0% found this document useful (0 votes)

82 views4 pagesFTE Series Float & Thermostatic Traps

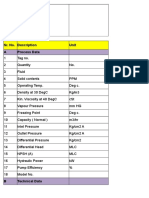

The document describes FTE series float and thermostatic steam traps. The steam traps have cast iron, ductile iron, or cast steel bodies and can operate at pressures up to 485 PSIG and temperatures up to 752°F. They contain a stainless steel thermostatic element, float, and lever mechanism to discharge condensate and vent air and gases. The document provides specifications, materials of construction, operating conditions, and maximum capacity tables for the different steam trap models.

Uploaded by

Alvaro Yaciel Rodríguez LagunesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

82 views4 pagesFTE Series Float & Thermostatic Traps

The document describes FTE series float and thermostatic steam traps. The steam traps have cast iron, ductile iron, or cast steel bodies and can operate at pressures up to 485 PSIG and temperatures up to 752°F. They contain a stainless steel thermostatic element, float, and lever mechanism to discharge condensate and vent air and gases. The document provides specifications, materials of construction, operating conditions, and maximum capacity tables for the different steam trap models.

Uploaded by

Alvaro Yaciel Rodríguez LagunesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd