Professional Documents

Culture Documents

Ac 24

Uploaded by

Yehezkhiel Octora Deni0 ratings0% found this document useful (0 votes)

5 views6 pages.

Original Title

AC_24

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views6 pagesAc 24

Uploaded by

Yehezkhiel Octora Deni.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

United States Patent (19) 11 Patent Number: 5,063,196

Doughty et al. (45) Date of Patent: Nov. 5, 1991

54) CHROMUM-FREE IMPREGNATED

OTHER PUBLICATIONS

ACTIVATED CARBON FOR ADSORPTION

OF TOXC GASES AND/OR WAPORS Military Problems with Aerosols and Nonpersistent Gases:

Chapter 4: "Impregnation of Charcoal" by Grabenstet

(75) Inventors: David T. Doughty, Coraopolis; James ter, R. J. and Blacet, F. E.-Division 10 of National

E. Groose, Mt. Lebanon, both of Pa. Defense Research Committee (1946)–pp. 40-87.

73 Assignee: Calgon Carbon Corporation, Primary Examiner-Paul E. Konopka

Pittsburgh, Pa. Attorney, Agent, or Firm-Reed Smith Shaw & McClay

21) Appl. No.: 371,430 57 ABSTRACT

22 Filed: Jun. 23, 1989 Impregnated activated carbon adsorbents for the re

moval of toxic materials from gas streams are used in a

51) int. C. ......................... B01J 20/22; B01J 20/20; variety of respiration and collective filter applications.

B01J 31/28; B01D 53/04 The activated carbon impregnated adsorbents in the

(52) U.S.C. ........................................ 502/417; 55/68; present invention remain effective in removing toxic

55/74; 55/71; 423/236; 423/240; 502/165; gases and/or vapors in military, industrial and other

502/167; 502/183; 502/184: 502/401 applications, and are free of chromium and its potential

58 Field of Search ............... 502/47, 401, 183, 184, health hazards. Generally, these activated carbons are

502/167, 150 comprised of an activated carbon adsorbent impreg

nated so as to result in an activated carbon containing 0

(56) References Cited to 14% copper and 2 to 16% zinc, optionally supple

U.S. PATENT DOCUMENTS mented according to the desired characteristics with

silver, triethylenediamine, and prepared with or with

1,519,470 12/1924 Wilson ................................ 502/417 out the use of organic acid. The adsorbent carbons of

2,523,875 9/1950 Morrell . ... 252/.447 the present invention have been found to be effective

2,920,051 1/1960 Wiig et al. ... 502/417 for removing a variety of toxic gases and/or vapors.

2,963,441 12/1960 Dolian ...... ... 252/190

3,251,365 5/1966 Keith ..................................... 131/10 The formulation of the impregnates, the method of

3,355,317 11/1967 Keith ........ ... 117/100 impregnation and the method of drying the activated

3,460,543 8/1969 Keith et al. ... 131/342 carbon after impregnation taught by the present inven

3,605,759 9/1971 Owens ...... ... 131/265 tion can be varied to adjust the performance character

3,618,691 11/1971 Kiefer ... ... 31/266 istics so as to meet both industrial and military toxic gas

3,935,294 1/1976 Teller ... ... 423/226 performance criteria, to achieve enhanced removal of

4,022,223 5/1977 Rainer ... ... 131/10.9 specific toxic gases and/or vapors, to have an extended

4,091,822 5/1978 Ihrig ........................................ 131/9 shelf like, as well as to obtain other advantages useful in

4,271,133 6/1981 Tellis ... ... 423/230 respirator and collective filter applications. The impreg

4,474,739 10/1984 Zackay. ... 423/230

4,531,953 7/1985 Groose .................................... 55/74 nated carbon adsorbents in the present invention possess

4,594,231 6/1986 Nishino et al. ... 502/417 desirable qualities regarding the toxicity and carcinoge

4,80,311 1/1989 Tolles ........... ... 423/236 nicity of the impregnates to the user, qualities that are

4,802,898 2/1989 Tolles .................................. 423/236 not found in a large number of prior art impregnates

FOREIGN PATENT DOCUMENTS

potentially useful in respirator and collective filter ap

plications.

