Professional Documents

Culture Documents

Roof Framing

Uploaded by

tiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roof Framing

Uploaded by

tiaCopyright:

Available Formats

Roof Framing Simplified

This direct approach involves full-size layouts

and stringing rafter lines

by Tom Law

T here isn't a cut in roof framing that can't be

calculated given a sharp pencil, a framing

to calculate imaginary ones. This way I could

find the length of the rafter and the angles of

square and a head for math. But my 20 years in the cuts without guesswork or error. This took

the trade have taught me that in some cases, me back up on the roof armed with a ball of

the theoretical calculation of rafter angles and nylon string, a sliding bevel and a level.

lengths is slower and leaves more room for er-

ror. While I think that it's important to under- String lines—First, I tacked a scrap piece of

stand the geometry of roof framing, the empiri- wood vertically on the opposite side of the

cal method can save time and frustration, and ridge beam from its intersection with the valley

contribute to your understanding of the pro- rafter. Then I tacked another block on the out-

cess. I'm better at solving problems when I can side of the top plate where the valley rafter

grasp them—literally. would sit. Between these sticks, I stretched

When I'm cutting a complicated roof and nylon string at the height of the top of the

things get foggy, I use two techniques to help rafter and along its imaginary center line. The

me produce rafters that fit the first time. I chalk string made it easy to visualize the actual rafter

lines on the plywood subfloor to represent a in place. For reassurance, I sighted across the

rafter pair in relation to its plates and ridge. rafter tops from the outside wall to check the

This two-dimensional diagram is laid out full alignment. I used the sliding bevel and level to

size. Pattern rafters can be tested right there on find the angle of all the cuts, being careful not

the job site. The other method I use is to deal di- to distort the string.

rectly with the components involved by getting Before I transferred the angles to the rafter

up on the roof and measuring the relationships stock, I made two templates (called layout tees)

between the rafter to be cut and the existing for marking out the ridge cut and rafter seats. I

plate and ridge with string and sliding bevel. made one for the bottom and one for the top of

I used this method several years ago when I the valley rafter. With some adjustments, they

built a Y-shaped house. One wing was for the fit when the center line drawn on the pattern

bedrooms and the other contained the kitchen, was in line with the string representing the cen-

dining room and family room. The stem of the ter of the rafter. The tees also allow you to test-

Y was the living room. The roof over the wings fit the bird's mouth to the plate before you

called for trusses, but the living-room rafters carve up costly rafter stock. With these pattern

were exposed. The problem was in framing the pieces tacked in place, I measured the length of

intersection of the three roofs. These beams the valley directly. Then I transferred this

were big, long and expensive, and all the cuts length and the angles on the tees to the valley-

would show. Had the house been a T shape, the rafter stock, and cut it to its finished dimen-

valley rafters would have been a textbook case, sions. It fit perfectly the first time.

and I could have found the information I With the valley rafter in place, I turned to the

needed in the rafter tables on my framing valley jacks. First I made another pattern, this

square. But since the intersection was 120° and time of the ridge cut of the common rafter. I

not 90°, I had to find the angles by calculation tacked it on the layout mark on the ridge and

or direct observation. I chose the latter. stretched the nylon line from it to the valley

rafter, being careful to keep it exactly parallel

Full-size layout—After setting the trusses, I to the common rafters. With the line simulating

chalked a full-size layout of the living-room the top center line of the longest jack, I used

common rafters and ridge on the subfloor be- starting at the outside wall, working toward the the sliding bevel to find the angles of the plumb

low. The ridge beam was a 4x14, and the com- junction of the Y. and side cuts. This time I transferred the angles

mon rafters were 4x8s on 4-ft. centers. I de- The valley rafter was next. Its location is directly onto the stock and cut it with a hand-

cided to tackle the easiest steps first. This gave shown above. Valley rafters are usually heftier saw. Each shorter jack was worked in the same

me time to think about the problem while re- than common rafters because they have a way, using the nylon line to find the location

ducing the parts in the puzzle. longer span, and have to carry the additional and length; the angles remained constant.

