Professional Documents

Culture Documents

Review Jurnal - EOR

Uploaded by

M Fadhil Muchtar0 ratings0% found this document useful (0 votes)

5 views4 pagesThis journal article reviews recent advances in the use of surfactants for enhanced oil recovery (EOR). It discusses 7 categories of surfactants - sodium dodecyl sulfate, internal olefin sulfonates, alpha olefin sulfonates, alkyl aryl sulfonates, cetyltrimethyl ammonium bromide, dodecyltrimethyl ammonium bromide, and alkyl trimethyl ammonium chlorides. For each surfactant, it describes the chemical type and structure, experimental conditions tested, and performance outcomes such as incremental oil recovery. The review finds that surfactants can increase oil recovery through mechanisms like reducing surface tension and interfacial tension between oil and water. Certain surfactants like internal

Original Description:

Original Title

102321049_Review Jurnal_EOR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis journal article reviews recent advances in the use of surfactants for enhanced oil recovery (EOR). It discusses 7 categories of surfactants - sodium dodecyl sulfate, internal olefin sulfonates, alpha olefin sulfonates, alkyl aryl sulfonates, cetyltrimethyl ammonium bromide, dodecyltrimethyl ammonium bromide, and alkyl trimethyl ammonium chlorides. For each surfactant, it describes the chemical type and structure, experimental conditions tested, and performance outcomes such as incremental oil recovery. The review finds that surfactants can increase oil recovery through mechanisms like reducing surface tension and interfacial tension between oil and water. Certain surfactants like internal

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views4 pagesReview Jurnal - EOR

Uploaded by

M Fadhil MuchtarThis journal article reviews recent advances in the use of surfactants for enhanced oil recovery (EOR). It discusses 7 categories of surfactants - sodium dodecyl sulfate, internal olefin sulfonates, alpha olefin sulfonates, alkyl aryl sulfonates, cetyltrimethyl ammonium bromide, dodecyltrimethyl ammonium bromide, and alkyl trimethyl ammonium chlorides. For each surfactant, it describes the chemical type and structure, experimental conditions tested, and performance outcomes such as incremental oil recovery. The review finds that surfactants can increase oil recovery through mechanisms like reducing surface tension and interfacial tension between oil and water. Certain surfactants like internal

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Nama : Muhammad Fadhil Muchtar Nasution

NIM : 102321049

Mata Kuliah : Metodologi Penelitian

TUGAS REVIEW JURNAL

Tema : Enhanced Oil Recovery (EOR)

Judul Jurnal : The Use of Surfactants in Enhanced Oil Recovery: A Review of Recent Advances

Terbit : 2020

Penerbit : Elsevier Ltd

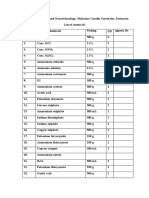

Surfactant's Formation Experimental

No Other Chemicals Performance

Name and Types Type Conditions

Sodium Dodecyl Alkyl Nanoparticles Various experimental - SDS with 0.2 wt% silica NPs

Sulfate (SDS) Sulfate (silica NPs, ZnO conditions including achieved incremental oil recovery

NPs), 1-dodecyl-3- high salinity and of 4.43% following

methylimidazolium temperature waterflooding.

chloride (M12) - SDS with 0.2 wt% SDS and 0.2

1

wt% silica NPs achieved

incremental oil recovery of 9.11%.

- Flooding with 0.2 wt% SDS and

0.05 wt% ZnO NPs achieved 35%

increase in oil recovery.

Internal Olefin Anionic - Various experimental - IOS surfactants (C15−18 IOS,

Sulfonates (IOS) surfactants conditions including C19−13 IOS, and C24−26 IOS)

2 temperature and salinity can withstand harsh reservoir

conditions of temperature and

salinity.

