Coking ProcessesFranklin RevillNo ratings yet

- Sodium PurificationDocument14 pagesSodium PurificationKonata IzumiNo ratings yet

- PDFDocument6 pagesPDFjamy862004No ratings yet

- Wood, Matusewicz, Reuter - 2009 - Ausmelt C3 Converting - International Peirce - Smith Converting CentennialDocument11 pagesWood, Matusewicz, Reuter - 2009 - Ausmelt C3 Converting - International Peirce - Smith Converting CentennialÁlvaro JaraNo ratings yet

- 135 137 PMR Jul09Document3 pages135 137 PMR Jul09syaNo ratings yet

- 5.2 Feedstock and Feedstock PretreatmentDocument4 pages5.2 Feedstock and Feedstock Pretreatmenttiara diah yepitalokaNo ratings yet

- An Introduction To Fire Heaters Part 1 PDFDocument7 pagesAn Introduction To Fire Heaters Part 1 PDFoswaldoNo ratings yet

- BF 00764506Document11 pagesBF 00764506Mohammed GhanemNo ratings yet

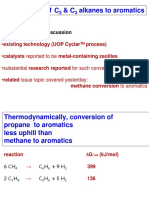

- Conversion of C & C Alkanes To Aromatics: Starting Points For DiscussionDocument13 pagesConversion of C & C Alkanes To Aromatics: Starting Points For DiscussionAmandaEdwinNo ratings yet

- Future Heavy Crude-Prod. & TechnologyDocument4 pagesFuture Heavy Crude-Prod. & TechnologyHARISHKOTHARU48No ratings yet

- An Introduction To Fire Heaters Part 1Document7 pagesAn Introduction To Fire Heaters Part 1Atharva OfficeNo ratings yet

- Weiland Vol 3 Issue 1Document4 pagesWeiland Vol 3 Issue 1madeehaNo ratings yet

- Rhenium A Hidden AssetDocument3 pagesRhenium A Hidden AssetAyman FawzyNo ratings yet

- Deactivation by Coking of Zeolite Catalysts. Prevention of Deactivation. Optimal Conditions For RegenerationDocument7 pagesDeactivation by Coking of Zeolite Catalysts. Prevention of Deactivation. Optimal Conditions For RegenerationBrunoBarrosNo ratings yet

- 2002 Development of Heavy Oil Hydrocracking Catalysts Using Amorphous Silica-Alumina and Zeolites As Catalyst SupportsDocument14 pages2002 Development of Heavy Oil Hydrocracking Catalysts Using Amorphous Silica-Alumina and Zeolites As Catalyst Supportsيا بقية الله ادركناNo ratings yet

- SGS 6 Basic Iron Sulphate in POX Processing of Refractory GoldDocument10 pagesSGS 6 Basic Iron Sulphate in POX Processing of Refractory Goldboanerges wino pattyNo ratings yet

- Use of Hydrometallurgy in Direct Processing of Base Metal PGM ConcentratsDocument14 pagesUse of Hydrometallurgy in Direct Processing of Base Metal PGM ConcentratsAFLAC ............No ratings yet

- Refractories Selectionforfor Cement Kiln IREFCON2012Document6 pagesRefractories Selectionforfor Cement Kiln IREFCON2012Saravana KumarNo ratings yet

- Organic Chemistry of Coke Formation: M. Guisnet, P. MagnouxDocument14 pagesOrganic Chemistry of Coke Formation: M. Guisnet, P. MagnouxaminsuhadiNo ratings yet

- TA201P Individual ProjectDocument17 pagesTA201P Individual Projecthacker noviceNo ratings yet

- Industrial Metal Catalysts 26072010Document53 pagesIndustrial Metal Catalysts 26072010gb130853100% (1)

- Modern Heterogeneous Oxidation Catalysis: Design, Reactions and CharacterizationFrom EverandModern Heterogeneous Oxidation Catalysis: Design, Reactions and CharacterizationNoritaka MizunoNo ratings yet

- PhysicsDocument10 pagesPhysicsmechanical_lecturerNo ratings yet

- DPP-3 Structure of Atom 04-01-2022 Online 2Document2 pagesDPP-3 Structure of Atom 04-01-2022 Online 2pw lover'sNo ratings yet

