Professional Documents

Culture Documents

IJCRT2203531

Uploaded by

mhm.mohammad90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJCRT2203531

Uploaded by

mhm.mohammad90Copyright:

Available Formats

www.ijcrt.

org © 2022 IJCRT | Volume 10, Issue 3 March 2022 | ISSN: 2320-2882

SYNTHESIS OF POLYSTYRENE BY FREE

RADICAL POLYMERIZATION AND ITS

CHARACTERISATION

1Aswin. S, 2Vijaya B and 3Murali. R*

1

PG Student, PG and Research Department of Chemistry, Nanjil Catholic College of Arts and Science,

Kaliyakkavilai- 629153, Tamilnadu, India

2

Research Scholar, Reg No. 18232102032013, PG and Research Department of Chemistry, Nanjil

Catholic College of Arts and Science, Kaliyakkavilai- 629153, Tamilnadu, India

3

Assistant Professor and Head, PG and Research Department of Chemistry, Nanjil Catholic College of

Arts and Science, Kaliyakkavilai- 629153, Tamilnadu, India

Abstract: Polystyrene is a synthetic aromatic thermoplastic polymer made from the styrene monomer.

Polystyrene can be clear, hard and rather brittle. In this study, polystyrene is prepared by free radical

polymerisation from styrene monomer with 200 mg of Bezoyl peroxide initiator. In the polymerisation

process, the carbon-carbon Pi-bond of vinyl group is broken and a chain of polymer is formed. The

polymer was characterized by FTIR, XRD and Gel permeation chromatography (GPC) for the

determination of Molecular weight. The polydispersity of polystyrene was found to be 2.274.

Index Terms- Polystyrene, Free radicals, Gel permeation chromatography, Polydispersity

I. INTRODUCTION

Plastics are widely used in modern society because of its low cost, strength, durability and versatile

properties. One such plastic material, polystyrene finds many applications from thermal insulator to food

packaging materials. It has been estimated that approximately 20 million tonnes of polystyrene are

produced annually (Schellenberg and Leder, 2006). The polystyrene was obtained by distillation of

Storax obtained from Turkish sweet gum trees and was manufactured industrially from the year 1869

(Ignazio Blanco et al. 2020).

Polymers are generally classified into thermoplastics, elastomers and thermosetting based on their

properties at different temperature. (Awad and Khalaf, 2019, Job Momanyi, 2019). Thermoplastics are

preferred over thermosetting polymers because of its low processing cost. Polystyrene is an aromatic

polymer and there are two groups. General purpose polystyrene (GPPS) and high impact polystyrene

(HIPS). The environmental degradation and impact caused by polymers can lowered by using recycled

polymers (Kalargaris et al. 2017).

Polystyrene is a polymer obtained from monomer styrene, which is a hydrocarbon obtained from

petroleum. Polystyrene is used in solid form and it is naturally transparent material, however it can be

coloured by adding colourants. Being thermoplastic polymer, polystyrene is in solid form at room

temperature but flows if heated above 100oC (its glass transition temperature). It gets solidified again

when it is cooled (Gowarikar et al. 2018).

IJCRT2203531 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org e630

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 3 March 2022 | ISSN: 2320-2882

There are many methods available for the preparation of polymers by radical means ( Matyjaszewski,

K. 1998, 1996). Polystyrene can undergo copolymerisation easily with monomers such as, vinyl

chloride, butadiene, acrylonitrile, acrylates among others giving products with unique properties. The

thermal and mechanical properties of modified polystryene finds many applications in industries which

improves the elasticity and performance of materials. Ignazio et al (2019) have reported the synthesis of

polystyrene nanocomposites with polyhedral oligomeric silsequioxanes which have better resistance to

thermal degradation. The effect of quenching induces a ductility to the polymeric materials. Rouabah et

al (2012) have reported the effect of quenching method on the mechanical and thermal properties of

polystyrene and reported the improvement of the impact strength of the material after quenching carried

out at 40°C.

Preparation of composite membrane made of styrene acrylonitrile (SAN) has been reported for the

separation of chromic acid from water (Sonny Sachdeva and Anil Kumar, 2008). Arvanitoyannis and

Biliaderis 1999 have reported the physical interaction between Polystyrene and starch by mixing these

two materials at different ratios.

