Professional Documents

Culture Documents

F 4

F 4

Uploaded by

Saba Gheni0 ratings0% found this document useful (0 votes)

11 views33 pagesOriginal Title

f4

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views33 pagesF 4

F 4

Uploaded by

Saba GheniCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 33

Fixed bed and fluidized bed

« Ref: BSL, McCabe & Smith

= Why fixed (or fluidized) bed?

@ Expensive Catalyst

¢ enzyme (immobilized)

@ Large Surface area

» Used in reaction/adsorption/ elution (for example)

= Goal: Expression for pressure drop, try some

examples

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

« Filled with particles

» Usually not spherical

@ To increase surface area

@ To increase void fraction

To decrease pressure drop

» For analytical calculation, assume all particles are

identical

@ Usable, because final formula can be modified by a

constant factor (determined by experiment)

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

= What are important parameters?

= (For example, for adsorption of a protein from a

broth)

rate of adsorption (faster is better)

¢ saturation concentration (more is better)

» From the product requirement (eg X kg per day),

density and product concentration in broth ==>

volumetric flow rate

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

Assume quick adsorption (rate of adsorption is high)

Calculate the surface area of particles needed for

operation

Sphericity <=> specific surface area <=> average particle diameter

Sphericity Qa) (* )

@ Volume of particle = V,, i, Vv.

@ Surface Area of particle = A,

@ Surface Area of sphere of same volume (V, =V,,) = A,

@ Sphericity =A/A,

@ May be around 0.3 for particles used in packed beds

lower sphericity ==> larger surface area

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

= Specific surface area

@=A,/V,

¢ Minimal value for sphere

¢ Some books use S to denote area (instead of A)

@ Assume all the particles are identical

==> all particles have exactly same specific surface area

Rings (Raschig,etc) — Tarus saddle Pall Ring

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

= What is the pressure drop we need, to force the fluid through

the column?

(i.e. what should be the pump spec)

« We know the volumetric flow rate (from adsorption

equations, productivity requirements etc)

« We know the area per particle (we assume all particles are

identical). And the total area for adsorption (or reaction in

case of catalytic reactor).

« Hence we can calculate how many particles are needed

» Given a particle type (eg Raschig ring) , the approximate

void fraction is also known (based on experimental results)

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

» What is void fraction?

= Volume of reactor = Vp

» Number of particles = N,,

= Volume of one particle = V,

» Volume of all the particles = V, * N, = Vai-parricies

Vy

Void fraction=¢ = 2. ew Va Vius-raericurs

R Ve

_Va=VoNp

Vp

= Knowing void fraction, we can find the reactor volume

needed

¢ Alternatively, if we know the reactor volume and void a V, (I-e)

fraction and the V,. we can find the number of particles “? — Vp

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

= To find void fraction experimentally

= Prepare the adsorption column (or reactor...) and fill it

with particles

» Fill it with water

= Drain and measure the quantity of water

» (= void volume)

» Calculate void fraction

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

» Since we know Vos No» €, we can find Vp

= Choose a diameter and calculate the length (i.e. Height)

of the column (for now)

In normal usage, both the terms ‘height’ and ‘length’ may

be used interchangeably (to mean the same thing)

¢ Adsorption rate, equilibrium and other parameters will

also influence the determination of height & diameter

= To calculate the pressure drop

Note: columns with large dia and shorter length (height)

will have lower pressure drop

What can be the disadvantage(s) of such design ?

(tutorial)

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed

« Tocalculate the pressure drop

You want to write it in terms of known quantities

Length of column, void fraction, diameter of particles, flow rate of

fluid, viscosity and density

= Obtain equations for two regimes separately (turbulent and laminar)

« Consider laminar flow

« Pressure drop increases with

velocity

viscosity

inversely proportional to radius

Actually, not all the reactor area is available for flow. Particles

block most of the area. Flow path is not really like a simple tube

Hence, use hydraulic radius

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar flow)

= Tocalculate the pressure drop, use Force balance

Force=AP Area

2

0

Area where flow occurs =

2

«. Force=AP aD

é

= Resistance : due to Shear +, Force=r Contact area

@ Find Contact Area

@ Find shear stress

» Until now, we haven’t said anything about laminar

flow. So the above equations are valid for both

laminar and turbulent flows

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar Flow)

