Professional Documents

Culture Documents

Aug 51-1

Uploaded by

srini_kalmulaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aug 51-1

Uploaded by

srini_kalmulaCopyright:

Available Formats

Textile Research Journal

http://trj.sagepub.com

A New Method for Raw-Wool Scouring and Grease Recovery

W. Fong, A.S. Yeiser and H.P. Lundgren

Textile Research Journal 1951; 21; 540

DOI: 10.1177/004051755102100802

The online version of this article can be found at:

http://trj.sagepub.com

Published by:

http://www.sagepublications.com

Additional services and information for Textile Research Journal can be found at:

Email Alerts: http://trj.sagepub.com/cgi/alerts

Subscriptions: http://trj.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

540

A New Method for Raw-Wool Scouring and

Grease Recovery*

W. Fong, A. S. Yeiser, and H. P. Lundgren

Western Regional Research Laboratory,† Albany, California

Introduction .

wax acids consist of four major series: the normal

fatty acids; the hydroxy acids; the ante-iso acids;

The operation of scouring raw wool is the first and

and the iso acids [32].

one of the most important steps in the processing of

Two methods are commonly employed for the

wool. The process demands extreme care; otherwise,

the ultimate quality of the wool is jeopardized. Dam- scouring of raw wool: the aqueous soap- or detergent-

soda ash process and the solvent process. Of these,

age incurred in scouring may affect carding, combing,

the aqueous method is by far the more common. The

spinning, weaving, and dyeing, and thus affect ulti-

mate wearing quality. scouring process is carried out in a long train con-

Raw wool is contaminated with 40% to 70% of sisting of four to six separate bowls through which

the wool is carried with a gentle mechanical action.

extraneous matter, of which 5% to 20% is suint,

10% to 40% is &dquo;grease&dquo; (more correctly, wax), and Soap or synthetic detergents and soda ash, added in

the remainder is sand, dirt, vegetable matter, urine, varying amounts to all bowls except the final rinse

and fecal matter. The primary objective in scouring bowl, perform the major scouring action. Conven-

tional aqueous scouring practice is slow and requires

is the removal of these impurities, leaving a white,

much space; there is danger of alkali damage to the

nonfelted, ash-free product that contains around 0.5 %

of residual grease. fibers; and the considerable felting which invariably

occurs leads to increased fiber breakage in the sub-

Wool suint is generally regarded as water-ex-

tractable material, presumably secreted by the sweat sequent carding operation [34].

Solvent extraction offers an alternative method

glands of the animal. It consists, in part, of a mix- of cleaning raw wool, yielding a degreased product

ture of potassium soaps of fatty acids, ranging from

with little fiber damage, minimum felting, and ready

valeric to palmitic acids [6]. In addition, suint con-

tains minor amounts of lactic, hippuric, and succinic recovery of grease. A subsequent rinse in water is

acids, urea, and lanaurin, a bile pigment derivative invariably required to remove the suint and dirt. A

batch-extraction process utilizing petroleum naphtha

which imparts the reddish-brown color to an aqueous

as the solvent has been successfully operated in this

solution of suint [23].

-

The greasy material in wool is secreted through country for over 50 years. More recently, there has

been considerable interest in the development of

the sebaceous glands of the animal. It is principally

a mixture of waxes, consisting of the esters of several

equipment [4, 11 for the continuous degreasing of

raw wool with trichloroethylene as the solvent. Al-

high-molecular-weight monohydric alcohols with fatty

acids [7]. The component alcohols consist of three though the solvent procedure offers features which are

desirable, the general acceptance of the method has

major series: the sterols, principally cholesterol; the been slow, chiefly because of economic considerations,

triterpene alcohols, closely related to the sterols; and industrial hazards from toxicity of escaping vapors,

the higher aliphatic alcohols. The component wool

and inflammability of some solvents.

*

Report of a study made under the Research and Marketing Although scouring costs have not been considered

Act of 1946.

Presented in part at the annual fall meeting of the Ameri- excessively high, it is generally agreed that there is

can Chemical Society, Chicago, Ill., Sept., 1950. need for improvement in scouring methods. There

t One of the laboratories of the Bureau of Agricultural is need for milder treatments and treatments leading

and Industrial Chemistry, Agricultural Research Adminis-

tration, U. S. Department of Agriculture. to less felting with consequent less fiber breakage in

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

541

carding. There is also need for speeded-up processing The results of the present investigation indicate

and for a process requiring less space. that the emulsifying power of suint is enhanced mark-

But perhaps the most immediate problem facing the edly by the addition of alcohol and salt. Moreover,

wool-scouring industry-indeed, the wool industry the emulsified grease can be separated and recovered

as a whole-is the means of disposal of effluent. from the scouring waste by a small increase in the

Wool-scouring wastes are among the most objection- alcohol concentration. These principles are the basis

able types produced by industry. For the most part, for a new process for the neutral scouring of wool,

they are dumped directly into streams. The contami- with simultaneous recovery of grease, removal of dirt,

nation and resulting putrefaction lead to most disa- and recycling of the alcohol, suint, and other deter-

greeable odors, and the extremely high B.O.D. of the gent additives. They have been applied experi-

effluent imposes a heavy pollution load on the stream. mentally in laboratory-scale continuous scouring op-

With the growing realization that water supplies eration.

are definitely limited, the wool industry is forced to Experimental Procedure

consider either appropriate treatment of the waste wa- In the development of a laboratory procedure for

ter or new methods of scouring in which there is no the investigation and evaluation of factors involved

effluent-disposal problem. All grease-recovery sys- in the scouring of raw wool, the principal considera-

tems are expensive. Furthermore, the potential tion was to adopt a method of testing which would

market for the grease is limited and unpredictable; simulate as closely as possible the operating conditions

hence, less than 10% of the potentially available in commercial scouring practice.

grease is recovered. Two standard test procedures were employed in

Solvent recovery has been suggested as a solution. the present studies. The first method, the single-

However, whereas solvent extraction does recover scour beaker test, is a standardized procedure in

grease, it also leaves the objectionable suint salts which wool is scoured in 500-ml. beakers immersed in

which must subsequently be removed in a backwash- a 60°C constant-temperature bath. A single 3-g.

ing operation and then discarded. Apparently, the sample of raw wool is scoured in two successive

removal of grease has little if any effect on reducing 400-ml. portions of the scouring solution for 3 min.

the B.O.D. of the backwashing waste [16]. in each beaker. Agitation of the scouring solution is

The primary objective of the present investigation provided by a glass weight attached to a short arm

of the raw-wool scouring process has been to evalu- on a windshield-wiper motor. After scouring, the

ate some of the underlying physicochemical principles sample is rinsed thoroughly in distilled water at room

involved in the cleaning operation as the basis for temperature, and dried in an oven at 100°C to con-

possible improved technical practice. These stud- stant weight. The residual-grease content of the

ies are directed toward the effect of the scouring scoured sample, determined by Soxhlet extraction

treatment on fiber properties, as well as the prob- with an organic solvent, serves as the basis for com-

lems of effluent disposal and grease recovery. parison of the effectiveness of various scouring

As a first consideration, the role of suint in the procedures.

