Professional Documents

Culture Documents

03

03

Uploaded by

Franky Ken0 ratings0% found this document useful (0 votes)

12 views41 pagesOriginal Title

11537859_03

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views41 pages03

03

Uploaded by

Franky KenCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

40

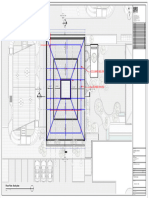

During the period between May 9 and 10", 1999, two boreholes

were drilted at the site, The borcholes are numbered 1 & 2. Each

borchole was drilled to a depth of 15.0 m, below the existing ground

surface. The tocations of the boreholes are shown in Figure No. 2.

limited scope of works was specified by the client, as the final des

the project is not defined at this stage.

‘The drilling was executed with Edico Drill using the rotary air

flush drilling method. The logs of the two boreholes are presented in

Appendix A attached to this report,

Sampling:

Samples were obtained continuously from the borcholes, through

ont the drilled depth. Double tube core barre! was used to obtain

undisturbed samples of bedrock materials, whereas split spoon samples

swere obtained from alluvial and mixed materials. The samples recovered

were cxamined, described and classified by our geotechnical engineers,

placed in proper sequence in wooden boxes and taken to our laboratories

for testing. ‘The moist samples were placed in waterproof plastic bags

before placing in wooden boxes.

Down the hole hammer was used at intervals of tow

engineering interest and where (he nature of the materials did not allow

for coring, in order to advance the boring.

Field Testing in Rorcholes:

Standard Penetration Tests (S.P.T.) were performed at

selected locations in the boreholes, to obtain approximate

consistencies and relative densities of the ground materials. The

tests were performed in accordance with:

ASTM D 1586-67 (1974), "Penetration Test & Split Barrel

Sampling OF Soils".

The (est resulls are shown on the boring logs at depths

corresponding to tests locations.

MH Station #2

399031

‘e\

The Stondard Penetiation ‘Test is defined in the legend to

boring logs. attached at the end of this report. Interpretation of the

test results is also given in the legend.

42 Laboratory Testing:

In order to determine the physical and mechanical properties of the

ground materials, Inboratory tests were performed on selected samples from

each borehole. ‘The following tests were performed according to Ametican

Socivty For Testing And Materials (ASTM) Standard, and the British B.S

Standards:

1. ASTM DB 2216-92, “Laboratory Determination Of Water (Moisture)

Content OF Soil, Rock And Soil Aggregate Mixtures"

2. ASTM D_ 422-92, standard test method for “Determination of

Particte Size Distribution”.

3. ASTM —D__ 422-63 (Re-Approved 1990), Standard Test

Method For “Particle -- Size Analysis Of Soil”, Hydrometer Method .

4. ASTM D4318-93,standard test method for, "Liquid Limit,

Plastic Limit, Plasticity Index of Soil”

5. ASTM D 2166-66, "Tests for Unconfined Compressive Strength of

Rock”.

6 BS. 1377 : Part 3 : 1990, Test 5, “Determination of The Sulphate

Content of Soil & Ground Water". Gravimetric method for acid extracts

in which hydrochtoric acid was used.

7. B.S. 1377 : Part 3: 1990, Test 7.3, “Determination of Acid-Soluble

Chloride Content”. Nitric Acid was used.

43 Laboratory Tests Resiilts:

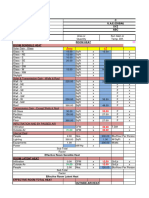

The laboratory tests results are summarized in Tables No. 1 & 2.

106

MH Station 2

$9901

“Table No. t

Laboratory Tests Results

| Undstiinad Can

Boring No LL: Liquid Limit

Moisture Content PL: Plastic Lirait

Bulk Density PI : Plasticity tndex.

4. : Unconfined Compressive Strength FS: Failure Strain

ub

816

MH Station 2

sooast

‘Table No, 2

Chemical Tests Results

BN

$0308) cL (ea)

BN : Boring Number $03 : Sulphate Content

1D: Depth of Sample Cl: Chloride Content

9726

MI Station # 2

899031

SO

SURFACE AND SUBSURFACE CONDITIONS

Ss

nel Materic

‘The two borcholes chilled show that there are general similarities and

continuities of the subsurface materials, in spite of some local variations.

A. generalized subsurface profile (AB) was constructed and is

presented in Figure No. 4. The profile was constructed through boreholes

No, 1& 2, and its location is shown in Figure No. 2. ‘The profile was

constructed by direct interpolation between the materials encountered in the

boreholes. ‘The fines connecting the various ground strata arc made for

illustration purposes only and are not to be considered as actual field conditions,

‘The geatogic description of the ground materials at the site ond the

approximate average depth at which they were encountered in the borcholes are

presented in Table No. 3.

Further information about the materials encountered can be obtained

fiom the logs of borings, Appendix A.

Mate

ils Physical and Mechanical Properties:

‘The field and laboratory tests results as well as the corresponding

material classification were summarized for the various ground materials and

are also presented in Table No. 3.

Aterberg limits test resulls were plotted on Casagrande Plasticity

Chart, Figure No. § to obtain the plasticity of the soils.

In order to obtain the degree of potential expansiveness, the

percentage of clay fraction for the tested samples were plotted against the

plasticity index for the same samples on the chart for the degree of

potential expansiveness (Williams & Donaldson , 1980 ), Figure No. 6

The results obtained from the particte size analysis tests were used

to obtain the textural classification of the soils as shown in Figure No. 7.

‘The tables given in the legend to boring logs, Appendix A, were used to

describe the consistency of the soils, and the strength and quality of the rocks.