Alpha Olefin Anionic Linear alpha- Various experimental - AOS surfactants exhibit high

Sulfonates (AOS) surfactants olefins, sulfur conditions including biodegradability and low toxicity.

trioxide (SO3) core-flood experiments, They have excellent wetting,

3

presence of CO2, and dispersing, foaming, emulsifying,

addition of clay NPs and and stabilizing abilities.

hydrophilic silica NPs

Alkyl Aryl Anionic Propylene tetramer, Various experimental - AAS surfactants are anionic

Sulfonates (AAS) surfactants benzene (for early conditions including surfactants and the most common

preparation), core-flood experiments, type of sulfonate surfactants.

4 nonferrous metal presence of nonferrous Surfactant solution increased oil

nanoparticles metal nanoparticles recovery by 1.7–2.1% of OOIP,

(NPs) (NPs) which was then increased by 6.9–

8.5% of OOIP using the NPs

Cetyltrimethyl Cationic - High salinity conditions - CTAB is a cationic surfactant

ammonium surfactant (brine with 3 wt% NaCl) also known as cetrimonium

Bromide (CTAB) bromide or hexadecyl trimethyl

ammonium bromide. CTAB

decreased surface tension of

aqueous solutions, with a higher

5

effect in brine (3 wt% NaCl)

compared to distilled water. IFT

between brine (3 wt% NaCl) and

oil decreased with increasing

CTAB concentration, resulting in

an EOR of 32.1–54.8% of OOIP.

Dodecyltrimethyl Cationic - High temperature (92 - Molecular formula: C15H34

6 ammonium surfactant ◦C), high salinity BrN. Using a formation brine with

Bromide (DTAB) formation brine a salinity of 196,014 ppm, oil

recovery was 8% of OOIP.

Adding 0.5 wt% DTAB to the

formation brine raised oil recovery

to about 55.9% of OOIP in

spontaneous imbibition tests.

Using 100 times diluted formation

brine in the presence of 0.5 wt%

DTAB achieved even higher

levels of oil recovery. Factors

influencing limestone wettability

include brine dilution, the use of

DTAB, and the presence of sulfate

and magnesium ions

Alkyl trimethyl Cationic - Various salinities up to - Molecular formula: CnH

ammonium surfactants 223802.8 ppm (2n+1)N + (CH3)3Cl−.

Chlorides

- Three studied surfactants:

- Dodecyl trimethyl

ammonium chloride

(DTAC)

- Tetradecyl trimethyl

ammonium chloride

(TTAC)

7

- Octadecyl trimethyl

ammonium chloride

(OTAC)

.

- DTAC had the lowest

adsorption, similar to TTAC,

while OTAC had substantially

higher adsorption attributed to its

stronger hydrophobic force from

its longer hydrophobic chain. This

makes it easier for OTAC to leave

the water phase and adsorb onto

limestone

Referensi:

Massarweh, O., & Abushaikha, A. S. (2020). The use of surfactants in enhanced oil recovery: A review of recent advances. Energy

Reports, 6, 3150–3178. https://doi.org/10.1016/j.egyr.2020.11.009

You might also like

- Plant Design of MIBKDocument59 pagesPlant Design of MIBKRegina Cruz Rillera100% (3)

- New Drilling Fluid Technology-Mineral Oil Mud: SPE, Chromalloy Drilling FluidsDocument7 pagesNew Drilling Fluid Technology-Mineral Oil Mud: SPE, Chromalloy Drilling FluidsElias Glz VegaNo ratings yet

- Agha Razi Dorman I 1990Document8 pagesAgha Razi Dorman I 1990Vinod KanapathyNo ratings yet

- J of Applied Polymer Sci - 2012 - Lai - A Water Soluble Acrylamide Hydrophobically Associating Polymer SynthesisDocument9 pagesJ of Applied Polymer Sci - 2012 - Lai - A Water Soluble Acrylamide Hydrophobically Associating Polymer SynthesisCamilo Andrés Guerrero MartinNo ratings yet

