Professional Documents

Culture Documents

Drdiecast 2014jan

Uploaded by

sobheysaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drdiecast 2014jan

Uploaded by

sobheysaidCopyright:

Available Formats

Dr.

Die Cast

Die Casting Machinery: Putting it all together (Are we ready yet?)

Servo and proportional controls field service engineers who stated; preference. So how do you manage

were introduced on die casting “when one of our machines goes emerging technology in your die

machines as long ago as the 1970s. down, you need two people (to casting company?

The skepticism of the owners troubleshoot), an electrical techni- How much automation is

said a lot about the lack of confi- cian and a hydraulics expert. When enough? What is your idea of a

dence they held for the technol- (machine X) goes down you only “Machine cell”? Will an HMI

ogy, the skills of their staff and need a mechanic.” (Human-Machine Interface)

the availability of support from By the way, if the thought of servo improve my productivity and up

the manufacturers. The back-up controls intimidate you, don’t acti- time? Would your machine cell

plan for a “high tech” machine of vate the cruise control on your auto- be fully integrated with an HMI

that vintage was not an inventory mobile. Cruise control consists of a interface computer or PLC to

of spare parts but a “redundant, servo operated system. Many other manage and monitor the reliability

mechanically adjustable” system. areas in the modern automobile are and safety of the cell? When is it

Servo controlled flow control valve controlled by servo feedback systems time to replace rather than rebuild?

blocks could be swapped out and including climate control, “fly by Have I trained my support staff or

replaced with a manually oper- wire” throttle bodies, transmission do I have people in place who will

ated stroke adjuster to control the shifter controls, ABS, etc. embrace the technology?

fast shot velocity. Linear encoder Today there are machines that I would like to suggest that maybe

back-ups consisted of a set of limit are entirely proportional/servo it is time to take a second look at

switches mounted in parallel with controlled. There are machin- the advancements in reliability in

the encoder/tail rod. The complex- ery companies that retrofit older machine controls and peripheral

ity (and sensitivity) of the systems machines with newer controls. automation systems. They just might

was summed up by one of the In a lot of ways, it’s a matter of be cost effective after all. !

Who’s Dr. Die Cast? Bob McClintic & Associates rmcclintic@ameritech.net

Robert P. McClintic 2544 Almar Street www.drdiecast.com

Die Casting Consultant Jenison, MI 49428-9108 616.669.2932

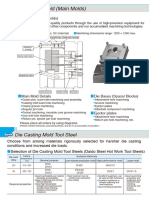

Extending Die Life: Maintenance & Welding Strategies

By: David Schwam

EXTENDING DIE LIFE:

Maintenance & Welding Strategies

Pages: 56 Item # 505 List Price: $40.00 By: David Schwam

NADCA has released a new publication based it’s popular 2012 webinar series on die care and maintenance. The

series, presented by Professor David Schwam from Case Western Reserve University, focused methods of die TEMPER

care and maintenance from the perspective of best approaches to preserve and extend die life. GOOD BAD

Understanding the failure mechanisms is important not only in the design and fabrication but also in the

maintenance and care of the dies. Following a brief review of failure mechanisms, this book describes methods

1000 F º

to make dies last longer; like preheating temperatures and temperature control during the die casting process,

spraying and internal cooling & creating a good balance between these two. The last section of this book will

cover die care and maintenance of the dies such as inspection, handling, cleaning, polishing, welding, and storage. NORTH AMERICAN DIE CASTING ASSOCIATION

Publication - 505

For more information visit www.diecasting.org/publications or email publications@diecasting.org.

www. diecasting.org/dce JANUARY 2014 1DIE CASTING ENGINEER | 11

You might also like

- Applied Automation - 2019 08Document16 pagesApplied Automation - 2019 08jairo73scribdNo ratings yet

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- v1 02Document17 pagesv1 02Ahmed Ali Alsubaih100% (3)

- Modern Approaches to Discrete, Integrated Component and System Reliability Engineering: Reliability EngineeringFrom EverandModern Approaches to Discrete, Integrated Component and System Reliability Engineering: Reliability EngineeringNo ratings yet

- Chemical Engineering Magazine 2016.03Document96 pagesChemical Engineering Magazine 2016.03Anonymous F1o5h61100% (1)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- E 452 ContentDocument16 pagesE 452 ContentPrakash AnnamalaiNo ratings yet

- Literature Review of CNC MachineDocument7 pagesLiterature Review of CNC Machinec5kgkdd4100% (1)

- Engineering School 2016-1Document1 pageEngineering School 2016-1Abdul Majid (Abdullah)No ratings yet

- Punching Machine Literature ReviewDocument4 pagesPunching Machine Literature Reviewjizogol1siv3100% (1)

- 2017 November DrdiecastDocument1 page2017 November DrdiecastsobheysaidNo ratings yet

