Professional Documents

Culture Documents

泵控制

泵控制

Uploaded by

Chunping Song0 ratings0% found this document useful (0 votes)

10 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pages泵控制

泵控制

Uploaded by

Chunping SongCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

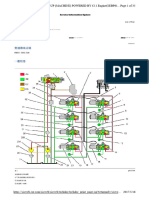

2004/06/28 Pump Regulation (RCNR3814)

‘smes - 1931 iozt48973,

Constant Control of Horsepower

‘Constant control ofthe horsepower is associated with the 1 to 9 setting of the engine

‘speed dial. The flow ofthe pump is contfled by the power Shift pressure when the

‘engine speed dials in the 1 through 9 position, The hydraulic output willbe set according

to the position ofthe engine speéd dial. Even though the pump is delivering the maximum,

flow, the controller will correct the power shift pressure‘n order to maintain the maximum

amount of flow. During the delivery of mide pressure and high pressure, the horsepower

‘of the main pump is controlled in order to prevent high horsepower ofthe pump with

lower engine horsepower, The conivoler fecelves feedback from the engine speed

‘sensor. The power shift pressure is proportional ta the target flow. The target flow is

calculated from the setting ofthe engine speed and the pressure of the delivery pump

pressure sensor. Thus, the pawer shift pressure will vary according tothe position of the

‘engine speed dial and the pressure of the delivery pump. The antistall feature for the

engine is used in order to prevent he engine from staling. "The antistal feature will be

activated, ifthe speed ofthe engine decreases 260 rpm below the position ofthe dial in

‘comparison to the setting ofthe engine speed lal

‘The power shift pressure is fixed for the positions of 1 through ®. The positions of {

through 4 of the engine speed dial have a different power shit pressure for each setting

‘The engine speed cial will set the desired RPM, which Will produce the desired flows. The

positions of 5 through 9 of the engine speed dial have a common paler shit pressure

‘that is fixed. The positions 1 through 9 use engine speed, the position ofthe engine

‘speed dial, and the pump pressure to set a fixed output. The output is fixed unt a

decrease of 250 RPM below the target RPM. Ata RPM of 250 below the target RPM, the

engine controler will adjust the power shift pressure in order to maintain engine RPM

within 250 RPM of the target RPM.

Control Of An Underspeed Condition

‘The underspeed condition is associated with a position of 10 of the engine speed dial

‘The 10 position of the engine speed cialis used when a large amount of horsepower is

required or a high ravel speed is requested. In this case, itis necessary to utilize the

Underspeed feature when the engine is being operated at a maximum horsepower. The

Underspeed feature wil maintain the speed of the engine at approximately maximum

power. The controller reads the engine speed and the controller will adjust the power shift

Pressure in order to regulate the engine speed. The controller controls the power shift

pressure in the underspeed condition. The engine maintains a speed of approximately

41950 rpm for the 312C, 2150 rpm for the 315C and 318C, and 1800 rpm for the 319C,

3200, 321C, 3220, 325C, and 330C in order to achieve the maximum horsepower

‘Therefore, when the engine speed is higher than the ful load speed, the output of the

pump wil increase and the power shift pressure will decrease. Also, when the engine

‘speed is lower than the target speed, the output of the pump will decrease and the power

shift pressure wil increase

‘The horsepower ofthe engine may decrease under the follwing conditions:

+ The engine becomes worn,

+ The quality ofthe fue is por

+ The engine is operating ta high alitide.

‘The controler will decrease the output of he pump and the controller wil increase the

Power shit pressure in order to reduce the load cn the engine withoUtreducing the

‘engine speed. This condition occurs’ he speed of the ehgine decreases below full load

speed

ion ea

sr=MCABinfoType=4&serviceMediaNumber=RCNR38 14&serviceleSystemControlNumber=i01294548-

03:16:36+08:00

or294548,

(© 2021 Caterpillar Inc.

Caterpilar

Confidential Green

hntpssis2.cat.commtidetall?

tab=2&serialNumber=MCASInfoType=4&serviceMediaNumb

-RONR3814&serviceleSystemControlNumber=i01294548

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6040电路图Document200 pages6040电路图Chunping SongNo ratings yet

- 变速箱动力流Document35 pages变速箱动力流Chunping SongNo ratings yet

- 变速箱 - 组装Document59 pages变速箱 - 组装Chunping SongNo ratings yet

- Volvo 挖机 380D 480D电路与液压全Document9 pagesVolvo 挖机 380D 480D电路与液压全Chunping SongNo ratings yet