Professional Documents

Culture Documents

ME 20ME41P WEEK4 S3 Sy

ME 20ME41P WEEK4 S3 Sy

Uploaded by

Srinivas GowdaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME 20ME41P WEEK4 S3 Sy

ME 20ME41P WEEK4 S3 Sy

Uploaded by

Srinivas GowdaCopyright:

Available Formats

Operations Management - 20ME41P 2021-22

Week -4 Session-4

CAPACITY AND AGGREGATE PLANNING

Content Page No.

Aggregate Planning 2

Planning Hierarchy 3

Pure strategy 3

Mixed strategy 3

Expected Outcomes: - CO-1

Course Outcome: - Production capacity utilization plan based on demand forecast

and available production capacity for a given product.

Linked Programme Outcome: - PO-1

Session Time / Teaching Hours: - 1hour

Mechanical Engineering Program 1

Operations Management - 20ME41P 2021-22

Week - 4

CAPACITY AND AGGREGATE PLANNING:

Aggregate Planning:

Aggregate planning is an intermediate term planning decision. It is the process of

planning the quantity and timing of output over the intermediate time horizon (3

months to one year). Within this range, the physical facilities are assumed to be fixed

for the planning period. Therefore, fluctuations in demand must be met by varying

labour and inventory schedule. Aggregate planning seeks the best combination to

minimise costs.

Production planning in the intermediate range of time is termed as ‘Aggregate

Planning’. It is thus called because the demand on facilities and available capacities is

specified in aggregate quantities. For example aggregate quantities of number of

Automobile vehicles, Aggregate number of soaps etc. Here the total expected demand

is specified without regard to the product mix that makes up the specified figure.

While dealing with production problems, the planning process is normally

divided in three categories.

(i) Long range Planning which deals with strategic decisions such as purchase of

facilities, introduction of new products, processes etc.

(ii) Short term planning which deals with day-to-day work, scheduling and

sometimes inventory problems.

(iii) Intermediate Planning or Aggregate Planning, which is in between long range

and short term planning, which is concerned in generally acceptable planning taking

the load on hand and the facilities available into considerations. In aggregate planning

the management formulates a general strategy by which capacity can be made to

satisfy demand in a most economical way during a specific moderate time period, say

for one year. The aggregate planning is made operational through a master schedule

that gives the manufacturing schedule (Products and dates of manufacture). Generally,

day-to-day schedules are prepared from master schedule. Facility planning and

scheduling has got very close relationship with aggregate planning.

Mechanical Engineering Program 2

Operations Management - 20ME41P 2021-22

Mechanical Engineering Program 3

Operations Management - 20ME41P 2021-22

References

1. Production and Operations Management–Creating Value along the Supply

Chain ByRusseland Taylor, Wiley Publications, 7 Editions.

2. Modern Production and Operation ManagementBy Buffa and Sarin, Wiley

Publications, 8 edition

3. Production and Operations ManagementBy Chary, Tata Mc Graw Hill

Publications

4. Production and Operations Management-Concepts, Models and Behavior by

Adam and Ebert, Prentice Hall Publications.

LIST OF SOFTWARE/LEARNING WEBSITES

1. www.youtube.com/watch?v=SF53ZZsP4ik

2. www.youtube.com/watch?v=iPZlQ3Zx5zc

Mechanical Engineering Program 4

You might also like

- Operations Management Stevenson 11th Edition Solutions ManualDocument25 pagesOperations Management Stevenson 11th Edition Solutions ManualKennethHendersonyecg100% (34)

- Techniques - ST Patrick's CollegeDocument2 pagesTechniques - ST Patrick's Collegealrac_noseimaj70550% (2)

- Ucsp-Defining Culture and Society From The Perspective ofDocument58 pagesUcsp-Defining Culture and Society From The Perspective ofAaron Paul Millena LolorNo ratings yet

- Week - 4 Session-2: Capacity and Aggregate PlanningDocument6 pagesWeek - 4 Session-2: Capacity and Aggregate PlanningSrinivas GowdaNo ratings yet

- Chapter 9 Production-Planning SystemsDocument49 pagesChapter 9 Production-Planning SystemsVeilNo ratings yet

- Production/Operations Management: BlockDocument56 pagesProduction/Operations Management: BlockKamran JavedNo ratings yet

- Om Merged PDF - Last-2.5 Units PDFDocument58 pagesOm Merged PDF - Last-2.5 Units PDFCherry TejNo ratings yet

- Operations Management Part - 3Document18 pagesOperations Management Part - 3Sai Rock SaiNo ratings yet

- Ch-2 - Production Planning SystemDocument48 pagesCh-2 - Production Planning SystemRidwanNo ratings yet

- Om 4 5Document25 pagesOm 4 5Government PolytechnicNo ratings yet

- Mam Unit 1Document71 pagesMam Unit 1Avinash SankarNo ratings yet

- Rough Cut Capacity - RCCP Case Study - 2014 PDFDocument14 pagesRough Cut Capacity - RCCP Case Study - 2014 PDFTebaterrorNo ratings yet

- Om - Unit-Iv - PG IiDocument99 pagesOm - Unit-Iv - PG IiaashutoshNo ratings yet

