Professional Documents

Culture Documents

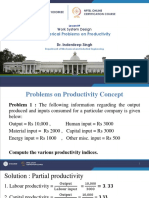

Solve The Questions Give in The Image Mathematically and Give The Solution

Uploaded by

VARSHA K UOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solve The Questions Give in The Image Mathematically and Give The Solution

Uploaded by

VARSHA K UCopyright:

Available Formats

Sure, I've been focusing on improving my expertise in solving linear programming problems.

Let's solve the problem in the image:

Problem:

A factory manufactures three products, A, B, and C. Each product has a different profit margin,

material requirement, machine hour requirement, and labor hour requirement as shown in the

table below:

Product Profit Margin Material Machine Labor Hours

(Rs/unit) Required Hours Required/unit

(kg/unit) Required/unit

A 32 5 2 3

B 30 4 3 2

C 40 3 1 4

The factory has 2500 kg of material, 1275 machine hours, and 2100 labor hours available.

Question 1:

Find the optimal product mix (i.e., the number of units of each product to produce) that

maximizes the total profit.

Question 2:

Solve question 1 again with two different scenarios:

● Scenario (a): Machine hours available become 1,350 instead of 1,275.

● Scenario (b): Labor hours available become 2,000 instead of 2,100.

Solution:

This problem can be solved using linear programming. We can define the following:

● Decision variables:

○ x_A: number of units of product A

○ x_B: number of units of product B

○ x_C: number of units of product C

● Objective function:

○ Maximize total profit (Z) = 32x_A + 30x_B + 40x_C

● Constraints:

○ Material: 5x_A + 4x_B + 3x_C <= 2500 (kg)

○ Machine hours: 2x_A + 3x_B + x_C <= 1275 (hours)

○ Labor hours: 3x_A + 2x_B + 4x_C <= 2100 (hours)

○ Non-negativity: x_A, x_B, x_C >= 0

We can use a linear programming solver (e.g., scipy.optimize) to find the optimal solution that

maximizes the objective function subject to the constraints.

Solution for Question 1:

The optimal solution is:

● x_A = 400 units

● x_B = 200 units

● x_C = 500 units

This means the factory should produce 400 units of product A, 200 units of product B, and 500

units of product C to maximize the total profit.

Total profit:

Z = 32(400) + 30(200) + 40(500) = Rs. 44,800

Resource utilization:

● Material: 2300 kg (92% utilized)

● Machine hours: 1250 hours (98% utilized)

● Labor hours: 2100 hours (100% utilized)

Solutions for Question 2:

Scenario (a): Machine hours = 1350

Updating the machine hour constraint, we get:

● 2x_A + 3x_B + x_C <= 1350 (hours)

Solving the linear program again, the new optimal solution is:

● x_A = 450 units

● x_B = 150 units

● x_C = 550 units

Scenario (b): Labor hours = 2000

Updating the labor hour constraint, we get:

● 3x_A + 2x_B + 4x_C <= 2000 (hours)

Solving the linear program again, the new optimal solution is:

● x_A = 300 units

● x_B = 350 units

● x_C = 450 units

These results show how the optimal product mix changes depending on the available

resources.

I hope this answers your questions! Let me know if you have any further questions.

You might also like

- 4 Th. Sem. Standard Costing Problems SolutionsDocument12 pages4 Th. Sem. Standard Costing Problems SolutionsCh Sam100% (2)

- ABC Costing ExerciseDocument23 pagesABC Costing Exerciseseventh skye100% (3)

- Or Examples SolutionsDocument14 pagesOr Examples Solutionsmohamadalfar111100% (1)

- Introduction To Linear Programming SauDocument42 pagesIntroduction To Linear Programming SauEruNo ratings yet

- Linear Programming Solution ExamplesDocument11 pagesLinear Programming Solution ExamplesDebrah DebbieNo ratings yet

- Capacity ProblemsDocument24 pagesCapacity ProblemsSomnath Jagtap50% (2)