- Xu 2010Document5 pagesXu 2010Jendral Yoga AryatamaNo ratings yet

- Use of An Effluent For Enhanced Oil Recovery: Subrata Borgohain Gogoi & Borkha Mech DasDocument5 pagesUse of An Effluent For Enhanced Oil Recovery: Subrata Borgohain Gogoi & Borkha Mech DasSirisha NNo ratings yet

- Elkady 2016Document20 pagesElkady 2016Tamkin TamrazliNo ratings yet

- Effects of Surfactants and Alkalis On The Stability of Heavy-Oil-in-Water EmulsionsDocument10 pagesEffects of Surfactants and Alkalis On The Stability of Heavy-Oil-in-Water EmulsionsEliasNo ratings yet

- Synthesis and Properties of A Novel Alkyl-Hydroxyl-Sulfobetaine Zwitterionic Surfactant For Enhanced Oil RecoveryDocument9 pagesSynthesis and Properties of A Novel Alkyl-Hydroxyl-Sulfobetaine Zwitterionic Surfactant For Enhanced Oil RecoveryYemima MNo ratings yet

- Study of Physiochemical Properties of Cetyltrimethylammonium Bromide (CTAB) Surfactant Its Micellization, Almond Oil Water Emulsification and Industrial ApplicationsDocument4 pagesStudy of Physiochemical Properties of Cetyltrimethylammonium Bromide (CTAB) Surfactant Its Micellization, Almond Oil Water Emulsification and Industrial ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Emulsion Polymerization of Vinyl Acetate in A Tubular Loop Reactor PDFDocument9 pagesEmulsion Polymerization of Vinyl Acetate in A Tubular Loop Reactor PDFPablo Gonzalez CortesNo ratings yet

- Separation and Purification TechnologyDocument6 pagesSeparation and Purification TechnologySTUDY CORNER chemistryNo ratings yet

- Synthesis and Properties of A Novel Alkyl-Hydroxyl-Sulfobetaine Zwitterionic Surfactant For Enhanced Oil RecoveryDocument6 pagesSynthesis and Properties of A Novel Alkyl-Hydroxyl-Sulfobetaine Zwitterionic Surfactant For Enhanced Oil RecoverySanjay singhNo ratings yet

- Numerical Studies of Oil Production From Initially Oil-Wet Fracture Blocks by Surfactant Brine ImbibitionDocument15 pagesNumerical Studies of Oil Production From Initially Oil-Wet Fracture Blocks by Surfactant Brine ImbibitionNassr Al BadriNo ratings yet

- 2001 Elemental Sulfur As An Effective Promoter For The Catalytic Hydrocracking of Arabian Vacuum ResidueDocument5 pages2001 Elemental Sulfur As An Effective Promoter For The Catalytic Hydrocracking of Arabian Vacuum Residueيا بقية الله ادركناNo ratings yet

- Principle of Enhanced Oil Recovery: Chapter 6 Surfactant FloodingDocument28 pagesPrinciple of Enhanced Oil Recovery: Chapter 6 Surfactant FloodingNgapene MichelharisNo ratings yet

- Isomerization Process, Reactions, Effects of Process Variables. IsomerizationDocument6 pagesIsomerization Process, Reactions, Effects of Process Variables. IsomerizationAlaa El-sherbinNo ratings yet

- Spe 190377 MsDocument21 pagesSpe 190377 MsSeyedeh Maryam MousaviNo ratings yet

- Articulo TesistaDocument18 pagesArticulo TesistaStefania ReyesNo ratings yet

- Study On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDocument7 pagesStudy On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDyshelly Nurkartika PascapurnamaNo ratings yet

- Liquido Ionico AcidoDocument3 pagesLiquido Ionico AcidoFelipe CunhaNo ratings yet

- Simultaneous Transesterification and Esterification of Unrefined or Waste Oils Over ZnO-La2O3 CatalystsDocument10 pagesSimultaneous Transesterification and Esterification of Unrefined or Waste Oils Over ZnO-La2O3 CatalystsAdriano Sant'AnaNo ratings yet