- Approvals - Listofproducts - Siemens 2019 PDFDocument3 pagesApprovals - Listofproducts - Siemens 2019 PDFHussain SyedNo ratings yet

- (TDS) Kumho KTR 301 PDFDocument2 pages(TDS) Kumho KTR 301 PDFjulio sierraNo ratings yet

- Thermo2 MidDocument4 pagesThermo2 MidnoelNo ratings yet

- Frac Fluid Presentation - FinalDocument112 pagesFrac Fluid Presentation - Finalayman morsy100% (1)

- Electronegativity and Electron Affinity - IBDP Chemistry HL FE2016 - KognityDocument4 pagesElectronegativity and Electron Affinity - IBDP Chemistry HL FE2016 - KognityshruthiNo ratings yet

- 2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationDocument11 pages2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationGuilherme Venturi RonchiNo ratings yet

- International, A Division of North American Aviatiorz, Inc., Canogu Pa,&, CaliforniaDocument2 pagesInternational, A Division of North American Aviatiorz, Inc., Canogu Pa,&, CaliforniaMateus PinheiroNo ratings yet

- Answer: Q1: What Is Plasma?Document7 pagesAnswer: Q1: What Is Plasma?حنين حسن شعبانNo ratings yet

- Kimia P1 SBP Mid Year SPM 2008Document44 pagesKimia P1 SBP Mid Year SPM 2008adeebspark100% (1)

- ch8 Crystallization PDFDocument10 pagesch8 Crystallization PDFLakshmi Narayan MeenaNo ratings yet

- Xii Physics NotesDocument170 pagesXii Physics Notesiamyasirali68No ratings yet

- AHRI Low-GWP AREP-Literature Review PDFDocument30 pagesAHRI Low-GWP AREP-Literature Review PDFAnonymous ffje1rpa100% (2)

- Project On Acetic AcidDocument21 pagesProject On Acetic AcidNaman Last To SurviveNo ratings yet

- Experimental Determination of Organic StructuresDocument11 pagesExperimental Determination of Organic StructuresJochebed MirandaNo ratings yet

- 01 Ib Chemistry (SL+HL) - S1.1 Introduction To The Particulate Nature of MatterDocument58 pages01 Ib Chemistry (SL+HL) - S1.1 Introduction To The Particulate Nature of MatterricardochavezrNo ratings yet

- CHE 10 SylDocument3 pagesCHE 10 SylConrado Galang Jr.No ratings yet

- Msa20111000007 87029177Document5 pagesMsa20111000007 87029177Mario Misael Machado LòpezNo ratings yet

- Stable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionDocument17 pagesStable Pure-Iodide Wide-Band-Gap Perovskites For Efficient Si Tandem Cells Via Kinetically Controlled Phase EvolutionPeter GuoNo ratings yet

- Carta Sicrométrica TraneDocument1 pageCarta Sicrométrica Tranejuan6esteban6alvar-1No ratings yet

- 10 - Enzymes - PPT - AutoRecoveredDocument65 pages10 - Enzymes - PPT - AutoRecoveredFaith WilliamsNo ratings yet

- Laser by Orazio SveltoDocument16 pagesLaser by Orazio SveltoArkayan Laha100% (1)

- Solid State: Objective Type Questions Multiple Choice QuestionsDocument5 pagesSolid State: Objective Type Questions Multiple Choice QuestionsSnehashis BoseNo ratings yet

- Chapter 7a Lecture Slides PDFDocument117 pagesChapter 7a Lecture Slides PDFjoseph changNo ratings yet

- WWW - Manaresults.Co - In: Set - 1 Code No: Rt32035Document2 pagesWWW - Manaresults.Co - In: Set - 1 Code No: Rt32035Asheesh KumarNo ratings yet

- PDF P324 06A (For Class) Lec Mod2 01c Material Balance (Orientation) PDFDocument12 pagesPDF P324 06A (For Class) Lec Mod2 01c Material Balance (Orientation) PDFvitaxnNo ratings yet

- R&ACDocument2 pagesR&ACsubramanian jNo ratings yet

- HTO Lab Manual Fall-18 PDFDocument52 pagesHTO Lab Manual Fall-18 PDFhumair khaliqNo ratings yet