Professional Documents

Culture Documents

CHEM IND 20210126 Min

Uploaded by

juan carlos suaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHEM IND 20210126 Min

Uploaded by

juan carlos suaCopyright:

Available Formats

SOLUTIONS FOR THE

CHEMICAL INDUSTRIES

ASME PRESSURE CLASS

BRAY.COM THE HIGH PERFORMANCE COMPANY

YOUR PROCESS CONTROL PARTNER

AGRI-CHEMICALS INDUSTRIAL GASES PIGMENTS

CHLOR-ALKALI SPECIALTY CHEMICALS PLASTICS & RUBBERS

FIBERS PETROCHEMICALS SURFACTANTS

The chemical industry involves a diverse collection of processes, with demanding applications

and extreme service conditions. Our broad portfolio of high-performance valves, actuators, and

controls ideally positions Bray to meet these challenging needs — from basic and commodity

chemicals, to polymers and specialty chemicals. With products engineered for safety, reliability,

and performance, you can count on Bray as your technical partner of choice — to provide

innovative solutions for years to come.

SOLUTIONS FOR THE CHEMICAL INDUSTRIES

Bray products are available for a variety of services, including:

> Vapors & Gases > High Temperature > Slurry

> High Purity > Cryogenic > Solids

> Liquids > Steam

ISOLATION VALVES CONTROL VALVES AUTOMATION

Reliable zero-leakage to shut off flow Engineered solutions to regulate flow Bray’s modular line of actuators

of process media to a given location of liquid or gas — with high precision, and direct-mount accessories offer

— usually for maintenance or safety accuracy, and fast response times — reduced size requirements, flexible

purposes. for a wide range of processes. configurations, and economic savings.

For complete product details and document downloads, visit BRAY.COM

CERTIFICATIONS

Our performance-tested products are in compliance with a variety of global certifications and approvals, including Lloyd’s

Register, UL, ABS and more.

Factory Certifications Product Certifications

and Approvals > API 607 > CE PED

> ISO 9001 and ISO 14001 > API 608 > CRN

> OHSAS 18001 > API 609 Category A & B > ISO 15848-1

> TSG > API 641 > GOST

> ATEX > SIL3 Certification

2 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

SAFETY SYSTEMS DEMAND RELIABILITY

For your critical Safety Instrumented System (SIS) needs, Packages can be configured and certified for safety

Bray offers custom engineered solutions featuring our line applications including Emergency Shut Down (ESD), High

of reliable valves, actuators, and controls. Integrity Pressure Protection Systems (HIPPS), and others.

SAFETY INSTRUMENTED SYSTEM (SIS) CAPABILITIES

Partnering with Bray for your SIS needs offers many advantages, such as:

> Single-source OEM responsibility for complete > Custom control panel designs.

automated valve packages. > 3D CAD modeling.

> Safety Integrity Level 3 (SIL 3) certified valve assemblies. > Valve flow modeling.

> Customizable configurations, including adaptation of > Finite Element Analysis (FEA).

Bray automation to non-Bray valves.

AUTOMATED VALVE ASSEMBLIES

Capabilities of Bray's automated valve assemblies include:

> Rugged actuator design — Bray's S98 scotch yoke > Positive Material Identification (PMI) — to verify materials

pneumatic actuator is cycle tested up to 4X the required on critical applications.

standard (EN15714-3 Actuator Performance Standard). > Fugitive emissions certification to API 641 and ISO 15848-1.

> Fast acting actuation — <1 second. > Firesafe certification to API 607.

> Partial stroke test (local and remote).

Triple Offset Butterfly Valves High Performance Butterfly Valves Flanged Ball Valves

Metal Seated Ball Valves Scotch Yoke Pneumatic Actuators Trunnion Mounted Ball Valves

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM |3

FUGITIVE EMISSIONS

KEEPING OUR

AIR CLEAN

Recognizing the importance of sustainability, socially Bray is committed to helping organizations around the world

responsible organizations have begun looking for ways tighten their grip on fugitive emissions. Our industry leading

to mitigate the environmental impact of their operations. range of low-emissions, quarter-turn valves are certified for

These efforts have brought attention to the volume of volatile maximum compliance with minimum environmental impact.

organic compounds released by industrial manufacturing Certification and testing standards include:

processes. With unintentional leaks from industrial equipment > API 641

(such as valves) comprising the vast majority of these fugitive > ISO 15848

emissions, environmental agencies have been forced to > TA Luft VDI 2440

establish emissions standards — often imposing heavy fines

on those in violation.

FUGITIVE EMISSION TEST FACILITIES

Bray Research & Development facilities in Houston, India, Run by trained and experienced fugitive emissions

and China include safe, dedicated areas with extensive specialists, our facilities include:

gas leakage detection equipment — used for product > Helium mass spectrometer.

development, validation, and production testing. > Tracer gas leak standards with calibrated depletion rates

— for accurate and precise testing and pressures up to

6,000 psi (414 bar).

> Measurement capabilities at extreme temperatures from

-320°F to 1,000°F (-196°C to 538°C).

