Professional Documents

Culture Documents

5352 - GV Sub Fig7061

Uploaded by

Bryan ST0 ratings0% found this document useful (0 votes)

14 views2 pagesThis document provides specifications for standard reducing tees made of cast or fabricated fittings for grooved-end pipe. It lists the nominal sizes, center to end dimensions, and approximate weights for reducing tees in various pipe sizes. The reducing tees come in a wide range of sizes, from 11⁄4 inch pipe connections up to 10 inch pipes, to allow for transitions between different diameter pipes.

Original Description:

Original Title

5352_GV-SUB-FIG7061

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for standard reducing tees made of cast or fabricated fittings for grooved-end pipe. It lists the nominal sizes, center to end dimensions, and approximate weights for reducing tees in various pipe sizes. The reducing tees come in a wide range of sizes, from 11⁄4 inch pipe connections up to 10 inch pipes, to allow for transitions between different diameter pipes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pages5352 - GV Sub Fig7061

Uploaded by

Bryan STThis document provides specifications for standard reducing tees made of cast or fabricated fittings for grooved-end pipe. It lists the nominal sizes, center to end dimensions, and approximate weights for reducing tees in various pipe sizes. The reducing tees come in a wide range of sizes, from 11⁄4 inch pipe connections up to 10 inch pipes, to allow for transitions between different diameter pipes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

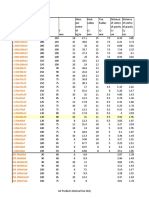

FITTINGS FOR GROOVED-END PIPE

FIG. 7061 C to E

O.D. O.D.

Reducing Tee Standard

C to E C to E

C to E

Cast Fabricated

FIGURE 7061 STANDARD REDUCING TEE

Nominal Size Center to End Approx. Wt. Ea. Nominal Size Center to End Approx. Wt. Ea. Nominal Size Center to End Approx. Wt. Ea.