14.9995 8/1973 Czechoslovakia .

1397678 6/1975 United Kingdom . 9 Chains, No Drawings

1.

5,063,196

2

with triethylenediamine, and optionally with copper

CHROMIUM-FREE IMPREGNATED ACTIVATED and silver.

(CARBON FOR ADSORPTION OF TOXC GASES U.S. Pat. No. 4,531,953 to Groose discloses an acti

AND/OR WAPORS vated carbon impregnated with copper, silver and/or

chromium mixtures and triethylenediamine.

GOVERNMENT CONTRACT In addition to the foregoing prior art patents, other

This invention was made with Government support references disclose that activated carbon impregnated

under Contract DAAA 15-86-C-0030 awarded by the with triethylenediamine (TEDA) has been found to be

United States Army Chemical Research Development particularly effective for gas masks for removing cyano

and Engineering Center. The Government has certain O gen chloride, without the need for chromium. Refer

limited rights in this invention. ences also disclose that activated carbon may be in

FIELD OF THE INVENTION pregnated with copper and/or silver for removal of

additional toxic gases or vapors often required for mili

The present invention relates to impregnated acti 5 tary protective mask applications.

vated carbon adsorbents for removal of toxic materials Other references, including the 1946 NDRC report

in respiration and collective filter applications and, in by Grabenstetter et al. describe the use of copper, silver,

particular, to a chromium free impregnated carbon chromium and molybdenum or vanadium impregnants

adsorbent for the removal of toxic gases and/or vapors. on activated carbon to remove hydrogen cyanide and

BACKGROUND OF THE INVENTION 20

cyanogen chloride. Other organic base impregnations

of charcoal are disclosed, including the use of amines

Activated carbon has long been used to remove toxic such as diethylene trianine and others are also found in

gases and vapors from a stream of gas. These activated prior art.

carbons are useful in respirators, collective filters and

other applications, and often involved the use of special in The use of impregnated activated carbon adsorbents

respirators and collective filters, either for military or

25

impregnants to remove gases that would not otherwise industrial applications, require special considerations

be removed through the use of unimpregnated activated regarding the toxicity and carcinogenicity of the im

carbons. These impregnated activated carbon adsor pregnants to the user. These considerations eliminate a

bents for removal of toxic gases and/or vapors have large

been known and used for many years. The prior art use in number of prior art potential impregnants from

respirator and collective filter applications. This

formulations contain copper, chromium and silver im 30 is especially the case with hexavalent chromium, which

pregnated on an activated carbon. These adsorbents are

effective in removing a large number of toxic materials. involves potential health hazards.

Accordingly, it is an object of the present invention

Generally, it is known that removal of cyanogen

chloride, hydrogen cyanide and cyanogen require the to provide an activated carbon that has the advantages

presence of chromium and copper on the activated 35 inof aremoving chromium-free adsorbent while remaining effective

toxic gases and/or vapors through the

carbon for effective removal. Copper and silver have

been shown to be effective in the removal of arsine and impregnation of the activated carbon adsorbent with

phosphine. Chlorine, hydrogen chloride, hydrogen flu copper and zinc. It is a further object of the invention to

oride and hydrogen sulfide are also removed by the provide an activated carbon absorbent for use in both

military and industrial respirator and collective filter

presence of copper impregnates on activated carbon. 40 applications.

