Professional Documents

Culture Documents

2021 GMC Breach & Sanction

2021 GMC Breach & Sanction

Uploaded by

Theophilus Oduro-Nyarko0 ratings0% found this document useful (0 votes)

9 views8 pagesGmc

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGmc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views8 pages2021 GMC Breach & Sanction

2021 GMC Breach & Sanction

Uploaded by

Theophilus Oduro-NyarkoGmc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

MINERALS COMMISSION

Mineral House # 12 Switchback Road Residential Area, Cantonment

GL.060-1131

P.O. Box M248, Accra-Ghana

[BE (238 302) 772789 1 779828/773053 / 771318 FAX: (239 302)773524

E-mail info@mincom.gov.gh, Website: wwwmincom.gov.gh

ID/F/Vol.2187

May 4, 2021

The General Mine Manager

Ghana Manganese Company

P.O. Box M183

Aoora.

RE: REPORT OF INVESTIGATION INTO A FATAL ACCIDENT INVOLVING

MB. ROLAND KUTULAM ON STH APRIL 20217 — MINERALS AND MINING (HEALTH,

SAFETY& TECHNICAL) REGULATIONS 12f, 16, 17, 26 OF 2012 (L, |. 2182). GHANA

MANGANESE COMPANY (GMC) LIMITED

We refer to an accident investigation report in respect ofthe accident on the above subject matter

as conducted by the Principal Inspector of Mines (Machinery) of the Takoradi Office.

‘The investigations conducted indicated the following Findings, Recommendations and Sanctions:

1. Findings

Having inspected the scene of the accident and interviewed the witnesses present during

and after the accident and workmen from some auxiliary departments, we find that:

i. The deceased (Roland Kutulam) and other three injured workmen (Edward Fynn,

Robert Quansah and Patrick Obeng Afum) went on night duty on the 8" April 2021

ii, The workmen were tasked to remove interlocked boulders from the ROM bin

discharge end.

il The workmen were using a lifting chain sling and an overhead crane in aiding the

removal of the interlocked boulders from the ROM bin.

\v. It appears the night workmen did not go through proper risk assessment before

commencement of the task.

vi.

Vii

viii.

xi

xii

xii

xiv.

The workmen reported to work at about 6:00pm and started work at about 6:15pm

making it impossible for them to have gone through proper risk assessment and

the isolation procedures in less than 15 minutes before starting the task.

One person's handwriting was found to have written the names for three workmen

involved in the activity on the risk assessment form.

Different signature for the deceased (Roland Kutulam) was found on the risk

assessment sheet and other training sheets indicating that somebody signed the

risk assessment for the deceased after the accident had occurred.

No supervisor or safety officer took part in the risk assessment and isolation

procedures for the task.

Isolation (lockout, tag out and tryout) was not properly done. This is because the

deceased (Roland Kutulam) had his padlock inside his locker as at 15" April 2021

when the locker was forced opened by the investigation team. His isolock should

have been on the isolation panel.

Ill trained and incompetent contract plant operators were hired from K. KANSCO

Company Limited to undertake services on the mine.

The crane was inspected and tested on the 8" April 2021 by the maintenance team

before commencement of the task and found to be in good condition.

The overhead crane operator was not trained and certified.

The Safety Department failed to ensure proper documentation and best safety

practices on the mine.

The accident occurred in the presence of the production superintendent and two

supervisors.

The process used for dislodging or removing the interlocked boulders from the

ROM bin discharge end was wrong. The use of a chain sling and the overhead

crane for removal of boulders at this area is only acceptable when the crusher has

chocked with boulders. To dislodge interlocked boulders from the ROM bin

discharge end, a metal bar is normally used.

The metal bars for the removal of the boulders when chocked in the ROM bin were

at their disposal but they did not make use of them.

vill

xix.

xx

xxi

xxili,

wiv.

xxv,

There were traces of yellow paint from the cross beam on the runways at where

the cross beam of the crane was positioned. This indicated that there was

structural stress between the cross beam and the runways due to overloading of

the crane and this pulled the cross beam together with the crane hoist down.