In./DN(mm) In./mm Lbs./Kg In./DN(mm) In./mm Lbs./Kg In./DN(mm) In./mm Lbs./Kg

11⁄4 x 11⁄4 x 1 23⁄4 1.5 5x5x2 51⁄2 14 10 x 10 x 8 9 64.7

32 x 32 x 25 70 0.7 125 x 125 x 50 140 6.4 250 x 250 x 200 229 29.3

11⁄2 x 11⁄2 x 1 23⁄4 1.8 5 x 5 x 21⁄2 51⁄2 14.3 12 x 12 x 4 10 75.1

40 x 40 x 25 70 0.8 125 x 125 x 65 140 6.5 300 x 300 x 100 254 34.1

11⁄2 x 11⁄2 x 11⁄4 23⁄4 1.8 5x5x3 51⁄2 14.6 12 x 12 x 5 10 75.6

40 x 40 x 32 70 0.8 125 x 125 x 80 140 6.6 300 x 300 x 125 254 34.3

2x2x1 31⁄4 C 2.6 5x5x4 51⁄2 C 17.9 12 x 12 x 6 10 76.2

50 x 50 x 25 83 1.2 125 x 125 x 100 140 8.1 300 x 300 x 150 254 34.6

2 x 2 x 11⁄4 31⁄4 1.7 6x6x1 61⁄2 20.5 12 x 12 x 8 10 76.3

50 x 50 x 32 83 0.8 150 x 150 x 25 165 9.3 300 x 300 x 200 254 34.6

2 x 2 x 11⁄2 31⁄4 C 2.7 6 x 6 x 11⁄4 61⁄2 20.7 12 x 12 x 10 10 77.6

50 x 50 x 40 83 1.2 150 x 150 x 32 165 9.4 300 x 300 x 250 254 35.2

21⁄2 x 21⁄2 x 1 33⁄4 4.1 6 x 6 x 11⁄2 61⁄2 21.0 14 x 14 x 6 11 101

65 x 65 x 25 95 1.9 150 x 150 x 40 165 9.5 350 x 350 x 150 279 45.8

21⁄2 x 21⁄2 x 11⁄4 33⁄4 4.2 6x6x2 61⁄2 C 26.4 14 x 14 x 8 11 103

65 x 65 x 32 95 1.9 150 x 150 x 50 165 12.0 350 x 350 x 200 279 46.7

21⁄2 x 21⁄2 x 11⁄2 33⁄4 4.3 6 x 6 x 21⁄2 61⁄2 C 26.5 14 x 14 x 10 11 104

65 x 65 x 40 95 2.0 150 x 150 x 65 165 12.0 350 x 350 x 250 279 47.2

1 1 3 1

2 ⁄2 x 2 ⁄ 2 x 2 3 ⁄4 4.4 6x6x3 6 ⁄2 C 26.5 14 x 14 x 12 11 105

65 x 65 x 50 95 2.0 150 x 150 x 80 165 12.0 350 x 350 x 300 279 47.6

3x3x1 41⁄4 C 7.0 6x6x4 61⁄2 C 26.5 16 x 16 x 10 12 129

80 x 80 x 25 108 3.2 150 x 150 x 100 165 12.0 400 x 400 x 250 305 58.5

3 x 3 x 11⁄4 41⁄4 5.8 6x6x5 61⁄2 C 28.0 16 x 16 x 12 12 130

80 x 80 x 32 108 2.6 150 x 150 x 125 165 12.7 400 x 400 x 300 305 59.0

1 1 3

3 x 3 x 1 ⁄2 4 ⁄4 5.9 8x8x2 7 ⁄4 32.7 16 x 16 x 14 12 132

80 x 80 x 40 108 2.7 200 x 200 x 50 197 14.8 400 x 400 x 350 305 59.9

1 1 3 1

3x3x2 4 ⁄4 C 5.5 8 x 8 x 2 ⁄2 7 ⁄4 33.0 18 x 18 x 10 15 ⁄2 194

80 x 80 x 50 108 2.5 200 x 200 x 65 197 15.0 450 x 450 x 250 394 88.0

3 x 3 x 21⁄2 41⁄4 6.3 8x8x3 73⁄4 33.5 18 x 18 x 12 151⁄2 196

80 x 80 x 65 108 2.9 200 x 200 x 80 197 15.2 450 x 450 x 300 394 88.9

3 3 1

4x4x1 3 ⁄4 7.0 8x8x4 7 ⁄4 C 50.0 18 x 18 x 14 15 ⁄2 201

100 x 100 x 25 95 3.2 200 x 200 x 100 197 22.7 450 x 450 x 350 394 91.2

1 3 1

4 x 4 x 1 ⁄4 5 9.6 8x8x5 7 ⁄4 34.7 18 x 18 x 16 15 ⁄2 203

100 x 100 x 32 127 4.4 200 x 200 x 125 197 15.7 450 x 450 x 400 394 92.1

4 x 4 x 11⁄2 5 10.2 8x8x6 73⁄4C 54.0 20 x 20 x 12 171⁄4 246

100 x 100 x 40 127 4.6 200 x 200 x 150 197 24.5 500 x 500 x 300 438 111.6

4x4x2 5C 10.2 10 x 10 x 2 9 52.2 20 x 20 x 14 171⁄4 248

100 x 100 x 50 127 4.6 250 x 250 x 50 229 23.7 500 x 500 x 350 438 112.5

1 1 1

4 x 4 x 2 ⁄2 5C 11.2 10 x 10 x 2 ⁄2 9 52.6 20 x 20 x 16 17 ⁄4 250

100 x 100 x 65 127 5.1 250 x 250 x 65 229 23.9 500 x 500 x 400 438 113.4

4x4x3 5C 11.4 10 x 10 x 3 9 53.0 20 x 20 x 18 171⁄4 252

100 x 100 x 80 127 5.2 250 x 250 x 80 229 24.0 500 x 500 x 450 438 114.3

5x5x1 51⁄2 13.6 10 x 10 x 4 9 53.6 24 x 24 x 16 20 342

125 x 125 x 25 140 6.2 250 x 250 x 100 229 24.3 600 x 600 x 400 508 155.1

1 1

5 x 5 x 1 ⁄4 5 ⁄2 13.7 10 x 10 x 5 9 54.2 24 x 24 x 18 20 345

125 x 125 x 32 140 6.2 250 x 250 x 125 229 24.6 600 x 600 x 450 508 156.5

5 x 5 x 11⁄2 51⁄2 13.8 10 x 10 x 6 9 55.0 24 x 24 x 20 20 347

125 x 125 x 40 140 6.3 250 x 250 x 150 229 24.9 600 x 600 x 500 508 157.4

C - Cast ductile iron, all others are fabricated steel.

Center to end dimensions and weights may differ from those shown in chart, contact an Anvil Representative for more information.

