Professional Documents

Culture Documents

Compressive Strength Formula For Concrete Using Ul

Compressive Strength Formula For Concrete Using Ul

Uploaded by

S M Faisal MahmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressive Strength Formula For Concrete Using Ul

Compressive Strength Formula For Concrete Using Ul

Uploaded by

S M Faisal MahmoodCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/283621340

Compressive Strength Formula for Concrete using Ultrasonic Pulse Velocity

Article in International Journal of Engineering Trends and Technology · August 2015

DOI: 10.14445/22315381/IJETT-V26P203

CITATIONS READS

31 8,630

4 authors, including:

Bayan S. Al-Nu'man

34 PUBLICATIONS 62 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

engineering education View project

All content following this page was uploaded by Bayan S. Al-Nu'man on 28 August 2018.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Trends and Technology (IJETT) – Volume 26 Number 1- August 2015

Compressive Strength Formula for Concrete using Ultrasonic

Pulse Velocity

Prof. Dr. Bayan S. Al-Nu’man 1, Bestoon R. Aziz 2, Sabr A. Abdulla 2, Sirwan E. Khaleel 2

1 Professor of civil engineering, Ishik University, Erbil, Iraq.

2 Civil engineer, Hawler Construction Labs, Erbil, Iraq.

Abstract — This paper investigates the relationship is a good correlation between UPV and the

between the ultrasonic pulse velocity (UPV) and the compressive strength; however, a relationship with a

compressive strength of concrete. The specimens used in the wide variation will be acquired if the data of UPV and

study were made of concrete with a varied cube compressive the compressive strength of concrete having different

strength from 18 to 55MPa. Number of specimens was over mixture proportions are put together and analyzed.

800 received from various construction projects of

controlled concrete quality and tested by the Hawler

No clear rules have been presented to describe how

Construction Laboratories (HCLabs) in Erbil, Kurdistan the relationship between UPV and the compressive

Region of Iraq, during the last half of 2014. strength of concrete changes with its mixture

The UPV measurement and compressive strength tests were proportion. Therefore, there exists a high uncertainty

carried out at the concrete age of 28 days. The experimental when one tries to make use of UPV to predict the

results show that although the UPV and the compressive strength of concrete in different mixture proportions.

strength of concrete are related, no unique relationship can Thus, this study tries to adopt an influencing factor,

be established to cover all concrete specimens. the coarse aggregate content, as a medium to

It is found, from a companion research, that with certain investigate the relationship between UPV and the

levels of concrete coarse aggregate content, certain clear

relationships can be established.

compressive strength of hardened concrete. This paper

This paper proposes the UPV - strength relationship uses over 800 concrete specimens and categorizes the

formulas/curves for concrete having the range from 18 to specimens according to a strength range of (18 – 55)

55MPa of concrete strength. These curves were verified to MPa. The UPV measurement and compressive

be suitable for prediction of hardened concrete strength with strength tests were carried out at the age of 28 days.

a measured UPV value. Other proposals found in literature

are compared and discussed. II. RESEARCH SIGNIFICANCE

It is believed that the proposed formulas may be This paper proposes a new direction to establish a

appropriately applied and used for the service of the local

clear relationship formulas / curves between UPV and

construction practice of the country.

the compressive strength of concrete to improve the

application of the UPV method on non-destructive

Keywords: concrete strength; NDT; ultrasonic pulse

velocity. evaluation of concrete strength in the construction

projects in Iraq.

The importance of the established formulas stems

I. INTRODUCTION from the fact that the over-800 investigated specimens

Construction laboratories commonly provide are true practical specimens brought to the Hawler

ultrasonic pulse velocity (UPV) test to assess Construction Laboratories (HCLabs) from

questionable concrete quality and strength. However, construction projects from all over the Kurdistan

precise prediction of strength is difficult to obtain. Region in Iraq. Proposal of a companion work along

This work attempts to set an acceptable with other proposals found in literature are compared

recommendation based on a broad data from the local and discussed.

construction projects. A recommendation is set for the HCLabs to follow, as

Many previous works made use of the UPV of the UPV test is continuously required by the

concrete to predict compressive strength and it is of construction projects officials.

paramount importance in such research work to study

the relationship between UPV and compressive III. EXPERIMENTAL DETAILS

strength(1-5). Pulse velocity is influenced by many

variables, however, including mixture proportions, A. Materials

aggregate type, age of concrete, moisture content, and Materials used for making specimens include ordinary

others.(1) Portland cement C, fine aggregate FA, coarse

The factors significantly affecting the concrete aggregate CA, and with or without high-range water-

strength have little influence on UPV. As a result, a reducing admixture SP. The cement used was Portland

statistical study is important to tie strongly the UPV Type I. River sand with and river coarse aggregate

and compressive strength. were used as fine and coarse aggregates, respectively.