4 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

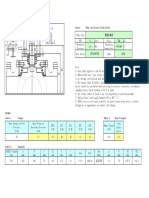

PRODUCT APPLICATION GUIDE

PROCESS

SPECIALTY CHEMICALS

PLASTICS & RUBBERS

INDUSTRIAL GASES

PETROCHEMICALS

AGRI-CHEMICALS

CHLOR-ALKALI

SURFACTANTS

PIGMENTS

FIBERS

PRODUCT BRAND TYPE MODEL

CONTROL Flow-Tek Segmented Ball Series 19

VALVES

V-port

BALL VALVES Amresist PFA Lined Acris

Flow-Tek Severe Service Series M1, M4

Trunnion Mounted 1B

Flanged (2-pc) Series F15/F30

Flanged (1-pc) Series RF15/RF30

3-piece Triad

Multi-port MPF/MPT

BUTTERFLY Amresist PFA Lined Acris

VALVES

Bray Triple Offset Tri Lok

High Performance McCannalok

Resilient Seated Series 2X, 3X

KNIFE GATE Bray Unidirectional 950

VALVES

940

Bidirectional 740

762

768

CHECK VALVES Rite Swing Check 205, 210

ACTUATORS Pneumatic

Bray Scotch Yoke Series 98

Hydraulic Series 98H

Scotch Yoke

Pneumatic Series 92/93

Rack & Pinion

Gear Operator Series 04, 05

Flow-Tek Gear Operator FTG

CONTROL Bray Positioner Series 6A/6P

ACCESSORIES

Proximity Sensor Series 54

Valve Status Series 5A/5B/5C

Monitor

Solenoid Series 60/62/63

Filter Regulator Series 55

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM |5

CONTROL VALVES | BALL VALVES

CONTROL VALVES | SEGMENTED BALL

> Segmented ball valve for modulating control and on-off applications in gas, liquid,

and slurry services.

> Uninterrupted flow path with customizable profiles and trim materials is ideal for

handling solids and viscous media.

> Splined stem-to-segment connection provides precise control with low hysteresis.

> Optimized seat design provides constant sealing force, even at low differential

pressures.

> Optional replaceable liners and hard coatings for highly abrasive applications.

Size Range NPS 1 to 16 DN 25 to 400

Temperature Range -50°F to 500°F -46°C to 260°C

Flow-Tek Series 19 Pressure Ratings ASME Class 150 | 300 | 600

Fugitive Emissions ISO 15848-1

CONTROL VALVES | V-PORT

> Bidirectional, bubble-tight shutoff and modulating control in a single package.

> Standard and custom characterized ports allow for precise control over a wide

flow range.

> Non-turbulent flow path offers higher Cv, with rangeability in excess of 800:1.

> Wide range of seat materials to meet application needs, including high pressures

and temperatures.

> Adjustable live-loaded stem sealing system with certified low emission packing.

Size Range NPS 1⁄2 to 12 DN 15 to 300

Temperature Range -50°F to 650°F -46°C to 343°C

Pressure Ratings ASME Class 150 | 300 | 600

Flow-Tek V-Control Fugitive Emissions API 641 | ISO 15848-1 | TA Luft VDI 2440

SIL 3 Capable

BALL VALVES | PFA LINED

> Fully PFA lined body, ball, and stem provides unsurpassed resistance to corrosion.

> Bidirectional zero-leakage sealing in standard and full port configurations.

> Robust 1-piece ball and stem in full port design, with optional V-port for

modulating.

> Adjustable PTFE packing provides positive stem sealing and reduces fugitive

emissions.

> ISO 5211 top mounting plate simplifies actuator mounting.

Size Range NPS 1⁄2 to 6 DN 15 to 150

Temperature Range -49°F to 400°F -45°C to 204°C

Pressure Ratings Up to 250 psi Up to 17 bar

Amresist Acris

SIL 3 Capable (Full Port)

6 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

BALL VALVES

BALL VALVES | SEVERE SERVICE (2-PIECE AND 3-PIECE BODY)

> Application-specific designs for extreme process conditions in unidirectional

and bidirectional applications.

> Energized ball & seats with wide sealing surfaces ensure reliable performance

during all operating conditions.

> 360° mate-lapped ball & seats provide uninterrupted sealing and extend valve life.

> Matched trim materials and hard coatings equalize thermal expansion rates to

improve performance and extend valve life.

> One-piece blowout-proof stem with gall resistant dual thrust bearings protect

against actuator misalignment and stem sideloading.

> Adjustable live-loaded stem sealing system with certified low emission packing.

Flow-Tek Series M1 Size Range NPS 1⁄2 to 36 DN 15 to 900

SIL 3 Capable Temperature Range Up to 1100°F Up to 593°C

Pressure Ratings ASME Class 150 to 4500

Fugitive Emissions API 641 | ISO 15848-1

BALL VALVES | SEVERE SERVICE (UNIBODY)

> Forged heavy-wall unibody design for extreme pressures and temperatures in

unidirectional applications.

> Energized ball & seats with wide sealing surfaces ensure reliable performance

during all operating conditions.

> 360° mate-lapped ball & seats provide uninterrupted sealing and extend valve life.

> One-piece blowout-proof stem with upper bearing protects against actuator

misalignment and stem sideloading.

> Standard 4-year performance warranty.

Flow-Tek Series M4 Size Range NPS 1⁄2 to 4 DN 15 to 100

Temperature Range Up to 1100°F Up to 593°C

Pressure Ratings ASME Class 1700 to 4500

BALL VALVES | TRUNNION MOUNTED

> API 6D forged construction is ideally suited for a wide range of applications.

> Self-relieving seat design allows for safe operation without the need for

dedicated bleed lines.

> Pressure energized stem sealing system includes sealant injection ports

compliant with ISO 15848-1.

> Double block and bleed capable, with standard drain and vent ports.

> Available API 607 certification and NACE MR0175 compliance.

Size Range NPS 2 to 24 DN 50 to 600

Flow-Tek Series 1B Temperature Range -50°F to 600°F -45°C to 315°C

SIL 3 Capable Pressure Ratings ASME Class 150 | 300 | 600

Fugitive Emissions ISO 15848-1

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM |7

BALL VALVES

BALL VALVES | FLANGED

> Available in 2-piece (full port) and 1-piece (standard port) body configurations.

> Adjustable live-loaded stem sealing system with certified low emission packing.

> Seat design ensures bidirectional zero-leakage performance with low operating

torque.

> Optional cavity fillers reduce the potential for media entrapment and process

contamination.

> Available API 607, API 608, and NACE MR0175 compliance.

Size Range NPS 1⁄2 to 12 DN 15 to 300

Temperature Range -50°F to 750°F -46°C to 399°C

Pressure Ratings ASME Class 150 | 300

Fugitive Emissions API 641 | ISO 15848-1 | TA Luft VDI 2440

Flow-Tek Series RF15/RF30, F15/F30

SIL 3 Capable

BALL VALVES | 3-PIECE BODY

> Modular design available in full or standard port, with a variety of end

connections.

> Encapsulated bolting and dual body seals provide added protection against

external leakage.

> Adjustable live-loaded stem sealing system with certified low emission packing.

> Optional cavity fillers reduce the potential for media entrapment and process

contamination.

> Available API 607, API 608, and NACE MR0175 compliance.

Size Range NPS 1⁄4 to 4 DN 8 to 100

Flow-Tek Triad Series Temperature Range -50°F to 550°F -46°C to 287°C

SIL 3 Capable Pressure Ratings Up to 2200 psi Up to 151 bar

Fugitive Emissions API 641 | ISO 15848-1 | TA Luft VDI 2440

BALL VALVES | MULTI-PORT

> Multi-directional flow control with flanged, threaded, or weld-in end connections.

> 3-way and 4-way configurations in standard or full port, for diverting or mixing

applications.

> Live-loaded stem packing design ensures positive sealing to the atmosphere.

> Four-seat design maintains balanced seat loading and proper ball alignment.

> Optional cavity fillers reduce the potential for media entrapment and process

contamination.

Size Range NPS 1⁄2 to 12 DN 15 to 300

Flow-Tek Series MP Temperature Range -25°F to 500°F -31°C to 260°C

Pressure Ratings ASME Class 150 | 300

8 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

BALL VALVE ACCESSORIES

MEDIA CONTAINMENT UNIT

Flow-Tek's Media Containment Unit (MCU) has been engineered to provide increased

environmental protection and plant safety, through a secondary seal — which can be

monitored for early detection of stem leaks.

> Designed for both automated and manual service with Flow-Tek's modular

line of automation accessories.

> Available sealant injection system for emergency shut-off or third seal.

> Investment cast stainless steel unit is highly corrosion-resistant.

> Easily installed in the field onto existing Flow-Tek ball valves.

> Lowers operating costs by reducing lost production time due to fugitive

emissions and unscheduled maintenance.

Flow-Tek MCU

BODY CAVITY FILLERS

Available body cavity fillers reduce body cavity volume in order to minimize

freezing, seizing and trapped media, ensuring smooth valve operation, even in

tough conditions.

> Cavity fillers reduce the potential for media entrapment in the void between

the ball and the valve body.

> Retrofittable design reduces cavity volume by more than 90%.

> Prevents cross-process contamination.

> Ideal for polymerizing media and sanitary applications.

Flow-Tek Body Cavity Fillers > Available materials include TFM, Tek-Fil, UHMWPE.

SPRING RETURN HANDLES

Spring return handles are manufactured from heavy duty stainless steel

components, to withstand frequent daily use in refueling, sampling, drains, and

other OSHA applications that require positive closure of a manual valve.

> Locking device is standard, for locking the valve in the preferred position.

> Available in 3 sizes to fit compatible Flow-Tek full or standard port ball valves.

> Mounts directly to rugged investment cast ISO 5211 mounting pads.

> Easily retrofitted on existing compatible Flow-Tek lever operated ball valves.

Flow-Tek Series SRH

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM |9

BUTTERFLY VALVES

BUTTERFLY VALVES | PFA LINED (2-PIECE BODY)

> Fully PFA lined disc and body provide unsurpassed resistance to corrosion,

permeation, and microbial contamination.

> Bidirectional zero seat leakage with streamlined disc engineered for maximum

flow (Cv) with minimal resistance.

> Acriseal™ live-loaded self-adjusting stem sealing system eliminates leak paths

and reduces fugitive emissions.

> Energized flange seals maintain proper sealing between valve and pipe flange.

> Optional Titanium Grade 7 disc and shaft for highly corrosive environments.