Further information about the materials encountered and theit physical

and mechanical properties can be obtained from Table No. 1.

10726

MH Station # 2

$ 99081

150068

En vores py b ON ainBiy

: “suoisueu:

yaus.

i 30 Sv0A8; Un ue suojsawy) 30!

| Pappeqart pew ysiow) ==! jone28 popuncagns,

uum uew

“useas0 04 UsIODA,

ig6zt-

\sract

Is’sce-

sent

IsrbLt

Is's9u-

js Zol-

\s'sal-

Is'cou-

—r-—__

‘s0eyng punoig BuNsiKy sob

@y 31140ud SOVIUNSENS G3ZWYENIO

Table No.3

Materials ‘Types and Prope

‘Summary of Tests

Results

Alluvial deposits of

creamy silty mart with

gravels af limestone and

chert,

LL26.7%

PLi13.7%

PLI3.9%

Gravel.0.8%

Sand:24.6

silt: 47.7

Clay : 26.9

PE: Medium

‘TC: Sandy & Silty

chy

& i] Creamy, moist, fractured, | D: Very poor

£ 1 | weak marlstone with St Weak to very weak

& 2 cas assessed by the

fillings of moist marl geotogie hannie.

pales Yellowish to creamy, eed “a6 Fr ed

’ ist \ 1:22. -244 to Medium

ss] is | 2 [Map ee rant pu: M2-12.7 4C : Clay & Sandy

hin layers of Pista 125 Sit, Sandy & Silty

marlstone. Gravel :1.6~ 169

Sand :22.5~ 35.7

Silt: 32.7455,

Clay : 16-294

Ne

Clay to Clay

MC: Moisture Content

PL: Plastic Limit ‘qu: Unconfined Compressive Strength

PL Plasticity Indes ‘St: Rock Strength Description

VL Liquid Limit RQD: Rock Quality Designation

P: Plasticity D: Rock Quality Description

TC: Textutal Classification Ns Number & Blows (0 em)

PE : Potential & Expansiventess

FOR: End OF Boring

‘to Boring Logs, Appendix A

1RR6

MAH Station #2

849081

PLASTICITY INDEX PI. (%)

Figure No. $: Casagrande Plasticity Chart

ARAB CENTER FOR ENGINEERING STUDIES

1126

CHART OF EXPANSIVENESS TES

MODIFIED

( Millloms and Donaldson 1980 )

(s)

2

§

2

z

S

;

30 40

CLAY FRACTION (%)

Pa. cuassmncariOn

o

13.92

TEXTURAL CLASSIFICATION CHART

CLAY (&)

52,

I SAND (8)

a.

Sendy ct

wheat”

Figure No. 7: Textural Classification Chart

ARAB CENTER FOR ENGINEERING STUDIES

1596

53

sa

‘e\

No ground water was encountered, in any of the boreholes to the depths,

drilled.

Ground Water And Ce

Sulphate Content in Ground Material

‘the sulphate content expressed as sulphur (rioxide (SOs) for the soil

samples tested from boreholes, are shown in Table No. 2.

ulphate attack to concrete, is a well documented phenomenon and is:

caused by the presence of the high sulphate content either by the ingress from the

sulphate of the surrounding environment such as foundations soils, or by the

presence of sulphate in the concrete ingredients such as the sand or aggregate, oF

both, ‘The aitick results in a considerable intemal expansion which may lead to

cracks and disintegration of the concrete.

‘The British Code of Practice BS 5328 : Part 1 :1990 “Guide to

Specifying Concrete” have stated requirements for concrete exposed to sulphate

attack, depending on the concentration of the sulphate in the surrounding soil or

in water, These requirements state the type of water to cement ratio to be used,

‘the minimum cement content and maximum free water to cement ratio. A copy

of BS 5328 : Part | requirements is attached to this repost in Appendix B.

‘The British Building Research Establishment (BRE), in: UK have

shed Digest 363 “Sulphate and acid resistance of concrete in tlie ground”,

1991, in which the sites are divided into five categories of increasing severity,

based on the sulphate contents of the soil or ground water (Table 1). However,

having classified the site on the bases of sulphate level, type of exposure (Table

Ja) and type of conerete (Tableth), further recommendations for concrete in

acidic conditions are given in Table 2 and Fig. |

Changes made to the basic classification given in Table | are

commutative, Table 1 states for each of the five categories cement type,

’nimum cement content, and maximum free water/cement ratio. A copy of

Tables 1, La, 1b, le, and 2 and fig 1 (procedure for classification of site) of BRE

Digest 363 are attached to this report in Appendix B.

Due {0 the sulphate content present in the foundations soils and ground

water, this site is classified within Class (1) as categorized in BS "5328 : Part 1.

‘The requirements of BS 5328 : Part 1 is to use ordinary portland cement or

combination of Porttand cements to BS 12, and Pfa to BS 3892: Part 1

containing not tess than 25 % Pfa and not more than 40% Pfa by mass of Pfa

plus cement. The requirements for minimum cement content and maximum

water cement ratio arc given in Table 1, class 1, presented in Appendix B.

MH Station #2

‘$9901

[a

‘The classification of the site on the basis of the sulphate level ean be

determined according to Table | of BRE Digest 363. However, modifications to

this classification should be made by the designers once the type of exposure to

sulphate (such as types of floors exposures, static ground water and permeabitity

of soils, the location and thickness of the structure and the hydrostatic head), and

the (ypes of concrete used (such as precast concrete, cast-in-sitt concrete, wall

units, piles, ete.) are finally determined.