- Safety - System ESD PSDDocument9 pagesSafety - System ESD PSDMakiber100% (1)

- Simulation Optimization Decision Support System For Ship Panel Shop OperationsDocument9 pagesSimulation Optimization Decision Support System For Ship Panel Shop Operationsfilipeacribeiro26No ratings yet

- Carat 10,500 To 92,000 KN: Highest Value Creation For Sophisticated ApplicationsDocument46 pagesCarat 10,500 To 92,000 KN: Highest Value Creation For Sophisticated ApplicationsNagaraju MuruguduNo ratings yet

- Valves in The Digital AgeDocument2 pagesValves in The Digital Agefabiano nogueiraNo ratings yet

- Volume11 Issue2 Verification Horizons Publication HRDocument60 pagesVolume11 Issue2 Verification Horizons Publication HRDeniz KurtNo ratings yet

- Manager Plant Technical Services Dow Chemical, U.S.A. Freeport, TexasDocument8 pagesManager Plant Technical Services Dow Chemical, U.S.A. Freeport, TexasAugust Carl Bokingkito MalabagoNo ratings yet

- Cellular Manufacturing ThesisDocument7 pagesCellular Manufacturing Thesishan0fus1gij2100% (2)

- CD1604 State of Technology On PLCs PACs PCsDocument39 pagesCD1604 State of Technology On PLCs PACs PCsAldrian MacuaNo ratings yet

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (1)

- Delta PackExpoInnovationStage LCMotionArchitectureSolutions 2017 0926Document32 pagesDelta PackExpoInnovationStage LCMotionArchitectureSolutions 2017 0926dangkhuyenmaiNo ratings yet

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- How To Build A Mobile Machine: From Concept To ProductionDocument3 pagesHow To Build A Mobile Machine: From Concept To ProductionThai ThazanNo ratings yet

- AB ManualDocument132 pagesAB ManualMohamed MeeranNo ratings yet

- SMT007 July2021Document110 pagesSMT007 July2021Adair NettoNo ratings yet

- CG - August 2023 - EH - Flow Measurement ll-APPROVEDDocument19 pagesCG - August 2023 - EH - Flow Measurement ll-APPROVEDabrahamkalil-1No ratings yet

- Formal Verification: An Essential Toolkit for Modern VLSI DesignFrom EverandFormal Verification: An Essential Toolkit for Modern VLSI DesignRating: 4 out of 5 stars4/5 (4)

- Dissertation Cad CamDocument7 pagesDissertation Cad CamHelpWithWritingPaperSiouxFalls100% (1)

- Schneider Final Distribution WD Light Control Pricelist - WEF 1st Nov., 2018Document68 pagesSchneider Final Distribution WD Light Control Pricelist - WEF 1st Nov., 2018chauhanrinkuNo ratings yet

- Board ManualDocument40 pagesBoard ManualMicu Adrian DanutNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Chemical Engineering-May 2013-The Petroleum Refining OutlookDocument90 pagesChemical Engineering-May 2013-The Petroleum Refining OutlookDan MatNo ratings yet

- Whitepaper Dcs Migrations IstecDocument17 pagesWhitepaper Dcs Migrations IstecRohit ShahNo ratings yet

- Life-Cycle Costing: Using Activity-Based Costing and Monte Carlo Methods to Manage Future Costs and RisksFrom EverandLife-Cycle Costing: Using Activity-Based Costing and Monte Carlo Methods to Manage Future Costs and RisksNo ratings yet

- Basics of Balancing 202Document8 pagesBasics of Balancing 202Nigo VillanNo ratings yet

- Steckel Mill 1 PDFDocument178 pagesSteckel Mill 1 PDFSomnathNaskarNo ratings yet

- Drdiecast 2011mayDocument2 pagesDrdiecast 2011maysobheysaidNo ratings yet

- Mechatronics Control Kit User'S Manual: Important Notice!Document56 pagesMechatronics Control Kit User'S Manual: Important Notice!eedemvarerNo ratings yet

- Assembly Part Handling.Document3 pagesAssembly Part Handling.anuradhaNo ratings yet

- I/O Systems: State of Technology ReportDocument35 pagesI/O Systems: State of Technology ReportVignesh RajanNo ratings yet

- NI Mechatronics Machine Design GuideDocument46 pagesNI Mechatronics Machine Design GuideGautam TyagiNo ratings yet

- Zinc Whiskers What You Should Know NowDocument6 pagesZinc Whiskers What You Should Know NowPrasetya W.INo ratings yet

- IE 458-Design For AssemblyDocument33 pagesIE 458-Design For AssemblymustufahaiderNo ratings yet

- Robust Tactical Qualification Decisions in Flexible ManufacturingDocument18 pagesRobust Tactical Qualification Decisions in Flexible ManufacturingNguyen QuynhNo ratings yet