Size Range NPS 1 to 24 DN 25 to 600

Amresist Acris ® Temperature Range -20°F to 320°F -29°C to 160°C

Pressure Ratings Up to 150 psi Up to 10 bar

Fugitive Emissions ISO 15848-1

BUTTERFLY VALVES | TRIPLE OFFSET

> Designed for high pressure, high temperature, and critical service applications.

> Bidirectional, torque seated, metal-to-metal sealing with zero leakage.

> Splined disc-to-stem connection prevents misalignment and minimizes hysteresis.

> Fully adjustable stem sealing system with certified low-emission packing.

> Field-replaceable sealing components minimize maintenance costs and extend

valve service life.

Size Range NPS 3 to 48 DN 80 to 1200

Temperature Range -320°F to 842°F -196°C to 450°C

Pressure Ratings ASME Class 150 | 300 | 600 | 900

Tri Lok Fugitive Emissions API 641 | ISO 15848-1 | TA Luft VDI 2440

SIL 3 Capable

BUTTERFLY VALVES | HIGH PERFORMANCE

> Designed for high pressure, high temperature, and critical service applications.

> Energized resilient seat design provides bidirectional, zero leakage shutoff

throughout the full pressure range.

> Double offset geometry reduces seat wear and extends valve service life.

> Fully adjustable stem sealing system with certified low-emission packing.

> Optional firesafe and metal seat designs available.

Size Range NPS 2 to 66 DN 50 to 1650

Temperature Range -320°F to 842°F -196°C to 450°C

Pressure Ratings ASME Class 150 | 300 | 600

McCannalok Fugitive Emissions API 641 | ISO 15848-1 | TA Luft VDI 2440

SIL 3 Capable

10 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

BUTTERFLY VALVES

BUTTERFLY VALVES | RESILIENT SEATED (1-PIECE BODY)

> Industry leading bidirectional butterfly valve designs since 1986.

> Streamlined disc engineered for maximum flow (Cv) with minimal resistance.

> Spherically machined and polished disc edge for zero leakage and longer seat life.

> Internal disc-to-stem connection isolates the line media from the valve stem.

> Tongue and groove seat is locked in place, allowing use in dead end services.

Size Range NPS 2 to 20 DN 50 to 500

Temperature Range -20°F to 400°F -29°C to 204°C

Pressure Ratings Up to 175 psi Up to 12 bar

Bray Series 30/31

SIL 3 Capable

BUTTERFLY VALVES | RESILIENT SEATED (2-PIECE BODY)

> 2-piece wafer or lug style allows for ease of assembly and maintenance.

> Engineered disc maximizes flow and minimizes resistance, providing a high Cv.

> Spherically machined and polished disc edge for zero leakage and longer seat life.

> 1-piece disc/stem design provides complete protection from particle entrapment.

> Tongue and groove seat is locked in place, allowing use in dead end services.

> Available with stainless steel body for corrosive environments.

Size Range NPS 1 to 20 DN 25 to 500

Temperature Range -20°F to 400°F -29°C to 204°C

Pressure Ratings Up to 150 psi Up to 10 bar

Bray Series 20/21

SIL 3 Capable

BUTTERFLY VALVES | PTFE LINED (2-PIECE BODY)

> 2-piece wafer or lug style body with epoxy coating.

> Stainless steel disc can be encapsulated in a variety of materials.

> Blowout proof stem and disc are pressed together for a positive connection.

> PTFE seat is isostatically molded to provide superior chemical resistance.

> Resilient seat energizer provides uniform force for bubble tight shutoff.

Size Range NPS 2 to 24 DN 50 to 600

Temperature Range 0°F to 392°F -18°C to 200°C

Pressure Ratings Up to 150 psi Up to 10 bar

Bray Series 22/23

SIL 3 Capable

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM | 11

KNIFE GATE VALVES | CHECK VALVES

KNIFE GATE VALVES | UNIDIRECTIONAL

> Engineered for on/off services, ranging from general purpose to severe media,

including slurries, powders, and solids.

> 1-piece body with a wide range of soft or metal seat options.

> Optional deflection cone and purge ports.

> Available energized quad seal packing for enhanced gland sealing.

> Designed for manual and automated applications.

Size Range NPS 2 to 36 DN 50 to 900

Temperature Range -65°F to 392°F -54°C to 200°C

Pressure Ratings Up to 150 psi Up to 10 bar

Bray Series 940, 950

KNIFE GATE VALVES | BIDIRECTIONAL

> Engineered for on/off services, ranging from general purpose to severe media,

including slurries, powders, and solids.

> Available in 1-piece or 2-piece body styles.

> Steel-reinforced, elastomer sleeve designed for bidirectional zero-leakage shutoff.

> Optional deflection cone and purge ports.

> Available energized quad seal packing for enhanced gland sealing.

> Designed for manual and automated applications.

Size Range NPS 2 to 36 DN 50 to 900

Temperature Range -65°F to 392°F -54°C to 200°C

Pressure Ratings Up to 150 psi Up to 10 bar

Bray Series 740, 762, 768

CHECK VALVES | SWING CHECK

> Flow-activated, wafer design, swing check valve.

> Resilient or metal seated models offer zero-leakage in all pressure classes.

> High-flow, low pressure drop design.

> Limited movement of internal parts reduces wear and enhances service life.

> Full line of accessories available to meet many application needs.