In addition to a number of other inorganic materials

which have been impregnated on activated carbon, SUMMARY OF THE INVENTION

various organic impregnants have been found useful in

military applications for the removal of cyanogen chlo Generally, the present invention comprises an acti

ride. Examples of these include triethylenediamine 45 vated carbon adsorbent impregnated to contain, de

(TEDA) and pyridine-4-carboxylic acid. Tartaric acid pending on the particular characteristics desired, a final

has also been found to be used with other materials in composition by weight containing a mixture 6-1.6%

various applications. total copper and zinc, within the range of 0% to 14%

A search of the prior art has uncovered patents which copper and 2% to 16% zinc. Silver, triethylenediamine,

disclose a variety of agents impregnated in activated 50 and/or tartaric acid may or may not be required, de

carbon to remove toxic vapors from a gas stream. pending on the desired application.

British patent No. 2,187,725 discloses activated char Specific embodiments of the present invention com

coal impregnated with transition metal salts preferably prise an activated carbon adsorbent impregnated so as

consisting of cobalt, nickel or zinc acetate. to result in a composition containing from about 6% to

U.S. Pat. No. 3,355,317 to Keith et al. discloses the 55 8% copper, 6% to 8% zinc, and optionally 0.03% to

use of the oxides of cobalt, copper, zinc, iron and no 0.05% silver and/or 2% to 4% triethylenediamine.

lybdenum on activated carbon to remove hydrogen Zero to 10% tartaric acid may also be added during

cyanide from tobacco smoke. preparation of this composition. The adsorbent of this

U.S. Pat. Nos. 2,920,050 and 2,920,051 both to Blacet embodiment of the present invention has been found to

et al. describe the preparation of whetlerite type filters be effective for removing gases and/or vapors including

which include copper, chromium, silver and molybde chlorine, hydrogen chloride, hydrogen cyanide, cyano

num impregnants. gen, cyanogen chloride, sulfur dioxide, hydrogen sul

U.S. Pat. No. 4,801,311 to Tolles discloses a whetler fide, formaldehyde and others, which are hereinafter

ite type activated carbon filter material impregnated referred to as "toxic gases and/or vapors'.

with copper, silver, and molybdenum and/or vanadium 65 The present invention is useful in respirator and col

salts together with triethylenediamine. lective filter applications, and meets both military and

U.S. Pat. No. 4,802,898 to Tolles discloses a whetler industrial toxic gas and/or vapor performance criteria.

ite type activated carbon filter material impregnated The formulation of the impregnants can be varied to

5,063,196

3 4.

adjust the performance characteristics to achieve the bon was then dried in thin beds in a forced air convec

desired enhanced removal of specific toxic gases and/or tion oven for 30 min. at 100 C., and 30 min. at 130 C.

vapors and extended shelf life. Other advantages of the After cooling, the activated carbon was reimpregnated

present invention will become apparent from the fol with approximately 55 ml solution per 100 g activated

lowing detailed description of the presently preferred carbon in a similar manner. The drying profile used for

embodiments of impregnant compositions. the twice impregnated product was: 100° C., 30 min;

PRESENTLY PREFERRED EMBODIMENTS 130° C., 30 min; 160° C., 45 min; 180° C., 45 min. The

cooled activated carbon was impregnated with TEDA

General Preparation Conditions according to the method of U.S. Pat. No. 4,531,953.

Samples were impregnated by the "addition-titra 10 Addition of tartaric acid to the impregnation solution

tion' method where solution is slowly added nearly to gives additional improvement in the HCN performance

the point that the activated carbon appears wet. In this of the activated carbon.

method, the pore volume is almost filled with solution. Testing

Other methods of impregnation can also be utilized.

One or two impregnation "cycles' can be used; sample 15 The results of hydrogen cyanide, cyanogen chloride

metal loadings are calculated based on preparation con and aging tests of a test sample of ASZ-TEDA and a

ditions, not actual analysis. Samples are then checked production sample of ASC (prior art chromium impreg

by nitric acid extraction and atomic absorption analysis. nated activated carbon) are shown in Table II.