For Listings/Approval Details and Limitations,

See Fitting Size chart on next page for O.D. visit our website at www.anvilintl.com or

contact an Anvil® Sales Representative.

PROJECT INFORMATION APPROVAL STAMP

Project: q Approved

Address: q Approved as noted

Contractor: q Not approved

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

GL-9.15

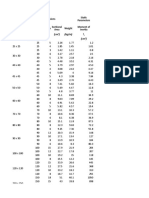

FITTINGS FOR GROOVED-END PIPE

NSF/ANSI 61

Gruvlok fittings are available through 24" nominal pipe

For Listings/Approval Details and Limitations,

size in a variety of styles. Use the Fitting Size Table to visit our website at www.anvilintl.com or

contact an Anvil® Sales Representative.

convert nominal pipe size to corresponding pipe O.D.

Galvanized Gruvlok Fittings are

These fittings are designed to provide minimum NSF-61 and Low Lead Approved

pressure drop and uniform strength.

Depending on styles and size, Gruvlok fittings are

provided in various materials including ductile iron,

forged steel or fabricated steel.

Pressure ratings of Gruvlok standard fittings conform to

those of Fig. 7001 Gruvlok coupling.

FLOW DATA – FRICTIONAL RESISTANCE MATERIAL SPECIFICATIONS

(EXPRESSED AS EQUIVALENT STRAIGHT PIPE)

CAST FITTINGS:

Nom. Pipe Wall Elbow Tee

O.D. Ductile iron conforming to ASTM A 536, Grade 65-45-12

Size Thickness 90° 45° Branch Run

Malleable iron conforming to ASTM A 47

In./DN(mm) In./mm In./mm Ft./m Ft./m Ft./m Ft./m

FABRICATED FITTINGS:

1 1.315 0.133 1.7 0.9 4.4 1.7

25 33.4 3.4 0.5 0.3 1.3 0.5 1-12" Carbon steel, Schedule 40, conforming to ASTM A 53, Grade B

11⁄4 1.660 0.140 2.3 1.2 5.8 2.3 14-24" Carbon steel, 0.375 wall, conforming to ASTM A 53, Grade B

32 42.2 3.6 0.7 0.4 1.8 0.7

11⁄2 1.900 0.145 2.7 1.3 6.7 2.7 COATINGS:

40 48.3 3.7 0.8 0.4 2.0 0.8 Rust inhibiting paint – Color: ORANGE (standard)

2 2.375 0.154 3.4 1.7 8.6 3.4 Hot Dipped Zinc Galvanized conforming to ASTM A 153 (optional)

50 60.3 3.9 1.0 0.5 2.6 1.0

21⁄2 2.875 0.203 4.1 2.1 10.3 4.1 Other Colors Available (IE: RAL3000 and RAL9000)

65 73.0 5.2 1.2 0.6 3.1 1.2

3 O.D. 2.996 0.197 4.3 2.2 10.8 4.3

76.1 76.1 5.0 1.3 0.7 3.3 1.3

3 3.500 0.216 5.1 2.6 12.8 5.1

80 88.9 5.5 1.6 0.8 3.9 1.6 FITTING SIZE

41⁄4 O.D. 4.250 0.220 6.4 3.2 16.1 6.4

108.0 108.0 5.6 2.0 1.0 4.9 2.0 Nominal Nominal

O.D. O.D.