It should be noted however, that practical experience have indicated that

mixes having both the minimum cement content and maximum free water to

cement ratio recommended above may result in conerete of low level of

workability, such that full compaction to achieve dense conerete of the necessary

degree of impermeability to resist, as muuch as possible chemical attack, cannot

be casily achieved. { may be therefore, practical to increase the cement content

while maintaining, the recommended water to cement ratio in order to obtain the

appropriate workability to achieve full compaction of the concrete.

Alternatively, workabilily/compaction can be enhanced by using a plasticizing or

superplasticizing admixtures. The admixtures should comply with BS 5075

Parts 1 and 3. Admixtures containing calcium chloride are not recommended for

sulphate resisting, or any reinforced concrete.

The CIRIA Guide to Concrete Construction in the Gulf Region, 1983,

recommended maximum limit of sulphates as (S03), in the coarse or fine

aggregate used for concrete as 0.4 % and recommended maximum limits for

total sulphate content in concrete from all sources expressed as a percentage by

weight of cement as 4% in all cases. It is our opinion that these limits must be

adopted and specified for contamination of the concrete and its ingredients in

onler to achieve durable concrete.

Conetete cast in the ground will eure under the conditions normally

favored for strength development and durability provided that the temperature

rise due to the heat of hydration is kept low. In the particular case of resistance

to sulphate attack, a period of air curing (o the structures has been shown to

provide a protective layer associated by allowing the access of air to adry

conerete surface for several weeks after the normal curing schedules (BRE

Digest 363). It is emphasized however, that since good curing entails keeping

the surface wet, the subsequent treatment of dry surface should be regarded as a

specific secondary process.

MU Station #2

899031

35

PX

‘The chloride content for the same soil samples are also shown in Table

Chloride Coment in Grewnd Materials:

No, 2.

BS 5328, Part | grade soits and ground waters in five steps of sulphate

concentéation : 0.2. % total sulphate (SOs), or 1.0g/L in 2:1 soil water extract is

considered significant. However, there is no widely accepted view on the

concentiation which chlorides become significant in soil or ground water, but

fimited experience in the Gulf Region suggests it may be as low as 0.05 %

panicularly in situations where alternate wetting and drying. or capillary rise

affect the conerete.

Chloride do not react expansively with portland cement as do sulphates,

‘Their effect when present in concrete is to increase the risk of corrosion of

embedded metals of which the greatest volume used is steel reinforcement.

They can be tolerated in plain conercte, although when present in farge amount

some surface dampness may result, but widespread and serious damage has been

caused by the use of chtoride-contaminated aggregates in reinforced concrete.

‘The corrosion products occupy more than twice the volume of steel,

and their formation can be accompanied by very high tensile pressures as great

as 32 N/mm2, resulting in cracking of the concrete, frequently followed by

spalling of the cover. _ In severe cases of corrosion there may be a reduction in

section of the reinforcing bars, leading to a toss of tensile strength of the

reinforced concrete.

‘Therefore, it is of utmost importance to ensure that the maximurn Himits

for chlorides. and sulphates in the aggregate components and in the concrete, are

not exceeded, ‘These limits must be clearly stated in the technical specifications

of the project.

‘The CIRIA Guide to Conerete Construction’ in the'Gulf Region, 1983,

recommended maximum limit of chlorides, as CL, in the coarse and fine

aggregates used for concrete as 0.03 and 0.06, respectively, and recommended

maximum limits for total chloride content in concrete from all sources expressed

as a percentage by weight of cement as 0.15 % for reinforced concrete made with

Portland cements containing less than about 4 %C7A (e.g. sulphate resisting

Portland cement) and 0.03 % for reinforced concrete made with Portland

cements containing 4 % or more C?A (OPC and ASTM Type I and IT usually

contain more than 4% C?A). For un-reinforced concrete the limit is 0.6 %.

Additionally, it is advisable that concrete cover for the stecl

reinforcement be increased in the members to protect the steel from the ingress

of the chlorides preseat in the surrounding environment. Surface protection and

sealing of the concrete and steel_may also be considered.

18726

MM Station #2

$9903

a

fe

Evidences of concrete eracking and stect corrosion were observed on

many of the old concrete elements existing in the area. White corrosion can be

initiated at lower chloride level in suiphate resisting porttand cement concrete

than in ordinary Portkind cement, the use of sulphate resisting portland cement

blended with pezzolanie materials, can reduce the risk of damage caused by the

sulphate contaminated aggregates. If chtorides are also present, the use of

sulphate resisting cement may inerease the risk of corrosion of reinforcing stech.

Sulphates may. be present in the environment to which the concrete is

exposed, often in combination with chlorides. ‘Their main effect is on the

concrete itself, where their attack leads (o internal expansion and disruption,

‘Their effect can be reduced by the usc of sulphate-resisting cements, cements

containing blast-furnace stag or pozzolanie, or in severe exposure conditions, by

protceting the concrete hy tanking.

Where sulphates and chlorides occur together, problems are accentuated

hecause sulphate-resisting cements provide less protection to stect against attack

in the presence of chlorides. Current research is giving grounds of increasing

concem that where sulphates and chlorides occur together, the use of sulphate-

resisting cement may be inadvisable, (CIRIA Guide to Concrete Construction in

the Ciul Region, 1983). Sulphate-resisting cements do not make concrete

immune from sulphate attack but only make it better able to withstand moderate

concentrations. of sulphate since it contains less tricalcium aluminate (C’A) than

OPC, to reduce the effect of the reaction between the C°A and sulphate.

However, CA can also combine with chloride which might otherwise cause

reinforcement to rust.