The second test method is a cumulative scouring

scouring process was investigated. The detergent

properties of suint salts in scouring are recognized; procedure similar to that described by Leonard and

Winch [15] as a quantitative test for the evaluation

however, it appears that suint salts have never been of wool-scouring detergent systems. Stainless-steel

used to their fullest effectiveness. The Duhamel

8-1. beakers serve as the scouring bowls. A specially

scouring process [5], developed in France, is based constructed constant-temperature bath maintains the

on the use of a water extract of suint. The raw wool

temperature of scouring, which is 60°C. Four motor-

is first steeped in hot water to dissolve the suint. driven wringers, mounted permanently above the

This suint solution is continuously clarified of grease

constant-temperature bath in juxtaposition to the

and dirt by centrifuging, and is then returned to the

scouring bowls, serve as the squeeze rolls for the in-

first two bowls and used as the major scouring agent. dividual bowls. For agitation, an up-and-down mo-

In modern practice, the recovered aqueous suint solu- tion is imparted by means of a flat, perforated, stain-

tion is fortified by the addition of controlled amounts less-steel disk attached by a slender rod to the arm of

of soap or synthetic detergent and alkali. a windshield-wiper motor. The scouring operation

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

542

FIG. 1. The scouring of raw wool in solutions of methyl

alcohol with and withozct added sodium chloride.

FIG. 2. The scouring of f raw wool in solutions of ethyl

alcohol with and without added sodium chloride.

consists of feeding a series of 10-g. samples of grease

wool in a loose carded form through the first bowl and

tained for the homologous series of primary straight-

squeeze roll, onto the second bowl, and so on, through chain alcohols, f rom methyl to hexyl, obtained by

the system. The time of immersion in each bowl is

3 min. The scoured samples are thoroughly rinsed scouring the standard raw wool at varying alcohol

concentrations with and without added O.lIV sodium

in distilled water, dried, and extracted.

chloride. Although no alkali was added, the scouring

For use as a standard wool, a large lot of medium

solutions were slightly basic (pH 7.5) because of the

California wool was opened and blended in an ex-

dissolved suint. The reported residual-grease values

perimental-type opener [33]. The opened wool was are based on the oven-dry weight of the scoured

placed in a closed container and stored in a cold room wool.

at 4°C to minimize any aging effect which might

alter the scouring characteristics. For the scouring

Analysis of the curves reveals several significant

points that are common to the effects produced by the

trials, small portions were further homogenized by water-soluble alcohols examined. As the alcohol

repeated hand-carding and mixing. This standard concentration is increased, there is an initial decrease

wool in the carded form had a shrinkage of 33%,

in the residual-grease content to a minimum value;

consisting of 100’o grease, 9% suint, and 14% dirt, further addition of alcohol causes a sharp rise in the

on the basis of the grease wool.

residual-grease content; and, finally, with the com-

Analytical-grade reagents were used in all cases pletely water-miscible alcohols at higher concentra-

unless otherwise stated. All solutions were made up

with laboratory distilled water.

tions, a gradual decrease takes place. With the in-

completely miscible alcohols-butyl, amyl, and hexyl

Results -phase separation occurs before a maximum in the

curve is observed. The value of the residual-grease

With the single-scour beaker test method, a study content at the minimum decreases progressively from

was made of the effect of added water-soluble alco- methyl to butyl and then increases. The presence

hols and salts on the scouring efficiency. Figures 1 of added sodium chloride enhances the scouring

to 6 are representative of the experimental results ob- power of the alcohols at the lower concentrations;

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

543

FIG. 3. The scouring of raw wool in solutions of n- FiG. 4. The scouring of raw wool in solutions of n-

propyl alcohol with and without added sodium chloride. butyl alcohol witla and witho2-ct added sodium chloride.

FIG. 6. The scouring of raw wool in solutions of n-

FIG. 5. The scouring of f raw wool in solutions of n- hexyl alcohol with and without added sodizon chloride.

amyl alcohol with and without added sodiun2 chloride.

That the improvement in scouring resulting from

however, at alcohol concentrations beyond the mini- the addition of alcohol at the lower alcohol concen-

mum a reverse effect is observed. Detailed interpre- trations is dependent upon the presence of the natural

tation of these observations is presented in the Dis- suint in wool is substantiated by the scouring of

cussion section. desuinted wool. (The raw wool is desuinted by steep-

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

544

ing in water at room temperature.) With the re- anol, etc., were investigated, and results similar to

moval of suint before scouring, the building action of those for the primary aliphatic alcohols were ob-

the alcohol disappears, as is shown rather conclusively tained. The addition of glycols or glycerols has no

in Figure 7 for butyl alcohol. beneficial effect.

Other similar polar-nonpolar organic compounds In the alcohol runs presented above, the con-

such as iso-propyl alcohol, iso-, secondary, and ter- centration of the added sodium chloride was held con-

tiary butyl alcohol, acetone, methyl ethyl ketone, stant at O.1N in all cases. The effect of the addition

methyl cellosolve, phenol, benzyl alcohol, cyclohex- of varying amounts of sodium chloride in the pres-

ence of a constant concentration of butyl alcohol ( 2 %

by weight) is shown in Figure 8. Although the

change in scouring efficiency is small, there is an opti-’

mum concentration at about O.1N salt. Even in the

absence of alcohol, sodium chloride improves the ex-

tent of grease removal, as illustrated in Figure 9. As

in the case of the alcohol, removal of suint before

scouring nullifies the effect of salt-that is, the in-

creased scouring efficiency is due to the synergistic

interaction between the salt and suint. Other neu-

tral alkali-metal salts show a similar behavior. When

added in ion-equivalent amounts, the order of effec-

tiveness of those studied was NA,SO, = NaI >

NaCI = NaBr = NaN03 = K,SO, > NaF.

While the residual-grease content determined by

solvent extraction is the accepted index for deter-

mining the efficiency of scouring, conclusions based

on this factor alone may at times be misleading. This

is illustrated in Figure 10, where the residual-ash

FIG. 7. The e ff ect of f prior desuinting on the efficiency

content, determined by igniting the scoured samples

in a muffle oven at 600°C, is plotted as a function of

of grease removal in solutions of n-butyl alcohol.

FIG. 8. The effect of sodium

chloride concentration in a 2a/o (by

The scouring of raw wool in aq2ieons sodium

weight) n-butyl alcohol solution on FIG. 9.

the scouring of f raw wool. chloride solutions.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

545

methyl alcohol concentration, with and without added addition cannot be attributed to the incomplete re-

sodium chloride. Figure 11 shows the effect of so- moval of the salt in the rinse operation. This di-

dium chloride alone on residual-ash content. In both vergent effect of added alcohol and added salt on the

instances there is a definite trend toward a higher displacement of grease and dirt from wool emphasizes

ash content with increasing concentration. A con- that the removal of these two components occurs by

trol experiment with clean wool showed that the in- separate mechanisms.

crease in ash content in the case of sodium chloride Figure 12 shows the effect of the hardness of water

(expressed as parts per million of calcium carbonate)

on the scouring efficiency of the alcohol-suint-salt

system. The trial was conducted with butanol, at a

constant concentration of 2% by weight, and O.1N

salt solution, to which the required hardness was in-

troduced as calcium chloride. The pronounced ad-

verse effect of calcium is due undoubtedly to the for-

mation of insoluble calcium suint salts, as encountered

in the case of ordinary soap. Other alkaline-earth

and heavy-metal salts have a similar effect.