Size Range NPS 1 to 60 DN 25 to 1500

Temperature Range -50°F to 650°F -46°C to 343°C

Pressure Ratings Class 125 to 2500

Rite 210

12 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

ACTUATION

ACTUATOR | PNEUMATIC & HYDRAULIC SCOTCH YOKE

> Modular design allows for a wide range of configurations, for both single and

double acting applications.

> Designed for reliable, high-cycle operation with simplified maintenance.

> Compact design offers a high torque-to-weight ratio, with easy field configuration.

> Symmetrical or canted yokes provide optimized torque output.

> ATEX, SIL 3 capable, IP66/IP67M; PED upon request.

Bray Series 98 Pneumatic Torque Output Range 2,744 to 885,100 in-lb 310 to 100,000 Nm

SIL 3 Capable Temperature Range -50°F to 300°F -46°C to 149°C

Pressure Ratings 40 to 150 psi 2.8 to 10.3 bar

Bray Series 98 Hydraulic

SIL 3 Capable

ACTUATOR | PNEUMATIC RACK & PINION

> Modular design available for single or double acting applications.

> Enclosed and self-contained construction with internal air porting.

> Permanently lubricated, with independently adjustable travel stops.

> Anodized aluminum body with polyester coated end caps; special materials

and coatings available for added corrosion resistance.

> ATEX, SIL 3 capable, PED.

Torque Output Range Up to 44,130 in-lb 4,986 Nm

Bray Series 92/93 Temperature Range -40°F to 350°F -40°C to 149°C

SIL 3 Capable Pressure Ratings Up to 140 psi Up to 10 bar

ACTUATOR | MANUAL GEAR

> Heavy duty, self-lubricating, self-locking design for on/off or modulating

applications.

> Valve position indicator with independently adjustable travel stops.

> Declutch, chainwheel, lockout, square nut, and stainless steel housing

options available.

Bray Series 04, 05

Torque Output Range 2,000 to 70,000 in-lb 226 to 7,900 Nm

Temperature Range Up to 250°F Up to 120°C

Flow-Tek Series FTG

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM | 13

CONTROL ACCESSORIES

CONTROL ACCESSORIES | ELECTRO-PNEUMATIC POSITIONER

Precision digital control with proven reliability, Series 6A positioners are designed

with ease of installation, simple calibration, efficiency, and economy in mind.

> Zero bleed design with LCD display and auto calibration function.

> Standard 4-20 mA input. Optional Hart, Profibus PA, or Fieldbus

communications protocols available.

> Available polycarbonate, aluminum, or stainless steel enclosure.

Bray Series 6A > Intrinsically safe (Ex ia, ib) or explosion proof (Ex d) available on request.

SIL 2 Capable SIL 2 capable.

> Intelligent features include Partial Stroke Test, Fail in Place, Fail Safe, and Valve

Performance Test.

Bray Series 6A Explosion Proof

SIL 2 Capable

CONTROL ACCESSORIES | PNEUMATIC POSITIONER

Outstanding control and split-range capability for a wide range of quarter-turn

valves with Double Acting or Single Acting/Spring Return actuators.

> 2-stage pilot relay design provides precise response characteristics using

a 3-15 psi pneumatic control signal.

> High visibility dome position indicator with 3 gauges as standard.

> Anodized and powder-coated aluminum construction for corrosion resistance.

Bray Series 6P > Simple calibration with independent zero and span adjustments.

SIL 2 Capable > 4-20mA position feedback transmitter and/or limit switches available.

CONTROL ACCESSORIES | INDUCTIVE PROXIMITY SENSOR

Series 54 Inductive Proximity Sensors provide non-contact valve position

monitoring solutions for reliable plant operation. Compact design mounts easily

to VDI/VDE 3845 compliant quarter-turn actuators.

> Two independent sensors for open and close valve position indication.

> Rugged design is resistant to shock, vibration, UV, and corrosion.

> IP66/67/69K enclosures with hermetically sealed sensors protect against

environmental ingress.

> Non-contact sensing eliminates the effects of mechanical wear, switch welding,

Bray Series 54 arcing, and sparking.

SIL 2 Capable > LED indication for sensor power, switch, and solenoid status.

> Available AS-i sensor for digital networks solutions.

14 | © 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM

CONTROL ACCESSORIES

CONTROL ACCESSORIES | VALVE STATUS MONITOR

Series 5A, 5B, and 5C Valve Status Monitors (VSM) provide reliable visual and

electrical position indication on all VDI/VDE 3845 compliant quarter-turn rotary

actuators. Suitable for general purpose environments (5A and 5B), intrinsically safe

areas (5A and 5B), or hazardous locations (5C).

> Shatterproof and UV-resistant dome indicators are double sealed to prevent

water ingress.

> IP66/67/68 rated enclosures provide ensure reliable operation in all operating

environments.

> Intrinsically safe (Ex ia) or explosion proof (Ex db, tb) available on request.

> Spring loaded splined cams facilitate easy and accurate switch setting.

Bray Series 5A, 5B, 5C > CommPro (AS-i), Device Net, and Profibus DP network protocols are available

+ Optional Resin Housing for digital network solutions.

> Multiple switch options with imperial or metric conduit connections and easy

access terminal strips.

CONTROL ACCESSORIES | SOLENOID

Suitable for use with single or double acting actuators, these Series 60/63

solenoid valves are available with 1⁄2 NPT conduit connections or DIN connectors

with PG9 cable gland.