1976

MA Station #2

$9903!

A

Generally, where resistance is necded against sulphate altack, but there

is NO significant risks of chloride-indueed corrosion, SULPHATE-RESISTING

CEMENT to BS 4027 or ASTM Type V (i.e. cement with a maximum CA

content of 3.5 or 5.0.%, respectively gives better protection)

Recommendations

Where improved resistance is needed against chloride corrosion of the

reinforcement, but there is NO significant to sulphates, Cement with a medium

to high C?A content is preferced. OPC or ASTM Type usually have high CA

contents and ASTM Type Il usually has a medium C*A content.

Where resistance is needed against both sulphates and chlorides,

conerete may need to be protected form the soit and groundwater with

waterproof membrane or tanking, and a compromise has to be made on the type

of cement used. Generally. a cement containing at least 3.5 % but not more than

9A is preferred, Each situation shoutd be considered on its merits.

In this case where both sulphate and chloride existence is very slight,

then the minimum considerations stated above shalt be satisfied.

However, it is advisable that the designer consult CIRIA Guide to

Concrete Construction in the Gulf Region or any other simitar reference, once

the exposure conditions of the designed structures are finally determined, in

order to determine, more accurately, the cement type (Figure 6 and range of

specifications limits requirements for minimum cement content, maximum water

coment ratio and minimum cover for teinforeement (Table 13). Figure 6 and

‘Table 13 are attached in this report in Appendix B,

2006

MII Station #2

$9903

60

le

CONCLUSION. EE

According to field and laboratory investigations, subsurface conditions.

engineering analysis and practical experience, it can be conchided that the proposed

Duilding can be satisfactorily supported by the ground at the site, provided that the

following recommendations are followed:

61

Forandation Depth And Txpe:

The foundations of the proposed building shall be laid below the top

overburden material of alluvial deposits into materiats of creamy (o yellowish

tar! and marlstone encountered in all boreholes at depths ranging between 1 to

3m. The foundations shall be laid jnto coherent materials, and any friable, or

soft inclusions of silly clay or any other material, shall be removed before

forndations construction.

Moreover, the foundations depth may vary according to architectural

considerations, however, it should not be tess than 2.0m below the minimum

adjacent, finished ground level.

‘The encountered foundations ground is suitable to support the structural

loads using. spread footings with tie beams, however sitip footings mmay also be

used, if required.

62

wable Bearing Presst

‘The allowable bearing pressure corresponding to the encountered

highly fractured, creamy, thinly bedded weak marlstone was estimated

using the following equation, recommended by Tomlinson, for strip

foundation on rock mass with closed joints:

qua=eN+05yBN, + yDNy

Ne. Ny & Nyare given as a function of the friction angle . Correction for

the footing shape mnay also be applied.

The shcar strength parameters were estimated according to Kuthawy and

Goodman, as a tinction of the rock quality designation (RQD), and the

unconfined compression strength que, a8:

30°

30° 60°

2106

MAH Station #2

‘$9031

63

‘The obtained parameters for the highly fractured marlstone4vé

RQD : 0 %, therefore g? was taken as 30 for marlstone, and 20 for

the marl.

uc 1 Very weak as assessed with the geologic hammer (Unconfined

compression test could not be carried out due to the highly fractured

nature of the material), taken as 5 kg/cm? for marlstone, and 1

kg/cm? for the creamy marl.

‘Therefore, based on the obtained results, and considering the

existence of weaker marl materials within the zone of influence of the

Foundations, and based on our previous experience with similar materials,

recommended that the allowable net foundation bearing pressure be

taken as 2.2 kg/em?, for the whole site, provided that the recommendations

given in paragraph 6.1 for "Foundation Depth And Type", are satistied.

Important Note: ‘The above conclusions apply to the arcas of the site

represented by the drilted boreholes, In case that the plan area of the

proposed schoo! building and its layout over the site did not satisfy the

above conditions, additional test borings are recommended in other areas

of the site to confirm that the above conclusions and recommendations

apply.

Foundation Sett

With the foundations designed and constructed in accordance with the

above recommendations, the settlement is cstimated to be within the tolerable

limits.

An estimate of the ar

the following relationship :

pated foundation settlement was carried out using

4B? Lye 1,

Ey

in which,

s : Immediate, or elastic foundation settlement,

Qe: Specified maximum net foundation pressure.

By : Characteristic Dimeasion of the foundation.

1: Poisson's Ratio, token as 0.33

Fy __: Deformation Modulus, estimated as 150 kg/em2

I,& Ip : Shape & Depth Correction Factors.

‘The obtained settlement was insignificant, and negligible. Moreover, most

of this settlement will take place during the construction period

22126

MH Station # ?

'S99031

64

65

66

67

68

A

It is expected that the excavation will be through top soil of silty ck

and marl deposits, and through, highty fractured, weak marlstone and mart,

‘erefore, conventional excavation equipment such as loaders and dozers, will

be sufficient for the excavation works. However, pnoumatic equipment such as

jack hammers with compression and rock breakers may be required, in some

Jocations for the exeavation of marlstone materials.

Excavation

Lopes

size the instability problems, the temporary side excavation

during construction should be sloped at a face inclination not steeper than one

horizontal to twa vertical (HH: 2V).