TABLE II

Hydrogen Cyanide and Cyanogen Chloride Testing Of ASC and ASZ-TEDA Samples

Hydrogen Cyanide Life (min) Cyanogen Chloride Life (min)

AGED AGED3

SAMPLE2 AR/6 AR/50 50/50 80/50 AR/20 50/50 80/80 80/80

ASZ/4% TEDA 32 30 33 30 32 57 58 57

ASC 33 33 39 36 75 94. 69 46

The Hydrogen Cyanide life (breakthrough time) test is sensitive to the presence of either Hydrogen Cyanide or

Cyanogen,

Test conditions are referred to as (Precondition Humidity)/(Test Humidity). "AR" means sample tested as received.

"Aged" means sample maintained for 7 days at 45 C., 85% relative humidity.

The calculated loadings are typically accurate to about

+/-0.5% weight. Samples tested herein have been The hydrogen cyanide and cyanogen test results in

dried in a forced air draft convection oven on shallow Table II indicate that performance is relatively insensi

trays. Other methods of drying the activated carbon

(including at elevated temperatures in N2) can also be 35 tive

the

to humidity. The test lives are also comparable to

ASC sample used as a reference. The cyanogen

employed, again according to the desired characteris chloride performance of ASZ-TEDA is quite depen

tics of the activated carbon. The drying temperatures dent on humidity. Test life is relatively low under dry

used vary, and include the methods as provided in the conditions, and increases as moisture is added to the

specific data below. system during preconditioning. This behavior is differ

ASZ-TEDA Composition ent than that of ASC. ASC has better dry performance,

Preparation reaches peak lifetime at 50/50 conditions, and decreases

as more water is added. At 80/80 conditions, cyanogen

The samples were prepared in batches of approxi chloride life of ASZ-TEDA is only slightly lower than

mately 1 Kg and dried in a laboratory oven. The com ASC.

position of a typical impregnation solution used is 45 The most striking improvement in performance be

shown in Table I. As used herein, ASZ refers to acti tween ASZ-TEDA over ASC is that cyanogen chlo

vated carbon impregnated with copper, zinc and op ride performance of ASZ-TEDA does not deteriorate

tionally silver. ASZ-TEDA refers to the same formula with aging at 45° C. and 85% relative humidity. The

tion additionally impregnated with TEDA as set forth ASC reference lost 33% of its effectiveness under these

in Table I. 50 same conditions.

TABLE I The results of physical property tests and chemical

analysis of the product are shown in Table III.

Sample impregnation Solution for Preparation of ASZ

Material Quantity TABLE III

250 ml H2O 55 Physical Properties of an ASZ-TEDA Sample

100 g (NH4)2CO Predicted Analyzed

250 ml NH4OH (conc.) Cu 6.0% 6.4%

72.0 g ZnCO3 Zn 6.0 5.5

68.2 g CuCO3Cu(OH)2 (Basic Copper Carbonate) Ag 0.05 0.06

0.5 g AgNO3 TEDA 4.0 ND

50 g Tartaric Acid (Optional) Moisture ND 2.52%

Quantities are based on 500g coal-based activated carbon, 12 x 30 mesh. Apparent Density ND .590 g/ml

ND means "not determined."

Two impregnation cycles were generally used. The

first impregnation solution was added to dry coal-based

activated carbon in approximately 25 ml aliquots at the 65 Tartaric Acid

ratio of 70 ml per 100 g activated carbon. The activated As shown in Table IV, incorporation of up to 10%

carbon was shaken during addition to avoid pooling of tartaric acid in the solution used to impregnate the

the solution. The partially impregnated activated car product resulted in noticeable improvement in the hy

5,063,196

5

drogen cyanide and cyanogen life of the adsorbent of TABLE VI-continued

the present invention.

TABLE IV

Effect of Tartaric Acid on Hydrogen Cyanide and

Cyanogen Performance of Cu-Zn Samples

Final Hydrogen Cyanogen

Tartaric Drying Cyanide Chloride

Cu (%) Zn (%) Acid (%)" TEDA (%) Temp (C) Life (min) Life (min)

8 6 O 4. 180 23 52

8 6 5 4. 18O 27 ND

8 6 O 4. 18O 32 56

8 6 0. 4. 220 22 51

8 6 O 4. 220 30 56

6 6 O 4. 80 26 60

6 6 10 4 180 29 56

6 6 O 2 180 24 46

6 6 5 2 180 26 42

During processing and drying, tartaric acid decomposes; as such, its presence may or may not be detectable

in the final product.