Although several previous studies (1-5) concluded that, Both sand and river coarse aggregate were not from

for concrete with a particular mixture proportion, there the same source. The grading curves for fine and

ISSN: 2231-5381 http://www.ijettjournal.org Page 9

International Journal of Engineering Trends and Technology (IJETT) – Volume 26 Number 1- August 2015

coarse aggregates were all conforming to Iraqi

Specification IOS 45 – 1984(6). The mix proportions

are not known, however, most construction projects

officials claim that they are based on ACI approach. (7)

B. Specimens

Over 800 concrete cube specimens were used in this

study. Various concrete mix proportions were used

most of which were based on ACI 211.1 –

Reapproved 2009 (7). To simplify the analysis task,

these cubes were having strength in the range (18 –

55)MPa, and their UPV should be > 3.5 km/s. It is

widely agreed (8) that concrete with UPV (2 to 3.5

km/s) is of very poor to doubtful quality, and that

concrete with UPV (3.5 to >4.5 km/s) is of good to

excellent quality.

All the specimens were cast in steel cube molds (150

mm) and kept in their molds for approximately 24

hours in the laboratory. After removing the molds,

concrete cubes were cured in water at 20 °C and tested

at ages of 28 days. The ultrasonic pulse velocity and

compressive strength of three saturated surface dry

SSD specimens were measured according to the

specification of ASTM C 597 and ASTM C 39,

respectively.

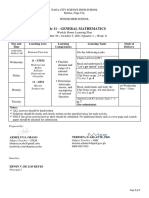

Fig.1 Schematic diagram of pulse velocity test circuit.

(9)

C. Equipment

The principle of ultrasonic pulse velocity IV. STATISTICAL STUDY

measurement involves sending a wave pulse into Statistical study was made on the direct UPV

concrete and measuring the travel time for the pulse to measurements for 848 cubes to evaluate and verify the

propagate through the concrete. The pulse is generated normal distribution of the direct UPV measurements.

by a transmitter and received by a receiver. The cumulative frequency distribution function is

As illustrated in Fig. 1, ultrasonic pulse velocities plotted in Fig. (2). For the 848 cubes with mean UPV

were measured by a commercially available pulse of 4.06 km/s and standard deviation of 0.234, it can be

meter, used by the HCLabs* with an associated seen that the direct UPV measurements are normally

transducer pair through a direct transmission mode. distributed.

The transducer pair had a nominal frequency of 54

kHz.

In the experimental work, the transmitter and receiver

were placed at the top and bottom surfaces of a cube

specimen, in parallel direction to the destructive load.

Knowing the path length (L), the measured travel time

(t) can be used to calculate the pulse velocity (v) as

follows

v = L/t.................... (1)

where L is the travel path length of ultrasound in the

cube. The concrete surface must be prepared in

advance for a proper coupling agent. Firm contact of

the transducers against the concrete surface is needed.

Direct velocity measurements were taken as the

average of 10 readings for each cube tested. The direct

V. RELATIONSHIP BETWEEN UPV AND 28-DAY

path length for these measurements was through the

STRENGTH OF CONCRETE CUBES

cube thickness of 150 mm. Direct UPV was calculated

as the ratio of the path length to the time of flight. Fig.3 shows the relationship between UPV and

*Pulsonic Controls Instruction Manual 58-E4900. strength at the age of 28 days of concrete cubes

received by the HCLabs from various construction

projects in Erbil during the last half of 2014 and tested

ISSN: 2231-5381 http://www.ijettjournal.org Page 10

International Journal of Engineering Trends and Technology (IJETT) – Volume 26 Number 1- August 2015

at age of 28 days. A relationship curve, equation 2, is

drawn by exponential regression of all data points and fcu = 0.06 exp (1.60 v) for CA = 1200 kg/m3 .................................. (8)

its coefficient of determination R2 equals 0.0813, as

shown in Fig. 3. fcu = 1.03 exp (0.87 v) for CA = 1300 kg/m3...................... (9)

fcu = 11.804exp (0.2601v) ............(2) fcu = 1.39 exp (0.78 v) for CA = 1400 kg/m3..................... (10)