Surface Rrainage:

It is recommended to protect the foundation ground and excavation from

surface water both during and after construction by providing proper drainage

and protection system. Surface water should be diverted away from the edges of

the excavations,

Subsurface Drainage System:

No fice ground water was encountered within the proposed zone of

foundation depth, therefore, no subsurface drainage system is needed. However,

in order to prevent water dampness at the basement walls, and ground floor, if

any, all subsurface walls and bottom of foundations should be water insulated

with proper insulating materials. Water stops should be used at all construction

joints

Pre

ctipn of Foundation From Soil Environment :

“The chemical tests results indicated that the soil environment is slightly

hostile to the foundation concrete, ‘Therefore, no special considerations for

foundation protection are required (see paragraphs 5.4 and 5.5). However. all

subsurface structures should be totally protected by isolating the structures with

appropriate protective coating or sheeting which shall extend up to and little

above the finished ground level. Normal concrete cover (50-75 mm) shall

also be provided,

2306

MAH Station #2

$9903

69

6.10

TX

‘The top silty clay materials are not suitable for backfilling purposes

because of their plasticity. The marlstone crushings and creamy marl materials

resulting. during excavation works, are probably suitable as backfilling materi.

Uowever, the final decision shall be taken during construction and after testing.

spaction Criteria:

‘The materials to be used for backfilling purposes behind underground

walls and basement floor slab shall be a soil or soil-rock mixture which is free

from organic matter or other deleterious substances, 1t shall not contain rocks or

lumps over 15 cm in greatest dimension, and not more than 15 percent larger

than 7 em, ‘The plasticity index for the backfill material shall not be more than,

15 percent.

It shall be spread in lifts aot exceeding 25 em in uncompacted thickness,

moisture conditioned to_ its optimum moisture content, and compacted to a dry

density not less than 95 percent of the maximum dry density as obtained by

standard proctor compaction test (ASTM D 698).

Earth Pressure:

The underground walls of the building, ifany, drained and backfilled as

recommended above, shall be designed for an equivalent fluid pressure of 0.8

ginvem3 (800 kg/m3) plus a uniform lateral pressure which corresponds to the

maxitnum expected surface loads,

In all cases, additionat lateral pressures, if any, exerted on the

underground walls from footings and loads at higher levels of the adjacent

buildings shall be considered in the structural design.

MU Station #2

S90

ou

Seismisity of Site:

‘The study area is very close to the Jordan rif (the area is only few

Kilometers from the Jordan rift) and is in fact affected by the tectonics of

the rif. ‘The Jordan riN represents a focus of earthquake activity.

Therefore, any activity in the rift would certainly have a bearing on the

naturally or artificially instable carth blocks. According to the seismic

photomap published by the Geologie Survey of Israel and which includes a

record of the carthquakes measured in the area during the period of 1981

to 1993, there is evidence of the existence of numerous non-major

earthquakes of Richter magnitudes of more than 5.

According to Jordan National Building Code for Loads and Forees,

the site may be classified as class A according to this code, This region

has an earthquake intensity of VII to IX on Mercalli Scale, and of 0.75

intensity factor. This region is generally considered as the highest active

seismological zone according 0 this code. Major hazards shall be

expected in the arca of this region.

The seismic hazard for any particular site could be assessed by

Modified Mercalli intensity (Factor of intensity) or by Peak Ground

Acceleration (PGA).

The PGA is very widely used for the assessment of seismic hazards al

the sites of engineering projects. Due to the seismicity of the project area

and because of its proximity from the Jordan Valley, a PGA value of 0.1g

to 0.15g is recommentted for structural design purposes. (Richter 1958,

has developed a correlation between the Richter Magnitude, Modified

Mercalli Intensity, Vetocity, and Ground Acceleration. The above

recommended ground acceleration corresponds to an earthquake of @

Richter Magnitude of 7, and modified Mercalli intensity of VII).

2576

MH Station # 2

$9031

6.12

Modificd Mercalli. Scale is a measure of the intensity of

earthquakes and is correlated with Richter (Magnitude) Scale, as follows,

(Richter 1958):

uivatent Richter Ground Acceleration (2)

Iv 0.007 - 0.015

4

v 0.015 ~ 0.035

vl 0.035 ~0.07

5

vil 0.07 -0.15

6

vit 0.15 0.35

7

1K 0.35--0.70

Foundation Excavation Inspection:

The reconimendations given in this report are based on the assumption

that the subsurface materials and conditions do not deviate appreciably from

those disclosed in the borings.

Our office should be notifted, in writing, immediately after foundation

excavation and before foundation construction to inspect the excavations and

confirm that the requited ground is reached and all the undesirable and loose

1s are removed. Such inspection, and any other routine foundation

jan inspection (if requested), will be carried out at separate fees.

2626

MIT Station # 2

$9903

APPENDIX A

LOGS OF BORING

Mit Station #

599031

Sale

SAMPLER TYPE

Hm i al ld

ceamtee -COREARCL AUGER SHELBY OVE OWE DANE

goo rioey Bante GOON

ws rth

ecinay—Doind Vented EE aly ihe

Uk Uaiobea Casas

sown, nthe Stondrd Panton Ki requed io veo fie cenit omelet

1 eyo em) Ta ante of

yy jee Mlograme welght Fotling teventy Us

SU Mgt rompte e dotance of ty canines ong wat

Centres

Fig Grolnes_Soih Corte Groined Soils

Fee ewtcors |

Foy epee eet

ny ponies ero} tote [au ec dened with

ie ont i bt catty trove,

Pennvoted sever cc

som ih modo iggy [shorted wim ate.

eae

aed ese |taquin vic to loten

a opted fortoving by Yond.

ey wih et eo enna aga loing erheor|

eet eevee.

etd, wih Achy

by thon ol

Ma rwzovared a wech pone Be ot Regt of the core m,

secarer The porcentge of 09h of co

of nfo cove pleat tem conten oF

eee the ack Gv Dutgnaan ihe prcstogy of the som of legit

Wee he ttt agi oe cove

se

Ses an too sl cont nd fae cco by tl tlle

cian ni od et el io oP

fife 3 ween

"R teleton ta como ant neo nanan cnn tar

ie epee wih o ea erent)

as eT oF eg cone Tow Same! of em (Best on fone IIR

Rock Quotiy

Ta ai

eigestan tad

0-38

10

a7

now

oar sata

“PRAQ CENTER FOR ENGINEERING | STUOIES

LOG

PROJECT: Al-Nwaimah School Uullding

LOCATION: Jericho

DRITLING DATE: 09/05/09

DRILLING METHOD: rovany xR rivet

OF BORING

BORING No.: BHL (8 99031).