II. MATERIALS AND METHODS

Styrene monomer was purchased from and Benzol peroxide initiator was purchased

from . The boiling point of the styrene monomer is around 145 oC. Benzoyl peroxide decomposes with

the cleavage of its oxygen-oxygen bond at a temperature between 80 and 90 oC. First 200mg of benzoyl

peroxide initiator was weighed accurately and transferred to a 100ml glass beaker. Then 15 ml of

styrene was poured into beaker and stirred using magnetic stirrer until all the benzoyl peroxide get

dissolved. The beaker was placed on heating mantle and heated between 80oC to 90oC. The beaker was

continuously stirred till the polymerisation process gets over.

After few minutes, the beaker started bubbling with emanation of white smoke. Also

volume in the beaker decreased overtime with the increase in the viscosity of solution. To determine

completeness of the polymerisation process, a small amount of the solution was extracted using a

glassrod and a fibrous string was observed. Then the polymer was poured into a petridish to cool down

and solidify. Polystyrene solidifies in the beaker itself while pouring and was difficult to remove. The

solidified polystyrene was broken into pieces and used for characterization.

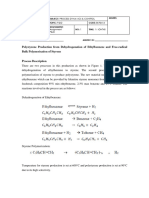

2.1. Mechanism:

Styrene is polymerized by a free-radical polymerisation mechanism. In this

polymerization process the initiator benzoyl peroxide decomposes at 80-90oC with the cleavage

Oxygen-Oxygen bond to give two benzoyloxy radicals, which then losses carbondioxide to form two

benzyl radicals;

The initiator radicals (R*) add to the C=C bond of styrene to produce a new, benzyl-type

free-radical, as shown below.

This radical then adds to another molecule of styrene, and the process continuous during

which the polymer chain starts to grow:

IJCRT2203531 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org e631

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 3 March 2022 | ISSN: 2320-2882

There is a possibility of addition of 5000 monomer units before the chain is terminated. The contribution

to the molecular weight by radical is negligible (0.02%). At last growth of polymer chain is terminated

by the combination of two radicals (either both polymer radicals or one polymer radical and one initiator

radical).

The overall equation for the polymerization process is as follows

III. RESULT AND DISCUSSION

The polystyrene was characterized by FTIR (Figure 1). The absorption bands at 3500-3000 cm-1 are

assigned to =C-H aromatic stretching vibration. The peaks at 2900 cm -1 and 2800 cm-1 are assigned to -

CH2 and –CH aliphatic stretching vibration. The bands at 1630 cm -1 and 1550 cm-1 indicates

deformation vibration of C-H in benzene ring. The bands at 750 cm -1 and 699 cm-1 can be attributed to

C-H out of plane bending vibration of benzene ring.

Figure 1. FTIR Spectrum of Polystyrene

The polymer was characterised by X-ray diffraction crystallography (XRD) (Figure 2)

which shows that polymer is amorphous in nature.

IJCRT2203531 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org e632

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 3 March 2022 | ISSN: 2320-2882

Figure 2. X ray Diffraction of Polystyrene

A polymer molecular structure strongly affects crystallinity. If it is regular and orderely,

it will be crystalline otherwise the polymer would be amorphous. There are two kinds of polystyrene one

is atactic polystyrene and another one is syndiotactic. The atactic polystyrene is amorphous in nature and

syndiotactic is crystalline.

To determine the molecular weight of prepared polymer and polydispersity Gel

permeation chromatography (GPC) was carried out and it is shown in Figure 3. Gel permeation

chromatography is a type of size exclusion chromatography, that separates polymer on the basis of size,

typically in organic solvents. The polymers are seperated to analyze as well as to purify the desired

product. When characterizing polymers, it is important to consider the dispersity (Đ) as well the

molecular weight. With GPC, number average molecular weight (Mn), the weight average molecular

eight (Mw) and the viscosity molecular weight (Mv) can be calculated.

Figure 3. Gel permeation chromatography of Polystyrene

The GPC of polystyrene sample gives the number average molecular weight (Mn) of 7388

and weight average molecular weight (Mw) of 16801. Therefore, the poly dispersity (Mw/Mn) was

found to be 2.274.

IJCRT2203531 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org e633

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 3 March 2022 | ISSN: 2320-2882

IV. CONCLUSION

Polystyrene was synthesised from styrene by free radical polymerisation with benzoyl

peroxide initiator. The viscosity of the mixture begins to increase when the polymerisation of styrene

starts. The viscosity of solution continued to increase until it get completely solidified.

V. ACKNOWLEDGEMENT

Authors would like to acknowledge the support provided by the Management of Nanjil Catholic College

of Arts and Science.