Because of the scattered distribution of data points,

this relationship curve does not correlate the UPV VI. COMPARISON WITH OTHER PROPOSALS

with the strength of hardened concrete well, that is, a The equations set 7 to 10 are compared hereby with

noticeable error may occur if one estimates the various proposals found in literature. Figs. (5), (6), (7)

strength of concrete by using this relationship curve and (8) shows respectively;

with a UPV value. Naik and Malhotra equation (9),

To improve the UPV-strength relationship of hardened

concrete, it is important to consider the influence of f'c = (– 109.6 + 33 v) “cylinder”

coarse aggregate content of concrete specimens on the

relationship. (1), (10) Raouf’s equation (11),

The new approach treats the coarse aggregate content

as a ruling factor in establishing the UPV-strength fcu = 2.016 exp (0.61 v)

relationship of hardened concrete based on the fact

that, for a particular coarse aggregate content, both SonReb equation (12)

UPV and strength of concrete are proportional to the

density of hardened concrete. fcu = 2.756×10 – 10 I1.311 (1000v)2.487

The exponential regression was applied to establish and Lin et al equations (1).

the UPV-strength relationship. Fig. 4 shows the f'c = 0.00055exp (2.50 v) “cylinder” “CA = 1100

relationship between UPV and strength of hardened kg/m3”

concrete having four coarse aggregate contents. In Fig. f'c = 0.00106 exp (2.37 v) “cylinder”“CA = 1000

4, four regression curves, based on a companion study kg/m3”

(10)

are associated with coarse aggregate contents of where fcu and f'c represent the cube and cylinder

1000, 1200, 1300 and 1400 kg/m3, respectively, and compressive strength (MPa) and v the UPV (km/s),

their corresponding coefficients of determination R2 respectively. The curves show the cube compressive

are 0.83, 0.87, 0.88, and 0.84, indicating good strengths (MPa) in which fcu = 1.2 f'c

relevance between data points and the regression

curves (10). These equations are shown with the data collected in

Fig. 4 reveals that, for concrete with a particular this work.

coarse aggregate content, both UPV and strength of In comparison with the data of this work, it can be

hardened concrete are exponentially related but with seen that most of the equations predicts a single value

different power. compressive strength on the average or on the lower

Thus, when introducing coarse aggregate content as a part of data which may underestimate /overestimate

key factor, one is able to better define the relationship the true value.

between UPV and strength of hardened concrete.

SonReb equation (12) predicts the values in which the

(10)

The developed equations are data of this work would approximately lie above

rebound number I = 30, and the equation lie in the

fcu = 8.8793exp (0.4247v) for CA = 1000 kg/m3....(3) approximate average of data points at rebound number

I=40. It may be said that rebound number is helpful in

fcu = 0.0574 exp (1.6013 v) for CA = 1200 kg/m 3...(4) indicating the strength condition of the tested concrete.

With values of I< 30, the concrete may be considered

fcu = 1.0332 exp (0.8674 v) for CA = 1300 kg/m3..(5) poor.

fcu = 1.3908 exp (0.7806 v) for CA = 1400 kg/m 3..(6) Lin et al equations (1) predict the local concrete

compressive strength mostly on the lower side

where fcu and v represent the cube compressive although they depend on the coarse aggregate content.

strength (MPa) and the UPV (km/s), respectively.

Equations (7) to (10) of this work seem of better

In a more convenient way, the above equations can be prediction of the compressive strength of the local

rewritten as follows: concrete specimens depending on the aggregate

content value.

fcu = 8.88exp (0.42v) for CA = 1000 kg/m3 ..........(7)

ISSN: 2231-5381 http://www.ijettjournal.org Page 11

International Journal of Engineering Trends and Technology (IJETT) – Volume 26 Number 1- August 2015

VII. PROPOSAL TO THE HCLABS

For the purpose of investigating a concrete with UPV

test, as it is usually required by the construction

officials, it is proposed hereby to the HCLabs officials

to follow the following points to assess the concrete

strength using UPV test:

ISSN: 2231-5381 http://www.ijettjournal.org Page 12

International Journal of Engineering Trends and Technology (IJETT) – Volume 26 Number 1- August 2015

1. UPV should be > 3.5 km/s, otherwise the

concrete shall be considered poor and the

strength is not conforming. Coring is

recommended to be the deciding test.

2. The practice of HCLabs of conducting

companion hammer test to obtain the rebound

number (SonReb approach) is helpful. However,

from the data of this work, rebound number

values < 30 may indicate poor concrete.

3. Equations 7, 8, 9, and 10 are recommended.

However, if no information on mix proportions is

presented, the lower value of these equations

shall be used as an assessment.