Copper, Zinc and TEDA Formulation Data

The improvements that result from the addition of 20 Life (min.) Life (min.)

tartaric acid are most noticeable at higher metal load Cyanogen Hydrogen

ings for adsorbents impregnated with 8% Cu and 6% Cu(%) Zn(%). TEDA(%) Chloride? Cyanide

Zn. For these adsorbents, hydrogen cyanide, cyanogen 0.00 2.00 1500 33.50 16.50

life increased from 21-23 minutes to 28-32 minutes. 0.00 8.00 3,000 48.50 24.00

0.00 8.00 1.500 45.50 6.50

(Table IV). The improvement in performance for adsor 25 8.00 0.00 3.000 45.00 19.50

bents containing 6% Cu and 6% Zn was not as marked; 0.00 12.00 3.000 50.00 22.00

in this case, performance improved from 24-26 minutes 12.00 0.00 1.500 35.00 17.00

to 28 minutes. At both the 6% and 8% Cu levels, little 8.00

0.00

0.00

1.25

4.500

3.800

57.80

47.00

17.50

15.50

effect on cyanogen chloride life was found. Perfor 4.00 8.00 3.000 50.00 9.50

mance improvements with less than 10% tartaric acid 30 00 4.00 0.000 3.30 2.00

were less dramatic. 4.00 4.00 3,000 52.50 19.50

Adsorbents of the present invention were prepared 0.00

4.00

0.00

0.00

3.000

0.000

14.50

4.60

2.00

11.50

using other organic acids to improve performance. 8.00 O.00 0,000 0.40 3.60

However, as shown in Table V, only maleic acid indi 0.00 4.00 0,000 3.00 4.50

cated any benefit for hydrogen cyanide, cyanogen per 35 4.00 4.00 0.000 0.70 22.70

formance. 0.00 0.00 3.000 20.70 2.60

4.00 0.00 3,000 36.20 ND

TABLE V 8.00 0.00 3,000 51.0 12.20

Test Lives of Adsorbents with Organic Acids 0.00 8.00 3.000 39.80 17.50

ASZ samples: 8% Cu, 6% Zn, 0.05% Ag, 4% TEDA 0.00 O.00 500 17.40 ND

and 10% of indicated acid, if added. 40 000 0.00 6,000 23.90 ND

9.70 0.00 0,000 0.00 5.50

Hydrogen Cyanide Cyanogen Chloride 9,70 0.00 3.000 43.60 ND

Acid Life (min) Life (min) 4.00 4.00 3.000 46.50 20.40

Salicylic 21 29 4.00 8.00 3,000 56.00 6.00

Acetic 24 33 4.00 6.00 4.000 68.00 24.00

Maleic 30 40 5.00 7.00 3.000 52.00 22.00

Potassium Hydrogen 20 38 45 3.00 5.00 3.000 52.00 7.00

Phthalic 3.00 7.00 5.000 60.00 6.00

(Without Acid) 23 52 4.00 4.00 3,000 60.00 18.00

4.00 6.00 4.000 6100 2100

4.00 0.00 1500 ND 7.00

With respect to maleic acid, the degree of improve 50

4.00

8.00

0.00

4.00

3,000

3,000

38.00

7100

12.00

28.00

ment was similar to that found for tartaric acid. Cyano 12.00 0.00 1,500 37.00 18.00

gen chloride performance of the adsorbent prepared 12.00 0.00 3.000 56.00 18.00

with maleic acid was lower than for adsorbent contain 5.00 5.00 5.000 ND 25.00

ing tartaric acid. 4.00

0.00

6.00

0.00

4.000

3.000

70.00

14.00

25.00

4.00

To understand the response of hydrogen cyanide, 55 0.00 0.00 6.000 20.00 6.00

cyanogen and cyanogen chloride to variations in the 8.00 8.00 3.000 65.00 26.00

compositional impregnant regions of 0-12% An, and 0.00 0.00 3.000 ND 0.00

0-6% TEDA, tests were performed in these ranges. 0.00

6.00

10.00

0.00

4,000

2.250

64.00

38.00

20.00

18.00

The results of these tests are set forth in Table VI. 5.00 5.00 3,000 59.00 26.00