The addition of alkali to the alcohol-suint system

results in an improvement in scouring which is in-

dependent of a salt effect. This improvement is due

to the conversion of the free fatty acids in the wool

grease to the corresponding soap. Under acidic con-

ditions, the alcohol-suint solution is totally ineffective.

The effect of temperature on the scouring efficiency

of a 2% butanol plus O.1N salt solution is illustrated

in Figure 13. The decrease in grease removal be-

low 40°C is reconciliable with the fact that wool

grease is a solid below this temperature region.

An investigation was made of the scouring be-

FIG. 10. The effect of methyl alcohol concentration, havior of raw and desuinted wool in an aqueous soap

with and without added sodium chloride, on the residual- solution with added butanol. The soap used was so-

ash content.

FIG. 12. The effect of water

hardness on the scouring efficiency

in sollttions containing 2% (by

FIG. 11. The effect of sodium chloride concentration on the weight) n-biityl alcohol and 0.1 N

residual-ash content. sodium chloride.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

546

FIG. 13. The effect of temperatul’e on the scouring

efficiency in solutions containing 2% (by weight) n-

butyl alcohol and 0.1 N sodium chloride.

FIG. 15. The scouring of raw wool and desuinted

wool in solutions of n-butyl alcohol with 0.05% Du-

ponol C.

FIG. 16. The scouring of raw wool and desuinted

wool in solutions of n-butyl alcohol with 0.05 /o Antarox

FIG. 14. The scouring of raw wool and desuinted A-180.

wool in solutions of n-butyl alcohol with 0.05 /o sodium

stearate.

butanol is detrimental to the function of the soap as a

dium stearate T. Baker, U.S.P. grade). At a

detergent. A behavior similar to that of soap was

(J. observed for Duponol C,* an anionic detergent (Fig-

constant soap concentration of 0.05 °~o by weight,

ure 15). The data plotted in Figure 16 for Antarox

there is a marked difference in the scouring efficiency

vs. butanol concentration curves (Figure 14), de-

A-180,-~ nonionic detergent, show a different re-

a

sult. In this case the presence or absence of the suint

pending upon whether the raw wool was initially de- has very little effect on the scouring behavior.

suinted or not. In the case of raw wool, the soap aids

The data presented up to this point were obtained

the scouring action of the suint and. improves the

by the single-scour beaker procedure, which gives

grease removal (compare with Figure 4 for the ef-

fect of butyl alcohol alone). If the suint is removed *

Kindly supplied by E. I. du Pont de Nemours & Com-

pany.

by prior desuinting, the building action of the butanol t Kindly supplied by Antara Products Division, General

disappears; at concentrations above 2% the added Aniline & Film Corporation.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

547

FIG. 17. A comparison of the c2imuLative scouring of

raw wool by the soap-soda method and by the alcohol-

soap-salt method.

a measure only of the effectiveness of a fresh solution.

Since raw-wool scouring is a continuous process, it

is important to evaluate the rate of exhaustion of

FIG. 18. Samples of wool scouring waste. Left-

Raw waste before treatment. Right-After addition off

different scouring formulations on a cumulative scour- n-butyl alcohol in an amount sufficient to saturate.

ing basis in which increasing amounts of wool are

scoured in the same bath. A comparison on this At a residual-grease content level of 0.6% it is seen

basis between the soap-soda method and the alcohol- that in the presence of added butyl alcohol about two

suint method is shown in Figure 17. The initial times as much wool can be scoured.

compositions of the scouring bowls for the two meth- Another important feature of alcohol addition is

ods are summarized in Table I. the marked effect of higher alcohol concentrations on

In the case of the alkali scour (Figure 17), the the stability of waste-scouring emulsions. As an ex-

residual-grease level remains fairly constant up to ample, it was observed that upon the addition of

around 60 g., at which point the curve rises rapidly, butyl alcohol to a scouring waste in an amount just

indicating that the cleaning power of the solution has sufficient to form a separate alcohol-rich layer (about

become exhausted. In the case of the alcohol scour, 7 % by weight) at 60 ° C, rapid coalescence of the

the residual-grease level is below that of the alkali; grease emulsion occurred. On allowing the solution

furthermore, the rise in residual-grease content as to stand for a short period of time, a grease-rich layer

successive samples were scoured is more gradual, collected on the surface and a dirt-rich layer on the

indicating that the rate of exhaustion is much slower. bottom, leaving a nearly clear amber-colored mother

TABLE I. INITIAL BOWL COMPOSITION*

*

Bowl No. 3 consisted of a rinse in distilled water at room temperature.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

548

liquor. Figure 18 shows a comparison of the scour- TABLE II. ALCOHOLS AS EMULSION-BREAKING AGENTS

ing waste before and after the addition of excess butyl

alcohol.

A further investigation was made into the action

of other alcohols as emulsion-breaking agents. A

summary of the concentrations required and the na-

ture of the sediment is given in Table II.

The concentrations of the first five alcohols re-

quired to break the emulsion correspond with those

at which the lowest scouring efficiency is reached in

the results reported in Figures 1 to 6. The direction

of sedimentation of the grease layer depends upon partition, presumably through transfer of the alcohol

the density of the solution. together with suint ions from the bulk phase to an

This observed emulsion-breaking property of al- interface. If emulsification is the basic factor in

cohols at the higher concentration is of particular scouring, then the interface to be considered is that

of the emulsified grease droplet. The most recent

significance, for it offers a method of regeneration of views on the role of interfacial films in the stability of

the spent scouring solution and recovery of the grease

emulsions have been those of Schulman and co-

in the alcohol-suint scouring process described be-

workers [25, 26, 27]. It has been found that for an

low.

oil-in-water emulsion of maximum stability, two emul-

Discussion sifying agents are necessary-one which is prefer-

The interaction between suint and alcohol which entially water-soluble and the other preferentially

oil-soluble. Aickin, in a study of the detergency to-

produces the results reported above may be inter- ward oil-soiled wool of a series of secondary fatty

preted either by an analysis of the interfacial rela- sulfates in the presence of added higher alcohols, has

tionships involved or by a consideration of the effect

of alcohols on micelle structure. Discussions of the interpreted his results on the basis of the above

effects produced by polar additives upon the prop-

theory [1].

If solubilization is a factor in detergency, then at-

erties of surface-active solutions have recently ap-

tention must be directed to the suint micelle-solution

peared in the literature [10, 13]. interface. McBain [17] has defined solubilization as

The known active components of suint are similar the spontaneous passage of a water-insoluble sub-

in structure to ordinary soaps or detergents. These stance into an aqueous-soap or detergent solution to

compounds are characterized by a charged, polar, or form a thermodynamically stable solution. This type

water-compatible, head and a long-chain, nonpolar, of solubility involves the incorporation of the sub-

or oil-compatible, tail. By virtue of this structure, stance within the hydrocarbon core of the micelle.

it is reasonable to expect that suint ions, like other With regard to raw-wool scouring, these processes

surface-active agents, are concentrated and oriented probably coexist, although emulsification is prob-

at an oil-water or an air-water interface. This be-

ably the predominant process.

havior is demonstrated by the lowering in surface Emulsification and solubilization are phenomena

tension of a suint solution [28]. Furthermore, in which are associated with the stability of the grease

the solution proper, under suitable conditions of in the solution proper. Of equal importance are those

concentration, temperature, pH, ionic strength, and factors which are involved in the transfer of the

dielectric constant, suint ions apparently aggregate grease from the fiber surface into the solution proper.