REFERENCES

[1] Schellenberg, J. and Leder, H.J. 2006. Syndiotactic polystyrene: process and applications. Adv.

Polym. Tech, 25: 141-151.

[2] Ignazio Blanco, Francesco Agatino Bottino, Gianluca Cicala, Giulia Ognibene and Claudio Tosto.

2020. Design, Preparation and Thermal Charaterization of Polystyrene Composites Reinforced with

Novel Three-Cages POSS molecules. Molecules, 25: 2697-2715.

[3] Awad, S A. and Khalaf, E M. 2019. Investigation of improvement of properties of polypropylene

modified by nanosilica composities. Compos. Commun, 12: 59-63.

[4] Job Momanyi, Michael Herzog and peter Muchiri. 2019. Analysis of Thermomechnical properties of

selected class of Recycled thermoplastic materials based on their applications. Recycling, 4 (3): 33-49.

[5] Kalargaris, I. Tian, G. and Gu, S. 2017. The utilisation of oils produced from plastic waste at

different pyrolysis temperatures in DI diesel engine. Energy, 131: 179-185.

[6] Gowariker, V. R, Viswanathan, N V, Jayadev Sreedhar. Polymer Science. New age International

Publishers, 4th Edition, 2018.

[7] Matyjaszewski, K. 1998. Controlled Radical Polymerization; ACS Symposium Series; American

Chemical Society: Washington, DC, Vol 685.

[8] Matyjaszewski, K. 1996. Curr. Opin. Solid State Mater. Sci. , 1, 769.

[9] Rouabah, F. Dadache, D. and Haddaoui, N. 2012. Thermophysical and Mechanical properties of

Polystyrene: Influence of free Quenching. International Scholarlt Research Network ISRN. Polymer

Science, Volume 22, Article ID 161364.

[10] Sonny Sachdeva and Anil Kumar. 2008. Synthesis and modeling of composite poly (styrene-co-

acrylonitrile) membrane for the separation of chromic acid. Journal of Membrane Science, 307: 37–52.

[11] Marta Worzakowska. 2015. Thermal and mechanical properties of polystyrene modified with esters

derivatives of 3-phenylprop-2-en-1-ol. J Therm Anal Calorim, 121: 235-243.

[12] Arvanitoyannis, I. and Biliaderis C. G. 1999. Physical properties of polyol-plasticized edible blends

made of methyl cellulose and soluble starch. Carbohydr Polym, 38:47-58.

IJCRT2203531 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org e634

You might also like

- Materials Characterization For StereolithographyDocument6 pagesMaterials Characterization For StereolithographymiercastroNo ratings yet

- ButadineDocument68 pagesButadineraihonaNo ratings yet

- The Use of Chitosan As A Solid Base Catalyst For TDocument8 pagesThe Use of Chitosan As A Solid Base Catalyst For TRicardo Fajardo DíazNo ratings yet

- Reporting in ABEDocument10 pagesReporting in ABEborromeojjulesNo ratings yet

- Hamza Kocserha TheeffectofexpandedperliteonfiredclaybricksDocument9 pagesHamza Kocserha TheeffectofexpandedperliteonfiredclaybricksvaleriacostacivilNo ratings yet

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Document8 pagesIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNo ratings yet

- 23 F Borsodi Full Paper IpcDocument9 pages23 F Borsodi Full Paper IpcHartono PrayitnoNo ratings yet

- 2793Document68 pages2793Jahadiel AguilarNo ratings yet

- Reologi Nanokomposit Polipropilen/Multiwalled Carbon Nanotube/OrganoclayDocument9 pagesReologi Nanokomposit Polipropilen/Multiwalled Carbon Nanotube/OrganoclayAyuAnatrieraNo ratings yet

- Wu-Fuel-2010-Pyrolysis-gasification of Plastics Mixed Plastics and Real-World Plastic WasteDocument11 pagesWu-Fuel-2010-Pyrolysis-gasification of Plastics Mixed Plastics and Real-World Plastic WastecloeNo ratings yet

- Module 4 Polymers & Green FuelsDocument8 pagesModule 4 Polymers & Green Fuelsdeepika seran100% (2)

- ARTICOLDocument16 pagesARTICOLDiaconescu Ovidiu-FlorinNo ratings yet

- PACCON2010 - Proceedings Anne 615pDocument1,037 pagesPACCON2010 - Proceedings Anne 615ppniramolNo ratings yet