Acknowledgement

The authors would like to express their gratitude to Mr.

Nazar H. Smail, Director of the Hawler Construction

Labs HCLabs, Erbil, Iraq, and his staff for their

support rendered in this study.

REFERENCES

[1] Lin,Y., Kuo, S-F, Hsiao C., Lai, C-P “Investigation of Pulse

Velocity- Strength Relationship of hardened Concrete” ACI

Materials Journal, V. 104, No. 4, July.-Aug. 2007 , pp. 344-

350.

[2] Tanigawa, Y.; Baba, K.; and Mori, H., “Estimation of

Concrete Strength by Combined Nondestructive Testing

Method,” In-Situ/Nondestructive Testing of Concrete, SP-82,

V. M. Malhotra, ed., American Concrete Institute,

Farmington Hills, Mich., 1984, pp. 57-76.

[3] Sturrup, V. R.; Vecchio, F. J.; and Caratin, H., “Pulse

Velocity as a Measure of Concrete Compressive Strength,”

In-Situ/NondestructiveTesting of Concrete, SP-82, V. M.

Malhotra, ed., American Concrete Institute, Farmington Hills,

Mich., 1984, pp. 201-227.

[4] Lin, Y.; Changfan, H.; and Hsiao, C., “Estimation of High-

Performance Concrete Strength by Pulse Velocity,” Journal

of the ChineseInstitute of Engineers, V. 20, No. 6, 1998, pp.

661-668.

[5] Lin, Y.; Lai, C. P.; and Yen, T., “Prediction of Ultrasonic

Pulse Velocity (UPV) in Concrete,” ACI Materials Journal,

V. 100, No. 1, Jan.-Feb. 2003, pp. 21-28.

[6] Iraqi Specification IOS 45 – 1984

[7] ACI 211.1 – Reapproaved 2009,Standard Practice for

Selecting Proportions for Normal, Heavyweight, and Mass

Concrete, An ACI Standard Reported by ACI Committee 211,

38pp.

[8] Whitehurst, E.A., Evaluation of Concrete Properties from

Sonic Tests, ACI Monograph No. 2, ACI, Detroit, MI (1966).

Cited by Guidebook On Non-Destructive Testing Of

Concrete Structures, IAEA, Vienna, 2002, IAEA–TCS–17

[9] Tarun R. Naik, V. Mohan Malhotra and John S.

Popovics,”The Ultrasonic Pulse Velocity Method” in the

Handbook of Nondestructive Testing of Concrete, Chapter 8,

2004.

[10] Bayan S. Al-Numan, Bestoun Ramadhan, Sabr Ali, and

Serwan Essmat, “Effect of Aggregate Content on the

Compressive Strength – UPV Relationship” to be published,

8pp.

[11] Raouf Z. and Ali Z.M. “Assessment of Concrete

Characteristics at an Early Age By Ultrasonic Pulse

Velocity", Journal of Building Research, Vol.2, No.1, May

1983, pp.31- 44.

[12] RILEM Draft Recommendation, 43-CND. (1993). Combined

non-destructive testing of concrete. Draft recommendation

for in situ concrete strength determination by combined non-

destructive methods. Materials and Structures, 26, pp.43-49.

ISSN: 2231-5381 http://www.ijettjournal.org Page 13

View publication stats

You might also like

- A Module in Research in Education 1: Office of The College of Teacher EducationDocument47 pagesA Module in Research in Education 1: Office of The College of Teacher Educationciedelle aranda83% (6)

- ASTM D2166 13 - Standard Test Method For Unconfined CompressiDocument7 pagesASTM D2166 13 - Standard Test Method For Unconfined CompressiIgnacio Padilla100% (1)

- Effect of Ground Borne Vibrations On Underground PipelinesDocument7 pagesEffect of Ground Borne Vibrations On Underground PipelinesJangdiniNo ratings yet

- Compressive Strength Formula For Concrete Using Ultrasonic Pulse VelocityDocument5 pagesCompressive Strength Formula For Concrete Using Ultrasonic Pulse VelocityCedricJohndelLeolaNo ratings yet

- Correlation Between Pulse Velocity and Compressive Strength of ConcreteDocument4 pagesCorrelation Between Pulse Velocity and Compressive Strength of ConcreteNazmulNo ratings yet

- Development of Statistical Quality Assurance Criterion For Concrete Using Ultasonic Pulse Velocity MethodDocument6 pagesDevelopment of Statistical Quality Assurance Criterion For Concrete Using Ultasonic Pulse Velocity MethodZiyad12No ratings yet

