Professional Documents

Culture Documents

Akr Hsse Performance Indicator

Akr Hsse Performance Indicator

Uploaded by

Rizky0 ratings0% found this document useful (0 votes)

6 views24 pagesOriginal Title

AKR HSSE PERFORMANCE INDICATOR

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views24 pagesAkr Hsse Performance Indicator

Akr Hsse Performance Indicator

Uploaded by

RizkyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

2 ARR os eosi0 1

AKR’s Golden Rules of HSSE

¢ Risk Assessment

(Routine-Non Routine Job Safety Analysis)

« Permit To Work

¢ Energy Isolation

* Confined Space Entry

+ Driving Safety

* Working at Heights

+ Lifting Operations

+ Management of Change

2 ARR e007

Operational Excellence

* HSSE - OE Expectations

are organized under 15 elements and spell out specific

requirements for the management of health, safety, security,

environment, reliability and efficiency. The expectations are

met through processes and programs put in place by local

management. In many cases, a single process may fulfill the

intent of one or more expectations. In some cases, one

expectation may require several processes to be put in place.

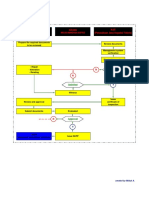

Planning, Program & Monitoring

Program

© Penyusunan Program HSSE Secara Komprehensif

© Penyempurnaan SOP-HSSE

» Improving Safety Culture

Safety Awareness

Leadership & Commitment

© Inspection

Socialization

> Training & Communication

© Sharing & discussion

Implementation

© "Zero Tolerance On Safety”

Monitoring

Integrated Audit System (KPI)

© Scoring System

Review

BOD Review

sungatcon

PARR core

New Audit Model in 2010

pamMpaign

LEADING « ee

62 % oy Hi Observation

nsrpstagnet on

o ARR -..

rungtterat con

OE Implementation (Cont.)

What

Provide subject matter expertise for

specie OF process

Operate incident tree

How

Coordinate & lead efforts regarding the proces.

Ete tt the roe, ‘documentation & records

Srdirate oF support process measurement &

ieetiestion

‘Condacy performance reporting & rens analyst.

Develop f implement the Continual improvement

Plan

tancain contact vith:

recess Sponsors

Other Process adsor,

ject matter experts

Appropriate tletiorks o¢ Communities of Practice.

lipate in OE Processes & recommend process

learned,

fxtract Lessons to help prevent

‘ture inci

re

‘allo the Teneis of Operation,

OE Implementation

What

Align around objectives.

Gemenstrate leadership

engagement & comitment.

Bulan OF culture

Support leaders, leadership team &

line management in HSE -OEN

Implementation & operation.

~ Asset leaders in establishing &

deploying functonl Sarda

Provide subject matter expertise,

Support unit's development,

implementation & inprovernent of

(OE Processes

Provide resources & suppert to

ensure success of a specifi

GE process

How

Exabloh communist ln von and objects

Implement HSSE » OES in unit.

‘Be accountable & hold others accountable for OF

performance.

Participate in & ensure others follow” OE Processes.

Role model & foll the Tenets f Operation

Driontzation of OF gaps,

Help establish O€ Processes, ther prioritization, &

governance.

ordinate integration of OF plans into business plan

assist in monitoring & folly.

Coordinate local HSSE OEMS Self Assessments

Follow the Tenets of Operation.

Provide HSSE rllaity support te line management.

Support HSSE - OE implementation effort trough

funetional expertise

Plan & implement subject matter, audits and reports

Provide technical support for HSSE & rellaitity

Fell the Tenets of Operation,

Serve as an advocate af the process to ensure that

the process accorded the appropriate priority &

fecetves funding, personnel, & other resources.

Ensure that process effectiveness & efficiency are

measured & verified at least annually.

Be accountable Tor progress on te Continual

Inmpravemest Pian

Coordinate vith other O€ Process Sponsors & link th

the business plan

oF ARR eo p.s0 7

Planning & Program (Cont.)

* Improve Operational performance for

branding

— Set up Operational excellence program

— Set up Terminal Booklets

— Set up HSSE-OE Golden Rules as a stepping stone

for OE program

srrgnagarat con

2 ARR e500

Planning & Program (Cont.)

* Improve Operational team’s knowledge & competencies

— W/ People dev continue to implement OTS training matrix

— Optimalisation doing internal training activities

* Improve team work w/ project team regarding to smoothing

project activities based on (Cost, Quality & Schedule)

— Improve intense communication w/ project team

Continue improve internal HSSE dept on knowledge,

competency & integrity for better performance

— Sharing of knowledge, Closed coordination and

communication

nga

oc aaa Planning & Program

* Continue encourage all dept regarding to integrated HSSE management

system within the AKR business Unit

— Improve technical knowledge head facilities end engineering spv

regarding to relevant codes &standards (cont implementing OTS

Training Matrix)

— Stimulate the Organizational Structure Work and leadership on HSSE

aspects getting on board. (Project leader, BM & OM)

— Internal Coaching on HSSE aspect for facilities

— Continuing Involvement on Facility Improvement comply to code,

standard, Govt. Regulation and other principles

* Monitor and improve implementation ISM & ISPS. Code for AKR-Vessels

— Doing routine audit both ISM & ISPS Code

— Sharing knowledge & practices regarding ISPS & ISM Code procedures

& practices

— Sharing knowledge on Vessel PMS (Plant Maintenance System)

comply to Class Requirements

“Continues learning is path of

excellence improvement”

7 ARR «

Sistem Pelaporan

Sue

* Laporan Bulanan kepada Kepala HSSE

* Riwayat Laporan Bulanan untuk Deputi CEO

* Laporan 3 Bulanan untuk BOD

* Rapat 3 Bulanan Koordinator dengan

pemimpin tim HSSE oleh Deputi CEO

(Kawasan Barat di Jakarta; Kawasan Timur di

Surabaya)

ARR -...

Tinjauan Ulang & Peningkatan yang

Berkelanjutan

* Rapat HSSE 3 bulanan dengan BOD

* Persetujuan Rencana Tindakan berasarkan

Hasil Audit & Rapat 3 bulanan Koordinasi

ot ARR eor::0

What are the Outcomes of Evaluating

Safety?

1. Penentuan kinerja yang dapat diterima (tidak

ada perubahan yang akan muncul dalam

operasi)

2. Penentuan bahwa kinerja adalah meningkat

jesrau kinan indikasi bahwa intervensi

ekerja

3. Penentuan bahwa kinerja adalah menurun

(Intervensi tambahan adalah dibutuhkan)

4. Penentuan bahwa kinerja adalah tidak dapat

diterima

(Intervensi haruslah diterapkan).

= ARR «>»

Lagging or Trailing Indicators of HSSE

Performance

Indikator Lagging atau Trailing dari Kinerja HSSE

* After-the-Fact Measures of Safety

Performance.

Setelah Pengukuran Fakta dari Kinerja Keselamatan.

> AKR

Most Common Lagging Indicator

of Safety Performance

Indikator Lagging Paling Umum dari Kinerja Keselamatan

> Kinerja Cedera, frekuensi catatan yang ada di

dalam OSHA yang terjadi pada 200,000 jam

dari pekerja.

> Day Away, Restricted work, dan Transferred

injury rate

> Tingkat cedera First aid injury rate

> Near miss rate.

2 ARR corcinic

Disadvantage of Using Lagging

Indicators of Safety Performance

Kerugian menggunakan Indikator Lagging terhadap Kinerja Keselamatan

* Data is Historical — If unacceptable

Numbers of Injuries Occur, it is Too Late to

Prevent Them

* Watch for Under-Reporting.

+Data History (telah terjadi) — Jika Jumlah dari Kecederaan yang tidak

dapat diterima terjadi, maka sudah terlalu terlambat untuk melakukan

pencegahan

+Memperhatikan yang berdasar pada angka di laporan

Leading Indicators of Safety

Performance

* Predictors of Future Safety

Performance Based on Selected

Criteria.