- 2020 - Balu - Biomimetic TiO2-chitosan Sodium Alginate Blended Nanocomposite Scaffolds For Tissue Engineering ApplicationDocument13 pages2020 - Balu - Biomimetic TiO2-chitosan Sodium Alginate Blended Nanocomposite Scaffolds For Tissue Engineering ApplicationsmgmingigigiNo ratings yet

- Mechanical Behavior and Surface Modification of CNTs That Are Functionalized With Polymer CompositesDocument9 pagesMechanical Behavior and Surface Modification of CNTs That Are Functionalized With Polymer CompositesIJRASETPublicationsNo ratings yet

- Jongprateep 2015Document6 pagesJongprateep 2015kamran ullahNo ratings yet

- 1 s2.0 S0959652622025173 MainDocument11 pages1 s2.0 S0959652622025173 MainMay PassarapornNo ratings yet

- 2014 - Synthesis and Characterization of Chitosan Grafted With Polystyrene Using Ammonium Persulfate InitiatorDocument3 pages2014 - Synthesis and Characterization of Chitosan Grafted With Polystyrene Using Ammonium Persulfate InitiatorCARLOS ALBERTO RAMIREZ BARRAGANNo ratings yet

- Kalium HydroxideZirconia Pillared Bentonite For Pa PDFDocument8 pagesKalium HydroxideZirconia Pillared Bentonite For Pa PDFChandra WauranNo ratings yet

- Asish Anatase Tio2Document11 pagesAsish Anatase Tio2Jhasaketan NayakNo ratings yet

- Effect of Nanocellulose On The Biodegradation, Morphology and Mechanical Properties of Polyvinylchloride/ Nanocellulose NanocompositesDocument9 pagesEffect of Nanocellulose On The Biodegradation, Morphology and Mechanical Properties of Polyvinylchloride/ Nanocellulose NanocompositesSubakti HungNo ratings yet

- Photocatalysis PaperDocument14 pagesPhotocatalysis PaperGoutham RNo ratings yet

- EmbeddDocument7 pagesEmbeddLUIS AUGUSTO BARBOSANo ratings yet

- Jianwu Cao, Xiumei Shi, Cong Zhang, Zhipeng Li, Nengneng Luo, Hong CuiDocument7 pagesJianwu Cao, Xiumei Shi, Cong Zhang, Zhipeng Li, Nengneng Luo, Hong CuiHolmes's ApprenticeNo ratings yet

- Removal of Copper Metal From Industrial Wastewater Using GCC AdsorbentDocument12 pagesRemoval of Copper Metal From Industrial Wastewater Using GCC AdsorbentIJRASETPublicationsNo ratings yet

- Synthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodDocument5 pagesSynthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodBunduc Burduhos Nergis DoruNo ratings yet

- Accepted ManuscriptDocument30 pagesAccepted ManuscriptASTRID BARCO TULANDENo ratings yet

- Conversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDocument7 pagesConversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDika CodNo ratings yet

- Conversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDocument7 pagesConversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDika CodNo ratings yet

- Preparation and Characterization of Zinc-Copper Oxide Doped PMMA FilmsDocument7 pagesPreparation and Characterization of Zinc-Copper Oxide Doped PMMA FilmsManu FaujdarNo ratings yet

- 1 s2.0 S0272884219324253 MainDocument8 pages1 s2.0 S0272884219324253 MainNguyễn Hoàng TuấnNo ratings yet

- Bioresources: Preparation and Properties of Pulp Black Liquor BriquettesDocument13 pagesBioresources: Preparation and Properties of Pulp Black Liquor BriquettesarjunanpnNo ratings yet

- Waste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesDocument8 pagesWaste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesShahidulHoqueSohelNo ratings yet

- The Role Played by The Interactions of Small Molecules With Chitosan and Their Transitiona TempraturesDocument14 pagesThe Role Played by The Interactions of Small Molecules With Chitosan and Their Transitiona TempratureslimnypjNo ratings yet

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Heliyon: Md. Ruhul Amin, Mohammad Asaduzzaman Chowdhury, Md. Are Fin KowserDocument12 pagesHeliyon: Md. Ruhul Amin, Mohammad Asaduzzaman Chowdhury, Md. Are Fin KowserhmossNo ratings yet

- Processing of Mixed-Plastic Waste To Fuel Oil, Carbon Nanotubes and Hydrogen Using Multi-Core ReactorDocument9 pagesProcessing of Mixed-Plastic Waste To Fuel Oil, Carbon Nanotubes and Hydrogen Using Multi-Core ReactorasqwhoqijrqiNo ratings yet

- Facile Synthesis of Precious Metal Free Ti Cu Nano Catalyst ForDocument15 pagesFacile Synthesis of Precious Metal Free Ti Cu Nano Catalyst Forcindy.medinaNo ratings yet

- Coating Applications Synthesis and CharacterizationDocument11 pagesCoating Applications Synthesis and Characterizationsternchen408No ratings yet

- UvarajDocument12 pagesUvarajsam regisNo ratings yet

- Synthesis of Carbon Nanodots From Cellulose NanocrDocument6 pagesSynthesis of Carbon Nanodots From Cellulose NanocrMarniatiNo ratings yet

- Environmental TechnologyDocument12 pagesEnvironmental TechnologySara NaseriNo ratings yet

- Polybenzoxazine-Montmorillonite Hybrid Nanocomposites: Synthesis and CharacterizationDocument8 pagesPolybenzoxazine-Montmorillonite Hybrid Nanocomposites: Synthesis and CharacterizationElangovan NatarajanNo ratings yet

- FYP PropsalDocument17 pagesFYP PropsalusamaNo ratings yet

- Mistura Sílica e Alumina - Miteva (2019) - Characterisation of Fuel Produced From Polyolefin Waste Over Al2O3-SiO2Document9 pagesMistura Sílica e Alumina - Miteva (2019) - Characterisation of Fuel Produced From Polyolefin Waste Over Al2O3-SiO2Katiane MesquitaNo ratings yet

- Accepted Manuscript: 10.1016/j.jallcom.2017.09.024Document27 pagesAccepted Manuscript: 10.1016/j.jallcom.2017.09.024Helya Chafshoh NafisahNo ratings yet

- International Journal of Modern EngineerDocument4 pagesInternational Journal of Modern Engineersooperstar330No ratings yet

- Yang 2017Document39 pagesYang 2017Kaique TozziNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument9 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesAde RothmansNo ratings yet

- Evaluation Effects of Biobased Plasticizer On The Thermal, Mechanical, Dynamical Mechanical Properties, and Permanence of Plasticized PVCDocument10 pagesEvaluation Effects of Biobased Plasticizer On The Thermal, Mechanical, Dynamical Mechanical Properties, and Permanence of Plasticized PVCsavanNo ratings yet

- FULLTEXT01 Perkalite ThesisDocument23 pagesFULLTEXT01 Perkalite ThesisTomGaliciaNo ratings yet

- JMC Co3O4forsupercapaDocument7 pagesJMC Co3O4forsupercapamac.zahara3344No ratings yet

- Photocatalytic Degradation of Methyl Orange Using Tio2/Sno2 Binary Nano CompositeDocument7 pagesPhotocatalytic Degradation of Methyl Orange Using Tio2/Sno2 Binary Nano CompositeasdaNo ratings yet

- Photolysis Study by FtirDocument8 pagesPhotolysis Study by FtirrakibhossainNo ratings yet

- 2013 Synthesis and Cationic Photopolymerization of A Difunctional Episulfide Monomer PDFDocument6 pages2013 Synthesis and Cationic Photopolymerization of A Difunctional Episulfide Monomer PDFMarion ChenalNo ratings yet

- Effect of Microwave Power Irradiation On PDFDocument20 pagesEffect of Microwave Power Irradiation On PDFwegene lemaNo ratings yet

- Development and Characterization of NiTiCu Alloy Using Powder Metallurgy RouteDocument14 pagesDevelopment and Characterization of NiTiCu Alloy Using Powder Metallurgy RouteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Priatmoko 2020 J. Phys. Conf. Ser. 1567 022022Document9 pagesPriatmoko 2020 J. Phys. Conf. Ser. 1567 022022Ragil SadewoNo ratings yet

- The Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyFrom EverandThe Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyNo ratings yet

- Handbook of Oligo- and PolythiophenesFrom EverandHandbook of Oligo- and PolythiophenesDenis FichouNo ratings yet

- Preview 2Document4 pagesPreview 2mhm.mohammad90No ratings yet

- Polystyrene Production From DehydrogenatDocument3 pagesPolystyrene Production From Dehydrogenatmhm.mohammad90No ratings yet

- Preview 2Document4 pagesPreview 2mhm.mohammad90No ratings yet

- Polystyrene Production From DehydrogenatDocument3 pagesPolystyrene Production From Dehydrogenatmhm.mohammad90No ratings yet

- NYLON 6 (H20) : Perry Equipment CorporationDocument2 pagesNYLON 6 (H20) : Perry Equipment CorporationZackNo ratings yet