- Engineering Documentation Control / Configuration Management Standards ManualFrom EverandEngineering Documentation Control / Configuration Management Standards ManualNo ratings yet

- Beyond The Big BrandsDocument3 pagesBeyond The Big BrandsEva LianNo ratings yet

- 41finger Print Based ATM and Locker SystemDocument118 pages41finger Print Based ATM and Locker Systempankaj_yadav007100% (2)

- PLC Vs DCSDocument3 pagesPLC Vs DCSjavierlinceNo ratings yet

- Seminarbrochure 2023 EnglishDocument13 pagesSeminarbrochure 2023 EnglishShadab AmeenNo ratings yet

- Optimal Control System Company Profile PDFDocument9 pagesOptimal Control System Company Profile PDFkarna patelNo ratings yet

- Medical Device Design for Six Sigma: A Road Map for Safety and EffectivenessFrom EverandMedical Device Design for Six Sigma: A Road Map for Safety and EffectivenessNo ratings yet

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Advanced Distillation Operation, Control, and Troubleshooting Training CourseDocument9 pagesAdvanced Distillation Operation, Control, and Troubleshooting Training CourseKarl KloudtNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Geneamp PCR System 9700Document53 pagesGeneamp PCR System 9700Bhavesh JoshiNo ratings yet

- Drdiecast 2010novDocument1 pageDrdiecast 2010novsobheysaidNo ratings yet

- DCM Part Shots August 2002Document1 pageDCM Part Shots August 2002sobheysaidNo ratings yet

- Drdiecast 2012marDocument1 pageDrdiecast 2012marsobheysaidNo ratings yet

- Semi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCDocument15 pagesSemi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCsobheysaidNo ratings yet

- Die Casting Design TipsDocument3 pagesDie Casting Design TipssobheysaidNo ratings yet

- Vier Cylinders 2022Document2 pagesVier Cylinders 2022sobheysaidNo ratings yet

- Die CastingDocument1 pageDie CastingsobheysaidNo ratings yet

- Rust Veto 211 D 1214 GB 0Document1 pageRust Veto 211 D 1214 GB 0sobheysaidNo ratings yet

- 2017 November DrdiecastDocument1 page2017 November DrdiecastsobheysaidNo ratings yet

- DCM Part Shots December 2002Document1 pageDCM Part Shots December 2002sobheysaidNo ratings yet

- 1 Introduction Ams Feb18 17Document41 pages1 Introduction Ams Feb18 17sobheysaidNo ratings yet

- GL XX Mobilarma 200Document2 pagesGL XX Mobilarma 200sobheysaidNo ratings yet

- Cimstar Qualstar LFZDocument2 pagesCimstar Qualstar LFZsobheysaidNo ratings yet

- Cimtech 609e - InsolDocument2 pagesCimtech 609e - InsolsobheysaidNo ratings yet

- Translean FREE 5S Checklist and Control ChartDocument1 pageTranslean FREE 5S Checklist and Control ChartsobheysaidNo ratings yet

- Tech Uddeholm-Vancron ENDocument11 pagesTech Uddeholm-Vancron ENsobheysaidNo ratings yet

- Product Information Flyer: Cimtech® 410CDocument2 pagesProduct Information Flyer: Cimtech® 410CsobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 285Document2 pagesProduct Information Flyer: CIMTECH® 285sobheysaidNo ratings yet

- Product Information Flyer: Producto RI-923Document2 pagesProduct Information Flyer: Producto RI-923sobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 420Document2 pagesProduct Information Flyer: CIMTECH® 420sobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 495-OIDocument2 pagesProduct Information Flyer: CIMTECH® 495-OIsobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 500Document2 pagesProduct Information Flyer: CIMTECH® 500sobheysaidNo ratings yet

- CIMTECH 400 With MSLDocument2 pagesCIMTECH 400 With MSLsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® 40Document2 pagesProduct Information Flyer: Cimstar® 40sobheysaidNo ratings yet

- Product Information Flyer: Cimstar® Qual Star XLDocument2 pagesProduct Information Flyer: Cimstar® Qual Star XLsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® Qual StarDocument2 pagesProduct Information Flyer: Cimstar® Qual StarsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® GPDocument2 pagesProduct Information Flyer: Cimstar® GPsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® 40LfDocument2 pagesProduct Information Flyer: Cimstar® 40LfsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® 55CDocument2 pagesProduct Information Flyer: Cimstar® 55CsobheysaidNo ratings yet

- Product Information Flyer: CIMSTAR® 3890Document2 pagesProduct Information Flyer: CIMSTAR® 3890sobheysaidNo ratings yet

- Quick Start Guide For The Futures Trading Secrets ProgramDocument4 pagesQuick Start Guide For The Futures Trading Secrets ProgramH C LimNo ratings yet