There were dents on the upper parts of the discharge point of the ROM bin and

the lifting chain sling as well as the throat of the hoist lifting hook.

Some of the metal components at the upper part of the discharge end of the ROM

bin had broken off with shinny surfaces indicating fresh cuts.

There was a deflection (bend) in the cross beam holding the hoist after the beam

was removed and positioned outside the accident scene.

The evidence at the scene of the accident appeared to suggest that while the

workmen were lifting the interlocked boulders the lifting chain got entangled with

the upper part of the ROM bin discharge end. Because the bin was heavier than

the capacity of the crane, there was a generation of tension between the ROM bin,

the lifting chain sling and the crane resulting in the failure of the cross beam of the.

hoist.

‘The boulders the workmen claimed to be lifting were not heavy enough and under

no circumstance should the weight from these boulders bring a whole cross beam

together with the crane down.

‘The production supervisors and the superintendent were present during the time

the task was being carried out but they did not ensure that the right procedures

were followed.

The production supervisors and the superintendent were negligent in the

discharge of their duties as the supervision was very poor. Those who were not

directly involved in the task found themselves (Isaac Adade and Emanuel Baidoo)

among the team.

Workmen were not paying attention during the dislodging of the interlocked

boulders at the Osborn crusher discharge end because they would have seen that

the chain sling had entangled with the upper part of the ROM bin discharge end

causing heavy tension between the ROM bin, the chain sling and the overhead

wowvi.

xxvii

xxviii

xxix.

200

xii,

worl,

rx.

xxiv,

crane. They would have also heard a heavy noise among the steel members.

Thus, the crane super structures and the ROM bin.

The negligence and incompetence exhibited by the crane operator during lifting

operations contributed to the failure of the cross beam of the crane. He overloaded

the crane and the support structures.

The accident was poorly reported to the Emergency Respond Team (ERT) as the

reporter did not indicate the nature of the accident and the number of injured

involved.

Emergency response and rescue procedures were not properly carried out. Thus,

* One ambulance for multiple injured workmen.

+ People without first aid training were the first to handle the injured.

* Aperson with waist injury was asked to sit at the front seat of the ambulance

instead of putting him at the recovery position.

‘* The rescue procedures were delayed as the ambulance stopped and picked

an

injured person who was standing at the roadside even though the

ambulance was

carrying seriously injured casualty.

The ERT breached the emergency response procedures which had been

established in the mine.

There were inadequate drivers for the ERT.

The injured were not accessed on the scene by the ERT before taking them to the.

mine hospital.

There was no paramedic in the ERT.

The three injured persons (Edward Fynn, Robert Quansah and Patrick Obeng

Afum) were discharged from the mine hospital on 10! April 2021

Only the staff in the IT Department had access to the IT server.

The only camera for the Osborn crusher area where the accident occurred was

found not to be working. Meanwhile, all the remaining 35 cameras on site were

working,

rowvii

il.

vi

vii.

vill,

xi,

xii.

xill

The last footage recovered from the camera monitoring the Osborn crusher CP01

area was dated 28 August 2020.

Neither the staff in the IT Department nor the control room operators were able to

detect the malfunctioning of the only camera at the Osborn Crusher CP01 area

where the accident occurred.

. Recommendations

Proper risk assessment should be carried out prior to commencement of every

task on the mine. The supervisors and the safety officers should partake in the risk

assessment, The risk assessment should be approved by the supervisors before

commencement of every task

Isolation procedures (lockout, tag out and tryout) should be done before every

equipment is worked on.

Every team member should endorse on the risk assessment form before

commencement of every task.

Approved SOPs should be followed when executing every task on the mine.

There should be continuous and effective supervision for every task on the mine.

Only the workmen who took part in the risk assessment for a particular task can

partake in that activity,

Workmen should concentrate fully when executing any task on the mine.

Only competent and certified equipment operator shall operate a crane and any

other machine on the mine.

Only trained and certified riggers should be used in lifting operations.

There should be effective training for the workmen on the emergency response

procedures established on the mine.

Qualified emergency response personnel and paramedics should be maintained

at the Emergency Response Department.

Management should engage adequate and trained drivers for the Emergency

Response Department.

Every supervisor in operational areas should be provided with two (2) way radio

for communication

xiv,

xviii

xix.

xxiii,

Management should engage the services of training officers for Engineering and

Production Departments.

Management should engage the services of competent and certified electricians

and mechanics to undertake maintenance works on all lifting equipment and

machines on the mine.

Qualified and certified supervisors should be engaged in all operations on the

mine.

The overhead crane should not be used in dislodging interlocked boulders in the

ROM bin.

The metal bars should be used for the removal of chocked boulders in the ROM

bin discharge end.

Management should engage qualified and competent workmen to undertake

services at the mine.

The Safety Department should ensure proper documentation and best safety

practices on the mine.

The IT Department should have a maintenance schedule for the cameras and

other IT facilities on the mine site.

Operational Managers should have access to the footages from cameras for the

operational areas.

The control room operators should have access to full display of the footages from

all the cameras on one screen at all time.

. Sanctions

For exhibiting gross incompetence and negligence during lifting operations

resulting in the death of Mr. Roland Kutulam, Mr. Edward Fynn (overhead crane

operator) is in breach of Regulations 550, 553 of 2012, L. |. 2182 and shall be

relieved of duty from the mine with immediate effect as per Regulation 2 (11) (a)

of 2012, L. |. 2482.

For exhibiting gross incompetence and negligence, for not ensuring due

procedures were followed and for not ensuring good supervision on the mine,

resulting in the death of Mr. Roland Kutulam, Mr. Vincent Essuman (Production

Supervisor) is in breach of the Regulations 287, 300, 515 (3) (4), 850, 553 of 2012,

ii

vi

vii

L. |. 2182 and shall be relieved of duty from the mine with immediate effect as per

Regulation 2 (11) (a) of 2012, L. |. 2182.

For exhibiting gross incompetence and negligence, for not ensuring due

procedures were followed and for not ensuring good supervision on the mine,

resulting in the death of Mr. Roland Kutulam, Mr. Godsman Ashemond (Senior

Production Supervisor) is in breach of the Regulations 287, 300, 515 (3) (d), 550,

553 of 2012, L. |. 2182 and shall be relieved of duty from the mine with immediate

effect as per Regulation 2 (11) (a) of 2012, L. 1. 2182.

For exhibiting gross incompetence and negligence, for not ensuring due

procedures were followed, for not engaging competent workmen and for not

ensuring good supervision on the mine, resulting in the death of Mr. Roland

Kutulam, Mr. Francis Alibah (Production Superintendent) is in breach of the

Regulations 287, 300, 515 (3) (d), 550, 563 of 2012, L. |. 2182 and shall be relieved

of duty from the mine with immediate effect in accordance with Regulation 2 (11)

(a) of 2012, L. 1. 2182

For exhibiting gross incompetence and negligence during the removal of

interlocked boulders from the Osborn crusher ROM bin, resulting in the death of

Mr. Roland Kutulam, Messrs. Robert Quansah and Jonas Boadi (Plant Operators)

are in breach of the Regulations 287, 300, 515 (3) (d), 550, 553 of 2012, L. |. 2182

and shall be given a one (1) month suspension from all duties on the mine without

pay with immediate effect as

per Regulation 2 (11) (a) of 2012, L. 1. 2182.