- Amine Sweetening: Diego Alejandro Ayala Gómez 2154120 Jeison Stiven Villota Narváez 2155605 Gas Engineering 2020Document35 pagesAmine Sweetening: Diego Alejandro Ayala Gómez 2154120 Jeison Stiven Villota Narváez 2155605 Gas Engineering 2020jeison villotaNo ratings yet

- An Overview of Chemical Enhanced Oil Recovery: Recent Advances and ProspectsDocument32 pagesAn Overview of Chemical Enhanced Oil Recovery: Recent Advances and ProspectsDavid LópezNo ratings yet

- Catalyst Acids Ie901175dDocument4 pagesCatalyst Acids Ie901175dZamri FadilahNo ratings yet

- Waste Lubricating Oil Treatment by Adsorption Process Using Different AdsorbentsDocument4 pagesWaste Lubricating Oil Treatment by Adsorption Process Using Different AdsorbentsjarnokorhonenNo ratings yet

- Propylene PolymersDocument72 pagesPropylene PolymersThùy LinhNo ratings yet

- Enhanced Oil Recovery 2019Document21 pagesEnhanced Oil Recovery 2019hkaqlqNo ratings yet

- Waste Lubricating-1Document4 pagesWaste Lubricating-1Tiffany noor afifNo ratings yet

- Chemical EORDocument56 pagesChemical EORAugusto Viera ZapataNo ratings yet

- Oilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDocument10 pagesOilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDaniel DamboNo ratings yet

- Bio Oil Upgrading by Means of Ethyl Ester ProductionDocument6 pagesBio Oil Upgrading by Means of Ethyl Ester ProductionVlad IonitaNo ratings yet

- Journal of Cleaner Production: Ying Tang, Jingfang Xu, Jie Zhang, Yong LuDocument6 pagesJournal of Cleaner Production: Ying Tang, Jingfang Xu, Jie Zhang, Yong Ludhairya.santreNo ratings yet

- A New Secondary Accelerator For The Sulfur Vulcanization - Kurien - Et - Al-2004-Journal - of - Applied - Polymer - ScienceDocument9 pagesA New Secondary Accelerator For The Sulfur Vulcanization - Kurien - Et - Al-2004-Journal - of - Applied - Polymer - Sciencemac_su038No ratings yet

- Surfactants For EOR Olefin Sulfonate Behavior at High Temperature and HardnessDocument7 pagesSurfactants For EOR Olefin Sulfonate Behavior at High Temperature and HardnessDavid LópezNo ratings yet

- 2015 B. Gaweł, C. Lesaint, S. Bandyopadhyay, G. Øye. The Role of Physic Chemical and Interfacial Properties On The Binary Coalescence of CrudeDocument8 pages2015 B. Gaweł, C. Lesaint, S. Bandyopadhyay, G. Øye. The Role of Physic Chemical and Interfacial Properties On The Binary Coalescence of Crude10_DAVID_10No ratings yet

- 3582 7663 1 SMDocument6 pages3582 7663 1 SMSarah AyundaNo ratings yet

- Study of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsDocument6 pagesStudy of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsDocument11 pagesSPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsGabriel SNo ratings yet

- Liquids Processing: WeeteningDocument16 pagesLiquids Processing: WeeteningAdjie satrioNo ratings yet

- A Study in Vulcanization of Neoprene Rubber (WRT) y Polymethylol Resin (RESOL)Document6 pagesA Study in Vulcanization of Neoprene Rubber (WRT) y Polymethylol Resin (RESOL)ASUPREMEA100% (1)

- Snamprogetti New MTBE Production Design PDFDocument13 pagesSnamprogetti New MTBE Production Design PDFViệt HàNo ratings yet

- AADocument30 pagesAAAhmed MajidNo ratings yet

- Deng2002 PDFDocument10 pagesDeng2002 PDFximenaesgNo ratings yet

- Papper Recup Mejorada - En.esDocument12 pagesPapper Recup Mejorada - En.esFernando AguilarNo ratings yet

- Effects of Interfacial Tension, Oil Layer Break Time, Emulsification and Wettability Alteration On Oil Recovery For Carbonate ReservoirsDocument12 pagesEffects of Interfacial Tension, Oil Layer Break Time, Emulsification and Wettability Alteration On Oil Recovery For Carbonate ReservoirsDavid LópezNo ratings yet

- Full Length Article: SciencedirectDocument11 pagesFull Length Article: Sciencedirectد. نوري الحدادNo ratings yet

- Liu 2015Document5 pagesLiu 2015Steven NuñezNo ratings yet

- SPE 164768 Experimental Investigation of Low Salinity Hot Water Injection To Enhance The Recovery of Heavy Oil ReservoirsDocument10 pagesSPE 164768 Experimental Investigation of Low Salinity Hot Water Injection To Enhance The Recovery of Heavy Oil ReservoirsMohanned KhairyNo ratings yet

- Anirban - 1655034 SeminarDocument19 pagesAnirban - 1655034 SeminarAnirban PalNo ratings yet

- Chew2017 Article TransesterificationOfPalmCookiDocument7 pagesChew2017 Article TransesterificationOfPalmCookiHeri Tamtowi SyaputroNo ratings yet

- Aniline From Nitrobenzene 1Document11 pagesAniline From Nitrobenzene 1Neha MiracleNo ratings yet

- Mechanistic Study of Nanoparticles-Assisted XanthaDocument7 pagesMechanistic Study of Nanoparticles-Assisted XanthaAbooNo ratings yet

- Submit - Kelompok 3 - Hydrophobic CoatingDocument16 pagesSubmit - Kelompok 3 - Hydrophobic CoatingAndi Kurnia SiregarNo ratings yet

- Combined Effects of Polymer-Surfactant..Document8 pagesCombined Effects of Polymer-Surfactant..Carolina AyalaNo ratings yet

- EOR With Penn State Surfactants: T.G. ArfDocument11 pagesEOR With Penn State Surfactants: T.G. ArfSajad FalahNo ratings yet

- Design and Optimisation of Purifi-Cation Procedure For Biodiesel WashingDocument10 pagesDesign and Optimisation of Purifi-Cation Procedure For Biodiesel WashingSagar DhuriNo ratings yet

- Hydroformylation: Fundamentals, Processes, and Applications in Organic SynthesisFrom EverandHydroformylation: Fundamentals, Processes, and Applications in Organic SynthesisNo ratings yet

- Ionic Liquid-Based Surfactant Science: Formulation, Characterization, and ApplicationsFrom EverandIonic Liquid-Based Surfactant Science: Formulation, Characterization, and ApplicationsNo ratings yet

- Oil Spill Response in the Marine EnvironmentFrom EverandOil Spill Response in the Marine EnvironmentRating: 3 out of 5 stars3/5 (2)

- Hydrogen & S-Block Elements - WorkbookDocument34 pagesHydrogen & S-Block Elements - WorkbookStudy BuddyNo ratings yet

- Ni DMG Solution PreparationDocument5 pagesNi DMG Solution PreparationNatarajan PalaniNo ratings yet

- Chemistry Lab Manual 1Document25 pagesChemistry Lab Manual 1Nischay SanjayNo ratings yet

- Lis of Chemicals NewDocument6 pagesLis of Chemicals NewDhanya K RNo ratings yet

- ChemistryWorkbook AnswersDocument24 pagesChemistryWorkbook AnswersStudent Research33% (3)

- Corrosion/Erosion in Sulfur Recovery: (Real-Life Examples)Document31 pagesCorrosion/Erosion in Sulfur Recovery: (Real-Life Examples)AnilNo ratings yet