to form micelles in much the same fashion as do This step in the detergency process is best considered

other surface-active agents. The colloidal nature of by an account of the grease-solution, solution-fiber,

suint in an aqueous solution is confirmed by sedimen- and grease-fiber interfacial free-energy relationships.

tation diagrams obtained in the ultracentrifuge [31]. In a thermodynamic analysis, the exact mecha-

It may be postulated that at low concentrations nism of interaction is irrelevant, and the relationship

the added alcohols influence grease removal by phase between bulk alcohol concentration, Cb, and surface

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

549

alcohol concentration, Cs, may be expressed as equations (3) and (4) :

At equilibrium, In order to test the above considerations in terms

of the results obtained for the scouring of raw wool

at varying alcohol concentrations, we shall assume

that at the same degree of grease removal for two

and thecorresponding free-energy change, L~F°, ac- successive members of the homologous series-that

companying this bulk-to-surface transfer will be is, at

the activities, a, of the adsorbed alcohols are equal:

For various homologous series it has been observed

( 14] that the energy of adsorption is a linear func- But since the activity may be considered in the limit-

tion of the chain length : ing case to be proportional to the concentration,

where vc is the number of carbon atoms in the hydro- then

carbon chain, and A and B are constants. The value

of L~ F° for homologous aliphatic compounds is gen-

erally around 600-800 cal. per mole CH~ group. This Upon rearrangement and combination with equation

behavior is an expression of the familiar Traube’s (3), the following relationship is derived:

rule. -

For a homologous series at equal molar concen-

trations, Cb equals a constant and, accordingly, from

This may be expressed in logarithmic form as

Since the free-energy change is a constant for a unit

increase in ve (equation (4) ), the general expression

for the nth member of the series becomes

In other words, in a plot of the logarithm of alcohol

concentration to give the same residual-grease con-

tent vs. the number, n, of carbon atoms (or CH2

groups) of the alcohol, the theory predicts a linear

decrease. From the slope of this plot, the free-energy

difference would be obtained by dividing by RT.

Arbitrarily selecting a residual-grease value of

2%, the corresponding molar alcohol concentration

for the homologous primary alcohol series required

to reduce the residual grease to this level (from the

Fm. 19. The relationship >between the concentration

data shown plotted in Figures 1 to 6) is plotted on

of initially added alcohol required to reduce the residual

a semilogaritW nic scale as a function of the number

grease to 2 /o and the chain length of the alcohol.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

550

of carbon atoms in Figure 19. Significantly, the as an explanation of the emulsion-breaking properties

linear decrease is observed in accord with the relation- of added alcohol at these concentrations. Finally, in

ship expressed above in equation (12). Also, the the case of the lower and completely water-miscible

change in the free energy of adsorption per CH, alcohols, the marked decrease in residual grease at

group as determined in the experimental plot is 770 higher concentrations is undoubtedly attributable to

cal. per mole CH2, in surprisingly good agreement the true solvent action of the alcohol on grease.

with the value of 600-800 cal. derived from surface-

tension data.

Application .

This analysis lends support to the view that the

initially added alcohol is involved in a surface phe- The foregoing results, obtained by beaker-scale

nomenon rather than in true solvent action. studies, show promise of possible practical application

An alternative consideration is the role of micelle in a process combining the scouring of raw wool un-

formation in the over-all picture of grease removal der neutral conditions together with the clarification

from wool. Whether the colloidal aggregrate or the of the effluent wastes and recovery of the grease.

long-chain ion of a soap or detergent is the active In order to develop the process and to obtain signifi-

constituent of a detergent bath is subject to conjec- cant information for application to possible pilot-scale

ture [19]. studies, a laboratory-scale, all-glass, continuous-flow

The effect of alcohol addition on the critical con- apparatus was designed. In these preliminary stud-

centration for micelle formation (CMC) of dodecyl- ies, 7a-butyl alcohol was selected for detailed investi-

ammonium chloride, determined by the dye-titration

gation because of the relatively low concentration re-

method of analysis, has shown that the added alcohols

quired for scouring, and because butyl alcohol func-

lower the CMC, and the decrease per mole of alco- tions more satisfactorily in emulsion-breaking than

hol continues with lengthening of the hydrocarbon

do the higher alcohols.

chain [2]. The interpretation is that alcohols and

other polar-nonpolar compounds form a new type

of micelle in which the polar-nonpolar molecules align

themselves between the soap molecules, with polar

heads oriented out [8, 9].

The observed increase in grease-removal efficiency

with the initial addition of alcohol may be interpreted

by the thesis that a lowering of the CMC is accom-

panied by an increase in detergent action. The effect

of salts in lowering of the CMC of solutions of anionic

detergents [3, 12, 18] is undoubtedly a factor in the

improved detergency of such solutions.

The subsequent decrease in scouring efficiency

which is apparent upon the further addition of al-

cohol may be also reconciled with the effect of alco-

hol on micelle structure. Ward [30] has shown by

conductance measurements that in the case of so-

dium dodecyl sulfate, micelles are no longer evident

in an aqueous ethyl alcohol solution above 40% by

weight concentration. Similar studies of dodecylam-

monium chloride in water-organic solvent systems

indicate that there is a transition from a colloidal ag-

gregate to an ordinary electrolyte as the percentage

of organic addend is increased [20, 21, 22].

This disappearance of colloidal properties at an

intermediate alcohol concentration may be advanced

FIG. 20. Continitoits-flow laboratory assevnbly for the

study of alcohol-suint scouring process.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

551

Description of f Apparatus In operation, fresh scouring solution containing

recovered suint in a 3 % (by weight) butyl alcohol

A photograph of the assembly is shown in Figure

solution is fed from the boiler of the alcohol-recovery

20, and a flow diagram in Figure 21. The scouring still through a glass-wool filter into the right end of

chamber, which has a capacity of 200 ml., consists the scouring chamber. The effluent scouring waste

essentially of an ordinary bulb-type laboratory con- is withdrawn from the left end into a waste receiver

denser modified to provide inlets and outlets for

both the wool and the scouring solution. To facilitate

consisting of a calibrated tube fitted with stopcock B, J

which is closed when the flow rate is being measured.

the sedimentation of the heavier dirt particles, the

The reclaimed butyl alcohol from the recovery still

chamber is mounted at an angle. The extension of

is collected in the distillate receiver, which is similar

the lower end serves as a dirt-collecting sump from

in construction to the waste receiver. Since the al-

which the accumulated dirt is discharged periodically

cohol distillate is a two-phase liquid system, an in-

by means of stopcock A. The temperature of scour- dication of the rate of distillation is obtained by clos-

ing is controlled by circulating water from a con- ing stopcock C and observing either the rate of flow

stant-temperature bath through the jacket surround- or the relative volume of the alcohol-rich and water-

ing the chamber. rich layers.