BLRVATION: 161.50

GROUND WATER DEPTH: WB.

‘TOTAL BORING DEPTH: 16.00

‘set (8)

a

DESCRIPTION

wa

‘Allarlal deposits of wilty mart with

trubreunded grarela of Limestone and

chert.

I LOG OF BORING

PROJECT: 41-Hnalinah School Dulbting RORING Ni

1 LOCATION: tericho RLRVATION: 161.60

DRILLING DATE: 09/05/00 GROUND WATER DEPTH: Nz.

DRITJING METIIOD: rotary am Fat ‘TOTAL BORING DEPTH: 16.00

mere | S| REC | RGD ‘.P.T (NY qa *

w |r] @ | @ = veh leven

Bit (8 99081),

are.

DESCRIPTION

PROJECT:A-Neaimah School Guttdirg

LOCATION: terioha

DRILLING DATE: 10/05/69

DRILLING METHOD: rotaxy am rust

LOG OF BORING

BORING No.: BHa (8 89091).

RLBYATION: 101.60

GROUND WATER DEPTH: N38,

TOTAL BORING DEPTH: 16.00

chert,

marirtone,

DESCRIPTION

‘Alluvial doposita of ality mart with

subrounded gravnls of limestone and

Yelloriah to ereamy, mofat marl

interbedded with thin lagers of

LOG OF BORING

PROJECT:AL-Nwalmah School Pullding

TOCATION: Jortcha

DRILLING DATR:

DRILLING METHOD: rovarr am Lat

ey 7

BORING No,: BH2 (S 99031).

BLEVATION: 141.50

GROUND WATER DEPTH: Xx.

TOTAL BORING DEPTH: 16.00

DESCRIPTION

Yellowish to ereamy, moist marl

Interbodded by thin Inyere of

mmarletone,

BQO | Rook qualtty Designation

SPT Standard Penetration Test

APPENDIX B

SULPHATE & CHLORIDE

MAL Station #2

$99031

Gnule 7, Concrete expgaed Ch euphinve attack

Gane

Ta ground

“Cement couplptng with

Denve, fatly

compacted concrete

ade wlth 20 mann

complying with

gan? oF BS 10¢T

MRS tor methods of analysts, and to IRE

ropectively

Non 19

ow

a

2 tb seceunmerated thatthe shanna content af ge dors mot exceed

wl ee

tess |hess [Less |Table t

Tear 02 [ran 1.0 [than 0.9

fazte |how foste |nsi2, Bs 145, bs¢se8

toes 1.0 1-2 This 12 combined with teas than 26 % pla

BS 12 combined with less than 70 % ggbs

S12 combined with 26 % (0 40% pla’

BS 12 combined with 70 X to 00% gabs

195 4246 with at least 70% gas

1S 6588 with at least 25 % pla

154027 (SRPC)

us 4248 (S50)

HS 12 combined with 2 % to 40% pla

1S 12 combined with 70% (o 00 % gabs

15 4246 with at feast 70 % gabs

15S GG8B with at least 25 % pla

185.6610 with not more than 40 % pf

US 4027 HFC}

us 4248 (SSC)

{Bs 4027 (SiPC)

Us 4248 (SSC)

1S 4027 and

U5 4248 (SSC) both with adequate

of the sulphate fs present as love soliy calctum sulphate, analas onthe bans of

ce ineancatton than tht obtained from the extraction of total SO,

protective coating (see BS8110)

BS 6610 with not more than 40 % pfa

EET)

{370

370

0.60

0.4

0

6

Tian should be made for agzesstes of moma maximus ace otver than 20% by

4.251 pater eateact may peer,

Thcterence should be made to DRE Cerrent

‘Digests 720 and 276 for aterpeetation tn relation to natural sols and Cty

/e

Well - compacted castin-situ concrete betwee 14.0in to 4.50:rm thickness and exposed on ali faces

to sulphate soit of il, Aggregates to G5 002 of OS 1047. For ollier exposures oF fypes of concrete

seo Tables ta and 1b,

‘nendations for concrote ORE Digest 363, 1991

Table 1: Classilication of sites ant

0 Cement — Minimum = Maximum free

Dy 2:4 waicrisoil type sco cement —waller/cement

textiact - git gh table te content ratio

gin Nolet

A Notes 182

SO,

1.0 360 045

extract 760 <1 |

As for Class 4

26.0 31.0 plus susface protection

see GP 102

Note + Cement content includes pfa and slag,

Note 2 Cement contents rctate to 20n1m nominal maximum size aggregate. fn order to maintain the cement cont

‘of the mortar fraction at similar valugs, the minimum cement contents given should be Increased by 40k

for 10mm nominal maximum size aggregate and may be decreased by 30 kgim3 for 40mm nonv

maximum size agoregate as described in Table 0 of DS $320 : Part 5.