» Find contact area

Wetted Area= A, Ve(Im8) 4 =v, (1-6)

» To calculate the shear stress, FOR LAMINAR FLOW

2

pa V=v,,.) 1-5 Vinas = 2Vieg

dr |,-« R

« Here V refers to velocity for flow in a tube

a HV ins — 4 HV 8H

R R “Dp

= However, flow is through bed, NOT a simple tube

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar Flow)

« Find effective diameter (i.e. Use Hydraulic radius), to

substitute in the formula

« Also relate the velocity between particles to some quantity

we know

= To find hydraulic radius (and hence effective dia)

Flow volume=eV,

Wetted Area=N,A, 9 = Va(l=2) 4

V ?

p

» Hydraulic diameter

D, <4 Flow Area =4 Flow Area* Column Height

4" ContactPerimeter ContactPerimeter * Column Height

__, Flowvolume

wetted area

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar Flow)

4e

Dy =

(l-e

A, /

BAY ne BV (12) % }

u 4e

= Vayg is average velocity of fluid “in the bed”, between

particles

= Normally, volumetric flow rate is easier to find

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar Flow)

» Can we relate volumetric flow rate to V,,.?

= Use anew term “Superficial velocity” (Vo)

v= Volumetric flow rate

° Column Area

« Le. Velocity in an ‘empty’ column, that will provide the

same volumetric flow rate

= Can we relate average velocity and superficial velocity?

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Laminar Flow)

A,/ A, /

_ »/ _ pf

— = ( al y,) = eae al va

é &

« Force balance: Substitute for t etc.

2

Fores=ap 7? eg Force=t Contact area

4

A, /

2nV, (1-2) sf }

2 ‘ WW A

ap 2D 2 Ny 1 g)| Se

4 e& V,

_zD° L

= Volume of reactor (say, height of bed = L)

A,/Y

> py, (l-e)| “°K ,

ap 00, RG) ae

4 ee 4

IT-Madras, Me

Fixed bed - ‘anne drop

calculation (Laminar Flow)

A,

AP ao, IA) ar 4) xD

400 e 4

= Pressure drop

A p®

ay, (t-e) ( “4,

AP =e

é€

= Specific surface area vs “average diameter”

Vv,

A, i 4 .

[*] = Define “average Dia” of particle as

p,-—°

» Some books (BSL) use D, , [*]

LIT-Madras, Momentum Transfer: July 2005-Dec 2003 Y,

Fixed bed - pressure drop

calculation (Laminar Flow)

= Pressure drop

2

2t¥,(I~#) ( % ) 72uLV,(I-e)

/D, = HEE)

AP = Dee

= However, using hydraulic radius etc are only

approximations

= Experimental data shows, we need to multiply the

pressure requirement by ~ 2 (exactly, 100/48)

erms of specific surface area

In terms of average particle diameter As

2 2 f

150 wLV, (1-2)? 25uLV, (1-2) ( “4, |

= —>27 COS AP =———__** 4

Dé 6e°

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Turbulent Flow)

= Pressure drop and shear stress equations

Force=AP =D e Force=t Contact area

= Only the expression for shear stress changes

« For high turbulence (high Re), \R

be

T

faa =constant —

Mg PVing

oth e=constant 14 pV;;,

H Vi

= However y,, = “2 v2

£ t=K p—>

€

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop

calculation (Turbulent Flow)

= We have already developed an expression for contact area

Wetted Area=W,4, _ Vell-e), ay, (ie)

=e R

vy, 0" ‘,

« Hence, force balance

Force=AP aD

(ooh

= Volume of reactor (say, height of bed = L)

D?

V,===L

4 ar-(xot [e002]

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

é=t Contact area

Fixed bed - pressure drop

calculation (Turbulent Flow)

In terms of average particle diameter In terms of specific surface area

weifeag] Slog]

= Value of K based on experiments ~ 7/24

= What if turbulence is not high?

« Use the combination of laminar + turbulent pressure drops:

valid for all regimes!

=the a e) _(7pLVy (1-e)

= APrrtutent = 4D,

AF asinar

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop calculation

(Laminar OR Turbulent Flow)

« If velocity is very low, turbulent part of pressure drop is

negligible

« If velocity is very high, laminar part is negligible

= Some texts provide equation for friction factor

f =

+F.