- Construction and Building Materials: Kamran Amini, Mehdi Jalalpour, Norbert DelatteDocument7 pagesConstruction and Building Materials: Kamran Amini, Mehdi Jalalpour, Norbert DelatteJatinder BhatiaNo ratings yet

- Non-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityDocument6 pagesNon-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityanpyaaNo ratings yet

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pages03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankNo ratings yet

- @constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Document11 pages@constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Phan Đào Hoàng HiệpNo ratings yet

- Shari Q 2013Document7 pagesShari Q 2013SivarajSivaNo ratings yet

- Construction and Building Materials: A.M.T. Hassan, S.W. JonesDocument7 pagesConstruction and Building Materials: A.M.T. Hassan, S.W. JonesHerison ScottonNo ratings yet

- International Journal of Impact Engineering: Lei Mao, Stephanie Barnett, David Begg, Graham Schleyer, Gavin WightDocument10 pagesInternational Journal of Impact Engineering: Lei Mao, Stephanie Barnett, David Begg, Graham Schleyer, Gavin WightPouya DarvishNo ratings yet

- Construction and Building Materials: Spyridon A. Paschalis, Andreas P. Lampropoulos, Ourania TsioulouDocument16 pagesConstruction and Building Materials: Spyridon A. Paschalis, Andreas P. Lampropoulos, Ourania TsioulouARNABNo ratings yet

- Evaluation of Bridge Performance Using Non Destructive Testing A Case StudyDocument7 pagesEvaluation of Bridge Performance Using Non Destructive Testing A Case StudyPRADEEPNo ratings yet

- 1 s2.0 S1877705817327376 MainDocument8 pages1 s2.0 S1877705817327376 MainOsama SalehNo ratings yet

- Plan of PCC PojectDocument8 pagesPlan of PCC PojectK Bhavish V SuvarnaNo ratings yet

- An Experimental Study On Self Compacting Concrete Using Electric Arc Furnace Oxidizing SlagDocument4 pagesAn Experimental Study On Self Compacting Concrete Using Electric Arc Furnace Oxidizing SlagEditor IJTSRDNo ratings yet

- Analytical and Experimental Investigation For Bond Behaviour of Newly Developed Polystyrene Foam Particles' Lightweight ConcreteDocument11 pagesAnalytical and Experimental Investigation For Bond Behaviour of Newly Developed Polystyrene Foam Particles' Lightweight Concretetimtoihochoi1No ratings yet

- Tensile Strength Behavior of Uhpc and Uhpfrc: SciencedirectDocument6 pagesTensile Strength Behavior of Uhpc and Uhpfrc: SciencedirectAkashNo ratings yet

- Estimation of Compressive Strength of Concrete Structures Using The Ultrasonic Pulse Velocity Method and Spectral Analysis of Surface Wave MethodDocument7 pagesEstimation of Compressive Strength of Concrete Structures Using The Ultrasonic Pulse Velocity Method and Spectral Analysis of Surface Wave MethodaabucharcuriNo ratings yet

- UPV ConsandBuildingMat 2016Document11 pagesUPV ConsandBuildingMat 2016Hasan al MahmudNo ratings yet

- Astm DurabiliyDocument63 pagesAstm Durabiliyosama anterNo ratings yet

- Maturity Method To Predict The Evolution of The Properties of Sprayed ConcreteDocument13 pagesMaturity Method To Predict The Evolution of The Properties of Sprayed ConcreteEdicson Gabriel Garcia MateusNo ratings yet

- Husham Issa Al-SaleemDocument21 pagesHusham Issa Al-SaleemlmiitobnykhpvdwuzyNo ratings yet

- Behavior and Strength of Beams Cast With Ultra Highstrength Concrete Containing Different Types of Fibers (Metalicas y Microfibras) Egipto 2013Document9 pagesBehavior and Strength of Beams Cast With Ultra Highstrength Concrete Containing Different Types of Fibers (Metalicas y Microfibras) Egipto 2013Mauro GelmiNo ratings yet

- Shear Behaviour of UHPC Concrete and Rebar Composites Part BDocument13 pagesShear Behaviour of UHPC Concrete and Rebar Composites Part BKorrapati Pratyusha 19PHD0497No ratings yet

- 1 s2.0 S0950061822023376 MainDocument14 pages1 s2.0 S0950061822023376 MainFarjallah Al-AssãadNo ratings yet