Mole 3 The minimum vakuo requirad in BS 8110: 1905 and BS 6328 ; Pail 4: 1090 Is 275kyhin® for uprolafor

structural concrete in contact with non-aggressive soi. A mioimum cement content of 300kg/m" (BS 01

and maximum fice water/cement ration of 0.60 is required for reinforced concrete. A minimum com

content of 220kgfm? and inaximum free waterfcement ration of 0.00 s pormissibte for C20 grade conc

velien using unretntorced sbip foundations and trench fil for low-rise buildings in Class 4,

i.

Tate 1a Modification tv Tulle 1 for olficr types of exposure to sulphates URE Digest 363, 1991

General recommendations

xposure

Floors On Hor hant-coe cootsiving saobata In:

Provide membrane betwoan the fil oc hard-core ondfoat fis,

Opss LE

a Provide. membrane between the fiLor haw) cose ans. any-sonctele,

Chose 3 Aand Hol recommended for use.as.a base for concrete loans.

Static groundwater

For normaly dry sites or soils with permebilly tess than 10°avs.

Tate 1 rolers to permeable seis

(ies t04ivsin Figure Gof BS 8001) (og. unfssured clay) where fs deeldos Not the groundwater is

sehich to mobile (09. Milly eta, the classification n Toble 1 for Ciasses 2, and 4

groundwater and would nckrte may be reduced by one Tess.

exposure to freo water. tales

pomieable soits, the amount of water

movement will depend on the

topography of the site and a

judgment or a site measureiwent

must be made to decide whether the

greanwvater is static or movie.

Hascment, embankment or ta hydrostatic head greater than five ines the thickness of the

i

ining walls roneole is created by the groundwater, the classification ia Table + |

1

Stoukd be increased by ono class. This required con be waived It a

iamier fo prevent moisture (ransfer trough the walls provided or

biter completion of normal curing, the concrete face thas fo be

exposed fo suiphale has been exposed lo air But protected from rain

{or several wocks.

Table 1b Moditcations te tilts Lor otter types of concrete BRE Digest 369, 1994

Concrete Type

Pooily compacted concicte de

for full compaction

1 olasses 2, 3 and A the requirements for typo of cement,

Cast-in-sity concrete over 45001 F

i round beams, vail cenvant content and waterteemseat rato given in Yable ¥ may bo

aus oe ples with smooth suifaces reduced by one class ifother durabitly and stasctoral

idorations permit,

which, after normal curing, have been con

exposed to air but protected from rain

for several weeks.

Cast-in-silu concrete {other than Inctease classification in Table 1 by one class

ground floor stabs) less Ahan 140m

thick or having many edges aml

corne’

Precast concrete: blocks Blocks should comply with BS 6073 and with BS 5628 : Part 3

telating fo use below ground for classes 2 and 3 pf Tabte 1. As an

bitemative to complince with the srininwin cement content and

Waterfcoment ratio given In Table 1 for Classes 1 to 9. autoclaved

Blocks (including aerated blocks - Alrerete - with a minimum

dlensily of GO0kgim’) or pressed blocks wih nore than 5

their feast cioss-sectional area carbonated’ may be used.

of

| Concrete biicks Comptiance with BS 6073 and with Table 1

Concrete Pipes Classification with respect to lype of cement may be reduced by

‘ene class for pipes complying with Part 100 and 120 of DS 6911.

Cement contents and watertcement ratios in Table t are not

felovant, 7

‘Goniplance wilh BS 1164, Porous Goncicle pines are not suitoble

for use in Class 3, 4 and 5 soils. HH _

Porcus cone

= atiated ty bxeakiny block sd opplying pheaoiphifalein - sec BRE information Paper 6/04

[a

BRE Digest 363, 1991

Table te Iypes of Cement

| Code type or Combination _ Coda Typo of Combination

A Porttand cement to US 12 1 Sulphate resisting Ponland coment to OS 4027.

High-stag blastturnace coment to OS 4246 containing not

less than 74% slag hy mass of nucteus.

-e-coments

1 Poilkand Masttenns

tobs 146,

Combinations of Portland cements to BS 12 and blastfurnace

© High stay blasttumace coment ta J

‘stag lo BS 6699 containing not less than 70% slag and not

BS 4246

‘more than 90% slag by nrass of slag plus cement.

1D. Combinations of Portiand cements

toBS {Zand blastiurnace slag to K_—_ Portland pfa cement to BS 6588 containing not tess than 26%

bs 6699 fa by mass of nucleus.

Combinations of Porting coments to BS 12 and pla to BS.

9002 : Pail 4 containing nol fess than 25% pla and not more:

ian 40% pfa by mass of pfa plus cement.

E_ Poiltand placements to DS.6503 A

F Combinations of Portiand cement

to BS 812 and pla to BS 3002:

mitt

G Pozzokwic pla-cement to BS 6610

Pel eeeceeReeee

fn codos 1 sind J, stag with akinina (A1,0,) content over 14% should be used only with

Portland cemnt fring low fo moderate CA content (Iypically tess than 10%).