- Denture Base ResinsDocument103 pagesDenture Base ResinsSusovan GiriNo ratings yet

- HW - 2 - 4.4.2020 - Pol. Sci. Tech - CorrectedDocument5 pagesHW - 2 - 4.4.2020 - Pol. Sci. Tech - CorrectedAbdullahNo ratings yet

- CH 14Document42 pagesCH 14SingAnn100% (1)

- Glycolysis PET WasteDocument13 pagesGlycolysis PET Wasteankur2061No ratings yet

- P00533e Background Document On Neodecanoic Acid - Ethenyl EsterDocument28 pagesP00533e Background Document On Neodecanoic Acid - Ethenyl EsterIlhamdi AkmalNo ratings yet

- From Reactor To Rheology in Industrial Polymers: Daniel J. ReadDocument19 pagesFrom Reactor To Rheology in Industrial Polymers: Daniel J. ReadulysesrrNo ratings yet

- Synthetic Resins in ProsthodonticsDocument40 pagesSynthetic Resins in Prosthodonticssankar100% (1)

- Specialty Elastomers For Automotive ApplicationsDocument71 pagesSpecialty Elastomers For Automotive ApplicationsGOVAJANo ratings yet

- Modeling and Simulation of Poly (Lactic Acid) PolymerizationDocument140 pagesModeling and Simulation of Poly (Lactic Acid) PolymerizationCamilo Botero ZapataNo ratings yet

- Polymer Chemistry and Hydrogel SystemsDocument8 pagesPolymer Chemistry and Hydrogel SystemsPeter Perez-CastroNo ratings yet

- Reaction Kinetics (5) : Xuan Cheng Xiamen UniversityDocument27 pagesReaction Kinetics (5) : Xuan Cheng Xiamen Universityahmadhelmiase7621No ratings yet

- Styrene Butadiene RubberDocument9 pagesStyrene Butadiene RubberNguyễn Văn MinhNo ratings yet

- Poly (Acrylamide-Co-Maleic Acid) Hydrogels For Removal of CR (VI) From Aqueous Solutions, Synthesis and SwellingDocument11 pagesPoly (Acrylamide-Co-Maleic Acid) Hydrogels For Removal of CR (VI) From Aqueous Solutions, Synthesis and Swellingnadher damanNo ratings yet

- Chloroprene Rubber 99259 WP PUBLIC Box393196BDocument229 pagesChloroprene Rubber 99259 WP PUBLIC Box393196BbowcoastieNo ratings yet

- Chapter 14Document16 pagesChapter 14SUNILNo ratings yet

- Polymers CDocument76 pagesPolymers Cαγαπημένη του ΧριστούNo ratings yet

- Use of Core/Shell Structured Nanoparticles For Biomedical ApplicationsDocument9 pagesUse of Core/Shell Structured Nanoparticles For Biomedical ApplicationsAngel LavadoNo ratings yet

- Acetylene Chemistry: W. E. Hanfordl D. L. FullerDocument7 pagesAcetylene Chemistry: W. E. Hanfordl D. L. FullermghaffarzadehNo ratings yet

- Chem. Rev. 2009, 109, 5069-5119Document51 pagesChem. Rev. 2009, 109, 5069-5119dhuglNo ratings yet

- (Leonard IDocument1,098 pages(Leonard IDiego Paredes Linares50% (2)

- Board of Intermediate Education: Senior Inter Model Paper ChemistryDocument2 pagesBoard of Intermediate Education: Senior Inter Model Paper Chemistryrathod adithNo ratings yet

- OrganicInorganicChemistryTY2013 PDFDocument13 pagesOrganicInorganicChemistryTY2013 PDFSeafuddin ShikNo ratings yet

- Polymer Notes 2014 Parts 5-7Document103 pagesPolymer Notes 2014 Parts 5-7RadhiNo ratings yet

- Industrial Applications of Spinning Cone Column Technology: A ReviewDocument15 pagesIndustrial Applications of Spinning Cone Column Technology: A ReviewMarina ButuceaNo ratings yet

- Chemistry Project ReportDocument27 pagesChemistry Project ReportDhruv ShrivastavaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument39 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsKc FajardoNo ratings yet

- Acrylic EmulsionsDocument15 pagesAcrylic EmulsionsAsim MerajNo ratings yet

- Polymers & PolymerizationDocument20 pagesPolymers & PolymerizationAtul GautamNo ratings yet

- RprotoDocument102 pagesRprotonvemanNo ratings yet