Toe = Ziaminar + Turbulent

Pr, Vs0¥e,

2uV, (1-e) Ay

WENN) 7 ve

2 Ps

i Veven

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop calculation

(Laminar OR Turbulent Flow)

2uv,(i-e)(“4, | ys

eo Ke Af

anti-2(% \)

f = —_—__a=e =}|——_-4 "|,

¥y Yo / PVo 12

ye Vo

« For pressure drop, we multiplied the laminar part by 2

(based on data) . For the turbulent part, the constant was

based on data anyway.

=|——__ 47s | o

48 pv, 12 3pV, 12

« Similarly..

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed bed - pressure drop calculation

(Laminar OR Turbulent Flow)

A,/

25u(1- ei 4

eae). faarolso,)) 5

3pV, 12 = 3pV, a

« Multiply by 3 on both sides (why?)

sy -(Seaea)2 f= (9). z

D, pV, 4 D,pv

» Packed bed friction factor = 3 f

Egn in McCabe and Smith

Reynolds number for packed bed

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Example

» Adsorption of Cephalosporin (antibiotic)

= Particles are made of anionic resin(perhaps resin coatings on ceramic

particles)

» void fraction 0.3, specific surface area = 50 m?/m*(assumed)

« column dia 4 cm, length 1 m

« feed concentration 2 mg/liter (not necessary to calculate pressure drop, but

needed for finding out volume of reactor, which, in this case, is given). Superficial

velocity about 2 m / hr

= Viscosity = 0.002 Pa-s (assumed)

= What is the pressure drop needed to operate this column?

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed Bed

= What is the criteria for Laminar flow? DV, p

= Modified Reynolds Number u(l-e)

» Turbulent flow:- Inertial loss vs turbulent loss

@ Loss due to expansion and contraction

« Packing uniformity

@ In theory, the bed has a uniform filling and a constant void fraction

@ Practically, near the walls, the void fraction is more

» Ergun Eqn commonly

used, however, other 0.8

empirical correlations are

also used &

» e.g. Chilton Colburn eqn Ot

f= A a a 4C 02

Re Re Edge Center Edge

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed Bed

« Sphericity vs Void Fraction

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fixed Bed

» Alternate method to arrive at Ergun equation (or similar correlations)

= Use Dimensional analysis

AP —dependent variable

P (without subscript, means fluid density or Py)

Dy LV Hs Deotunns E+ Oe. sphericity)

APD; DV. D

= peered)

pv, L Ho Deotunn

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fluidized bed

» When the fluid (moving from bottom of the column to the top)

velocity is increased, the particles begin to ‘move’ at (and above) a

certain velocity.

« At fluidization,

@ Weight of the particles == pressure drop (area)

@ Remember to include buoyancy

axD*

4

AP 7 =(p,-p,)(1-2)Y«

Lp Nine

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fluidized bed: Operation

« Empirical correlation for porosity

= Types of fluidization: Aggregate fluidization vs Particulate

fluidization

= Larger particles, large density difference (Pgo) 1p - PLU)

==> Aggregate fluidization (slugging, bubbles, etc)

= ==> Typically gas fluidization

@ Even with liquids, lead particles tend to undergo

aggregate fluidization

« Archimedes number gp ,D* Ap

Ar=——+—

STARS, Neen DSNS Lt

Fluidized bed: Operation

Porosity increases

Bed height increases

Fluidization can be sustained until terminal velocity is reached

If the bed has a variety of particles (usually same material, but

different sizes)

calculate the terminal velocity for the smallest particle

Range of operability =R

Minimum fluidization velocity = incipient velocity (min range)

Maximum fluidization velocity = terminal velocity (max range)

Other parameters may limit the actual range further

¢ e.g. Column may not withstand the pressure, may not be tall

enough etc

R=V/Vom

Theoretically R can range from 8.4 to 74

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fluidized bed: Operation

80

» Range of operation

depends on Ar

40

R

0

10° 10¢ 108

Ar

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

Fluidized bed: Operation

= Criteria for aggregate fluidization

¢ Semi empirical

( D, Ap

05

> } > 0.6 (for liquid)

PH

> 0.3 (for gas)

= Particulate fluidization

@ Typically for low Ar numbers

@ More homogenous mixture

IIT-Madras, Momentum Transfer: July 2005-Dec 2003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fixed Bed Adsorption of CO H Mixtures On Activated Carbon: Experiments and ModelingDocument19 pagesFixed Bed Adsorption of CO H Mixtures On Activated Carbon: Experiments and ModelingSaba GheniNo ratings yet

