Professional Documents

Culture Documents

6 Element UHF Yagi Antenna

Uploaded by

adel agustiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Element UHF Yagi Antenna

Uploaded by

adel agustiCopyright:

Available Formats

6 element UHF Yagi

antenna

This is a standard 6 elements design scaled for UHF application. All

material used in this project are easily obtainable tubes and rods which is

limited within a total budget of $18.

Design background

Element dimension in inch unless otherwise specified.

Element Reflector Drv. Element 1st director 2nd director 3rd director 4th director

Diameter 0.18 0.25 0.18 0.18 0.18 0.18

Length 7" 6.3" 5.8" 5.6" 5.3" 5"

Spacing from - 3.8" 0" 2.9" 6.8" 11" 15"

Drv. element

Based on computer simulation, this beam should have a forward gain of

10dbd while F/B ratio will be close to 16db. Usable bandwidth (SWR <

1:1.5) well exceeds 10MHz. Performance of the real product closely

resembles the expected characteristic. The beam has been duplicated

several times while a consistent performance in SWR, and directivity was

obtained.

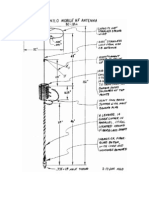

Constructing process

One of my concerns is how to maintain accuracy in dimension of the

elements during drilling activities (via hand held tools instead of drill press),

A 7/8" square tube is thus chosen as the boom material. Their flat surface

makes it much easier to be drilled. All reflector and directors are made of

threaded rods (10-24 diameter) while driven elements have a slightly larger

diameter of 1/4". This difference has nothing to do with radiation efficiency

(although the larger dimension does cause a difference in resonance

length). 1/4" diameter is chosen just because that is the smallest size

where matching nuts with long body are available. The nut is required so

that length adjustment of the driven element is possible.

The element length dimension (not spacing) listed in the above table refers

to brass material. If elements of other metal are employed, the length will

change. Threaded rods on the market are usually made of three types of

metal - brass, plated steel and stainless steel. To make it simple for cutting

estimation, steel based metal needs shorter element length. The reduction

factor is about 75-80% of brass. The length for reflector and directors are

not too critical since they will compensate with each other. The length of

the driven element is the most critical since it will have direct and severe

impact of the SWR response of the antenna. Easy adjustment of driven

element length is thus essential for the success of the whole project.

A 2"x3"x1" plastic box is used for the mounting of two driven elements. Two

square holes are opened on the box allowing the boom to penetrate. Driven

element position can be adjusted by sliding the box on the boom. This will

be handy when trimming of the antenna's high / low frequency response

limit is required.

The driven element is a combined mixture between 1/4" threaded rods,

nuts and bolts. The DE pair is mounted on a plastic box that provides

insulation and water proofing protection. The RG-58U feed line is first

routed inside the square tube. The spliced ends (core and screening layer

are then leaded through two holes on the tube and be connected directly

with bolts and nuts of the driven element. There is no need to install balun

for matching (although having one installed will help maintain a more

balanced radiation pattern). .

All threaded rods have to be prepared as listed in the above listed

dimension. Vertical holes are then drilled on the square aluminum tube

while the finished elements are mounted on the tube through these holes

with lock nuts.

Core conductor and shield of the RG-58 connected to both driven

elements.

The adjustable section of

the driven element -

Tune up procedure

In order to tune the antenna, it must be prepared and be mounted on an

environment that will be close to the final expected operating condition. I

use a tripod with a 4-ft pole as a temporary test jig. This provides a ground

clearance of about 5-ft. for the yagi. The antenna is first connected to a

transmitter via an in-line SWR meter. The transmitter should be able to

work on at least three frequencies - the low, center and high limit of the

expected operating band. With the antenna placed in an area with at least

5-10 ft clearance from nearly objects, key up the transmitter on all three

spots and mark down the observed SWR. Trim the length of both elements

for the driven element in equal status unless a dip is observed and lies on

the center of the expected operating range.

