Professional Documents

Culture Documents

Marine Spec 12V2000M61 1A

Marine Spec 12V2000M61 1A

Uploaded by

Lucas PereiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Spec 12V2000M61 1A

Marine Spec 12V2000M61 1A

Uploaded by

Lucas PereiraCopyright:

Available Formats

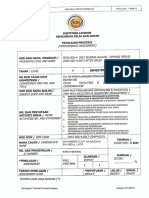

Marine

DIESEL ENGINE 12V 2000 M61

for vessels with unrestricted continuous operation (1A)

Engine Dimensions (LxWxH) mm (in) Mass, dry kg (lbs)

M61 1890x1400x1290 (74.4x55.1x50.8) 2600 (5732)

Engine with

Dimensions (L1xWxH₁) mm (in) Mass, dry kg (lbs)

gearbox type*

M61 - ZF 3050 2692x2130x2009 (106.0x83.9x79.1) 3290 (7253)

* gear ratio on request

Specifications are subject to change without notice. All dimensions are approximate, for complete information

refer to installation drawing. For further information consult your MTU distributor/dealer.

Typical applications: Work Boats, Ferries, Tugs, Barges and Large Sailing Yachts

Optional equipment and finishing shown. Standard may vary.

Engine type 12V 2000 M61

Rated power ICFN kW 600

(bhp) (805)

Speed rpm 1800

No. of cylinders 12

Bore/stroke mm (in) 130/150 (5.1/5.9)

Displacement, total l (cu in) 23.9 (1458)

Flywheel housing SAE 0

Gearbox model ZF 3050

Optimization of exhaust emissions* IMO II/EPA 2/CCNR II

Solas compliance Yes (without optional accessory kit)

* IMO – International Maritime Organisation

EPA – US Marine Directive 40 CFR 94

ReihnSchUO - CCNR, Stage II

Performance & fuel consumption 1) 12V 2000 M61 12V 2000 M61 12V 2000 M61

Speed rpm 1800 1600 1200

Maximum power kW 600 600 400

(bhp) 805 805 537

Power on propeller curve (n3) kW 600 420 180

(bhp) 805 563 241

Fuel consumption g/kWh 215 209 214

on propeller curve l/hr 129 87.8 38.5

gal/h 34.1 23.2 10.2

1) Tolerance +5% per ISO 3046, Diesel fuel to DIN EN 590 with a min L.H.V. of 42800 kJ/kg (18390 BTU/lb)

All pumps necessary for engine operation included. Heat exchanger version without sea water pump: -2 g/kWh

Standard equipment

Starting system Electrical starter 24 VDC

Auxiliary PTO Alternator, 140A, 28V, 2 pole

Gear driven lube oil pump, lube-oil duplex filter with diverter valve, lube-oil heat

Oil system

exchanger, handpump for oil extraction

Fuel feed pump, fuel pre-filter, fuel main filter with diverter valve, on-engine fuel oil

Fuel system

cooler, leak-off tank level monitored

Coolant-to-raw water plate core heat exchanger, self priming centrifugal raw water pump,

Cooling system

gear driven coolant circulation pump

Turbocharging with 2 water-cooled exhaust-gas turbochargers, on-engine intake air

Combustion air system

filters

Triple-walled, liquid-cooled, on-engine exhaust manifolds, twin exhaust outlet, exhaust

Exhaust system

bellows horizontal discharge

Mounting system Resilient mounts at free end

Engine management system Engine control and monitoring system (MDEC)

Optional equipment

Auxiliary PTO Alternator, 200A, 28V, 2 pole, bilgepump, on-engine PTOs

Fuel System Duplex fuel prefilter, fuel conditioning system

Subject to change. | 3234171 | Edition 01/19 | ESM 2019-08.