- Potentiality of Coir Coconut Husk and Sodium Bicarbonate Baking Soda As Compost Catalyst To Reduce Waste Among Filipino HouseholdsDocument38 pagesPotentiality of Coir Coconut Husk and Sodium Bicarbonate Baking Soda As Compost Catalyst To Reduce Waste Among Filipino HouseholdsHANNAH MARIE VINOYANo ratings yet

- Salt Analysis Past Papers 2021-2023Document14 pagesSalt Analysis Past Papers 2021-2023Masarrat Ahmad - 26660/TCHR/BNKMNo ratings yet

- 9IG Topic 4 ChemistryDocument52 pages9IG Topic 4 ChemistryredaNo ratings yet

- Titration - Questions 1 PDFDocument17 pagesTitration - Questions 1 PDFsaha khanNo ratings yet

- Group 1, 2,3 AnalysisDocument19 pagesGroup 1, 2,3 AnalysisLaila ChoudaryNo ratings yet

- Inventaris Alat Dan Bahan Lab Ilmu Kelautan Gd. 3 Lt. 2 (Biogeokimia)Document22 pagesInventaris Alat Dan Bahan Lab Ilmu Kelautan Gd. 3 Lt. 2 (Biogeokimia)Nur HayatiNo ratings yet

- Atoms, Ions, and Molecules: Chemistry For The Utterly ConfusedDocument7 pagesAtoms, Ions, and Molecules: Chemistry For The Utterly Confusedramanji1021No ratings yet

- Principles of Phase-Transfer Catalysis by Quaternary Ammonium SaltsDocument64 pagesPrinciples of Phase-Transfer Catalysis by Quaternary Ammonium SaltsBiswarup DasNo ratings yet

- InvestigatorydocxDocument15 pagesInvestigatorydocxGautam JainNo ratings yet

- Analysis of Group Iv CationsDocument5 pagesAnalysis of Group Iv CationsjudeNo ratings yet

- US7950794Document7 pagesUS7950794Hamada HamadaNo ratings yet

- Experiment 7Document10 pagesExperiment 7Jay Jay50% (2)

- Mineral NutritionDocument23 pagesMineral NutritionRahul KumarNo ratings yet

- 9701 w18 QP 23 PDFDocument12 pages9701 w18 QP 23 PDFkhalil rehmanNo ratings yet

- Sensing and Bio-Sensing Research: Finnegan M., E. Duffy, A. MorrinDocument9 pagesSensing and Bio-Sensing Research: Finnegan M., E. Duffy, A. MorrinMajidJgrNo ratings yet

- Preparation of Cobalt ComplexesDocument9 pagesPreparation of Cobalt ComplexesRian Kurniawan100% (1)

- 12 Chemistry Workbook. NCEA Level 2 (PDFDrive)Document164 pages12 Chemistry Workbook. NCEA Level 2 (PDFDrive)Phil LiuNo ratings yet

- 1 6htyjkDocument43 pages1 6htyjkBukhara PS PILEDUNo ratings yet

- Metode Kjehdal3 PDFDocument4 pagesMetode Kjehdal3 PDFVignette VeinmirionNo ratings yet

- Mock Che CHKLSTDocument3 pagesMock Che CHKLSTnassorussi9No ratings yet

- Jitendra Hirwani: Previous Year Problem Solving Iit Jee Main + Advanced Physical ChemistryDocument14 pagesJitendra Hirwani: Previous Year Problem Solving Iit Jee Main + Advanced Physical ChemistrySaptarshi DashNo ratings yet

- Stripping of Fe (III) From D2EHPA Using Different ReagentsDocument13 pagesStripping of Fe (III) From D2EHPA Using Different ReagentsZTINo ratings yet

- Xbridge Columns: (Care and Use Manual)Document12 pagesXbridge Columns: (Care and Use Manual)Angel VazquezNo ratings yet

- Acid Bases and Salts 2022-23Document8 pagesAcid Bases and Salts 2022-23Yasha RizviNo ratings yet