The ridge beam went up first. I found its weight of the valley jacks. In this case, the val- Laying out rafters with a framing square is

height by measuring on the full-size layout. The ley rafter was a 4x10. Because it's deeper, to something I do a lot. However, in situations

common rafters were then cut using patterns achieve the same height above the plate and that call for unusual intersections with com-

made from the layout. I nailed these in place ridge, its seat and ridge cuts also differed from pound angles, I spend my time dealing directly

those of the common rafters. I found it faster with the problem. This reduces confusion and

Tom Law is a builder in Davidsonville, Md. and easier to measure the actual distances than allows me to concentrate on the work.

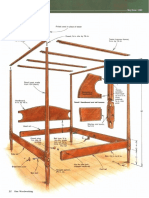

A Glossary of Roofing Terms

The names of the roof members (above), and

the rafter terms (defined below) vary according to

geographical region and roof style. For an explanation of

how hip and gable roofs are framed, see the following article.

Span—the horizontal distance between the outside allowances for the tail or ridge reduction.

edges of the top plates. Also called the unadjusted length.

Rise—the vertical distance measured from the wall's Bird's mouth—also called a rafter seat. It is the notch cut in

top plate to the intersection of the pitch line a rafter that lets it sit on the double plate. It

and the center of the ridge. is formed by the plumb heel cut and the seat

Run—the horizontal distance between the outside cut, which is a level line.

edge of the top plate and the center of the Plumb cut—any cut that is vertical when the rafter is in

ridge; in most cases, half the span. position on the roof. Also used as a reference

Slope—a measurement of the incline of a roof, the to the top cut on a rafter where it meets

ratio of rise to run. It is typically expressed the ridgeboard.

using 12 as the constant run. Level cut—any cut that is horizontal when the rafter is

Pitch—has become synonymous with slope in in position on the roof.

modern trade parlance. It is actually the ratio Tail cut—the cut at the outer end of the rafter. If cut at

of the rise to the span. A roof with a 24-ft. the outside edge of the double plate, it is a

span and a rise of 8 ft. has a 1-to-3 pitch. Its flush cut. All the other traditional tail cuts let

slope is 8 in 12. Two ways of saying the the rafter overhang the plates—heel cut

same thing. (level), plumb cut (vertical), square cut

Unit rise—the number of inches of rise per foot of run. (perpendicular to the length of the rafter) or

Unit run—this distance is always 12 in. combination level and plumb cuts.

Common difference—the difference between the length of a jack Side cut—also called a cheek cut, is the compound

rafter and its nearest neighboring jack on a angle required for the proper fitting of roof

regular hip or valley when they are spaced members that meet in an intersection of less

evenly. This is also the same measurement as than 90°, and other than level. This applies to

the length of the first, or shortest, jack. jacks that connect with hips and valleys.

Rafter pattern—a full-scale rafter template used to mark the Ridge reduction—rafter lengths are calculated to the center of

other rafters for cutting. It can be tried in the ridge of the roof. This doesn't take into

place for fit before cutting all the rafters. account the thickness of the ridgeboard. This

Layout tee—a short template cut from the same stock as allowance reduces the theoretical length of

the rafters and used for scribing repetitive the rafter by one-half the thickness of the

plumb cuts, tail cuts and bird's mouths. ridgeboard. The layout line drawn parallel to

Tail—the part of a rafter that extends beyond the the plumb cut that represents this allowance

heel cut of a bird's mouth to form the is called the shortening line.

overhang or eave. Dropping a hip—the amount by which the bird's mouth on a

Pitch line—an imaginary line, also called the measuring hip rafter must be deepened to allow the top

line, that runs parallel to the rafter edges at of the rafter to lie in the same plane as the

the height of the full depth of the heel cut on jack and common rafters. This ensures that

the bird's mouth. In common practice, rafters the roof sheathing will nail flat without

are measured along their bottom edge. having to bevel the top edges of the hip, a

Theoretical length—the length of a rafter without making process known as backing. —P.S.