- Mathematical Model For The Probability Distribution of In-Situ Concrete Compressive Strength in North CyprusDocument10 pagesMathematical Model For The Probability Distribution of In-Situ Concrete Compressive Strength in North CyprusManpreet SinghNo ratings yet

- Fattouh M. F. Shaker Parametric Study of CFSTDocument46 pagesFattouh M. F. Shaker Parametric Study of CFSTHarpreet SinghNo ratings yet

- Ultra High Performance FibreDocument12 pagesUltra High Performance FibreVicky KidileNo ratings yet

- Journal of Rehabilitation in Civil EnginDocument11 pagesJournal of Rehabilitation in Civil EnginKasmiNo ratings yet

- Abstrais de Renforcement Par Des FibrDocument153 pagesAbstrais de Renforcement Par Des FibrAbd El Nour KahlochNo ratings yet

- Construction and Building Materials: Mohamadreza Shafieifar, Mahsa Farzad, Atorod AzizinaminiDocument9 pagesConstruction and Building Materials: Mohamadreza Shafieifar, Mahsa Farzad, Atorod AzizinaminiTarun Singh RajputNo ratings yet

- Main Tension Steel in High Strength Concrete Deep and Short BeamsDocument13 pagesMain Tension Steel in High Strength Concrete Deep and Short BeamsbbeeNo ratings yet

- Sustainability 14 14024Document45 pagesSustainability 14 14024BitbitterNo ratings yet

- Electrical Resistivity Measurements For Quality Control During Concrete ConstructionDocument7 pagesElectrical Resistivity Measurements For Quality Control During Concrete ConstructionangthiankongNo ratings yet

- Department of Civil Engineering Sydney NSW 2006 AustraliaDocument51 pagesDepartment of Civil Engineering Sydney NSW 2006 AustraliaalexrodriguezabcNo ratings yet

- Effect of Rate of Loading On Compressive Strength of ConcreteDocument6 pagesEffect of Rate of Loading On Compressive Strength of Concretevelmurug_bala100% (1)

- Numerical Investigation On Ballistic Performance of Coarse-Aggregated Layered UHPFRCDocument14 pagesNumerical Investigation On Ballistic Performance of Coarse-Aggregated Layered UHPFRCFaizan RashidNo ratings yet

- Behavior of High-Performance Concrete Beams Having Tension Lap Spliced Anchor-Ended Bars Under Repeated LoadingDocument21 pagesBehavior of High-Performance Concrete Beams Having Tension Lap Spliced Anchor-Ended Bars Under Repeated Loadingmohamed ellithyNo ratings yet

- 2019 Vacuum A Modified Reference Area Method To Estimate Creep Behaviour of Service Exposed Cr5Mo Based On Spherical Indentation Creep TestDocument9 pages2019 Vacuum A Modified Reference Area Method To Estimate Creep Behaviour of Service Exposed Cr5Mo Based On Spherical Indentation Creep TestYingzhi LiNo ratings yet

- 1 s2.0 S1687404814000972 MainDocument12 pages1 s2.0 S1687404814000972 MainAhmed AjelNo ratings yet

- Effect of Types of Aggregate and Sand-To-Aggregate Volume Ratio On UPVDocument11 pagesEffect of Types of Aggregate and Sand-To-Aggregate Volume Ratio On UPVAmry DasarNo ratings yet

- Experimental Studies On M35 Grade Self Compacting Concrete: Mallesh M., Praveen S, Reena K, H. ErammaDocument5 pagesExperimental Studies On M35 Grade Self Compacting Concrete: Mallesh M., Praveen S, Reena K, H. ErammaSumit BistaNo ratings yet

- Ain Shams Engineering Journal: Ali Poorarbabi, Mohammadreza Ghasemi, Mehdi Azhdary MoghaddamDocument11 pagesAin Shams Engineering Journal: Ali Poorarbabi, Mohammadreza Ghasemi, Mehdi Azhdary MoghaddamJennifer Julieth Triana ForeroNo ratings yet

- Predicción de La Resistencia Del Hormigón Utilizando La Velocidad Del Pulso Ultrasónico y Las Redes Neuronales Artificiales 2007Document8 pagesPredicción de La Resistencia Del Hormigón Utilizando La Velocidad Del Pulso Ultrasónico y Las Redes Neuronales Artificiales 2007Miguel ArcelaNo ratings yet

- Prediction of Compressive Strength of High Strength Concrete Using Multiple Linear Regression Equation (MLRE) and Numerical ModelDocument12 pagesPrediction of Compressive Strength of High Strength Concrete Using Multiple Linear Regression Equation (MLRE) and Numerical ModelAtta MuhammadNo ratings yet