- Human Eye WorksheetDocument3 pagesHuman Eye Worksheetcartooncompany73No ratings yet

- Glucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionDocument2 pagesGlucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionRushikesh uNo ratings yet

- م م م م م م م م Kkkk אلد אلد אلد אلد א א א א Llll دאوאدא دאوאدא دאوאدא دאوאدאDocument47 pagesم م م م م م م م Kkkk אلد אلد אلد אلد א א א א Llll دאوאدא دאوאدא دאوאدא دאوאدאYoucef kahlrsNo ratings yet

- SK Pradhan ObituaryDocument1 pageSK Pradhan Obituarysunil_vaman_joshiNo ratings yet

- Ahmad Faizal Bin Ahmad Zahari (Resume)Document15 pagesAhmad Faizal Bin Ahmad Zahari (Resume)ahmad faizalNo ratings yet

- Contoh Sterilefiltration Pada Viral Vaccine Live AtenuatedDocument10 pagesContoh Sterilefiltration Pada Viral Vaccine Live Atenuatedkomang inggasNo ratings yet

- Sinamics FrekvensomformereDocument30 pagesSinamics Frekvensomformeremfonseca31No ratings yet

- R Gupta - Joint CSIR-UGC NET JRF Physical Sciences (2021, Ramesh Publishing House) - Libgen - LiDocument378 pagesR Gupta - Joint CSIR-UGC NET JRF Physical Sciences (2021, Ramesh Publishing House) - Libgen - LiVasudevan SubramaniyanNo ratings yet

- CH4404 Process Technology 1Document6 pagesCH4404 Process Technology 1hannahNo ratings yet

- App Chem Assign 1Document7 pagesApp Chem Assign 1Furqan MughalNo ratings yet

- Zero Gravity ManufacturingDocument17 pagesZero Gravity Manufacturingsunny sunnyNo ratings yet

- Original PDFDocument7 pagesOriginal PDFPriyaKumarNo ratings yet

- Introduction To Noise in Adc Systems: Ti Precision Labs - AdcsDocument15 pagesIntroduction To Noise in Adc Systems: Ti Precision Labs - AdcsSouptik PaulNo ratings yet

- Hight Speep Tool SteelDocument11 pagesHight Speep Tool SteelcadcamtaiNo ratings yet

- A Blessing and A Curse CEO Empathy by Andreas Konig - Case DownloadedDocument25 pagesA Blessing and A Curse CEO Empathy by Andreas Konig - Case Downloadedsarthak sethNo ratings yet

- Radar Systems Engineering - MATLAB & SimulinkDocument2 pagesRadar Systems Engineering - MATLAB & SimulinkAdfgatLjsdcolqwdhjpNo ratings yet

- Resume and AppDocument3 pagesResume and AppLORNA GUIWANNo ratings yet

- Use ArcGIS Dashboards To Share Imagery ResultsDocument12 pagesUse ArcGIS Dashboards To Share Imagery ResultsAlexandra RizacNo ratings yet

- ESM VS90 132 Brochure WorkDocument8 pagesESM VS90 132 Brochure WorkKM KarthikNo ratings yet

- Bath Uni Coursework Cover SheetDocument8 pagesBath Uni Coursework Cover Sheetvtdvkkjbf100% (2)

- Overtaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorDocument7 pagesOvertaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorJustamNo ratings yet

- Theory Summarized R1 To R5Document10 pagesTheory Summarized R1 To R5ALINDOGAN, KimleeNo ratings yet

- System Learning Plan Preparation: Krislizz International AcademyDocument11 pagesSystem Learning Plan Preparation: Krislizz International AcademyQhutie Little CatNo ratings yet

- Preboard Exam 1: Structural Engineering and ConstructionDocument6 pagesPreboard Exam 1: Structural Engineering and ConstructionEllen Bumal-oNo ratings yet

- Revision - The 1 Term Test Grade 12: A.Exercises I. PronunciationDocument16 pagesRevision - The 1 Term Test Grade 12: A.Exercises I. PronunciationBách LêNo ratings yet

- 2 TLE-CSS - SOP FinalDocument4 pages2 TLE-CSS - SOP FinalMam Lorna Es GeeNo ratings yet

- Research Paper 3 PDFDocument28 pagesResearch Paper 3 PDFSushmaSahuNo ratings yet

- Katalog Toplotne Pumpe Kompletan EngDocument48 pagesKatalog Toplotne Pumpe Kompletan EngVladimir ZaljevskiNo ratings yet

- Mark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Sentence That Best Combines Each Pair of Sentences in The Following QuestionsDocument14 pagesMark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Sentence That Best Combines Each Pair of Sentences in The Following QuestionsPhạm Trần Gia HuyNo ratings yet