4 4.500 0.237 6.7 3.4 16.8 6.7 Size Size

100 114.3 6.0 2.0 1.0 5.1 2.0

In./DN(mm) In./mm In./DN(mm) In./mm

51⁄4 O.D. 5.236 0.248 8.0 4.0 20.1 8.0

133.0 133.0 6.3 2.4 1.2 6.1 2.4 1 1.315 5 5.563

51⁄2 O.D. 5.500 0.248 8.3 4.2 20.9 8.3 25 33.4 140 141.3

139.7 139.7 6.3 2.5 1.3 6.4 2.5 11⁄4 1.660 61⁄4 O.D. 6.259

5 5.563 0.258 8.4 4.2 21.0 8.4 32 42.4 159.0 159.0

125 141.3 6.6 2.6 1.3 6.4 2.6 11⁄2 1.900 61⁄2 O.D. 6.500

61⁄4 O.D. 6.259 0.280 9.7 4.9 24.3 9.7 40 48.3 165.1 165.1

159.0 159.0 7.1 3.0 1.5 7.4 3.0 2 2.375 6 6.625

61⁄2 O.D. 6.500 0.280 10.0 5.0 24.9 10.0 50 60.3 150 168.3

165.1 165.1 7.1 3.0 1.5 7.6 3.0 21⁄2 2.875 8 8.625

6 6.625 0.280 10.1 5.1 25.3 10.1 65 73.0 200 219.1

150 168.3 7.1 3.1 1.6 7.7 3.1

3 O.D. 2.996 10 10.750

8 8.625 0.322 13.3 6.7 33.3 13.3

200 219.1 8.2 4.1 2.0 10.1 4.1 76.1 76.1 250 273.0

10 10.750 0.365 16.7 8.4 41.8 16.7 3 3.500 12 12.750

250 273.1 9.3 5.1 2.6 12.7 5.1 80 88.9 300 323.9

12 12.750 0.375 20.0 10.0 50.0 20.0 31⁄2 4.000 14 14.000

300 323.9 9.5 6.1 3.0 15.2 6.1 90 101.6 350 355.6

14 14.000 0.375 22.2 17.7 64.2 22.9 41⁄4 O.D. 4.250 16 16.000

350 355.6 9.5 6.8 5.4 19.6 7.0 108.0 108.0 400 406.4

16 16.000 0.375 25.5 20.4 73.9 26.4 4 4.500 18 18.000

400 406.4 9.5 7.8 6.2 22.5 8.0 100 114.3 450 457.2

18 18.000 0.375 28.9 23.1 87.2 31.1 51⁄4 O.D. 5.236 20 20.000

450 457.2 9.5 8.8 7.0 26.6 9.5 133.0 133.0 500 508.0

20 20.000 0.375 32.2 25.7 97.3 34.8 51⁄2 O.D. 5.500 24 24.000

500 508.0 9.5 9.8 7.8 29.7 10.6 139.7 139.7 600 609.6

24 24.000 0.375 38.9 31.1 113.0 40.4

600 609.6 9.5 11.9 9.5 34.4 12.3 The Fitting Size Chart is used to determine the

O.D. of the pipe that the fittings is to be used with.

For the reducing tee and branches, use the value that is corresponding to the branch Gruvlok Fittings are identified by either the Nominal

size. For example: for 6" x 6" x 3" tee, the branch value of 3" is 12.8 ft (3.9). size in inches or the Pipe O.D. in/mm.

GL-11.16

You might also like

- Weight of Copper Strip / Flat Kg. / Mt. Weight of Alluminium Flat KG/ MTDocument2 pagesWeight of Copper Strip / Flat Kg. / Mt. Weight of Alluminium Flat KG/ MTLikhithaNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFSyed Shoaib RazaNo ratings yet

- British Steel Universal Beams PFC DatasheetDocument2 pagesBritish Steel Universal Beams PFC DatasheetArjun S SanakanNo ratings yet

- Equal Steel Angle Angle Weight Surface AreaDocument9 pagesEqual Steel Angle Angle Weight Surface AreaChristian DelfinNo ratings yet

- Steel CatalogueDocument20 pagesSteel CatalogueHamish LaingNo ratings yet

- Standard Profile Inertia CalculatorDocument17 pagesStandard Profile Inertia CalculatorFian Ardiyana100% (1)

- ABB Pocket Book 11th Edition Chapter 16Document24 pagesABB Pocket Book 11th Edition Chapter 16macNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanNo ratings yet

- 5388 - GV Sub Fig7072Document2 pages5388 - GV Sub Fig7072Bryan STNo ratings yet

- 5548 Gv-Sub-Fig7060 Fig7076Document2 pages5548 Gv-Sub-Fig7060 Fig7076Bryan STNo ratings yet

- Equal Angles: Merchant Bar, StructuralDocument2 pagesEqual Angles: Merchant Bar, Structuralgani85No ratings yet

- Table of Structural Steel WeightDocument28 pagesTable of Structural Steel WeightEprizal lNo ratings yet

- Fittings For Grooved-End Pipe: FIG. 7060 FIG. 7076Document1 pageFittings For Grooved-End Pipe: FIG. 7060 FIG. 7076ErickNo ratings yet

- Plantilla Metrado AiscDocument86 pagesPlantilla Metrado AiscchinexxxNo ratings yet

- RV-K 0,6/1 KV: IEC 60502-1 and UNE 21123-4Document3 pagesRV-K 0,6/1 KV: IEC 60502-1 and UNE 21123-4Iván Abraham RamírezNo ratings yet