Cooling System Coolant preheating system, integr. seawater gearbox piping

Exhaust System Exhaust bellows vertical discharge SOLAS Kit

Mounting System Resilient mounts at driving end

Engine Management System In compliance with Classification Society Regulations (EMU+MEU)

Monitoring / Control System smartline, blueline, bluevision

Power Transmission Torsionally resilient coupling

Reverse reduction gearbox, el. actuated, gearbox mounts, trolling mode, trailing mode

Gearbox Options

free auxiliary PTO, hydraulic pump drives

Reference conditions:

> Power definition according ISO 3046

> Intake air temperature 25°C/Sea water temperature 25°C

> Intake air depression 15 mbar/Exhaust back pressure 30 mbar

> Barometric pressure 1000 mbar

Customization possible. Engines illustrated in this document may feature options not fitted as standard to standard engine.

Rolls-Royce Group

www.mtu-solutions.com

You might also like

- Tarea 2 EstadisticaDocument11 pagesTarea 2 EstadisticaDamián OR40% (5)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- International Standard: Small Craft - Deck Safety Harness and Safety Line - Safety Requirements and Test MethodsDocument24 pagesInternational Standard: Small Craft - Deck Safety Harness and Safety Line - Safety Requirements and Test MethodsnaufragatoNo ratings yet

- Howard Fine Suggested Female Audition Pieces 2013Document21 pagesHoward Fine Suggested Female Audition Pieces 2013CatherineEmilyLangleyNo ratings yet

- CRMDocument99 pagesCRMSudhir KumarNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- Offshore Electrical EngineeringFrom EverandOffshore Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Power Electronics Design Handbook: Low-Power Components and ApplicationsFrom EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesFrom EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesRating: 3 out of 5 stars3/5 (1)

- Propulsion_Engine_Performance_and_Emissions_Parameters_Mapping_accepted_20130627Document40 pagesPropulsion_Engine_Performance_and_Emissions_Parameters_Mapping_accepted_20130627naufragatoNo ratings yet

- Test bench algorithms for catamaran roll simulation (Lipko)Document11 pagesTest bench algorithms for catamaran roll simulation (Lipko)naufragatoNo ratings yet

- Research on Rolling Motion Mode of a Catamaran unmanned craft with Monitoring Function (Yongqiang-Songlin-Yang-Man-Xiaoping)Document6 pagesResearch on Rolling Motion Mode of a Catamaran unmanned craft with Monitoring Function (Yongqiang-Songlin-Yang-Man-Xiaoping)naufragatoNo ratings yet

- Transom Plate AdaptorDocument8 pagesTransom Plate AdaptornaufragatoNo ratings yet

- Gard Guidance On Freight Containers: Jeroen de HaasDocument171 pagesGard Guidance On Freight Containers: Jeroen de HaasnaufragatoNo ratings yet

- Diesel Engine S60: MarineDocument2 pagesDiesel Engine S60: MarinenaufragatoNo ratings yet

- Feeder Service To Promote Revitalization of The Container Transport in The Adriatic PortsDocument8 pagesFeeder Service To Promote Revitalization of The Container Transport in The Adriatic PortsnaufragatoNo ratings yet

- 5 - Passenger Ships Reference ListDocument21 pages5 - Passenger Ships Reference ListnaufragatoNo ratings yet

- Relazione Prof. Favaro Seminario - UD - 9.7.18 Caricazione ContainerDocument33 pagesRelazione Prof. Favaro Seminario - UD - 9.7.18 Caricazione ContainernaufragatoNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M93: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M93: MarinenaufragatoNo ratings yet

- Diesel Engine 8V 2000 M61: MarineDocument2 pagesDiesel Engine 8V 2000 M61: MarinenaufragatoNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M72: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M72: Marinenaufragato100% (1)

- Marine Spec 10V12V16V2000M86 1DDocument2 pagesMarine Spec 10V12V16V2000M86 1DnaufragatoNo ratings yet