- Experimental and Numerical Study of The Flexural Behaviour of Ultra-HighDocument14 pagesExperimental and Numerical Study of The Flexural Behaviour of Ultra-HighjayanthNo ratings yet

- Lim (2014) - BagusDocument18 pagesLim (2014) - BagusFerdinand Jaya PutraNo ratings yet

- Lamp Ro Poulos 2016Document15 pagesLamp Ro Poulos 2016Evonne LeeNo ratings yet

- Behavior of Reinforced Concrete Skew Slab Under Different Loading ConditionsDocument10 pagesBehavior of Reinforced Concrete Skew Slab Under Different Loading ConditionsGJESRNo ratings yet

- Ultrasonics: J. Alexandre Bogas, M. Glória Gomes, Augusto GomesDocument11 pagesUltrasonics: J. Alexandre Bogas, M. Glória Gomes, Augusto GomesBudhi AdjiNo ratings yet

- 1 s2.0 S0950061820338484 MainDocument17 pages1 s2.0 S0950061820338484 MainAhmed AlyNo ratings yet

- Construction and Building Materials: Hailin Yang, Yan Zheng, Shixu Mo, Penghui LinDocument14 pagesConstruction and Building Materials: Hailin Yang, Yan Zheng, Shixu Mo, Penghui LinAna Maria DuțăNo ratings yet

- Examining The Electrical Properties of Plain and Blended Cement ConcretesDocument8 pagesExamining The Electrical Properties of Plain and Blended Cement ConcretesRetana González Manuel AbrahamNo ratings yet

- Toowoomba Full Paper02Document7 pagesToowoomba Full Paper02Nuno FerreiraNo ratings yet

- Journal of Constructional Steel Research: H. Alhendi, M. CelikagDocument13 pagesJournal of Constructional Steel Research: H. Alhendi, M. CelikagmdkmlNo ratings yet

- (Unsure) Adaptation of 196-1 For MortarDocument30 pages(Unsure) Adaptation of 196-1 For MortarBelal MbadrNo ratings yet

- JournalReview - Group No. 3 - Ikan, Jervis IvanDocument12 pagesJournalReview - Group No. 3 - Ikan, Jervis IvanCarlo King SantosNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- 3D Finite Element Analysis of A Complex Excavation: TitleDocument6 pages3D Finite Element Analysis of A Complex Excavation: TitleFaten Abou ShakraNo ratings yet

- Method of Test For Strength Parameters of Soils by Triaxial Compression TestsDocument42 pagesMethod of Test For Strength Parameters of Soils by Triaxial Compression TestsFaten Abou ShakraNo ratings yet

- Sieve Analysis: ASTM D 422 - Standard Test Method For Particle-Size Analysis of Soils 1. ObjectiveDocument6 pagesSieve Analysis: ASTM D 422 - Standard Test Method For Particle-Size Analysis of Soils 1. ObjectiveFaten Abou ShakraNo ratings yet

- An Investigation On The Formation of Cracks at The Corner Turns of The Modular Block Earth WallsDocument12 pagesAn Investigation On The Formation of Cracks at The Corner Turns of The Modular Block Earth WallsFaten Abou ShakraNo ratings yet

- Specification CSIDocument12 pagesSpecification CSIFaten Abou ShakraNo ratings yet

- Application of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsDocument7 pagesApplication of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsFaten Abou ShakraNo ratings yet

- D6391-11 Standard Test Method For Field Measurement of Hydraulic Conductivity UsingDocument16 pagesD6391-11 Standard Test Method For Field Measurement of Hydraulic Conductivity UsingFaten Abou ShakraNo ratings yet

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsDocument7 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsFaten Abou ShakraNo ratings yet

- D5903-96 (2012) Standard Guide For Planning and Preparing For A Groundwater SamplingDocument5 pagesD5903-96 (2012) Standard Guide For Planning and Preparing For A Groundwater SamplingFaten Abou ShakraNo ratings yet

- A11. T164 PDFDocument13 pagesA11. T164 PDFFaten Abou ShakraNo ratings yet

- D5883-12 Standard Guide For Use of Rotary Kiln Produced Expanded Shale, Clay or SlateDocument3 pagesD5883-12 Standard Guide For Use of Rotary Kiln Produced Expanded Shale, Clay or SlateFaten Abou ShakraNo ratings yet

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 pagesDirect Shear Test of Soils Under Consolidated Drained ConditionsFaten Abou ShakraNo ratings yet