> Compact modular construction.

> Pilot operated spool control design, with single or dual coil.

> Low power, intrinsically safe, and hazardous location options available.

> NEMA 4, 4X, IP65 rated.

Bray Series 60, 63

CONTROL ACCESSORIES | FILTER REGULATOR

Designed to provide nominal filtration removal of solids and liquids from

compressed air, with accurate control to any pneumatic control device.

Recommended for use with the Bray Series 6A and 6P positioners.

> Provides 5 micron filtration.

> Locking knob allows for downstream pressure adjustment, and locks the

pressure setting in place.

> Threaded collar permits easy attachment of bracket for panel mounting.

> Bowl quick-release allows easy access to filter element without special tools.

Bray Series 55

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM | 15

SINCE 1986, BRAY HAS PROVIDED FLOW CONTROL SOLUTIONS

FOR A VARIETY OF INDUSTRIES AROUND THE WORLD.

VISIT BRAY.COM TO LEARN MORE ABOUT

BRAY PRODUCTS AND LOCATIONS NEAR YOU.

HEADQUARTERS

Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: +1.281.894.5454

All statements, technical information, and recommendations in this bulletin are for general

use only. Consult Bray representatives or factory for the specific requirements and material

selection for your intended application. The right to change or modify product design or

product without prior notice is reserved. Patents issued and applied for worldwide.

Bray® is a registered trademark of Bray International, Inc.

© 2021 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM B_1080_EL_CHEM IND_2021_01

THE HIGH PERFORMANCE COMPANY BRAY.COM

You might also like

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- A10-Habonim Booklet Accessories 251121Document47 pagesA10-Habonim Booklet Accessories 251121muhammad0umar-4No ratings yet

- Micro Finish Ball Valve CatalogueDocument18 pagesMicro Finish Ball Valve CatalogueProcess Controls & ServicesNo ratings yet

- CryogenicDocument104 pagesCryogenicIvan HoNo ratings yet

- Sicomat Catalogo GeneralDocument410 pagesSicomat Catalogo GeneralChriss VzzNo ratings yet

- RELIABLE Introduction LetterDocument3 pagesRELIABLE Introduction Letterrajkumar_kesirajuNo ratings yet

- Catalogue Bom Dinh Luong Blue WhiteDocument20 pagesCatalogue Bom Dinh Luong Blue WhiteNguyễn Minh GiápNo ratings yet

- Chemlube diester-based compressor lubricantsDocument2 pagesChemlube diester-based compressor lubricantsMohamad HudhaNo ratings yet

- BIAR_Brochure_ENDocument10 pagesBIAR_Brochure_ENtom2csfNo ratings yet

- M e Hyd - Print PDFDocument19 pagesM e Hyd - Print PDFRasheshNo ratings yet

- Drilling Product CatalogueDocument43 pagesDrilling Product Cataloguemin thantNo ratings yet

- HAWKS Company Profile-201110Document65 pagesHAWKS Company Profile-201110Mohamed RaafatNo ratings yet

- Broshura Gas Pipes enDocument32 pagesBroshura Gas Pipes enJayeshNarangNo ratings yet

- Flow Max Cat2Document20 pagesFlow Max Cat2Wat SuwatNo ratings yet

- Actuation: Product CatalogDocument52 pagesActuation: Product CatalogLuis Alberto Serrano MesaNo ratings yet

- Wilk IrsonDocument534 pagesWilk IrsonParis AnabelNo ratings yet

- Icc Es ReportDocument4 pagesIcc Es ReportDuy NguyenNo ratings yet

- 3M Mask 6000 SeriesDocument4 pages3M Mask 6000 SerieschrisNo ratings yet

- Pds Detail PageDocument2 pagesPds Detail PageAbraham EnriqueNo ratings yet

- A6-Habonim Booklet Control v04 210621 PDFDocument79 pagesA6-Habonim Booklet Control v04 210621 PDF장훈No ratings yet

- FLUIDYNE Seal Design Manual PDFDocument76 pagesFLUIDYNE Seal Design Manual PDFAKHLESH JHALLARE100% (1)

- Aerospace Composite AutoclaveDocument7 pagesAerospace Composite Autoclaveaecsuresh35No ratings yet

- OASIS Company Profile and Product ListDocument10 pagesOASIS Company Profile and Product Listgau111No ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Composited Lined Butterfly Valves (Series BFVSC)Document12 pagesComposited Lined Butterfly Valves (Series BFVSC)AgustinaDeWinneNo ratings yet

- ASME Codes & Standards Guide for Safety ValvesCodes & StandardsAPICodes & StandardsWorldwide ApprovalsDocument14 pagesASME Codes & Standards Guide for Safety ValvesCodes & StandardsAPICodes & StandardsWorldwide ApprovalsIbhar Santos MumentheyNo ratings yet

- Results EnclosuresDocument2 pagesResults Enclosuresl0k0tusNo ratings yet

- 01-01 - LESER-The Safety ValveDocument36 pages01-01 - LESER-The Safety ValveAdrian PetrascuNo ratings yet

- Cryogas - Profile - 2011 PDFDocument26 pagesCryogas - Profile - 2011 PDFRey LieNo ratings yet