- Numerical Investigation On Seakeeping Performance of SWATH With Three Dimensional Translating-Pulsating Source Green Function (Sun-Yao-Ye)Document11 pagesNumerical Investigation On Seakeeping Performance of SWATH With Three Dimensional Translating-Pulsating Source Green Function (Sun-Yao-Ye)naufragatoNo ratings yet

- PSICOLOGIA DA APRENDIZAGEM - BehaviorismoDocument12 pagesPSICOLOGIA DA APRENDIZAGEM - BehaviorismoArtur CordeiroNo ratings yet

- Tabela EquivalenciaDocument49 pagesTabela EquivalenciaOctavioCiconeNo ratings yet

- Biology CHP.17 Introduction To BiotechnologyDocument7 pagesBiology CHP.17 Introduction To BiotechnologySanjay BandkarNo ratings yet

- DLP Day 1Document3 pagesDLP Day 1Aisley Mae EspinarNo ratings yet

- Sunafil Preguntasseguridadysaludeneltrabajo 150522123858 Lva1 App6892Document38 pagesSunafil Preguntasseguridadysaludeneltrabajo 150522123858 Lva1 App6892Samuel100% (1)

- Desigualdades e InecuacionesDocument31 pagesDesigualdades e Inecuacionesaldimo64No ratings yet

- Penyelaras Penggunaan Kemudahan Dan InventoriDocument13 pagesPenyelaras Penggunaan Kemudahan Dan InventoriIzzat D-OneNo ratings yet

- Demanda Elvira MárquezDocument4 pagesDemanda Elvira MárquezLey MárquezNo ratings yet

- Memoria Descriptiva MirmacaDocument9 pagesMemoria Descriptiva MirmacaElmer BarrientosNo ratings yet

- 20928630Document6 pages20928630Eliecer Ortiz TapiasNo ratings yet

- Taouririt Kamel MemoireDocument188 pagesTaouririt Kamel Memoirekais ben mimounNo ratings yet

- PertDocument52 pagesPertMuhammad FawadNo ratings yet

- Caso Práctico Módulo 3Document3 pagesCaso Práctico Módulo 3Jhossiel Rodríguez RoblesNo ratings yet

- 636 401S418Document108 pages636 401S418Pedro Jose Aguilera MoralesNo ratings yet

- Imamate PDFDocument16 pagesImamate PDFsaidatuladaniNo ratings yet

- V GowinDocument42 pagesV GowinJoão Carlos Calado100% (1)

- Caso SilverDocument8 pagesCaso SilverRicardo FloresNo ratings yet

- Running Page: Internet Webpage 1Document3 pagesRunning Page: Internet Webpage 1lucyNo ratings yet

- New Process For Separating Propylene and Propane by Extractive Distillation With Aqueous AcetonitrileDocument8 pagesNew Process For Separating Propylene and Propane by Extractive Distillation With Aqueous AcetonitrileLoren LyleNo ratings yet

- Diseño LogicoDocument13 pagesDiseño LogicoMickelNo ratings yet

- BT5ADocument1 pageBT5AdcabreralNo ratings yet

- ABAQUS Python TutorialDocument4 pagesABAQUS Python TutorialAtul ChauhanNo ratings yet

- Biography of Srila PrabhupadaDocument2 pagesBiography of Srila Prabhupadamapl2891No ratings yet

- Case Study: Fraser Foods (FF)Document10 pagesCase Study: Fraser Foods (FF)EtNo ratings yet

- Declaracion de Impacto Ambiental para Una Planta de Acopio de Materiales RR - SsDocument54 pagesDeclaracion de Impacto Ambiental para Una Planta de Acopio de Materiales RR - SsRoyer Araujo Mejia100% (1)

- Good Transition Words in A Research PaperDocument5 pagesGood Transition Words in A Research Paperguzxwacnd100% (1)

- 1.1 Anteproyecto de La Etica EmpresarialDocument37 pages1.1 Anteproyecto de La Etica EmpresarialKelly Contreras CarreñoNo ratings yet