Professional Documents

Culture Documents

PQT Euro Grit

PQT Euro Grit

Uploaded by

Heri Febriyanto0 ratings0% found this document useful (0 votes)

16 views19 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views19 pagesPQT Euro Grit

PQT Euro Grit

Uploaded by

Heri FebriyantoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

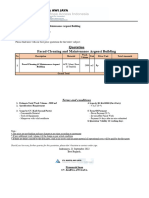

Jotun Paints

PAINTING QUALIFICATION TEST

BANYU URIP PROJECT MOBIL CEPU Ltd

ABRASIVE TEST OF EURO GRIT

Performance by:

Fabricator:

PT. JOTUN INDONESIA

PT. CITRA NIAGA UTAMA

PT. MULTI SERVINDO PRATAMA

Witness by:

Main Contractor:

TRIPATRA — SAMSUNG CONSORTIUM

Witness by:

Owner:

MOBIL CEPU LIMITED

PT. JOTUN INDONESIA

Indu 20 BERKS Ta Fae Webster conan

(Gharng Saat Baal 7520 indonesia ¥4271 00002057 “Ez 2 onezese Emel” cosine’ sevice ndonesaeotn.com

Jotun Paints

INTRODUCTION

All contractors shall perform Painting Qualification Test in accordance with

the Mobil Cepu Limited Specification Based on agreed schedule.

Several tests shall be carried out to meet all painting specification:

1. Rust Grade Assessment.

2. Pressurize Air Quality

2.1, Blotter Test

3. Abrasive Materials Quality

3.1. Conductivity Test

4. Blasted Surface Quality

4.1, Salt Content Test

4.2. Dust Level Test

4.3. Anchor Profile Test

4.4. Cleanliness Test

Attendance :

1. Mr. Petrus JM (Mobil Cepu Limited Representative)

2, Mr. Heri Febriyanto (Tripatra - Samsung Representative)

3. Mr. Agus P.S. (PT. Servindo/ PT. CITRA NU Representative)

4. Mr. Wiwid M (PT. Jotun Indonesia Representative)

PT. JOTUN INDONESIA

tan MALS MBZIOD BOARS |e

‘Giarong ara Oates! 7620 raoonla

Gra

Scope

Jotun Paints

To determine initial condition of Rust Grade at steel surface before Blasting and

Painting.

Equipment

SSPC Vis 1 standard book, Pictorial Standard.

Reference

1SO 8501-1 / SSPC Vis 1

Rust Grade A 100% MILL SCALE. Steel

surface largely covered with adherent mill scale

but little, if Any, rust.

| Rust Grade B- MILL SCALE + RUST. Steal

‘surface Which has begun to rust and from which

the mill scale has begun to flake.

Rust Grade C — 100% RUST. Steel surface on

which the mill scale has rusted away or from

which it can be scraped, but with slight pitting

visible under normal vision

Rust Grade D - RUST PITS. Steel surface on

which the mill scale has rusted away and on

which general Pitting is visible under normal

vision.

PT. JOTUN INDONESIA

Kavevan ngs M200 BERK? Fa Weoate JOTUN

Jotun Paints

PHOTOGRAPH BLOTER TEST

Test Result no oil & water intact on the collector

Prepared by Witness by Witness by ‘Accepted by

a

ef — |

eo a on

Petri ©

PT. MSP / PT CNU RA-S ISUN Mobil Cepr

oe webone

‘Geran Bera Sneed "7526 sone "622109062657 “2x eanezeso Eat

Site sonaendonesiaoun.com

Jotun Paints

3. ABI LI

3.4, CONDUCTIVITY TES

Scope

To determine the quantity of conductivity from abrasive materials that used in air blast

cleaning.

Equipment

1. Hanna Conductivity meter (S/N HE9930).

2. Distilled water.

3. Plastic/Giass Bottle.

4, Weight Measurement tools.

5. Digital Thermometer.

Reference

ASTM D—4940

Procedure ASTM - 4940

Wear gloves during the test.

Measure initial conductivity of purified water using Conductivity Meter.

Measure 300 mL abrasive and 300 mL Purified Water.

Put in the abrasive materials into cup for 300 mL and then put in the purified water

also 300 mL (Ratio 1: 1).

Stir the Jar for about 1 minute, let stand for 8 minutes and then stir it again about 1

minute.

Visualizes of presence of Oil either on top or as emulsion

Remove distilled water into clean glass jar and dried out

Measure Conductivity with Electronic Conductivity Gauge

Record temperature of the solution that used for measure.

}0.Rinse the Conductivity meter and all equipment with purified water before use it

again.

Result

NO @ BONS

22m

+ From measurement initial and final result, conductivity test for Euro Grit abrasives are

(17-4) = 16 Siem.

+ Check by visual, no oil or other contaminant in liquid.

Prepared by Witness by Witness by ‘Accepted by

*

— i.

Wiwid M Hery F:

Jotun Coating Advisor | PT.MSP/PTCNU | TRIPATRA-SAMSUNG | Mobil Cepu Ltd

PT. JOTUN INDONESIA

ean nau 210 Bok Wobsto -nnwjonnconap

Chang bore tones Tero mdcntla saz eeaner “advanmezese can” waren seanicom

45JOTUN

Jotun Paints

PHOTOGRAPH CONDUCTIVITY TEST ABRASIVE EURO GRIT

Pour the abrasives into water

z

Stir it 1 minute

4.8

Scope

Jotun Paints

‘ACI i

Lt le Meth«

For determine the presence of soluble contaminants on the blasted surface by use of

fiexible cells in the form of adhesive patches before painting or a similar treatment.

Equipment

1. Hanna Conductivity meter (S/N HE9930).

2. Elcometer 135 Bresle Patches.

3. Syringe with needle, 3 ml.

4. Distilled water.

5. Laser Thermometer.

Reference

ISO 8502-6 and 9

Procedure.

1. Wear gloves during the test. Calibrate the conductivity meter(for several Model)

2. Measure conductivity of purified water using Conductivity Meter.

3. Remove protective backing and foam centre from Bresle Patch.

4. Apply patch to surface. Press firmly around perimeter of patch to ensure a

complete seal.

Fill a small beaker with 15 mi of distilled water and determine the conductivity

(uSlem).

6. Fill syringe with 3 ml of de-ionised water.

Insert syringe into patch through spongy foam perimeter and inject 3 ml of de-

ionised water into patch. Do not remove syringe.

With syringe still in patch, reposition needle and evacuate any air in patch.

Remove syringe from patch, hold syringe with needle pointing upwards and expel

air.

10. Insert syringe into patch through spongy foam perimeter and inject remaining de-

ionised water into patch. Do not remove syringe.

11.After a suitable period of time (10 minutes)* suck the solution back into the syringe

and then immediately re-inject back into the patch.

12. Repeat step 10 until at least four injection/sucking cycles have been completed.

PT. JOTUN INDONESIA

Kanan nan IZOD BARK! Fae este wot

eee cece

conton

eer toreegeeneen

Jotun Paints

13.At end of last cycle extract as much solution as possible and remove syringe from

patch’.

14. Transfer the water back to the beaker and by use of the conduct meter determines

the conductivity (U:S/cm).

18.Determine the actual conductivity by subtracting the initial value of distilled water

from the final value.

16.To determine the result in mg/m2 multiply the actual conductivity by a factor of 6.

Calculate the Conductivity of the Sample.

Calculate the conductivity due to soluble salt contamination using the

Formula: (A-B) = C, where:

A= Conductivity of Extract

8 = Conductivity of Blank

C = Conduetivity due to surface soluble salt extraction

Entry Result

Conductivity of Extract (A) 3 ySicm

Conductivity of Blank (B) 0 pSicm

omen Due to Soluble Sait Extraction 3 pS/em

* Blank Water 15 mi constant in formula 6

Result

To determine the result in mg/m? (3-0) sS/cm X 6 = 18 mg/m? Conclusion: Accepted

fiom

Date / Weather / Time 24 October, 2012 / Clear / 09.36 am

Dry Temp. 31°C

‘Wet Temp. 23°C

‘Humidity 51%

Dew Point 20°C

‘Steel Temperature 29, 6°C

Prepared by Witness by Witness by

Y

Air eas

‘Aqus P Santosa

PT. MSP / PT CNU RIPATRA-SAMSUNG | Mobil Cepu Ltd

PT. JOTUN INDONESIA

Kanan inet 6200 BRK Fa Weoate wana com

ee nes rrunocaccnice | Saat cnenzesy Seu snmazese star conan eT craeiajeanicom

Jotun Paints

PHOTOGRAPH SALT TEST

1 mi distilled water

Install bresle patch

Salt contamination result 3 uS/em

PT. JOTUN INDONESIA

Kavos nat 82 1 W. fm

‘Ghreng Berar Sal 17820 donate "02 28 enoezes7 Ad 21 aonezese

Webster corton

Binet [Coseine’ sence novresegitn.oom

TLE}

Scope

To determine the presence, size and quantity of dust contamination blast cleaned surface.

Equipment

1. Adhesive Tape ~ Colorless and transparent self adhesive pressure sensitive tape,

25 mm wide.