- Rainwater GoodsDocument100 pagesRainwater GoodsAFW111No ratings yet

- Chemtrol PVC CPVCDocument60 pagesChemtrol PVC CPVCTHEARY THUNNo ratings yet

- Flos Low ResDocument8 pagesFlos Low ResAmir AmkaNo ratings yet

- Akarmak Autoclaves PDFDocument28 pagesAkarmak Autoclaves PDFAnonymous Hy5Ir9QXNo ratings yet

- CVA Gate Globe Check Strainers CatalogDocument95 pagesCVA Gate Globe Check Strainers CatalogRiss0No ratings yet

- SRP Retrievable Chem ToolDocument2 pagesSRP Retrievable Chem ToolValtour NencheNo ratings yet

- Weir Ball ValveDocument20 pagesWeir Ball ValveAmr ZayanNo ratings yet

- Synthetic Refrigeration Lubricant Product DataDocument2 pagesSynthetic Refrigeration Lubricant Product Datanauta007No ratings yet

- SEIM Manufacturing Program Screw Pumps Febr.2011 Rev.2aDocument36 pagesSEIM Manufacturing Program Screw Pumps Febr.2011 Rev.2areach_arindomNo ratings yet

- Catalog: Iron Plug ValvesDocument44 pagesCatalog: Iron Plug Valvesjose eduardoNo ratings yet

- Gsfe Catalogue PDFDocument160 pagesGsfe Catalogue PDFAlejandro GilNo ratings yet

- Ball Valve Is Designed For Cryogen Flow Isolation at - 196°C: in BriefDocument1 pageBall Valve Is Designed For Cryogen Flow Isolation at - 196°C: in BriefCatalin PruncuNo ratings yet

- Pds Aircol PDDocument2 pagesPds Aircol PDtribolasNo ratings yet

- BUL Parker IHP Welding enDocument20 pagesBUL Parker IHP Welding enMuhammad FerialNo ratings yet

- 2017 Exhibiting CompaniesDocument18 pages2017 Exhibiting CompaniesUmasankar Chakravorti0% (1)

- 1 - Split BodyDocument55 pages1 - Split BodyBoris BastosNo ratings yet

- Broen Aw-Catalogue PDFDocument14 pagesBroen Aw-Catalogue PDFAnonymous ItzBhUGoiNo ratings yet

- Arcoline 60Document2 pagesArcoline 60anantNo ratings yet

- Objasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Document4 pagesObjasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Nebojsa MirkovicNo ratings yet

- Sealing CatalogueDocument160 pagesSealing Cataloguenata18040No ratings yet

- Spiro Hoses - Catalogue 20-11-19 PDFDocument16 pagesSpiro Hoses - Catalogue 20-11-19 PDFPritesh KoratNo ratings yet

- Ptbig Profile 2023 v4Document15 pagesPtbig Profile 2023 v4maderainsancitaNo ratings yet

- Capella WF: Ultra High Performance Refrigeration Compressor LubricantDocument3 pagesCapella WF: Ultra High Performance Refrigeration Compressor LubricantJeremias UtreraNo ratings yet

- Permatex Silicone Ceramic Extreme Brake Lubricant 80653 (orange)Document2 pagesPermatex Silicone Ceramic Extreme Brake Lubricant 80653 (orange)answersfasterNo ratings yet

- Oil and Petrochemical OverviewDocument12 pagesOil and Petrochemical OverviewMarcus ViniciusNo ratings yet

- Blue Ray Profile With IsoDocument11 pagesBlue Ray Profile With IsosalesblueraynationalNo ratings yet

- Us Products Industrial Air BrochureDocument24 pagesUs Products Industrial Air BrochureAnonymous vRyv4wMNo ratings yet

- Hydro of Santoo Sealing Technologies Kezad UpdatedDocument6 pagesHydro of Santoo Sealing Technologies Kezad UpdatedSales DeptNo ratings yet

- Aircol SN RangeDocument2 pagesAircol SN RangecarmaNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Addendum - A - 1419 000 PTC 602Document9 pagesAddendum - A - 1419 000 PTC 602juan carlos suaNo ratings yet

- Ingenieria de Detalle para La Ampliación Y Optimización de Las Facilidades de Tratamiento de Fluidos Campo Rio SaldañaDocument1 pageIngenieria de Detalle para La Ampliación Y Optimización de Las Facilidades de Tratamiento de Fluidos Campo Rio Saldañajuan carlos suaNo ratings yet

- Cryogenic Ball Valve Technical BulletinDocument2 pagesCryogenic Ball Valve Technical Bulletinjuan carlos suaNo ratings yet

- 207.470.1 Siemens SIPART PS2 SIL-Certificate - QM11.F19 - SignedDocument1 page207.470.1 Siemens SIPART PS2 SIL-Certificate - QM11.F19 - Signedjuan carlos suaNo ratings yet

- Ga 55185 PDFDocument1 pageGa 55185 PDFjuan carlos suaNo ratings yet

- Central de Generación: Power Plant Pressure - Temperature Regulator ValveDocument1 pageCentral de Generación: Power Plant Pressure - Temperature Regulator Valvejuan carlos suaNo ratings yet

- 5.-Vitas-Gate-Valves - ValvitaliaDocument24 pages5.-Vitas-Gate-Valves - Valvitaliajuan carlos suaNo ratings yet