You might also like

- Geometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsFrom EverandGeometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsRating: 5 out of 5 stars5/5 (2)

- 2sat FireDocument128 pages2sat Fire황동규No ratings yet

- Time Loop Hunter 0.38.00 - Walktrhough: by KamelkidoDocument101 pagesTime Loop Hunter 0.38.00 - Walktrhough: by KamelkidoFrancois IsabelleNo ratings yet

- Stirling Coffee Cup - ProjectDocument5 pagesStirling Coffee Cup - ProjectRanyeri Lago RochaNo ratings yet

- Max Challenge NutritionDocument14 pagesMax Challenge NutritionAmber 'Bambi' Dench100% (1)

- Box Cars and One Eyed Jacks Gr3to5Document38 pagesBox Cars and One Eyed Jacks Gr3to5api-337183055100% (1)

- Building Tips and Tricks PDFDocument16 pagesBuilding Tips and Tricks PDFcodeethylNo ratings yet

- Wall Framing: & AccurateDocument4 pagesWall Framing: & AccurateCam VistainNo ratings yet

- FWW SecretaryDocument8 pagesFWW SecretaryCaio Bernardes Fonseca Weber AbramoNo ratings yet

- A Classic Bookcase in The Craftsman StyleDocument4 pagesA Classic Bookcase in The Craftsman StyleAnonymous QJ5j94luLmNo ratings yet

- And Vallev Frarmng: Gutter Track Ground Line. LatticeDocument2 pagesAnd Vallev Frarmng: Gutter Track Ground Line. LatticeRobertNo ratings yet

- Fine Homebuilding - Framing Gable EndsDocument4 pagesFine Homebuilding - Framing Gable EndsSrcNo ratings yet

- SpeedSquareInstructionBook3 PDFDocument22 pagesSpeedSquareInstructionBook3 PDFdhruvgoku0% (1)

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- Shaker Chest of DrawersDocument8 pagesShaker Chest of DrawersMonte William NorthNo ratings yet

- Scott McBride Roof - FramingDocument7 pagesScott McBride Roof - FramingMarius Camy PingaNo ratings yet

- Curved WallsDocument6 pagesCurved WallsCayddrick BallardNo ratings yet

- TablesDocument130 pagesTablesEnrique50% (2)

- Speed Square Instruction Book 2Document23 pagesSpeed Square Instruction Book 2BrentChadwell100% (6)

- Cabinetmaker's Tool ChestDocument8 pagesCabinetmaker's Tool ChestKeith WilliamsNo ratings yet

- Home Building TipsDocument245 pagesHome Building TipsoltaiyrxNo ratings yet

- An Everyday CabinetDocument8 pagesAn Everyday CabinetJonathan Hopkins100% (2)

- Are You Supposed To Slot T.O.M. Bridge Saddles?Document2 pagesAre You Supposed To Slot T.O.M. Bridge Saddles?Samuel Aires LourencoNo ratings yet

- Gamin Sailboat PlansDocument6 pagesGamin Sailboat PlansJim100% (11)

- Melting Display Shelves PlansDocument14 pagesMelting Display Shelves Plansmihai.stanNo ratings yet

- Fine - Woodworking.-.A Workbench That WorksDocument2 pagesFine - Woodworking.-.A Workbench That WorksSarasaNo ratings yet

- Making Guitar: Making - A - Guitar - NutDocument5 pagesMaking Guitar: Making - A - Guitar - NutIwan TejasukmanaNo ratings yet

- Working Drawings of Colonial Furniture 1922Document69 pagesWorking Drawings of Colonial Furniture 1922cgermaineeNo ratings yet

- English Layout SquareDocument2 pagesEnglish Layout Squarev00d00bluesNo ratings yet

- 1904 Ridealong Shop ProjectsDocument20 pages1904 Ridealong Shop ProjectsNilo Alberto Scheidmandel100% (1)

- Bench ChiselsDocument3 pagesBench ChiselsAnonymous QJ5j94luLmNo ratings yet

- Roof FramingDocument5 pagesRoof FramingSergioNo ratings yet

- RoutertableDocument5 pagesRoutertablesenthil karthik100% (1)