The grease wool, in a carded, sliver form, is in-

During operation of the system, stopcocks B and

troduced into the left end and is passed through the C are open, and the scouring waste and recovered

scouring chamber in counter-current flow to the scour- alcohol flow directly into the clarification unit. The

ing solution by means of a stainless-steel ladder chain. added butyl alcohol raises the concentration in the

Short lengths of stainless-steel wire spot-welded solution to the saturation point, causing the dirt and

along the chain engage the wool, facilitating its pas- grease to coalesce and separate into a top grease-rich

sage through the chamber. Mechanical agitation dur- layer and a bottom dirt-rich layer, leaving a clear

ing scouring is produced by a special drive mecha- reddish-brown solution between, which contains wa-

nism which imparts an oscillating advancing motion ter-soluble suint and sodium chloride. The clarifica-

to the chain. The feed rate of raw wool can be varied tion chamber is jacketed to permit temperature con-

from approximately 1 to 3 g. per min., and the corre- trol of this stage of the process.

sponding average time of immersion in the scour- A piston-type circulation pump, located at the

ing solution is from 3 to 1 min. The ratio of solution lowest point in the apparatus, draws the clarified

to raw wool is approximately 100: 1. solution (containing salt and suint in a saturated

FIG. 21. Flow diagram off

laboratory asservcbly for aLcol2oZ-

suint scouring process.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

552

butyl alcohol solution) upward through a glass-wool several times before drying and extracting to deter-

filter and feeds it into the alcohol-recovery still lo- mine the residual grease.

cated at the highest elevation in the system. Flow

through the remainder of the apparatus is by gravity, Results and Discussion

and hence the rate of circulation is easily controlled

A series of scouring tests, all at 60°C and 3 % al-

by alteration of the stroke of the pump. cohol, was conducted at varying solution-to-wool

The various units are interconnected by transparent

flow rates in order to determine the effect of this

plastic tubing. The still is heated by an electric heat- variable on scouring efficiency. The suint concen-

ing mantle controlled through a rheostat. tration gradually increased during the course of the

tests; however, as pointed out below, this factor is

Procedure .

of minor importance. Figure 22 shows that within

The wool used in this phase of the investigation the limitations of the apparatus the grease-removal

was taken from the skirted fleece of a California- efficiency is nearly independent of the relative flow

grown Romeldale. The fleece was opened and rates of scouring solution to raw wool. The cut-off

blended in the experimental opener, and was then point indicated by the vertical dotted line marks the

carded, in the grease state, by means of a sample point at which the input scouring solution is carried

machine card. The resultant web from the card was out entirely by the outgoing scoured wool. The

manually condensed into a sliver. This grease wool amount of solution carried out by the scoured wool

in the carded form had a shrinkage of approximately is unusually high because no provision was made to

33%, consisting of 13.3~lo suint, 10.1 ’10 grease, and squeeze the solution from the wool.

the remainder dirt, vegetable matter, moisture, etc. Even with adequate squeezing, the butyl alcohol

The scouring apparatus is charged initially with a carried out by the wool would still represent a major

distilled-water solution containing 0.5% (by weight) loss unless provisions were made for recovery. The

of sodium chloride. The over-all liquid hold-up of simplest means of recovery would be by a back-

the system is 1.5 1. Sufficient butyl alcohol is added washing operation in which fresh water is fed counter-

to the clarification chamber to produce a saturated currently to the wool, stripping the alcohol by dilution

solution. The circulation pump is then adjusted to or displacement. The efficiency of such an operation

give the desired flow rate, and the rate of distillation would be determined by the design of equipment,

is set to give a 3% solution in the bottom feed to the which is beyond the scope of this investigation.

scouring chamber. The extent of adsorption of the solute is an impor-

After equilibrium conditions are established, the tant factor in the success of the backwashing opera-

wool is fed manually into the inlet end, and the clean, tion. Speakman [29] reported that the amount of

scoured wool is removed. The scoured wool is rinsed alcohol adsorbed by wool changes abruptly between

FIG. 22. The effect of flow

rate ratio of solutions to wool on

the residual grease.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

553

ethyl and propyl alcohols, while amyl alcohol is not to which the suint concentration can rise before par-

adsorbed to any significant extent. This is attributed tial removal is necessary.

to the difference in molecular size of the alcohols in The final disposition of the suint wastes from the

relation to the size of the capillary spaces in wool. process has not been completely explored. Obviously,

The adsorbed alcohol is stable to heating at 100°C, the simplest solution is to recover the butyl alcohol

but it is readily displaced by water [24] . and discharge the remainder into the sewer if local

In a 3 % solution of butyl alcohol the wool fiber is regulations permit. Since the effiuent is highly con-

probably sufficiently swollen by the water to permit centrated and is relatively free of grease and dirt, it

adsorption of butyl alcohol. In order to determine should be readily amenable to biological treatment

whether butyl alcohol is selectively adsorbed by wool by municipal sewage-treatment plants. Another fac-

from an aqueous solution, a clean, scoured sample tor of interest is that the suint liquor, as a result of

of wool was immersed in a 3 % solution (solution-to- the bactericidal properties of butyl alcohol, does not

wool ratio, 10: 1) for 24 hrs. at 60°C. The concen- putrefy even on prolonged exposure. This is in

tration of butyl alcohol in solution before and after rather marked contrast to the usual wool-scouring

immersion was determined refractometrically with a waste, in which putrefaction occurs almost immedi-

dipping refractometer. No change in concentra- ately and gives rise to extremely objectionable odors.

tion was detectable by this method of analysis. An alternative suint-disposal method is recovery

During the course of scouring, as more and more by evaporation. This procedure at first appears at-

wool is fed through the system, the suint concentra- tractive since the suint solution is relatively concen-

tion in the recirculation scouring solution gradually trated and is free of dirt and grease. Unfortunately,

rises. The effect of this increasing suint concentra- there is no potential market for suint, except as a

tion on the efficiency of removal of grease is shown possible source of potash or fertilizer; hence, its re-

in Figure 23. The data were obtained at a constant covery seems rather impractical. There is a genuine

flow rate at 60°C in a 3 % butyl alcohol solution. need for more knowledge concerning the chemical

Although the results indicate that the residual- composition of suint, which might lead to economical

grease content of the scoured wool is relatively in- utilization of this large-volume waste. ’

dependent of suint concentration, it was observed In the clarification of the scouring waste by an in-

that the gradual build-up of suint causes a distinct crease in alcohol concentration, the major difficulty

discoloration of the scoured wool at the higher con- encountered is that of recovery of a pure grease from

centrations (above 3 %, approximately). This dis- the precipitated sludge. The grease and dirt tend to

coloration is believed to be due to an organic pig- coprecipitate from solution to form a strongly bonded

ment, lanuarin [23]. Since the color of the scoured complex.

product is of as great importance as the residual- As a first approach to this problem, an attempt

grease content, this factor will determine the level was made to selectively extract the grease from the

FIG. 23. The effect of suint build-up on

residual grease.

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

554

sludge by introducing a second water-saturated butyl to wools of high or low grease content and high or

alcohol phase. In practice this is a rather simple low suint content. In the case of the wool which

procedure, for it merely involves the addition of was low in suint content, it was necessary to start

sufficient butyl alcohol to form a two-phase liquid the scouring with suint accumulated from previous

system. The lighter butyl-alcohol-rich phase floats runs. Unless a suitable sequestering agent is em-

on the surface. The sludge, which is intermediate in ployed, pulled wools cannot be scoured successfully

density between the two liquid phases, floats at the in- by the process because of the presence of calcium from

terface, thus facilitating the extraction of the grease the depilatory operation.

into the top butyl alcohol layer. This top layer is In conclusion, although these carefully controlled

subsequently siphoned off, the grease recovered by laboratory experiments are of limited value in de-

distillation, and the butyl alcohol recycled. termining the technical feasibility of the process, cer-

If the extraction is carried out at an elevated tem- tain inherent advantages are evident:

perature (50° to 60° C) with adequate mixing, the

grease is soluble to the extent of 10%. However, Scouring is eff ected under neutral conditions,

1.

since the water-saturated butyl alcohol is a rather insuring a minimum of damage to the fiber.