TABLE VI 60 Silver was not included in these formulations, as it has no effect on the performance

of the samples tested on cyanogen chloride and hydrogen cyanide life.

Copper, Zinc and TEDA Formulation Data Error imits for Cyanogen Chloride life are its minutes,

Life (min.) Life (min.) Error limits for Hydrogen Cyanide life are t3 minutes,

Cyanogen Hydrogen

Cu(%) Zn(%) TEDA(%) Chloride? Cyanide

4.00 8.00 1.500 50.00 16.00

It has been found that the major contributor to cyan

0.00 8.00 4.500 62.50 18.50

65 ogen chloride life is TEDA in conjunction with copper

12.00 0.00 3.000 50.50 8.50 and zinc. Interactions between copper and TEDA and

4.00 8.00 3.000 56.50 6.50 zinc and TEDA are important, and contribute signifi

8.00 0.00 1,500 20.00 16.00 cantly in improving performance at higher metal levels.

7

5,063,196

8

Hydrogen cyanide/cyanogen protection is provided meets all current military specification tests for ASC

by copper and zinc, with zinc being more effective at Whetlerite. In addition, hydrogen cyanide, cyanogen

lower metal levels. and cyanogen chloride performance did not deteriorate

While presently preferred embodiments of the inven under tropical aging conditions.

tion have been described in particularity, the invention 5 Laboratory studies also show that good performance

may be otherwise embodied within the scope of the is attained in all critical areas with the present invention

appended claims. in specialized compositions containing a mixture of 0%

Specific Application AZ Compositions to 14% copper and 2% to 16% zinc. Silver and/or

Preparation and Testing

triethylenediamine may also be added, depending on

O desired performance characteristics. Tartaric, maleic

As used herein, AZ refers to copper and zinc impreg and/or other organic acids may also be incorporated

nated activated carbon formulations prepared in the into the preparation to improve performance. These

same manner as the ASZ-TEDA (Cu-Zn-Ag-TEDA) compositions can be tailored within the described

composition described in Table I, but without the addi 5 boundaries to meet specific desired performance char

tion of Ag or TEDA. AZ samples were also prepared in acteristics for any number of industrial, military and

the same manner as the aforementioned ASZ-TEDA other needs.

(Cu-En-Ag-TEDA) composition as described in Table What is claimed:

I, but again without the addition of Ag or TEDA, 1. An impregnated activated carbon adsorbent in

which are often not required for non-military toxic gas pregnated with at least one solution so as to provide a

and/or vapor applications. 20

composition of, by total elemental weight including said

The AZ embodiments of the present invention are activated carbon, from about 4 to 14% copper and 2 to

comprised of an activated carbon adsorbent impreg 12% zinc, from 0 to 10% silver and from about 1.5 to

nated with (depending on the particular characteristics 6% triethylenediamine.

desired) compositions resulting in a metals content of 2. An impregnated activated carbon adsorbent as set

0% to 14% copper and 2% to 16% zinc in the impreg 25 forth

nated activated carbon. The formulations of the impreg amountin ofclaim from

1, wherein said copper is present in an

5 to 8%, and said zinc is present in an

nants are varied, and demonstrate the that the perfor

mance characteristics of the chromium-free composi amount of about 5 to 8%.

