Professional Documents

Culture Documents

EDGE 475-500 7831 Performance Chart

EDGE 475-500 7831 Performance Chart

Uploaded by

Leonardo BarriosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EDGE 475-500 7831 Performance Chart

EDGE 475-500 7831 Performance Chart

Uploaded by

Leonardo BarriosCopyright:

Available Formats

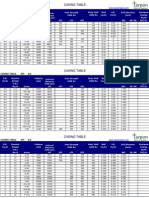

4.75" | 5.

00" 7831

(121 mm) (127 mm) CONFIGURATION

SPECIFICATIONS IMPERIAL METRIC LENGTH IMPERIAL METRIC

Maximum Differential Pressure 700 psi (4,825 kPa) (A) to Stabilizer 13.50 in (0.34 m)

Torque at Maximum Differential 5,460 ft-lb (7,405 N-m) (B) to Adj. Bend 54.76 in (1.39 m)

Stall Torque 8,190 ft-lb (11,105 N-m) (B) to Fixed Bend 48.00 in (1.22 m)

Flow Range 150 - 300 gpm (568 - 1,136 lpm) (C) Overall 334.51 in (8.50 m)

RPM Ratio 0.32 Revolutions / g (0.08 Revolutions / l)

RPM Range 47 - 95 rpm (47 - 95 rpm)

Recommended Hole Sizes 6.00 - 6.75 in (152 - 171 mm) ADJUSTABLE IMPERIAL METRIC

Maximum Weight on Bit 77,000 lb (34,300 daN) Make-Up ValueT T12,000 ft-lbT(16,300 N-m)T

Maximum Overpull (Static) 212,000 lb (94,300 daN)

Overall Weight 1,225 lb (556 kg)

Power Curve: 0 - 70% 71 - 80% 81 - 100% HARD RUBBER

6,000

100 300 gpm (1,136 lpm) (8,135)

90

Maximum Differential Pressure

Revolutions Per Minute - rpm

80 4,500

Torque - ft-lb (N-m)

225 gpm (852 lpm) (6,101)

70

60

50 150 gpm (568 lpm) 3,000

(4,067)

40

30

1,500

20 (2,034)

10

0 0

0 100 200 300 400 500 600 700 800

(689) (1,379) (2,068) (2,758) (3,447) (4,137) (4,826) (5,516)

Differential Pressure - psi (kPa)

0 - 3° ADJUSTABLE Degrees / 100 ft (30 m) FIXED HOUSING Degrees / 100 ft (30 m)

BEND 6.00" HOLE SIZE 6.25" HOLE SIZE 6.75" HOLE SIZE BEND 6.00" HOLE SIZE 6.25" HOLE SIZE 6.75" HOLE SIZE

0.39° 1.4 2.4 0.2 2.6 - 2.9 P 1.50° 8.9 9.9 7.6 10.0 5.1 10.3 P

0.78° 4.0 5.0 2.7 5.1 0.2 5.5 R 1.75° 10.5 11.5 9.3 11.7 6.8 12.0 R

C E E

1.15° 6.4 7.4 5.1 7.5 2.6 7.9 D 1.90° 11.5 12.5 10.3 12.7 7.7 13.0 D

1.50° 8.6 9.6 7.4 9.8 4.9 10.1 I 2.00° 12.2 13.2 10.9 13.3 8.4 13.7 I

1.83° 10.8 11.8 9.5 11.9 7.0 12.3 C 2.12° 13.0 14.0 11.7 14.1 9.2 14.5 C

T T

2.12° 12.6 13.6 11.4 13.8 8.9 14.1 E 2.25° 13.8 14.8 12.6 15.0 10.1 15.3 E

2.38° 14.3 15.3 13.1 15.5 10.6 15.8 D 2.50° 15.5 16.5 14.2 16.6 11.7 17.0 D

2.60° 15.7 16.7 14.5 16.9 12.0 17.2 B 2.60° 16.1 17.1 14.9 17.3 12.4 17.6 B

U U

1 STAB

1 STAB

1

STAB

SLICK

SLICK

SLICK

2.77° 16.8 17.8 15.6 18.0 13.1 18.3

I I

2.90° 17.7 18.7 16.4 18.8 13.9 19.2 L L

B

2.97° 18.1 19.1 16.9 19.3 14.4 19.6 D D

3.00° 18.3 19.3 17.1 19.5 14.6 19.8 S S

1 STAB

SLICK

1 STAB

SLICK

1 STAB

SLICK

Figures are for reference only. Stabilized build rates assume a lower stabilizer 0.125" undergauge.

Actual performance may vary based on tool and operating conditions. Refer to temperature and

A mud scaling curves for optimal performance and reliability. Rotating above 1.50° may cause

damage to the performance motor at certain RPM's. Running above 80% will be done so at

client's risk. Contact your R3 EDGE representative to confirm ideal operating specifications.

Updated July 2014.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Casing TableDocument29 pagesCasing TableTafhim HimelNo ratings yet

- DynaDrill (SLB) 5 IN 7-8 Lobe 8.4 STGDocument1 pageDynaDrill (SLB) 5 IN 7-8 Lobe 8.4 STGLeonardo BarriosNo ratings yet

- EDGE 475-500 - 7845 Performance ChartDocument1 pageEDGE 475-500 - 7845 Performance ChartLeonardo BarriosNo ratings yet

- BP Terms and AbbreviationsDocument2 pagesBP Terms and AbbreviationsLeonardo BarriosNo ratings yet

- 12.250 TKC66Document1 page12.250 TKC66Leonardo Barrios100% (1)

- 12.25 T606XDocument1 page12.25 T606XLeonardo BarriosNo ratings yet

- Mecha 6.75-GT64D-1036837 6inch GaugeDocument1 pageMecha 6.75-GT64D-1036837 6inch GaugeLeonardo BarriosNo ratings yet

- Mecha 6.5-MME84-910000Document1 pageMecha 6.5-MME84-910000Leonardo BarriosNo ratings yet

- Mecha 6.75-GT64D-1033973 RSS BitDocument1 pageMecha 6.75-GT64D-1033973 RSS BitLeonardo BarriosNo ratings yet

- Shock Sub Tool: Impact and Vibration Reduction ToolDocument4 pagesShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Stabilizer Product SheetDocument2 pagesStabilizer Product SheetLeonardo BarriosNo ratings yet

- SPC Zones of TexasDocument1 pageSPC Zones of TexasLeonardo BarriosNo ratings yet

- CSG Fraccing ChemicalsDocument1 pageCSG Fraccing ChemicalsLeonardo BarriosNo ratings yet

- Scoping Doc For HHRESDocument3 pagesScoping Doc For HHRESLeonardo BarriosNo ratings yet