2. Effluent clarification and grease recovery are

poor grease solvent and since the grease is strongly

bonded to the dirt and surrounded by a protective part of the process.

3. The alcohol is relatively nontoxic, relatively non-

shell of water, the rate of extraction is slow and in-

inflammable, readily available, and easily recoverable

complete. Even under the best conditions, less than

50% of the total grease available can be recovered by distillation.

4. The suint can be recycled as fresh scouring solu-

from the floating sludge. Attempts to improve the ef-

tion in a continuous operation.

ficiency of the extraction by the addition of various 5. The presence of the alcohol inhibits putrefaction

additives have thus far proved unsuccessful.

of the scouring solution, thus making possible the re-

An alternative method of grease recovery is the

use of the scouring solution over an extended period.

use of conventional plate-and-frame filter presses.

6. The process appears adaptable to existing scour-

This method has proved successful in the recovery of

grease from the sludge obtained by the acid-cracking

ing equipment.

7. The process operates within a relatively nar-

and from the calcium hypochlorite processes for the

row concentration range and is, therefore, potentially

treatment of wool-scouring wastes. Grease recovery

more economical than are conventional solvent meth-

as high as 75 % has been obtained by this procedure.

ods which require complete distillation in each cycle.

In the alcohol-recovery step, the concentration of

butyl alcohol in the clarified suint solution is reduced It may be of interest to mention the possible adap-

from 7% (saturated) to 3 % by removal of excess tation of the basic principles discussed in this re-

alcohol in the overhead vapors. This is readily port to processes other than raw-wool scouring-e.g.,

accomplished because, although butyl alcohol boils at commercial-laundry practice, oil recovery from seed

a higher temperature than does water ( 117.71 °C at

meal, etc.

760 mm.), the volatility of the alcohol in an aqueous

solution is much greater than is that of water-that

Summary

is, the vapor given off from such a solution is richer study of the influence of the lower homologs of

A

in butyl alcohol than is the solution itself. If re- primary, aliphatic alcohols in aqueous solution on the

covery of alcohol is carried out by means of a con- scouring of raw wool by the natural suint salts is re-

tinuous, simple distillation, as illustrated in the flow ported. As the chain length of the alcohol is in-

diagram (Figure 21), a material balance relating creased, progressively less added alcohol is required for

feed composition to vapor composition and bottom effective grease removal. A maximum effect of alcohol

composition will show that it is necessary to distill concentration is reached, beyond which added alcohol

over approximately one-tenth of the total feed in tends to break the grease emulsion and correspond-

order to accomplish the necessary separation and re- ingly less grease is extracted. For the completely

covery of butyl alcohol. water-miscible alcohols at higher concentrations, the

It has been established by investigation of several grease is removed by the solvent action of the

different types of wool that the process is applicable alcohol. That the lower concentrations of alcohol in-

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

555

fluence scouring by synergistic interaction with 8. Harkins, W. D., and Mittleman, R., J. Colloid Sci.

suint is illustrated by the ineff ectiveness of alcohols in 4, 367 (1949).

9. Harkins, W. D., Mittleman, R., and Corrin, M. J.,

these concentrations when raw wool is previously

J. Phys. & Colloid Chem. 53, 1350 (1949).

desuinted by steeping in warm water. Consideration 10. Herzfeld, S. H., Corrin, M. L., and Harkins, W. D.,

of the thermodynamic aspects of the process shows J. Phys. & Colloid Chem. 54, 271 (1950).

that at low concentrations added alcohols influence 11. Hoffman, M. T., U. S. Patent 2,479,358 (1949).

12. Klevens, H. B., J. Phys. & Colloid Chem. 52, 130

grease removal by phase partition. The correlation

is in agreement with Traube’s rule. (1948).

13. Klevens, H. B., Chem. Revs. 47, 1 (1950).

These experimental results have provided the basis 14. Langmuir, I. J., J. Am. Chem. Soc. 39, 1848 (1917).

for the demonstration, on a limited laboratory scale, 15. Leonard, E. A., and Winch, A. R., Am. Dyestuff

of a continuous alcohol-suint scouring process for Reptr. 37, P202 (1948).

raw wool, under neutral conditions, with the simul- 16. Lowell Textile Institute, Proc. Wool Scouring

Waste Conference, Lowell, Mass., 1950.

taneous recovery of grease. n-Butyl alcohol has been

17. McBain, J. W., "Advances in Colloid Science," Vol.

intensively studied because its properties seem par- I, New York, Interscience Publishers, 1942.

ticularly suited to the process. A 3 % solution is 18. Merrill, R. C., and Getty, R., J. Phys. & Colloid

optimum for scouring. Further addition of alcohol Chem. 52, 774 (1948).

to about 7% concentration, saturating the water, 19. Preston, W. C., J. Phys. & Colloid Chem. 52, 84

causes the scouring emulsion to break and the (1948).

20.Ralston, A. W., and Blake, A. E., J. Am. Chem. Soc.

grease and dirt to separate. The alcohol concen- , 1327 (1949).

71

tration is then readjusted by distillation and the solu- 21. Ralston, A. W., and Eggenberger, D. N., J. Phys.

tion used again for scouring. _

& Colloid Chem. 52, 1494 (1948).

22. Ralston, A. W., and Hoerr, C. W., J. Am. Chem.

Soc. 68

, 851 (1946).

Acknowledgments 23. Rimington, C., and Stewart, A. M., Proc. Roy. Soc.

The authors wish to thank Miss Barbara Wash- (London) 110B, 75 (1932).

24. Rizzo, F. J., and Christian, H., Am. Dyestuff Reptr.

auer for the residual-ash determinations. They are 27, 2 (1938).

also grateful to Mr. Richard T. Morris for the 25. Schulman, J. H., and Cockbain, E., Trans. Faraday

Soc. 35, 716 (1939).

glass-blowing work in the laboratory assembly for

continuous-flow operation.

26. Schulman, J. H., and McRoberts, T. S., Trans.

Faraday Soc. 42, 165 (1946).

27. Schulman, J. H., and Riley, D. P., J. Colloid Sci. 3,

Literature Cited 383 (1948).

28. Scott, E., and Mengi, K. P., J. Soc. Chem. Ind. 53,

1. Aickin, R. G., J. Soc. Dyers Colourists 60, 41 211 (1934).

(1944). 29. Speakman, J. B., Trans. Faraday Soc. 26, 61 (1931).

2. Corrin, M. L., and Harkins, W. D., J. Chem. Phys. 30. Ward, A. F. H., Proc. Roy. Soc. (London) 176A,

14, 640 (1946). 412 (1940).

3. Corrin, M. L., and Harkins, W. D., J. Am. Chem. 31. Ward, W. H., Unpublished data.

Soc. 69, 683 (1947). 32. Weitkamp, A. W., J. Am. Chem. Soc. 67, 477

4. Drum, H. S., and Hopkins, A., U. S. Patent 2,368,- (1945).

916(1945) (to Smith, Drum and Company). 33. Wilson, J. F., Hilgardia 11, 149 (1938).