Prediksi dari Kinerja Keselamatan di Masa Depan Berdasarkan

Kriteria yang telah dipilih.

Advantage of Using Leading

Indicators of Safety Performance

* If performance indicators show poor or

unacceptable performance, modifications or

changes can be made before injuries actually

occur

* Focus is on the process, not the end result.

-Jika indikator kinerja menunjukkan kinerja yang buruk atau tidak

dapat diterima, modifikasi atau perubahan dapat dilakukan

sebelum cedera yang sesungguhnya terjadi

Fokus adalah pada proses, bukan pada hasil akhir.

sntiane con

ARR e505

sowgtoeggatam

Disadvantage of Using Leading

Indicators of Safety Performance

Measures are not Absolute

Most Measures are Subjective

No single Measure says it all

Several Measures are Recommended, Not

Just One.

*Pengukuran-pengukurannya tidak mutlak

+Pengukurannya kebanyakan adalah subjektif

“Tidak ada pengukuran yang menyatakan keseluruhan

+Beberapa Pengukuran adalah Disarankan, Tidak Hanya Satu.

or AKR

Indikator Leading vs Indikator Lagging

* Ketika membuat prediksi, tidak ada hal yang pasti

* Indikator Lagging dari keselamatan adalah

akurat, tetapi hal tersebut memberikan informasi yang

terlambat

* Indikator Leading dari Keselamatan adalah tidak

mutlak, tetapi hal tersebut dapat membantu

mencegah cedera sebelum cedera itu terjadi

* Kesuksesan yang lebih besar dapat diwujudkan ketika

lebih banyak indikator leading yang digunakan.

ABR co 80

* Lagging Indicators Focus on Injuries

* Leading Indicators Focus on the

Safety Process.

Leading indicator

Facility & Operation Performance 20

AKR’s HSSE___ ‘enesconosena tron ‘

Performance _

Indicator wecanaese

Statist Performance Vale in %

Zero Fatality 4

Zero LT

Zero Spilage

Zero Cross Over

Zero Product Quality,

Zero Potential Fatality Incident

Restricted Workday Cases

Medical Treathment Cases

Property Damage

Traific Accident

First Aid Cases

Pelanggaran SO? Operation

Financial

Zero Down Time due to Incident

Zero Direct+Indirect Cost due to Incident 2

38

+ ARR «>

* Lagging Indicators Focus on Injuries

* Leading Indicators Focus on the

Safety Process.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 13 - 17.09.2020 - Webinar EPSC PS FundamentalsDocument33 pages13 - 17.09.2020 - Webinar EPSC PS FundamentalsRizkyNo ratings yet

- 121-Article Text-269-1-10-20220112Document9 pages121-Article Text-269-1-10-20220112RizkyNo ratings yet

- How To Change M-Files Desktop and Web UI ThemeDocument8 pagesHow To Change M-Files Desktop and Web UI ThemeRizkyNo ratings yet

- Traffic Hazard Checklist: Consider The Following Yes No Comments / ActionDocument2 pagesTraffic Hazard Checklist: Consider The Following Yes No Comments / ActionRizkyNo ratings yet

- Soda Solvay Dense For Export: Soda Ash / Sodium CarbonateDocument2 pagesSoda Solvay Dense For Export: Soda Ash / Sodium CarbonateRizkyNo ratings yet

- Polyethylene Fittings Water Gas Under Pressure: For andDocument8 pagesPolyethylene Fittings Water Gas Under Pressure: For andRizkyNo ratings yet

- Owner (KKKS) Dirjen Pjit (Perusahaan Jasa Inspeksi Teknis) : Migas/Minerba/EbtkeDocument1 pageOwner (KKKS) Dirjen Pjit (Perusahaan Jasa Inspeksi Teknis) : Migas/Minerba/EbtkeRizkyNo ratings yet

- Basic of Piping MaterialDocument41 pagesBasic of Piping MaterialRizkyNo ratings yet