- Framing A Roof Valley PDFDocument6 pagesFraming A Roof Valley PDFRobertNo ratings yet

- Flatten A Workbench's Top PDFDocument5 pagesFlatten A Workbench's Top PDFTayfun Suna100% (1)

- Kite Time: REQUIRING No Tails To Balance Them inDocument4 pagesKite Time: REQUIRING No Tails To Balance Them inFrenchwolf420No ratings yet

- Guitarra Clasica Muy Bueno 2016Document72 pagesGuitarra Clasica Muy Bueno 2016carlosNo ratings yet

- ABlanket Chest With LegsDocument6 pagesABlanket Chest With LegsAnonymous QJ5j94luLmNo ratings yet

- Pythagorean Theorem TextbookDocument41 pagesPythagorean Theorem TextbookDean WiebeNo ratings yet

- Line and Batter Part 3 - Frames & Line Bars, Professional Column, Waller and Dyker. Winter 2011/3Document2 pagesLine and Batter Part 3 - Frames & Line Bars, Professional Column, Waller and Dyker. Winter 2011/3Mark JurusNo ratings yet

- The Hand-Cut Mortise and Tenon: HandworkDocument4 pagesThe Hand-Cut Mortise and Tenon: HandworkwitwatersrandNo ratings yet

- Making A Frame and Panel BedDocument3 pagesMaking A Frame and Panel BedAnonymous QJ5j94luLmNo ratings yet

- All-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalDocument7 pagesAll-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalFernando AgudeloNo ratings yet

- June07 ArtsandmysteriesDocument3 pagesJune07 ArtsandmysteriesJelaiNo ratings yet

- How To Build A Barristers BookcaseDocument5 pagesHow To Build A Barristers BookcaseAnonymous QJ5j94luLmNo ratings yet

- Hanging A Cabinet DoorsDocument5 pagesHanging A Cabinet DoorsAnonymous QJ5j94luLmNo ratings yet

- PicnicTable PDFDocument2 pagesPicnicTable PDFAvi KarmonNo ratings yet

- A Circular Saw in The Furniture Shop-FinewoodworkingDocument4 pagesA Circular Saw in The Furniture Shop-Finewoodworkingkurt100% (1)

- Planking PrimerDocument8 pagesPlanking PrimermouradNo ratings yet

- Cheerful ChapterchapOneDocument8 pagesCheerful ChapterchapOnekq9yzcgkdtNo ratings yet

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmNo ratings yet

- 3 Way To Make DoorDocument5 pages3 Way To Make Doorendik yudya pramonoNo ratings yet

- Pennsylvania Spice BoxDocument6 pagesPennsylvania Spice BoxAnonymous QJ5j94luLmNo ratings yet

- Cross-Vault CeilingDocument6 pagesCross-Vault Ceilingadam yassineNo ratings yet

- LECTURE 1 StaircaseDocument21 pagesLECTURE 1 StaircaseMohamed JallohNo ratings yet

- December 2015 PWM Pages 39 42Document4 pagesDecember 2015 PWM Pages 39 42JuanRodriguez100% (2)

- BookcasePlans PDFDocument26 pagesBookcasePlans PDFFlogamag100% (1)

- How To Build A DoorDocument12 pagesHow To Build A DoorOkidok OkickiNo ratings yet

- 1311 PWM PanelRaiserDocument8 pages1311 PWM PanelRaiserMarco VenezianoNo ratings yet

- Making A Piecrust Tea TableDocument148 pagesMaking A Piecrust Tea TableMaksims GrigorjevsNo ratings yet

- Fine Homebuilding - Framing A Cross-Gable RoofDocument5 pagesFine Homebuilding - Framing A Cross-Gable RoofSrcNo ratings yet

- Setting Up Shop With Online ExtrasDocument114 pagesSetting Up Shop With Online ExtrasKeith WilliamsNo ratings yet

- 18th Century Six-Board ChestDocument6 pages18th Century Six-Board ChestSteven HeinsNo ratings yet