For not ensuring proper documentation and best safety practices on the mine,

Messrs. George Bentum and Edem Galley, the Safety Officer and Health & Safety

Superintendent respectively, are in breach of the Regulations 42 (c), 287, 300, 515

(3) (@), 550, 553 of 2012, L. |. 2182 and shall be given waming letters in

conformance to Regulation 2 (11) (a) of 2012, L. |. 2182

For not ensuring the cameras on mine site are maintained in good working

condition and for not been able to produce footages from the only camera at the

Osborn crusher area where the accident ocourred:

viii.

a) Mr. Adu Gyamfi (Acting IT Manager) is in breach of the Regulations 287,

515, 550, 553 of 2012, L. |. 2182 and shall be given a three (3) month

suspension from all duties on the mine without pay with immediate effect in

conformance to Regulation 2 (11) (a) of 2012, L. 1. 2182.

b) Mr. Bernard Kwame Kramo (IT System Administrator) is in breach of the

Regulations 287, 515, 550, 553 of 2012, L. |. 2182 and shall be given a

three (3) month suspension from all duties on the mine without pay with

immediate effect in conformance to Regulation 2 (11) (a) of 2012, L. |. 2182.

©) Mr. Razak Salifu Taylor (IT Technician) is in breach of the Regulations 287,

515, 550, 553 of 2012, L. |. 2182 and shall be given a two (2) month

suspension from all duties on the mine without pay with immediate effect in

conformance to Regulation 2 (11) (a) of 2012, L. |. 2182.

For poor control and management of the cameras on mine site and for not been

able to notice that the only camera monitoring the Osborn crusher area was faulty,

Messrs. Jonathan K. Mensah and Benjamin Mensah, the Electrical Supervisor and

Senior Electrical Supervisor respectively, are in breach of the Regulations 287,

515, 850, 553 of 2012, L. |. 2182 and shall be given a one (1) month suspension

from all duties on the mine without pay with immediate effect in conformance to

Regulation 2 (11) (a) of 2012, L. 1. 2182

For not ensuring best safety practices on the mine site, Ghana Manganese

Company Limited is in breach of the Regulations 35, 55, 550, 553 of 2012, L. |.

2182 and shall pay a fine of cedi equivalent of USD 5,000.00 to Minerals

Commission in conformance to Regulation 56 of 2012, L. |. 2182.

Yours,

KOFI ADJEI

(CHIE!

FOR:

hfully,

F INSPECTOR OF MINES)

AG. CHIEF EXECUTIVE OFFICER

Cc, Head of MinCom — Takoradi Office

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gorter PCV (Autosaved)Document21 pagesGorter PCV (Autosaved)Theophilus Oduro-NyarkoNo ratings yet

- Comparing Differences Estrella Delta Vs Part WindingDocument2 pagesComparing Differences Estrella Delta Vs Part WindingTheophilus Oduro-NyarkoNo ratings yet

- B EN UFM Series6-SonicExplorer Software Manual-Version1-0-8Document85 pagesB EN UFM Series6-SonicExplorer Software Manual-Version1-0-8Theophilus Oduro-NyarkoNo ratings yet

- Low Voltage Motor Maintenance ProcedureDocument9 pagesLow Voltage Motor Maintenance ProcedureTheophilus Oduro-NyarkoNo ratings yet

- Oil Pressure Sensor InstructionsDocument4 pagesOil Pressure Sensor InstructionsTheophilus Oduro-NyarkoNo ratings yet

- EN - Borschuere Installation MaintenanceDocument26 pagesEN - Borschuere Installation MaintenanceTheophilus Oduro-NyarkoNo ratings yet

- Understanding Glaucoma ENDocument44 pagesUnderstanding Glaucoma ENTheophilus Oduro-NyarkoNo ratings yet

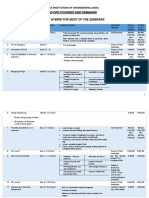

- Virtual / Hybrid For Most of The Seminars: 2022 CPD Courses and SeminarsDocument9 pagesVirtual / Hybrid For Most of The Seminars: 2022 CPD Courses and SeminarsTheophilus Oduro-NyarkoNo ratings yet

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument11 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyTheophilus Oduro-NyarkoNo ratings yet

- Light Inspection-SRMS Main Control Room AreaDocument3 pagesLight Inspection-SRMS Main Control Room AreaTheophilus Oduro-NyarkoNo ratings yet