5. Fawcett, H. W., Wool Record 35, 661 (1929). 34. Wool Industries Research Association, "Wool Re-

6. Freney, M. R., Council Sci. Ind. Research ( Aus- search : Vol. 4: Carding," Leeds, England, 1948.

), Bull. No. 130 (1940).

tralia

7. Gillespie, D. T. C., J. Textile Inst. 39, 45 (1948). (Manuscript received May 28, 1951.)

Downloaded from http://trj.sagepub.com by satish aparaj on November 19, 2007

© 1951 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

You might also like

- Walmart Plan of ActionDocument4 pagesWalmart Plan of Actionfaizan akbar100% (1)

- Az 104t00a Enu Powerpoint 01Document24 pagesAz 104t00a Enu Powerpoint 01Galacticsolutions PltNo ratings yet

- Chapter Thirteen: DC Drives Using Controlled RectifiersDocument38 pagesChapter Thirteen: DC Drives Using Controlled Rectifiersyemane gebremichal100% (2)

- Haagen DazsDocument8 pagesHaagen DazsAlicia JennyNo ratings yet

- Polyhedron #140 - Llurth DreierDocument8 pagesPolyhedron #140 - Llurth DreierGeorge Krashos100% (1)

- Auto Levelling in SpinningDocument19 pagesAuto Levelling in SpinningMd. Humayun KabirNo ratings yet

- Processing of Leather by Microbial EnzymeDocument13 pagesProcessing of Leather by Microbial EnzymeSajjad Hossain Shuvo100% (1)

- A Cleaning and Efficient Approach To Improve Wet Blue S 2017 Journal of CleaDocument8 pagesA Cleaning and Efficient Approach To Improve Wet Blue S 2017 Journal of CleaDes RiliNo ratings yet

- Assignment ON: Eco-Textiles Chemical Processing of Textile MaterialsDocument10 pagesAssignment ON: Eco-Textiles Chemical Processing of Textile Materialsila03No ratings yet

- Agarwal 2021Document5 pagesAgarwal 2021Farah TalibNo ratings yet

- Leather Manufacturing (Fat Liquoring)Document17 pagesLeather Manufacturing (Fat Liquoring)Pia JoNo ratings yet

- DesizingDocument40 pagesDesizingaqsa imranNo ratings yet

- Sloan 2008Document5 pagesSloan 2008517wangyiqiNo ratings yet

- Definition:: ScouringDocument13 pagesDefinition:: Scouringপ্রমিত সরকারNo ratings yet

- A Systematic Review On Potential Bio Leather SubstituteDocument11 pagesA Systematic Review On Potential Bio Leather Substitutekhouloud hosniNo ratings yet

- Cotton: Impurities Present in Impurities Present in Impurities Present in Impurities Present inDocument10 pagesCotton: Impurities Present in Impurities Present in Impurities Present in Impurities Present invenkateswarluNo ratings yet

- Scouring of WoolDocument4 pagesScouring of WoolArunraj Arumugam0% (1)

- Studies On The Use of Enzymes in Tanning Process: Part I. High Exhaust Vegetable TanningDocument12 pagesStudies On The Use of Enzymes in Tanning Process: Part I. High Exhaust Vegetable TanningDhanny S OktafiantoNo ratings yet

- Rohit Raj - FS Assignment 2-Converted-CompressedDocument38 pagesRohit Raj - FS Assignment 2-Converted-CompressedRohit RajNo ratings yet

- Wool Carbonising: Learning ObjectivesDocument10 pagesWool Carbonising: Learning ObjectivesAbel TayeNo ratings yet

- Assignment of DesizingDocument8 pagesAssignment of DesizingAltaf Ur RehmanNo ratings yet

- Application of Enzymes and Chitosan Biopolymer To The Antifelting Finishing ProcessDocument6 pagesApplication of Enzymes and Chitosan Biopolymer To The Antifelting Finishing ProcessDesyree VeraNo ratings yet

- 8 Preparation of Protein Fibres PDFDocument36 pages8 Preparation of Protein Fibres PDFYashica GuptaNo ratings yet

- Bio ScouringDocument14 pagesBio ScouringPrachi GehlotNo ratings yet

- Fabric Science-3: Assignment-1Document10 pagesFabric Science-3: Assignment-1n ramanNo ratings yet

- Studies On The Use of Enzymes in Tanning Process PDFDocument12 pagesStudies On The Use of Enzymes in Tanning Process PDFbramastya liliekNo ratings yet

- Preperatory ProcessesDocument47 pagesPreperatory Processesashpika100% (1)

- Plant FibresDocument13 pagesPlant Fibresgaurav saxena100% (1)

- Chemical Properties of Local Black Soap Produced From Cocoa Pod Ash and Palm Oil WasteDocument3 pagesChemical Properties of Local Black Soap Produced From Cocoa Pod Ash and Palm Oil WasteEditor IJTSRDNo ratings yet

- Ecofriendly Methods of Pre Treatment Textile ProcessingDocument41 pagesEcofriendly Methods of Pre Treatment Textile ProcessingNikithaaNo ratings yet

- Wet Processing Engineering - Wikipedia, The Free EncyclopediaDocument10 pagesWet Processing Engineering - Wikipedia, The Free EncyclopediaVikas KumarNo ratings yet

- A Review On Characterization of Sheep Wool Impurities and Existing Techniques of Cleaning Industrial and Environmental ChallengesDocument20 pagesA Review On Characterization of Sheep Wool Impurities and Existing Techniques of Cleaning Industrial and Environmental Challengesmahadev barNo ratings yet

- Desizing 140503101043 Phpapp01Document43 pagesDesizing 140503101043 Phpapp01satexNo ratings yet

- Jun 2012Document8 pagesJun 2012HarshithNo ratings yet

- Textiles ProcessingDocument38 pagesTextiles Processingوائل مصطفىNo ratings yet

- Textile Dyeing and Printing: AssignmentDocument8 pagesTextile Dyeing and Printing: AssignmentshailajaNo ratings yet

- Watersaving Cleaning Processing of Sheep Wool andDocument9 pagesWatersaving Cleaning Processing of Sheep Wool andbettieboomNo ratings yet

- Textile DyesDocument5 pagesTextile Dyesapi-27596299No ratings yet

- APO Question With Ans 2Document6 pagesAPO Question With Ans 2nahid hasanNo ratings yet

- Lanazym Wool DocumentDocument6 pagesLanazym Wool DocumentnorthernmeldrewNo ratings yet

- Grey Room Operations: Fabric Inspection Involves Following Three Processes Perching Burling MendingDocument38 pagesGrey Room Operations: Fabric Inspection Involves Following Three Processes Perching Burling MendingBhaswati PandaNo ratings yet

- Wool ScouringDocument18 pagesWool ScouringMd. Asiqul AlamNo ratings yet

- Analytical Methods For Quantitative and Qualitative Determination of Hydrocarbons and Oil and Grease in Water and WastewaterDocument12 pagesAnalytical Methods For Quantitative and Qualitative Determination of Hydrocarbons and Oil and Grease in Water and Wastewaterwaleed El-azabNo ratings yet