- Listado de Marcas aceptadas-GAB-P-022 PDFDocument42 pagesListado de Marcas aceptadas-GAB-P-022 PDFDiegoNo ratings yet

- Fig 143XU Globe CraneFS DS 1702 P153 - 1Document1 pageFig 143XU Globe CraneFS DS 1702 P153 - 1atnkpr_vn9368No ratings yet

- Astm A75Document4 pagesAstm A75gefNo ratings yet

- Topworks - Ball FloatingDocument5 pagesTopworks - Ball Floatingjuan carlos suaNo ratings yet

- Refinery Piping Corrosion Case Study: Steam Tracing Causing Caustic GougingDocument4 pagesRefinery Piping Corrosion Case Study: Steam Tracing Causing Caustic Gouginganaswara santhoshNo ratings yet

- Topworks - V5 BS Top DimensionDocument1 pageTopworks - V5 BS Top Dimensionjuan carlos suaNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- Ejercicio de RecicloDocument16 pagesEjercicio de Reciclojuan carlos suaNo ratings yet

- Valtek MK1 IOMDocument12 pagesValtek MK1 IOMJuan HernandezNo ratings yet

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- Varistroke-I Servo Replacement Procedure: Product Manual 26836 (Revision F, 10/2017)Document39 pagesVaristroke-I Servo Replacement Procedure: Product Manual 26836 (Revision F, 10/2017)mecambNo ratings yet

- AR-1 Antilock Relay Valve (SD-13-4795)Document8 pagesAR-1 Antilock Relay Valve (SD-13-4795)emmanuelNo ratings yet

- MCQ On Fluid PowerDocument12 pagesMCQ On Fluid Powerraj kunduNo ratings yet

- Questions 2Document8 pagesQuestions 2Shivakumar TcNo ratings yet

- Instruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736Document124 pagesInstruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736Gangsar DwikaNo ratings yet

- Butterfly Valves: Fig. 014 - Ari-Ziva - ZDocument14 pagesButterfly Valves: Fig. 014 - Ari-Ziva - ZErdincNo ratings yet

- Power Loss and Heat Dissipation Characteristics of High-Power Electromechanical ActuatorsDocument5 pagesPower Loss and Heat Dissipation Characteristics of High-Power Electromechanical Actuatorsboda balajiNo ratings yet

- FRACASSRotary Hinge EMADocument2 pagesFRACASSRotary Hinge EMAFabián AcevedoNo ratings yet

- Pdn1000 2us CoverDocument19 pagesPdn1000 2us CoverGuillermo RastelliNo ratings yet

- Man B&W Me EngineDocument20 pagesMan B&W Me EngineSoumyadeep Bhattacharyya100% (7)

- Valvitalia's Satisfaction of Energy CustomersDocument8 pagesValvitalia's Satisfaction of Energy Customerstallervt100% (1)

- Fluro CatalogueDocument48 pagesFluro Cataloguer rajeshNo ratings yet

- Waterman SS-250 Series Slide GatesDocument12 pagesWaterman SS-250 Series Slide GatesHarrianni ZakriNo ratings yet

- General Twin Seal 06Document24 pagesGeneral Twin Seal 06Gk GaneshNo ratings yet

- Fail-Safe Quarter-Turn Actuator Technical SpecificationsDocument2 pagesFail-Safe Quarter-Turn Actuator Technical SpecificationsCesar JimenezNo ratings yet

- Eaah3690 Full PDFDocument11 pagesEaah3690 Full PDFlupaescu-2No ratings yet

- Installation and Operating Instructions For Avid Eazical Ir PositionerDocument9 pagesInstallation and Operating Instructions For Avid Eazical Ir PositionerFlavioNo ratings yet

- Valves and InstrumentsDocument296 pagesValves and InstrumentsRommel Heredia TejadaNo ratings yet

- Bomba Con Filtro Automatico PDFDocument88 pagesBomba Con Filtro Automatico PDFHector100% (2)

- Alfa MiTo 1.4 16V Multiair - enDocument164 pagesAlfa MiTo 1.4 16V Multiair - enAJUSA Asistencia Técnica100% (1)

- Model A Deluge Valve Features and OperationDocument4 pagesModel A Deluge Valve Features and OperationmanbkkNo ratings yet

- ELFI Valve (Prop - DC ValveDocument9 pagesELFI Valve (Prop - DC ValvealoordominicNo ratings yet

- Wheel Loader 950h & 962h-Electrohydraulic SystemDocument67 pagesWheel Loader 950h & 962h-Electrohydraulic SystemMaquinaria Pesada Servis100% (3)

- Linear Units For Ontrac On-Off - and Modulating Contol ActuatorsDocument8 pagesLinear Units For Ontrac On-Off - and Modulating Contol ActuatorsAnnie De WildeNo ratings yet

- TapcoEnpro: Petrochemical Valve & Control ExpertiseDocument4 pagesTapcoEnpro: Petrochemical Valve & Control ExpertiseInspection EngineerNo ratings yet

- Maha Automation BrochureDocument12 pagesMaha Automation BrochureMahadevappagowdaNo ratings yet

- 02 ClutchDocument14 pages02 ClutchBeary McBeary100% (1)

- Automation of Drilling Process Using Electro-Pneumatics SystemDocument5 pagesAutomation of Drilling Process Using Electro-Pneumatics SystemifyNo ratings yet