To test the directivity of the antenna briefly, one can use it to monitor signal

from a far away station. By making azimuth changes 360 degree around,

the changes in the received signal can tell the general 3db-beam width

characteristic.

Feel free to Email me if more detail is required.

Patrick Wong Oct-98.

You might also like

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- UHF Yagi AntennaDocument5 pagesUHF Yagi AntennaChris BusNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Varied 2 Meter Homebrew Antennas-ERC TrainingDocument15 pagesVaried 2 Meter Homebrew Antennas-ERC TrainingIndika WithanageNo ratings yet

- Cheap Yagi Antennas For VHFDocument7 pagesCheap Yagi Antennas For VHFNarain TopandasNo ratings yet

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- Antenna HandoutDocument8 pagesAntenna HandoutPhil BoxxNo ratings yet

- GPS Helix Antenna Construction GuideDocument6 pagesGPS Helix Antenna Construction GuideGuadalajara Jalisco100% (1)

- Design of Dual Band Patch AntennaDocument19 pagesDesign of Dual Band Patch AntennaThomas LeeNo ratings yet

- Folded Dipole, Yagi-Uda & Log-Periodic AntennasDocument64 pagesFolded Dipole, Yagi-Uda & Log-Periodic AntennasLear SoyonNo ratings yet

- A Short Boom, Wideband, Three Element Yagi For 10 Meters: L. B. Cebik, W4RNL (SK)Document3 pagesA Short Boom, Wideband, Three Element Yagi For 10 Meters: L. B. Cebik, W4RNL (SK)GaldinoNo ratings yet

- Yagi-Uda Antenna Theory Design SimulatioDocument13 pagesYagi-Uda Antenna Theory Design Simulatiosadun KumaraNo ratings yet

- 3 El HexDocument9 pages3 El HexSilva JoséNo ratings yet

- 2 Meter Sling Shot AntennaDocument7 pages2 Meter Sling Shot AntennaNiko DiamesisNo ratings yet

- Antenna Design Considerations for Low Power Wireless SystemsDocument2 pagesAntenna Design Considerations for Low Power Wireless Systemsleorio88No ratings yet

- Corner Reflector Antenna DesignDocument10 pagesCorner Reflector Antenna DesignLey LallaveNo ratings yet

- Build a 6m 5-Element LFA Yagi Antenna with 11 dBi GainDocument10 pagesBuild a 6m 5-Element LFA Yagi Antenna with 11 dBi GainآكوجويNo ratings yet

- Build an Indoor FM Moxon Antenna for Strong ReceptionDocument4 pagesBuild an Indoor FM Moxon Antenna for Strong ReceptionIacob LaurentiuNo ratings yet

- Basic Yagi Antenna Design For The ExperimenterDocument9 pagesBasic Yagi Antenna Design For The ExperimenterKrista JacksonNo ratings yet

- 2 Meter Backpack Quad AntennaDocument27 pages2 Meter Backpack Quad Antennaadel agustiNo ratings yet

- G7FEK Limited Space AntennaDocument12 pagesG7FEK Limited Space AntennaAdelmar Francisco ErmidaNo ratings yet

- Cebik Antenna OptionsDocument191 pagesCebik Antenna Optionsadel agustiNo ratings yet

- Collinear ReportDocument15 pagesCollinear ReportRemonIbrahimNo ratings yet

- Aperture Coupled Wide-Band Micro Strip Antenna Design: - Srivatsa Bhargava JDocument18 pagesAperture Coupled Wide-Band Micro Strip Antenna Design: - Srivatsa Bhargava Jkavirasu1990No ratings yet

- JUNANTDocument3 pagesJUNANTHoward EnnacoNo ratings yet

- Build a High-Gain Slim Jim Antenna for Ham Radio Bands Under 40 CharactersDocument9 pagesBuild a High-Gain Slim Jim Antenna for Ham Radio Bands Under 40 CharactersAmanda HardyNo ratings yet