3. An impregnated activated carbon adsorbent as set

tions in the present invention can be tailored to achieve forth in claim 1, wherein said copper is present in an

enhanced removal of specific toxic gases. 30

amount of from about 6 to 8%, said zinc is present in an

Table VII sets forth the results of sample gas life

challenges of Chlorine, Hydrogen Chlorine, Sulfur amount of about 6 to 8%, said silver is present in an

Dioxide, Formaldehyde and Hydrogen Sulfide for a amount of about 0.03 to 0.05% and said triethylenedi

typical AZ formulation. amine is present in an amount of about 2 to 4%.

TABLE VII 35 4. An impregnated activated carbon adsorbent as set

forth in claims 1, 2 or 3, also impregnated so as to in

Sample Gas Life Challenge Resuits for AZ Activated Carbons clude up to 10% organic acid.

Formal- Calgon 5. An impregnated activated carbon adsorbent as set

NIOSH NIOSH NIOSH dehyde H2S forth in claims 1, 2 or 3, also impregnated so as to in

Cl2 HC1 SO2 (100 ppm/ Capacity

(min) (min)" (min)" min) (wt.%) 40 clude up to 10% of at least one organic acid selected

ASC > 120 > 120 117 > 120, 7.4 from the group of maleic and tartaric acid.

> 120 6. An impregnated activated carbon adsorbent as set

AZ > 120 > 120 02 > 120, 79 8.0 forth in claims 1, 2 or 3, wherein at least one solution

(5% Cu, including 0 to 10% organic acid and said copper, zinc

6% Zn)

"NIOSH Test conditions are 32 L.P.M. per sample cartridge, 12 x 30 screen mesh

45 and silver is used to impregnate the activated carbon

size, 1 ppm breakthrough, 25 C., 50% humidity. with said organic acid, copper, zinc, and silver, and

Two (2) test cycles were run. wherein the activated carbon is dried after each impreg

nation, and thereafter impregnated with said triethyl

Table VIII sets forth the results of tests on various enediamine.

AZ activated carbon formulations challenged with sul- 50 7. An impregnated activated carbon adsorbent as set

fur dioxide. forth in claims 1, 2 or 3, wherein at least one solution

TABLE VIII including 0 to 10% organic acid and said copper, zinc

SO2 Challenge Results for AZ Activated Carbons and is used to impregnate the activated carbon with said

Cu (wt %) Zn (wt %) SO2 Life (min.) 55 organic acid, copper, zinc, and silver, and wherein the

4. 4 72

activated carbon is dried after each impregnation by

4. 8 75 heating said activated carbon at up to ignition tempera

6 6 74 ture, and thereafter impregnated with said triethylene

8 4. 78 diamine.

8 8 82 8. A method of preparation of an impregnated acti

7 O 56 60

vated carbon adsorbent as set forth in claims 1, 2, or 3,

using at least one solution so as to provide said copper,

Conclusions zinc and silver, said solution additionally impregnating

said activated carbon with 0 to 10% organic acid,

Laboratory studies show that well-balanced perfor wherein the activated carbon is dried after each impreg

mance in all critical areas is attained with the present 65 nation, and thereafter impregnating said activated car

invention composition containing from 6-8% Cu, 6-8% bon with said triethylenediamine.

Zn, 0.03–0.05% Ag and 2-4% TEDA. When this com 9. A method of preparation of an impregnated acti

position is used, the impregnated activated carbon vated carbon adsorbent as set forth in claims 1, 2, or 3,

5,063,196

9 10

using at least one solution so as to provide said copper, nation by heating said activated carbon at up to ignition

zinc and silver, said solution additionally impregnating temperature, and thereafter impregnating said activated

said activated carbon with 0 to 10% organic acid, carbon with said triethylenediamine.

wherein the activated carbon is dried after each impreg- s: : a 2k x:

10

15

20

25

30

35

45

50

55

60

65

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Manajemen OperasiDocument9 pagesManajemen OperasiYehezkhiel Octora DeniNo ratings yet