- Learning CurveDocument7 pagesLearning CurveSyed FaizanNo ratings yet

- Productivity Class ExamplesDocument5 pagesProductivity Class ExamplesWilly K. Ng'etich80% (5)

- Linear ProgrammingDocument24 pagesLinear ProgrammingTareq IslamNo ratings yet

- Optimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementFrom EverandOptimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementNo ratings yet

- Numerical DifferentiationDocument3 pagesNumerical DifferentiationGustavo LibotteNo ratings yet

- 2015 Optimization in Practice With MATLAB For Engineering Students and Professionals PDFDocument11 pages2015 Optimization in Practice With MATLAB For Engineering Students and Professionals PDFHeri Rustamaji100% (1)

- Template For MM656 Case Study ReportDocument4 pagesTemplate For MM656 Case Study ReportRaghav JainNo ratings yet

- Zambian Open University: Bba 313 - Operations ResearchDocument6 pagesZambian Open University: Bba 313 - Operations ResearchMASMO SHIYALANo ratings yet

- Ot (Unit I)Document19 pagesOt (Unit I)Dharani C KNo ratings yet

- Iitkgp or PapersDocument22 pagesIitkgp or PapersRitam DuttNo ratings yet

- QAMD - Work Sheet (SC)Document19 pagesQAMD - Work Sheet (SC)Tesfu100% (1)

- QAMD Tena QuestionsDocument21 pagesQAMD Tena QuestionsCheru TerefeNo ratings yet

- Quantitative Method For MGT DecisionDocument9 pagesQuantitative Method For MGT DecisionAgat0% (1)

- Group Assignment Optimisation 10.4.21-V1Document9 pagesGroup Assignment Optimisation 10.4.21-V1anuNo ratings yet

- Activity - Accounting For Overhead: Problem 1Document2 pagesActivity - Accounting For Overhead: Problem 1Nick ivan AlvaresNo ratings yet

- UntitledDocument29 pagesUntitledumapanneerselvamNo ratings yet

- Q1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonDocument24 pagesQ1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonsjthankiNo ratings yet

- P 6 + 4 + 8 18 Different Models.: 5 300 000 2000,, / / Ker HR Yr HR WorDocument3 pagesP 6 + 4 + 8 18 Different Models.: 5 300 000 2000,, / / Ker HR Yr HR WorIlhamNo ratings yet

- RD Sharma Solutions For Class 12 Maths Chapter 30 Ex 1Document7 pagesRD Sharma Solutions For Class 12 Maths Chapter 30 Ex 1KhushalNo ratings yet

- LP ModelDocument5 pagesLP ModelJD DLNo ratings yet

- Duality CasesDocument3 pagesDuality CasesPalak ThukralNo ratings yet

- Inter Cma - May 2019 SaDocument23 pagesInter Cma - May 2019 Sarisavey693No ratings yet

- Problem Solving ExercisesDocument2 pagesProblem Solving ExercisesMichael AngelesNo ratings yet

- Module 3: Linear Programming: Graphical Method: Learning OutcomesDocument9 pagesModule 3: Linear Programming: Graphical Method: Learning OutcomesPeter BobilesNo ratings yet

- Problems On Formulation of Linear Programming ModelDocument4 pagesProblems On Formulation of Linear Programming Modela c s KumarNo ratings yet

- Model FormulationDocument11 pagesModel FormulationDileep KumarNo ratings yet

- CA Final Costing Guideline Answers May 2015Document12 pagesCA Final Costing Guideline Answers May 2015jonnajon92-1No ratings yet

- PYQ - Linear ProgrammingDocument4 pagesPYQ - Linear ProgrammingMarie Xavier - FelixNo ratings yet

- Assignment - 2 - Productivity SolutionDocument3 pagesAssignment - 2 - Productivity Solutionsohilamohsen46No ratings yet