Fable 2 Requirements fcr concrete exposed fo attack from ackks of pl 2.5 Ribighet 309, 1991

Moinily

‘Chiange in Ciassitication with respect to

of Wats mums cement content and niaximum

Conesete it ete fa) | (tata | yaterfcement rato for ihe tyne of cement

Use Contact wits, {pth | RLMeMe | Ts tte socommended on the basis of sulphate in Tables

1, teand 1b

Viton aebvncing ehasses for coments = G into

Classes 3-4, clionse the higher coment content

tion

g

Foundations

including

poured

No Change,

‘Advance by one Te

piles. Ete

For piles

mado by

spectat

techniques,

wing tow | Ground

watercement | Containing

ratio, stighly | wastes or

stringent made-up

requirements | graund to55 [Advance by two fess |

may be ~ Advance by one fess

[applicable _ ee | Advance by tines fess

ina | S38 = No Change

Ground

[SEE eee eee fe

Extewat Ground [25 | TH : Provide suiloce protection SO, is above Class 3

Suilsee Con:

taining a Wo Giiange

wastes oF

madeup PAS PM Provide suilace prat if SO, is above Class 2

around

ae A [Re Giange”

Pipes to Naturat ‘No Change Ee

BS 5O11 vwatereffivent _ [Re Cha

Parts 100& | doemstic Provide suse praiecion wing WSO, Ts avve Gis 3

120 sewage Biovidesitaceproiocien ting WSO, f above Glass 2

Frovkie sotacepicketien ning respecive eT SO, |

Chssiication _

[No Chan

Concrete noi sutaiie

‘No Change.

Parous pipes | Land

toBS 1194 | Drainaye

Haturat | Advance by one clos

Culverts water offizent ‘Ravanee by one classes

castin-sita = mi ‘Advance by two olaes

of precast Industrial iM ‘Advance by two classes i

f vent M = Advonceto Class

~| thik aetic ~~| Seo diary Floors = Ministry ot Ag Fish and Food 1967 ond Concicte in Ni

acid) Parlows, Goments and Concrole Association, Farm Not.9:1900

Silage

rovicoturat | fpcipaty | Contact Misty of Ag Fish and Food fr eaten econnenatons

and Foctic acts) eee if

Industiat | Aesd spillage ww | ~

industiat Refer to anecialist producers of acid resistance finishes and CP 204

SEE EEE rocesses Bee Eee

a

it site URE Digeersed Wt

Fup Paceline tor cheesiest

TATORAL

OUND WATER EEF

«| [ee | D WASTIECONTAINING

CALCULATE

EQUIVALENT SO,

‘and add to

OETERMINED SO,

SLASSIFY SITE ON BASIS:

OF 0,

choose:

Type of cement

Waleddeement tatio

Cement content

hom Taiblo 1

PRE: CLASSIFY SITE ON GASIS OF pH

CHANGE:

Woterfeement ratio

Coment content

cording to Toto 2

>

Figures Tyjneaf exposure cominwns

MesEstase arene unten tnenntccon chelaean ob anead tsi

1

Reconnmentlecoent tape

Pareboceeteeutenasee Tate

IE” Gromdtevel wettabsexapllsgyee

bd Supertestoressinbond ih HO eK ofainthoene se

ry r 0

Recuurwerdedeenent type

Ferevectete crea, see Table 1

1 Grownstesctuaincapy een

py lmnicn stare watertie

Aa atat hate

SS waterable

ves Me coasts apse aw

bane

Supecsewetunesshaat

a

eee reconmenteacarecnpe Oop Z

STN Forcuncicernera se table 13

eter aererancntion te HOPKOWSO

Figen a) shouldbe stameitiseiesedehurahproceronmaghibe seeded

santa the ui well stove capilory se eo, ad with NO ik of water nteodces atthe suetace by trig

sate.

o @

foi aten, eh

For concrete eriteia

seoTable 3

ecomceded

cement ype

posure comition

GVO 0 SIA | Sptaitrsone vel)

(or Saar?) | tmtewidatzane”

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ramboll APAC Brochure - 0123 - 1-3Document21 pagesRamboll APAC Brochure - 0123 - 1-3Franky KenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E-20heat Load SheetcDocument6 pagesE-20heat Load SheetcFranky KenNo ratings yet

- 1982 08 GuidelinesForFoundationUnderAggressiveEnvironmentsDocument8 pages1982 08 GuidelinesForFoundationUnderAggressiveEnvironmentsFranky KenNo ratings yet

- 05.1 - Web STR - Client Letter - Business - To - Client-MgtDocument2 pages05.1 - Web STR - Client Letter - Business - To - Client-MgtFranky KenNo ratings yet

- TCM STR RoofDocument1 pageTCM STR RoofFranky KenNo ratings yet

- 22 Skype Interview Questions & Answers: Order ID: 0028913Document10 pages22 Skype Interview Questions & Answers: Order ID: 0028913Franky KenNo ratings yet

- 03.1 - Client Letter - Business - To - client-mgt-WebEarthDocument2 pages03.1 - Client Letter - Business - To - client-mgt-WebEarthFranky KenNo ratings yet

- Brochure10 1Document31 pagesBrochure10 1Franky KenNo ratings yet

- 3+TIPS+FOR+PASSING+YOUR+SKYPE+INTERVIEW TrackedDocument3 pages3+TIPS+FOR+PASSING+YOUR+SKYPE+INTERVIEW TrackedFranky KenNo ratings yet

- Compro Andal. Booklet. V3.R10 2020 03 10 - Compressed-R3Document54 pagesCompro Andal. Booklet. V3.R10 2020 03 10 - Compressed-R3Franky KenNo ratings yet

- Sika Solutions For Waste Water Treatment Plants LowDocument48 pagesSika Solutions For Waste Water Treatment Plants LowFranky KenNo ratings yet

- Design Advisory Committee - 12 December 2019 - MinuteDocument37 pagesDesign Advisory Committee - 12 December 2019 - MinuteFranky KenNo ratings yet

- Seismic Retro GL Masonry NepalDocument233 pagesSeismic Retro GL Masonry NepalFranky KenNo ratings yet