- An102 Antenna Design Feb 11 PDFDocument5 pagesAn102 Antenna Design Feb 11 PDFmohammedmraja94No ratings yet

- Planar Band-Notched Ultra-Wideband Antenna With Square-Looped and End-Coupled ResonatorDocument7 pagesPlanar Band-Notched Ultra-Wideband Antenna With Square-Looped and End-Coupled ResonatorNidhi PanditNo ratings yet

- CollantDocument2 pagesCollantpogee752No ratings yet

- Sloping Array DipoleDocument5 pagesSloping Array DipoleutammarryNo ratings yet

- 70cm Quadruple QuadDocument5 pages70cm Quadruple QuadJosé Antonio Miranda100% (1)

- Wearable Antennas For Medical Application: A ReviewDocument16 pagesWearable Antennas For Medical Application: A ReviewVardhan ShahNo ratings yet

- Phased Array UTDocument32 pagesPhased Array UTMathew John100% (1)

- Build A 9dB, 70cm Collinear AntennaDocument3 pagesBuild A 9dB, 70cm Collinear Antennadr3x100% (1)

- An102 Antenna Design Feb 11Document5 pagesAn102 Antenna Design Feb 11Ezequiel AriasNo ratings yet

- Bandwidth of Planar Antennas For Uwb (6Ghz - 8,5Ghz)Document6 pagesBandwidth of Planar Antennas For Uwb (6Ghz - 8,5Ghz)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- AntennaCH6Document30 pagesAntennaCH6Abraham GadissaNo ratings yet

- An All Purpose High Gain Antenna For 2400 MHZDocument8 pagesAn All Purpose High Gain Antenna For 2400 MHZMahendra SinghNo ratings yet

- What Are Ultrasonic Phased ArraysDocument4 pagesWhat Are Ultrasonic Phased ArraysAshadi Angka NolNo ratings yet

- Antena Tipo LazoDocument2 pagesAntena Tipo LazoMarllory CobosNo ratings yet

- RFID Receiver Antenna Project For 13.56 MHZ BandDocument5 pagesRFID Receiver Antenna Project For 13.56 MHZ BandJay KhandharNo ratings yet

- Fractal Magic DIY HDTV AntennaDocument56 pagesFractal Magic DIY HDTV Antennadetroit_me2553100% (3)

- Co-Axial Feed O' Slot Circularly Polarized Corner Truncated Rectangular Micro-Strip Patch AntennaDocument4 pagesCo-Axial Feed O' Slot Circularly Polarized Corner Truncated Rectangular Micro-Strip Patch AntennamonikaNo ratings yet

- UltrasonicDocument26 pagesUltrasonicJayesh88% (8)

- Construir Antena OmniDocument18 pagesConstruir Antena Omnianon-771596No ratings yet

- Antenna Wifi Omni VerticalDocument15 pagesAntenna Wifi Omni VerticalFaziri Abdul HaqNo ratings yet

- Fractal Magic DIY HDTV Antenna PDFDocument56 pagesFractal Magic DIY HDTV Antenna PDFDarin ArmsteadNo ratings yet

- 7-Element-Yagi-Uda-Beam-Pune Hams Tech TalkDocument18 pages7-Element-Yagi-Uda-Beam-Pune Hams Tech TalkVAS TECHNOLOGYNo ratings yet

- 7-Element Yagi REPORTDocument13 pages7-Element Yagi REPORTbashir abdirahman husseinNo ratings yet

- A High Performance Airband Antenna For Your Ultralight / Lightsport AircraftDocument9 pagesA High Performance Airband Antenna For Your Ultralight / Lightsport AircraftDecebal ScorilloNo ratings yet

- Swra 227 DDocument16 pagesSwra 227 DBhaskara Naik SNo ratings yet

- Simple Data AntennasDocument4 pagesSimple Data AntennasszczypiorNo ratings yet

- Design and Construction of A Yagi-Uda Antenna For The 433 MHZ BandDocument4 pagesDesign and Construction of A Yagi-Uda Antenna For The 433 MHZ BandognianovNo ratings yet