- Dimensions of ANGLE Steel Equal European Standard EN 10025-1/2Document1 pageDimensions of ANGLE Steel Equal European Standard EN 10025-1/2Neil SoansNo ratings yet

- Dimensions of Equal Angle BarsDocument7 pagesDimensions of Equal Angle BarsLon OdiNo ratings yet

- YSLYDocument3 pagesYSLYRagil AnggaNo ratings yet

- Tabel BajaDocument3 pagesTabel Bajaheri nurdianzhahNo ratings yet

- Ysly: Home Delta Cable Control CableDocument5 pagesYsly: Home Delta Cable Control CableMartin PutraNo ratings yet

- British Steel Universal Beams PFC Datasheet PDFDocument2 pagesBritish Steel Universal Beams PFC Datasheet PDFMayur MandrekarNo ratings yet

- SteelDocument4 pagesSteelvgteeNo ratings yet

- LIYCYDocument3 pagesLIYCYkaryasentosatechNo ratings yet

- British Steel Universal Beams PFC Datasheet PDFDocument2 pagesBritish Steel Universal Beams PFC Datasheet PDFTony OngNo ratings yet

- British Steel Universal Beams PFC Datasheet PDFDocument2 pagesBritish Steel Universal Beams PFC Datasheet PDFSam FarizoNo ratings yet

- Osw PDFDocument1 pageOsw PDFunnikrishnanNo ratings yet

- Angle and Channel Section ListDocument20 pagesAngle and Channel Section ListRajveer SinghNo ratings yet

- Cable Size For DG SetDocument1 pageCable Size For DG Setsaneesh81No ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- CivataDocument38 pagesCivataVeysel KoçNo ratings yet

- Angle IronDocument9 pagesAngle IronChibuike AlaohuruNo ratings yet

- Calculo Perfil C Sometido A FlexionDocument6 pagesCalculo Perfil C Sometido A FlexionJonathanPobletePerezNo ratings yet

- Standard Profile Inertia CalculationDocument17 pagesStandard Profile Inertia CalculationFian ArdiyanaNo ratings yet

- Hollow Section Steel SizesDocument1 pageHollow Section Steel SizesTanzeem JanNo ratings yet

- ABB - 12 - E - 16 Materials and Semi-Finished Products For Switchgear InstallationsDocument24 pagesABB - 12 - E - 16 Materials and Semi-Finished Products For Switchgear InstallationsHan HuangNo ratings yet

- Liycy-Oz-Jz Delta PDFDocument3 pagesLiycy-Oz-Jz Delta PDFEdy WijayaNo ratings yet

- Structural Tees Asian Size: I V Z T TDocument2 pagesStructural Tees Asian Size: I V Z T TBunheng LonNo ratings yet

- L Equal AnglesDocument1 pageL Equal AnglesM. Murat ErginNo ratings yet

- Angle Size ChartDocument1 pageAngle Size ChartAbhinav KumarNo ratings yet

- Description Kebutuhan Material Ton: List Material Project. 180' X 56' X 12'Document5 pagesDescription Kebutuhan Material Ton: List Material Project. 180' X 56' X 12'SBS CONSULTANT BATAMNo ratings yet

- ChannelsDocument1 pageChannelsGustavNo ratings yet

- ProfilesDocument1 pageProfilesvitty_1983No ratings yet

- Uk Sections Datasheets 100723Document20 pagesUk Sections Datasheets 100723pkdscdubaiNo ratings yet

- (MM X MM) (CM) (CM) : Size Dimensions Depth Thickness Weight H S Static Parameters Sectional Area Moment of Inertia IDocument2 pages(MM X MM) (CM) (CM) : Size Dimensions Depth Thickness Weight H S Static Parameters Sectional Area Moment of Inertia IKakoy Lagusan EcobenNo ratings yet

- Tee Normal y Reductora - LEDEDocument4 pagesTee Normal y Reductora - LEDEDiana V. RosalesNo ratings yet

- Pipes Dimension PropertiesDocument6 pagesPipes Dimension PropertiesJanzxhel Alva OlazoNo ratings yet

- Pipe Properties and DimensionsDocument6 pagesPipe Properties and DimensionsJanzxhel Alva OlazoNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsInfinity GHNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSérgio BernardesNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPratyadip DuttaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsvysakh51No ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSherin ShajiNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsYaziq NabilNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetsarathNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsHusam AhmedNo ratings yet