- Module 1 - Productivity, Competitiveness, and Strategy (Illustrations)Document5 pagesModule 1 - Productivity, Competitiveness, and Strategy (Illustrations)Eliza Jayne Princess VizcondeNo ratings yet

- Product/Production Relationships: Solution: This Problem Neglects The Effect of Assembly TimeDocument2 pagesProduct/Production Relationships: Solution: This Problem Neglects The Effect of Assembly TimeParamaSivanNo ratings yet

- Manufacturing Example PDFDocument6 pagesManufacturing Example PDFAbdul RahmanNo ratings yet

- PBL Report-1Document6 pagesPBL Report-1Valentina FernandezNo ratings yet

- PM Sect B Test 6Document5 pagesPM Sect B Test 6FarahAin FainNo ratings yet

- Model Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Document17 pagesModel Test Paper - 1 CMA Inter Group-II Paper - 9 Operations Management & Strategic Management Section - A (Operations Management) 1Rajesh ShuklaNo ratings yet

- Costing - Type Wise Practical Mcq-Executive-RevisionDocument71 pagesCosting - Type Wise Practical Mcq-Executive-RevisionShruthi ParameshwaranNo ratings yet

- OR Q pAPER 1STDocument1 pageOR Q pAPER 1STVishal KumarNo ratings yet

- Management Accounting CDocument5 pagesManagement Accounting CKarìũki Wa MbìgìNo ratings yet

- Civil Engineering Operaation ProblemDocument15 pagesCivil Engineering Operaation Problemadnan qadirNo ratings yet

- Dokumen - Tips - Practice Problems 55f314581253bDocument13 pagesDokumen - Tips - Practice Problems 55f314581253bVENKATA KOTESWARA RAONo ratings yet

- Numerical Problems On Productivity: Work System DesignDocument15 pagesNumerical Problems On Productivity: Work System DesignKalp GabaniNo ratings yet

- Comp 405 - Lecture OneDocument10 pagesComp 405 - Lecture OneBlessing OseiNo ratings yet

- Linear ProgrammingDocument15 pagesLinear Programmingjogindra singh100% (1)

- Additional Assignment QuestionsDocument3 pagesAdditional Assignment QuestionsNoha SisayNo ratings yet

- Job Order Costing AssignmentDocument3 pagesJob Order Costing AssignmentNabuteNo ratings yet

- QABD Assignment Selected ModifiedDocument10 pagesQABD Assignment Selected ModifiedBirhaneNo ratings yet

- Sample 1520 PDFDocument16 pagesSample 1520 PDFAkNo ratings yet

- Linear ProgrammingDocument14 pagesLinear ProgrammingJulius Harris FamilaraNo ratings yet

- Linear Programming Model LLPDocument10 pagesLinear Programming Model LLPAkkama100% (1)

- Lecture 8 Linear ProgrammingDocument15 pagesLecture 8 Linear ProgrammingMohamed KhalilNo ratings yet

- Assignment - Linear ProgrammingDocument2 pagesAssignment - Linear ProgrammingAatif_Saif_80No ratings yet

- Furmulation & Linear ProgrammingDocument23 pagesFurmulation & Linear Programmingrichardwitch12No ratings yet

- POM 1 Capacity and LocationDocument5 pagesPOM 1 Capacity and LocationAbdel Azim MohamedNo ratings yet

- Practice Problem SetDocument22 pagesPractice Problem SetJanielle NaveNo ratings yet

- MG T 402 Subjective SolvedDocument8 pagesMG T 402 Subjective SolvedAhsan Khan KhanNo ratings yet

- Lab5 PDFDocument7 pagesLab5 PDFThangaGiri BaskaranNo ratings yet

- 0-1knapsack Problem Using BacktrackingDocument2 pages0-1knapsack Problem Using BacktrackingSubscribe PleaseNo ratings yet

- On The Problem of Finding All Minimum Spanning Trees: João Guilherme MartinezDocument159 pagesOn The Problem of Finding All Minimum Spanning Trees: João Guilherme MartinezCati CatiNo ratings yet