- Practical Stair Building and Handrailing: By the square section and falling line systemFrom EverandPractical Stair Building and Handrailing: By the square section and falling line systemNo ratings yet

- TDI Extended Range and Trimix KQDocument29 pagesTDI Extended Range and Trimix KQTiago rNo ratings yet

- Yoshie PapercraftDocument41 pagesYoshie PapercraftNando J CJNo ratings yet

- A Bad Day Third Conditional 1bfs9l6Document1 pageA Bad Day Third Conditional 1bfs9l6gd cuentasNo ratings yet

- BurlesqueDocument13 pagesBurlesqueaman100% (1)

- Aerofilm Instruction From SADocument2 pagesAerofilm Instruction From SAipseNo ratings yet

- UntitledDocument782 pagesUntitledPaul ClarkeNo ratings yet

- 12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFDocument16 pages12.tehničke Karakteristike Bagera MH-5 (Engleski Jezik) PDFadamajaks1985100% (2)

- Fomrhi No.52 July 1988Document56 pagesFomrhi No.52 July 1988Matthew DaillieNo ratings yet

- WishDocument2 pagesWishVy anhNo ratings yet

- Basketball Module g11 PE L5Document9 pagesBasketball Module g11 PE L5Rafael AnianoNo ratings yet

- Techspec XS enDocument2 pagesTechspec XS enpesumasinadNo ratings yet

- 00 Ghosts of Saltmarsh-pages-DeletedDocument1 page00 Ghosts of Saltmarsh-pages-Deletedyami edwardNo ratings yet

- Photo - PHP Fbid 391292857588696 Id 134075539977097 Set A.136969626354355.35844.134075539977097 FT Fbid.353846991347493Document4 pagesPhoto - PHP Fbid 391292857588696 Id 134075539977097 Set A.136969626354355.35844.134075539977097 FT Fbid.353846991347493anon_407879035No ratings yet

- E-Claim Format 2017 Final ValleyDocument1,508 pagesE-Claim Format 2017 Final ValleyAnonymous 9v1U7cNo ratings yet

- Menu No Soup Thick Thin Salads Simple SaladDocument26 pagesMenu No Soup Thick Thin Salads Simple Saladapi-3749066No ratings yet

- Most Sounds On CD - Casio VZ-1 VZ-8M VZ-10M - EbayDocument2 pagesMost Sounds On CD - Casio VZ-1 VZ-8M VZ-10M - EbayAngel Jose TrinidadNo ratings yet

- SinTitulo2 InglesDocument1 pageSinTitulo2 InglesBillNo ratings yet

- Song Activity Last Christmas Activities With Music Songs Nursery Rhymes 75737Document2 pagesSong Activity Last Christmas Activities With Music Songs Nursery Rhymes 75737petreadana_474146449No ratings yet

- Gigapixel AI For Video Help DocumentDocument6 pagesGigapixel AI For Video Help DocumentEmmanuel TovarNo ratings yet

- Didactic Support (Used To)Document1 pageDidactic Support (Used To)Boujemaa Al MallamNo ratings yet

- Head Gasket Replacement and Head Stud Install: Flopster843Document26 pagesHead Gasket Replacement and Head Stud Install: Flopster843fishhunter18No ratings yet

- ING 6 - Prepositions of TimeDocument2 pagesING 6 - Prepositions of TimeAlice RibeiroNo ratings yet

- Spek Teknis AFKUPengadaan Peralatan Kantor Bidang 1 Batch 1revDocument10 pagesSpek Teknis AFKUPengadaan Peralatan Kantor Bidang 1 Batch 1revArtha Arjuna MandiriNo ratings yet

- Netl20716 0-380572 (Uk)Document44 pagesNetl20716 0-380572 (Uk)Sergio TavsNo ratings yet

- Erik Mongrain Fates Tab PDFDocument2 pagesErik Mongrain Fates Tab PDFAnthonyNo ratings yet

- MicroservicesDocument9 pagesMicroservicesJimmy KumarNo ratings yet