- Audience Not Distinguished - Tables Can Not Be at The End - Titles of Tables and Graphs - Convert Tables To Graphs 7 / 10Document5 pagesAudience Not Distinguished - Tables Can Not Be at The End - Titles of Tables and Graphs - Convert Tables To Graphs 7 / 10Saba GheniNo ratings yet

- Anas GhawanmehDocument24 pagesAnas GhawanmehSaba GheniNo ratings yet

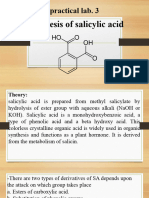

- Synthesis of Salicylic Acid: Practical Lab. 3Document12 pagesSynthesis of Salicylic Acid: Practical Lab. 3Saba GheniNo ratings yet

- POPE Vessel Literature DigitalDocument5 pagesPOPE Vessel Literature DigitalSaba GheniNo ratings yet

- D 6Document1 pageD 6Saba GheniNo ratings yet

- Polystyrene ProductionDocument8 pagesPolystyrene ProductionSaba GheniNo ratings yet

- D 8Document1 pageD 8Saba GheniNo ratings yet

- Carbon CreditDocument2 pagesCarbon CreditSaba GheniNo ratings yet

- Quattro ESEM - DatasheetDocument4 pagesQuattro ESEM - DatasheetSaba GheniNo ratings yet

- Bioreactors - 2Document35 pagesBioreactors - 2Saba GheniNo ratings yet

- D 2Document1 pageD 2Saba GheniNo ratings yet

- Bioreactors 2Document25 pagesBioreactors 2Saba GheniNo ratings yet

- Bioreactors - 2Document35 pagesBioreactors - 2Saba GheniNo ratings yet

- Bioreactors 1Document32 pagesBioreactors 1Saba GheniNo ratings yet

- CNT 1Document11 pagesCNT 1Saba GheniNo ratings yet

- Journal of Photochemistry and Photobiology A: Chemistry: Qiangshun Wu, Huijuan Wang, Chengwu YiDocument12 pagesJournal of Photochemistry and Photobiology A: Chemistry: Qiangshun Wu, Huijuan Wang, Chengwu YiSaba GheniNo ratings yet

- Science of The Total EnvironmentDocument10 pagesScience of The Total EnvironmentSaba GheniNo ratings yet

- F 1Document38 pagesF 1Saba GheniNo ratings yet

- Heterogeneous Photo-Fenton Degradation of Phenolic Aqueous Solutions Over Iron-Containing SBA-15 CatalystDocument10 pagesHeterogeneous Photo-Fenton Degradation of Phenolic Aqueous Solutions Over Iron-Containing SBA-15 CatalystSaba GheniNo ratings yet

- Fluid Bed Reactors: Chapter (Not in Book) CH EN 4393 Terry A. RingDocument23 pagesFluid Bed Reactors: Chapter (Not in Book) CH EN 4393 Terry A. RingSaba GheniNo ratings yet

- Cryogenics: X.X. Chu, Z.X. Wu, R.J. Huang, Y. Zhou, L.F. LiDocument5 pagesCryogenics: X.X. Chu, Z.X. Wu, R.J. Huang, Y. Zhou, L.F. LiSaba GheniNo ratings yet

- Water 15 01630 Factorial Experimental DesignDocument17 pagesWater 15 01630 Factorial Experimental DesignSaba GheniNo ratings yet

- Neethling 3Document8 pagesNeethling 3Saba GheniNo ratings yet

- Applied Energy: Contents Lists Available atDocument10 pagesApplied Energy: Contents Lists Available atSaba GheniNo ratings yet

- Journal Pre-Proof: Environmental ResearchDocument35 pagesJournal Pre-Proof: Environmental ResearchSaba GheniNo ratings yet

- CACE 2020 120 Original V0Document62 pagesCACE 2020 120 Original V0Saba GheniNo ratings yet

- Advanced Mass Transfer, 8337Document2 pagesAdvanced Mass Transfer, 8337Saba GheniNo ratings yet

- MIDTERMDocument4 pagesMIDTERMSaba GheniNo ratings yet

- 2 Casting FormingDocument56 pages2 Casting FormingSaba GheniNo ratings yet