- Broadband Microstrip Patch Antennas for 3GDocument5 pagesBroadband Microstrip Patch Antennas for 3Galokcena007No ratings yet

- 2-Meter Vertical Dipole ArrayDocument15 pages2-Meter Vertical Dipole ArrayJacky SinurayaNo ratings yet

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- 1P5b 0732Document6 pages1P5b 0732Arun KumarNo ratings yet

- Chameleon Antennas Hybrid Micro-MiniDocument26 pagesChameleon Antennas Hybrid Micro-MiniRamon LobosNo ratings yet

- Gu3wgn Data Notes Final1Document2 pagesGu3wgn Data Notes Final1adel agustiNo ratings yet

- Importance of SH&EDocument2 pagesImportance of SH&Eadel agustiNo ratings yet

- 40m Short AntennaDocument1 page40m Short Antennaadel agustiNo ratings yet

- Cebik Antenna OptionsDocument191 pagesCebik Antenna Optionsadel agustiNo ratings yet

- Capa de ComponentesDocument1 pageCapa de Componentesadel agustiNo ratings yet

- Articles of AgreementDocument2 pagesArticles of Agreementadel agustiNo ratings yet

- Form of TenderDocument1 pageForm of Tenderadel agustiNo ratings yet

- Frank Radio Mini-YagiDocument5 pagesFrank Radio Mini-Yagiadel agustiNo ratings yet

- Form VCB Service & Test FormDocument1 pageForm VCB Service & Test Formadel agustiNo ratings yet

- Form of TenderDocument1 pageForm of Tenderadel agustiNo ratings yet

- Form CT Test CCPDDocument1 pageForm CT Test CCPDadel agustiNo ratings yet

- Earthworks CDocument38 pagesEarthworks Cadel agustiNo ratings yet

- Condition of ContractDocument11 pagesCondition of ContractTiyo DoankNo ratings yet

- Tennis Court CDocument7 pagesTennis Court Cadel agustiNo ratings yet

- D3 ElectricFittingsDocument1 pageD3 ElectricFittingsadel agustiNo ratings yet

- 2 Meter Vertical DipoleDocument16 pages2 Meter Vertical DipoleMubinNo ratings yet

- PreliminaryDocument23 pagesPreliminaryadel agustiNo ratings yet

- 6 WoodCarpentryDocument3 pages6 WoodCarpentryMuhammad AgungNo ratings yet

- 5 PlasterDocument3 pages5 PlasterMuhammad AgungNo ratings yet

- D3 ElectricFittingsADocument1 pageD3 ElectricFittingsAadel agustiNo ratings yet

- 58 WaveDocument7 pages58 WaveAlba IrsandiNo ratings yet

- DipoloDocument30 pagesDipolojorgevergarasalasNo ratings yet

- 6m Yagi 3elementDocument2 pages6m Yagi 3elementadel agustiNo ratings yet

- 40m 2 El HQ Traps YagiDocument81 pages40m 2 El HQ Traps Yagiadel agustiNo ratings yet

- Oil Spill ResponseDocument3 pagesOil Spill ResponseFachlefi D RezaNo ratings yet

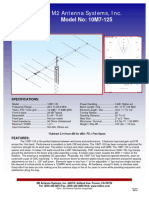

- M2 Antenna Systems, Inc. Model No: 10M7-125: SpecificationsDocument9 pagesM2 Antenna Systems, Inc. Model No: 10M7-125: Specificationsadel agustiNo ratings yet

- Calculator According To DO5MCHDocument3 pagesCalculator According To DO5MCHadel agustiNo ratings yet

- Astm A710Document3 pagesAstm A710Cristian Otivo100% (1)

- CBSE Class 10 Maths Sample Paper Set 6Document4 pagesCBSE Class 10 Maths Sample Paper Set 6darshilsinghgharwarNo ratings yet

- How To Make Lampblack - AllDocument6 pagesHow To Make Lampblack - AllclaudjiuNo ratings yet