- Bab 1Document2 pagesBab 1Yehezkhiel Octora DeniNo ratings yet

- Bab 3Document4 pagesBab 3Yehezkhiel Octora DeniNo ratings yet

- EH0030 Liftware Self Stabilizing Eating Utensils For Individuals With Hand Tremor-EDocument7 pagesEH0030 Liftware Self Stabilizing Eating Utensils For Individuals With Hand Tremor-EYehezkhiel Octora DeniNo ratings yet

- CJ Feed Jombang Produksi Pakan Ternak Unggas, Babi, dan UdangDocument1 pageCJ Feed Jombang Produksi Pakan Ternak Unggas, Babi, dan UdangYehezkhiel Octora DeniNo ratings yet

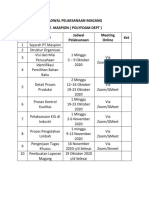

- Jadwal Pelaksanaan MagangDocument1 pageJadwal Pelaksanaan MagangYehezkhiel Octora DeniNo ratings yet

- DN Eon KK2 024Document43 pagesDN Eon KK2 024Yehezkhiel Octora DeniNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationYehezkhiel Octora DeniNo ratings yet

- Projek AkhirDocument1 pageProjek AkhirYehezkhiel Octora DeniNo ratings yet

- 10 1 1 140 8246 PDFDocument50 pages10 1 1 140 8246 PDFDouglas FelixNo ratings yet

- Yehezkhiel Octora Deni Anno KusumaDocument1 pageYehezkhiel Octora Deni Anno KusumaYehezkhiel Octora DeniNo ratings yet

- Liquid-liquid equilibria of propionic acid-water-solvent ternariesDocument12 pagesLiquid-liquid equilibria of propionic acid-water-solvent ternariesYehezkhiel Octora DeniNo ratings yet

- Tutorial Aspen SaidahDocument28 pagesTutorial Aspen SaidahYehezkhiel Octora DeniNo ratings yet

- MAGANG DI PT MASPIONDocument19 pagesMAGANG DI PT MASPIONYehezkhiel Octora DeniNo ratings yet

- OPTIMASI REAKSI KIMIADocument3 pagesOPTIMASI REAKSI KIMIALinaniyyatul MNo ratings yet

- KOROSIDocument1 pageKOROSIYehezkhiel Octora DeniNo ratings yet

- Permasalahan Pada RO MembraneDocument9 pagesPermasalahan Pada RO MembraneYehezkhiel Octora DeniNo ratings yet

- Tugas Manajemen Operasi - 10411710000024 - Yehezkhiel Octora Deni Anno KusumaDocument4 pagesTugas Manajemen Operasi - 10411710000024 - Yehezkhiel Octora Deni Anno KusumaYehezkhiel Octora DeniNo ratings yet

- FGO Event ReqDocument1 pageFGO Event ReqYehezkhiel Octora DeniNo ratings yet

- Catatan PADocument2 pagesCatatan PAYehezkhiel Octora DeniNo ratings yet

- Recovery of Propionic Acid Using Reactive Extraction: January 2006Document7 pagesRecovery of Propionic Acid Using Reactive Extraction: January 2006Yehezkhiel Octora DeniNo ratings yet

- Process VariableDocument51 pagesProcess VariableLance HernandezNo ratings yet

- ADocument3 pagesAYehezkhiel Octora DeniNo ratings yet

- SOP EPS PREFORMINGDocument3 pagesSOP EPS PREFORMINGYehezkhiel Octora DeniNo ratings yet

- Data-data operasional keteranganDocument5 pagesData-data operasional keteranganYehezkhiel Octora DeniNo ratings yet

- Overlord Volume 2Document240 pagesOverlord Volume 2Yehezkhiel Octora DeniNo ratings yet

- Angka BoxDocument1 pageAngka BoxYehezkhiel Octora DeniNo ratings yet

- (Nissekai) NGNL Vol 4 PDFDocument304 pages(Nissekai) NGNL Vol 4 PDFYehezkhiel Octora DeniNo ratings yet

- DPDocument8 pagesDPYehezkhiel Octora DeniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)