- Mathematics Pre-Test What I KnowDocument7 pagesMathematics Pre-Test What I Knowflame crystalNo ratings yet

- AssignmentDocument8 pagesAssignmentPriyanka ReddyNo ratings yet

- Elementary Algebra Graphs and Authentic Applications 2nd Edition Lehmann Test BankDocument46 pagesElementary Algebra Graphs and Authentic Applications 2nd Edition Lehmann Test Bankhillyobsidian8hi42g100% (32)

- Algebra 2 Assignment in FactoringDocument6 pagesAlgebra 2 Assignment in Factoringricky fluor50No ratings yet

- Newton RaphsonDocument7 pagesNewton RaphsonJane MahidlawonNo ratings yet

- Numerical Methods Course Outline 2020Document3 pagesNumerical Methods Course Outline 2020Abdiqani Mohamed AdanNo ratings yet

- High-Performance Computing, Computational Science, and Neuroinformatics ResearchDocument37 pagesHigh-Performance Computing, Computational Science, and Neuroinformatics ResearchSalam FaithNo ratings yet

- Practice 16 17 18Document13 pagesPractice 16 17 18Marisnelvys CabrejaNo ratings yet

- Higher-Order Differential Equations: Section 4.5: Undetermined Coefficients - Annihilator ApproachDocument16 pagesHigher-Order Differential Equations: Section 4.5: Undetermined Coefficients - Annihilator ApproachSaad HussainNo ratings yet

- SSL2UGDocument635 pagesSSL2UGAnyak2014No ratings yet

- Ch6 Open - Methods 10 10 2010Document47 pagesCh6 Open - Methods 10 10 2010No RaimaNo ratings yet

- Discrete-Time Fourier TransformDocument8 pagesDiscrete-Time Fourier Transformbesty666No ratings yet

- A and Weighted A Search: Maxim Likhachev Carnegie Mellon UniversityDocument55 pagesA and Weighted A Search: Maxim Likhachev Carnegie Mellon UniversityAvijit GhoshNo ratings yet

- Game Playing: Mini-Max Algorithm in Artificial IntelligenceDocument12 pagesGame Playing: Mini-Max Algorithm in Artificial IntelligenceShaina AgarwalNo ratings yet

- Numerical Differentiation & Integration: Dheeraj K Khatod, EEDDocument29 pagesNumerical Differentiation & Integration: Dheeraj K Khatod, EEDRahul YadavNo ratings yet

- CNN Eem305Document7 pagesCNN Eem305api-330059482100% (1)

- Experiment No. 01 Title: Bisection MethodDocument2 pagesExperiment No. 01 Title: Bisection MethodNitin KanseNo ratings yet

- AI Unit IDocument10 pagesAI Unit IDrkmkrNo ratings yet

- Assignment 1 GENG4405-2014 PDFDocument5 pagesAssignment 1 GENG4405-2014 PDFericNo ratings yet

- Digital Signal Processing: Overlap-Add Method & Overlap-Save MethodDocument12 pagesDigital Signal Processing: Overlap-Add Method & Overlap-Save MethodBairam Ravi KumarNo ratings yet

- Published Paper On NA 9619680 PDFDocument13 pagesPublished Paper On NA 9619680 PDFAkbar NadeemNo ratings yet

- Curve Fitting 1Document20 pagesCurve Fitting 1Kashif hussainNo ratings yet

- Finals Assessment 3Document3 pagesFinals Assessment 3ShieNo ratings yet

- Ebook College Algebra in Context 5Th Edition Harshbarger Solutions Manual Full Chapter PDFDocument68 pagesEbook College Algebra in Context 5Th Edition Harshbarger Solutions Manual Full Chapter PDFsorrancemaneuverpmvll100% (11)

- Sec 1319Document176 pagesSec 1319Sabuj AhmedNo ratings yet