- Pretreatment For Dyeing and Printing of TextilesDocument37 pagesPretreatment For Dyeing and Printing of TextilesSenelisile Moyo100% (2)

- INDEXDocument4 pagesINDEXarchuydv154No ratings yet

- Shellac and OrpimentDocument9 pagesShellac and OrpimentRaju UllengalaNo ratings yet

- Rayons - LyocellDocument4 pagesRayons - LyocellmaryamNo ratings yet

- Textile 5-Viscose RayonDocument21 pagesTextile 5-Viscose Rayonmt khanNo ratings yet

- Surfactants Used in Textie IndustriesDocument15 pagesSurfactants Used in Textie IndustriesRoshanNo ratings yet

- Pretreatment of Wool - Part-1Document5 pagesPretreatment of Wool - Part-1Mohammed Atiqul Hoque Chowdhury50% (2)

- Textile Pre Treatment Right First TimeDocument53 pagesTextile Pre Treatment Right First Timewsarakarn100% (1)

- Bio Finish in TextilesDocument35 pagesBio Finish in Textilessahu_disha100% (2)

- Wool Scouring-Converted - Docx..bakDocument18 pagesWool Scouring-Converted - Docx..bakMd. Asiqul AlamNo ratings yet

- Impact of Surfactant Composition and Surfactant Structure On Foam Control PerformanceDocument7 pagesImpact of Surfactant Composition and Surfactant Structure On Foam Control PerformancemirgytooNo ratings yet

- Improving The RemovalDocument19 pagesImproving The RemovalFathi MustafaNo ratings yet

- An9941901793 PDFDocument4 pagesAn9941901793 PDFAdufe RufaiNo ratings yet

- Modified Method For The Determination of Unsaponifiable Matter in Oils and FatsDocument4 pagesModified Method For The Determination of Unsaponifiable Matter in Oils and FatsAdufe RufaiNo ratings yet

- An9941901793 PDFDocument4 pagesAn9941901793 PDFAdufe RufaiNo ratings yet

- An9941901793 PDFDocument4 pagesAn9941901793 PDFAdufe RufaiNo ratings yet

- Enzymes: Application of Enzymes in Leather ProcessingDocument11 pagesEnzymes: Application of Enzymes in Leather ProcessingbalachandarNo ratings yet

- Handbook Tanning and Leather FinishingDocument4 pagesHandbook Tanning and Leather FinishingWilliam BulmerNo ratings yet

- tc3 150925142656 Lva1 App6891Document97 pagestc3 150925142656 Lva1 App6891PramothThangarajuNo ratings yet

- Reducing The Environmental Impact of The Unhairingeliming Process in The Leather Tanning IndustryDocument10 pagesReducing The Environmental Impact of The Unhairingeliming Process in The Leather Tanning IndustryfonsynickNo ratings yet

- Pretreatment For Protein FiberpptDocument22 pagesPretreatment For Protein FiberpptAbel TayeNo ratings yet

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentFrom EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNo ratings yet

- Ijftr44165 741Document11 pagesIjftr44165 741srini_kalmulaNo ratings yet

- Apr 51-7Document10 pagesApr 51-7srini_kalmulaNo ratings yet

- Apr 51Document9 pagesApr 51srini_kalmulaNo ratings yet

- JuteDocument26 pagesJutesrini_kalmulaNo ratings yet

- Ijftr 33 (3) 304-317Document10 pagesIjftr 33 (3) 304-317srini_kalmulaNo ratings yet

- PLC's & Its Applications: BY Anil KumarDocument51 pagesPLC's & Its Applications: BY Anil Kumarsrini_kalmulaNo ratings yet

- Karen Robards Green EyesDocument200 pagesKaren Robards Green Eyesmalik_pooja100% (1)

- MI0024 Software Engineering-Model Question PaperDocument7 pagesMI0024 Software Engineering-Model Question PaperSarika NairNo ratings yet

- C1C DatasheetDocument6 pagesC1C DatasheetAnirudh DeoNo ratings yet

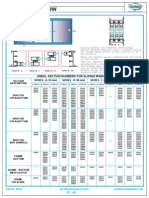

- 21) Sliding Window SectionsDocument39 pages21) Sliding Window SectionsTarun Kaw100% (2)

- Fundamental Concepts of Community Health NursingDocument26 pagesFundamental Concepts of Community Health NursingSarah Jane MaganteNo ratings yet

- Xalk178f 2015062Document3 pagesXalk178f 2015062YOO SHINNo ratings yet

- You Must Be A Big GiverDocument1 pageYou Must Be A Big GiverEricBoamahNo ratings yet

- Feminists, Philosophers, and MysticsDocument22 pagesFeminists, Philosophers, and MysticsNazeer Ahmad100% (1)

- How To Reset The Vcenter Server Appliance Root Password - Virtualhome - BlogDocument4 pagesHow To Reset The Vcenter Server Appliance Root Password - Virtualhome - BlogAdolfo Javier Acevedo RomeroNo ratings yet

- Chapter 3.2Document63 pagesChapter 3.2SIDDHARTH KUMARNo ratings yet

- My Courses: Home UGRD-GE6114-2113T Week 10: Midterm Examination Midterm ExamDocument11 pagesMy Courses: Home UGRD-GE6114-2113T Week 10: Midterm Examination Midterm ExamMiguel Angelo GarciaNo ratings yet

- 2010 2011spectrum CatalogueDocument190 pages2010 2011spectrum CatalogueDavid Covarrubias FarfanNo ratings yet

- Dcs Mi-8mtv2 GuideDocument115 pagesDcs Mi-8mtv2 GuideCristianNo ratings yet

- Week 2A - Time Value of MoneyDocument48 pagesWeek 2A - Time Value of MoneyWgp 87100No ratings yet

- CH - 6 Saturated Oil ReservoirsDocument37 pagesCH - 6 Saturated Oil ReservoirszazoNo ratings yet

- Financial Accounting and Reporting - SLK - 02Document9 pagesFinancial Accounting and Reporting - SLK - 02Its Nico & SandyNo ratings yet

- Yash Pate: Analysis, Fabrication & Testing of Vertical Axis Wind TurbineDocument2 pagesYash Pate: Analysis, Fabrication & Testing of Vertical Axis Wind TurbineSheikh NasiruddinNo ratings yet

- Similarity and Congruence Summary : AB PQ PR QRDocument9 pagesSimilarity and Congruence Summary : AB PQ PR QRkaziba stephenNo ratings yet

- Skellig Reading Guide (Part 1)Document12 pagesSkellig Reading Guide (Part 1)Enzo Cassinello BernalNo ratings yet

- SSC Science 3 SLM Q4 M5 V1.0 CC Released 8jun2021Document24 pagesSSC Science 3 SLM Q4 M5 V1.0 CC Released 8jun2021redox franciscoNo ratings yet

- m817TM - 209 2320 260 10Document413 pagesm817TM - 209 2320 260 10mettheo18189100% (2)

- Certificate of Compliance: Certificate Number Report Reference Issue DateDocument1 pageCertificate of Compliance: Certificate Number Report Reference Issue DateJohn Armely Arias GuerreroNo ratings yet

- Proposed Cavite Institute of Research, DesignDocument30 pagesProposed Cavite Institute of Research, DesignGilbert JavierNo ratings yet

- 02intro and Design DataDocument7 pages02intro and Design DataAyush SarrafNo ratings yet