- A10. D4767 PDFDocument14 pagesA10. D4767 PDFFaten Abou ShakraNo ratings yet

- A2. D1883 PDFDocument9 pagesA2. D1883 PDFFaten Abou ShakraNo ratings yet

- Liquid Limit, Plastic Limit, and Plasticity Index of Soils: Standard Test Methods ForDocument16 pagesLiquid Limit, Plastic Limit, and Plasticity Index of Soils: Standard Test Methods ForFaten Abou ShakraNo ratings yet

- Engineering Vibration Communication and Information Processing 2019 PDFDocument756 pagesEngineering Vibration Communication and Information Processing 2019 PDFPaulo Venicio Alves VieiraNo ratings yet

- Library Science Journal Indexed in Scopus DatabaseDocument15 pagesLibrary Science Journal Indexed in Scopus DatabaseAbid HussainNo ratings yet

- 2023 Practice Paper 2 Higher (Calculator)Document20 pages2023 Practice Paper 2 Higher (Calculator)Ege IscanNo ratings yet

- Intro To Medtech Clinical Chemistry ReviewerDocument11 pagesIntro To Medtech Clinical Chemistry Reviewerjesanndei100% (1)

- Gotco Operation ManualDocument251 pagesGotco Operation ManualBrett KingNo ratings yet

- 1.1C Fiber Used in Technical TextilesDocument10 pages1.1C Fiber Used in Technical TextilesDhrubo AdhikaryNo ratings yet

- Pel-Dk - Differential Pressure TransmitterDocument1 pagePel-Dk - Differential Pressure TransmitterKerim JumanazarowNo ratings yet

- Unit 2: Human Resource Policies & StrategiesDocument26 pagesUnit 2: Human Resource Policies & Strategiesmaalvika singhNo ratings yet

- PMMA Resist - Product InformationDocument8 pagesPMMA Resist - Product InformationMałgosiaSikora-JasińskaNo ratings yet

- SML-Sanjeewa Kumara (KAN00129429) NEWDocument67 pagesSML-Sanjeewa Kumara (KAN00129429) NEWAmarshana100% (1)

- Rosicrucian Digest, November-December 1988Document44 pagesRosicrucian Digest, November-December 1988Valerio777100% (1)

- Maf651 Seminar 2 Sustainability Development & Environmental ManagementDocument33 pagesMaf651 Seminar 2 Sustainability Development & Environmental ManagementAISHAH HUDA AHMAD DAUDNo ratings yet

- Theory of MindDocument14 pagesTheory of Mindmerisa.jamesNo ratings yet

- Pre-Stress Modal Analysis of A Centrifugal Pump Impeller For Different Blade ThicknessesDocument10 pagesPre-Stress Modal Analysis of A Centrifugal Pump Impeller For Different Blade Thicknessesravi kumar B v ANo ratings yet

- ComentariuDocument24 pagesComentariuBianca ApavalloaieNo ratings yet

- DLP-MATH5-Q1-W9-division of FractionsDocument3 pagesDLP-MATH5-Q1-W9-division of FractionsRheanel Esquejo-SarmientoNo ratings yet

- Offshore Field Development PlanDocument14 pagesOffshore Field Development Planvarsha dNo ratings yet

- Semantics ReviewerDocument5 pagesSemantics ReviewerRJ EscañoNo ratings yet

- Ahmad Samir Ismail: Personal InformationDocument4 pagesAhmad Samir Ismail: Personal InformationMohamedNo ratings yet

- The Economics of RecyclingDocument5 pagesThe Economics of RecyclingNazrin VahidovaNo ratings yet

- SUMMER 2023 BUS 498 EXIT Marketing AssesmentDocument15 pagesSUMMER 2023 BUS 498 EXIT Marketing AssesmentRakibul Islam 1911961042No ratings yet

- Sepax 2 BenefitDocument2 pagesSepax 2 BenefitAndry WigunaNo ratings yet

- General Mathematics - Module #3Document7 pagesGeneral Mathematics - Module #3Archie Artemis NoblezaNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Module Front OfficeDocument21 pagesModule Front OfficeLorilie Royo RizalonNo ratings yet

- Forces and MatterDocument14 pagesForces and MatterCallista lynn AdrianNo ratings yet

- JWI586 UsermanualwebDocument16 pagesJWI586 UsermanualwebengineerNo ratings yet

- Lec-5 (The Utility Approach) PDFDocument18 pagesLec-5 (The Utility Approach) PDFWasiq BhuiyanNo ratings yet

- Chapter IDocument1 pageChapter IVincent louise G. AgustinNo ratings yet