2. White paper.

Reference

ISO 8502-3

Procedure

1. Remove the first 3 tums of tape from the roll. Remove or cut a piece of tape

approximately 200mm long.

2, Press about 150 mm freshly exposed tape firmly on the surface of the steel.

3. Rub the tape thoroughly against the steel with the thumb or with the roller. Do this

three (3X) times in each direction so that each stroke takes about 5 to 6 seconds.

4, Remove the tape and place it in a piece of glass, cardboard or white paper. Make

sure it adheres well to the surface.

5. Assess the quantity of dust on the tape by comparing visually an area of the tape

with the equivalent sized areas of the pictorial shown in the standard (reverse

side)

6. Assess the predomination dust particle size on the adhesive tape by comparing

with the reference table in the standard which defines six (6) dust particle size

classes (designated as 0, 1, 2,3 4 & 5)

7. Carry out a sufficient number of the test to characterize the surface under test. For

every surface of one particular type and aspect, carry out not less than three

separate tests. If the results do not have a spread of one or less quantity rating,

carry out at least two additional tests to establish mean.

8. After completing the test and before panting the steel surface, remove any tape or

adhesive left on the test surface.

PT. JOTUN INDONESIA

awosan i 2109 Ble Webste SSPC Vis 1 standard book (ISO- Sa 3- Blast Cleaning to Visually Clean Steel)

When viewed with magnification, the surface shall be free from visible oil, grease

and dirt and shall be free from mill scale, rust, paint coating and foreign matter. It

shall have uniform metalic colors.

Result

Based on Test Pipe 4" PQT. Cleanliness test shall according to SSPC Vis 1 standard book Blast

Cleaning to Visually clean steel. Result of cleanliness test is SSPC SP 5 ISO Sa-3

Ambient Condition

Date /Weather/Time 24 October, 20127 Clear /09.30 am

Dry Temperature 31°C

Wet Temperature 23°C

Humility 31%

Dew Point 20°C

Steel Temperature 296°C

PT. JOTUN INDONESIA

anata naa MMOD BERKS Te ae etete winoun comin

‘Grarang Barat Boke $7S20 nconenia 8221 89962087

cee

ints

Jotun Pai

PHOTOGRAPH SURFACE CLEANILESS

Initial condition after blast cleaning

Photo SSPC Vis 1 standard book Similar with A Sa 3 (SSPC SP 5)

Prepared by Witness by Witness by ‘Accepted by

:

_— P42 5 Dw 25.4

wiwid M /AqusP Santosa | — Hery Febryanto Petrus JM”

Jotun Coating Advisor | PT.MSP/PTCNU | TRIPATRA-SAMSUNG | Mobil Cepu Ltd

Pr. JOTUNINDONESIA

eooeeens)

Kaveean w oe Woveso :wjonn conan

‘Ghareng Gerat Bal 17520 ueala "aziz onoezss7 “82 z1a0pe26s0 Ema!” ; contomer serve ndanesiaiotn.com

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- QCP & Report Rev 03Document30 pagesQCP & Report Rev 03Heri FebriyantoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- WDC-Weekend Work Plan Requests - 9 - 10 Sept '23Document3 pagesWDC-Weekend Work Plan Requests - 9 - 10 Sept '23Heri FebriyantoNo ratings yet

- Surat Non PKPDocument1 pageSurat Non PKPHeri FebriyantoNo ratings yet

- Progress Report (3100) As of Nov-14-2023Document1 pageProgress Report (3100) As of Nov-14-2023Heri FebriyantoNo ratings yet

- RAB Repair External Coating by Pass StackDocument4 pagesRAB Repair External Coating by Pass StackHeri FebriyantoNo ratings yet

- Structur Organisasi Fix Rev. 1Document1 pageStructur Organisasi Fix Rev. 1Heri FebriyantoNo ratings yet

- Training HES Induction ProsysDocument12 pagesTraining HES Induction ProsysHeri FebriyantoNo ratings yet

- Quotation For Painting CV. KAJ - Proj 4Document8 pagesQuotation For Painting CV. KAJ - Proj 4Heri FebriyantoNo ratings yet

- Curiculum Vitae Heri Updated December 2020Document7 pagesCuriculum Vitae Heri Updated December 2020Heri FebriyantoNo ratings yet

- Check List Blasting & Painting Equipment: Tripatra-Samsung ConsortiumDocument1 pageCheck List Blasting & Painting Equipment: Tripatra-Samsung ConsortiumHeri FebriyantoNo ratings yet

- Check List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumDocument1 pageCheck List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumHeri FebriyantoNo ratings yet