- K Park 24 TH Edition ChangesDocument8 pagesK Park 24 TH Edition ChangesAnkit ChoudharyNo ratings yet

- Practical File ON Programming For Problem Solving Lab (: 21BTCS181)Document15 pagesPractical File ON Programming For Problem Solving Lab (: 21BTCS181)Vaibhavi SinghNo ratings yet

- Mil STD 882eDocument104 pagesMil STD 882ecihan dağNo ratings yet

- VW Crafter 2f Component Locations EngDocument118 pagesVW Crafter 2f Component Locations EngHugo Emilio Garcia Gonzalez100% (2)

- Manual Mta TemperaturaDocument2 pagesManual Mta TemperaturaChristian JacoboNo ratings yet

- Review of Dr. Mark Cheng's "Prehab-Rehab 101" SeriesDocument6 pagesReview of Dr. Mark Cheng's "Prehab-Rehab 101" SeriesWilliam TortorielloNo ratings yet

- The Management of Productivity and Technology in Manufacturing PDFDocument333 pagesThe Management of Productivity and Technology in Manufacturing PDFmythee100% (2)

- Learn Meanings of 96 Difficult WordsDocument400 pagesLearn Meanings of 96 Difficult WordsVaishali Venkatesh PrasadNo ratings yet

- Regina Downtown Community Support Team ReportDocument28 pagesRegina Downtown Community Support Team ReportJeremy SimesNo ratings yet

- History of DentistryDocument24 pagesHistory of DentistryEzhilarasi INo ratings yet

- Types of DC Motors Notes Electric DrivesDocument77 pagesTypes of DC Motors Notes Electric DrivesJyothish VijayNo ratings yet

- Dental Cements: Dr. Hamida KhatunDocument39 pagesDental Cements: Dr. Hamida Khatunsakib samiNo ratings yet

- Novec1230 RoomIntegrityDocument2 pagesNovec1230 RoomIntegritynastyn-1No ratings yet

- GCMS-QP2010 User'sGuide (Ver2.5) PDFDocument402 pagesGCMS-QP2010 User'sGuide (Ver2.5) PDFnguyenvietanhbtNo ratings yet

- Revised Bsy Elementary Siatonwest 2 and Pio-Macahig - 2014-15 As of June 6 2014Document31 pagesRevised Bsy Elementary Siatonwest 2 and Pio-Macahig - 2014-15 As of June 6 2014api-273918959No ratings yet

- Careers at FEWA-DubaiDocument8 pagesCareers at FEWA-DubaiJnanamNo ratings yet

- 286129Document23 pages286129Cristian WalkerNo ratings yet

- Company Introduction PT GEADocument8 pagesCompany Introduction PT GEABegawan Half DoneNo ratings yet

- SF-2012AH-QG User' S ManualDocument61 pagesSF-2012AH-QG User' S Manualkamal hasan0% (1)

- Letter of Request For Brgy. ProfileDocument2 pagesLetter of Request For Brgy. ProfileRhea Mae MacabodbodNo ratings yet

- Baxa Resumen PDFDocument12 pagesBaxa Resumen PDFChepe Camacho100% (3)

- تركيب وتشغيل وحدات تكييف الهواءDocument49 pagesتركيب وتشغيل وحدات تكييف الهواءOmar NabilNo ratings yet

- Mumbai: City of DreamsDocument14 pagesMumbai: City of DreamsAnika WahalNo ratings yet

- Daniel J. Wood - Realm of The Vampire - History and The Undead-Galde Press (2013)Document156 pagesDaniel J. Wood - Realm of The Vampire - History and The Undead-Galde Press (2013)Jerry KanneNo ratings yet

- The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6Document1 pageThe Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6cgranzore8833% (3)

- Balanced Scorecard ThesisDocument59 pagesBalanced Scorecard Thesisapi-3825626100% (5)

- LPI PH PDFDocument4 pagesLPI PH PDFHumberto Tapias CutivaNo ratings yet