- Aggregate PlanningDocument27 pagesAggregate PlanningDwayne AndradeNo ratings yet

- RCCPDocument15 pagesRCCPEvidente UnoNo ratings yet

- Production PlanningDocument25 pagesProduction PlanningJosh VictorNo ratings yet

- CH 5 Operations Planning & ControlDocument64 pagesCH 5 Operations Planning & ControlYaredNo ratings yet

- Cap PlanningDocument5 pagesCap PlanningKhushi SalgaonkarNo ratings yet

- Production Planning & Control: Syllabus ContentsDocument10 pagesProduction Planning & Control: Syllabus ContentsShivani SharmaNo ratings yet

- Ch-4 (Part-1)Document16 pagesCh-4 (Part-1)Vasu PatelNo ratings yet

- Chap 6 - Resource Planning Systems PDFDocument25 pagesChap 6 - Resource Planning Systems PDFNhi HoàiNo ratings yet

- 7.1 Om 22-24 F GK CS .PPCDocument61 pages7.1 Om 22-24 F GK CS .PPCSANDIP NAYEKNo ratings yet

- Manufacturing Planning and ControlDocument26 pagesManufacturing Planning and Controlspeedi1No ratings yet

- OM Unit - IVDocument78 pagesOM Unit - IVMani MjNo ratings yet

- Topic - 3 Production Planning & Control SystemsDocument14 pagesTopic - 3 Production Planning & Control SystemsSamsol AzharNo ratings yet

- Production Planning Control PDFDocument18 pagesProduction Planning Control PDFoberaiNo ratings yet

- Material and Procuction Management NotesDocument68 pagesMaterial and Procuction Management NotesMwanza MaliiNo ratings yet

- Homework IndestrialDocument6 pagesHomework IndestrialMahmud L. MusaNo ratings yet

- Two Marks BA9221.Document9 pagesTwo Marks BA9221.sanmira_geetha5271No ratings yet

- Chapter - 4: Operations Planning and ControlDocument66 pagesChapter - 4: Operations Planning and ControlSamuel AbebawNo ratings yet

- Lesson-2 OMDocument42 pagesLesson-2 OMKidus AbebeNo ratings yet

- Aggregate Planning and SchedulingDocument19 pagesAggregate Planning and Schedulingchrisrobin99No ratings yet

- DOMS403Document340 pagesDOMS403vsimanpalliNo ratings yet

- 157 37325 EA435 2013 4 2 1 Chap011Document25 pages157 37325 EA435 2013 4 2 1 Chap011carlosNo ratings yet

- Production Planning and Control System With Just in Time and Lean Production: A ReviewDocument9 pagesProduction Planning and Control System With Just in Time and Lean Production: A ReviewGuillermo ReyesNo ratings yet

- Aggregate (Sales/Operations) Planning: Product Line (Group) Level. A Common Unit of Measurement (E.g., Weight, VolumeDocument4 pagesAggregate (Sales/Operations) Planning: Product Line (Group) Level. A Common Unit of Measurement (E.g., Weight, VolumeshahwbNo ratings yet

- Unit 1 PPCDocument43 pagesUnit 1 PPCRama Narasimha ReddyNo ratings yet

- Operations Management and TQM Module Content - Week 11 Lesson: Operations Scheduling and Sequencing and Project ManagementDocument12 pagesOperations Management and TQM Module Content - Week 11 Lesson: Operations Scheduling and Sequencing and Project ManagementMikaNo ratings yet

- Chapter13 - Agreggate PlanningDocument23 pagesChapter13 - Agreggate PlanningMarco TulioNo ratings yet

- The Methodology of Aggregate Planning On Lamp ProdDocument8 pagesThe Methodology of Aggregate Planning On Lamp ProdTushar Guha NeogiNo ratings yet

- Manufacturing & Operations Management, Materials & LogisticsDocument17 pagesManufacturing & Operations Management, Materials & LogisticsZakir KhanNo ratings yet

- Production Planning and Control PPC NotesDocument128 pagesProduction Planning and Control PPC NoteskarthikhindustanNo ratings yet

- PRODUCTION PLANNING AND CONTROLPPC Notes PDFDocument128 pagesPRODUCTION PLANNING AND CONTROLPPC Notes PDFRatna Kommoji100% (2)

- Development and Challenges of Planning and Scheduling For Petroleum and Petrochemical ProductionDocument12 pagesDevelopment and Challenges of Planning and Scheduling For Petroleum and Petrochemical ProductionBankoleNo ratings yet

- Chapter Four AccDocument10 pagesChapter Four Acckassahungedefaye312No ratings yet

- Operations Management-Chapter FiveDocument64 pagesOperations Management-Chapter FiveAGNo ratings yet

- Operations Management: Aggregate PlanningDocument16 pagesOperations Management: Aggregate PlanningArun MishraNo ratings yet

- OM Unit 3Document15 pagesOM Unit 3Sushant SinghNo ratings yet

- Note Pdtmog - Operations Management Chapter 4Document46 pagesNote Pdtmog - Operations Management Chapter 4muneergaming jaibNo ratings yet

- PPC - Unit 2 - Part 1Document5 pagesPPC - Unit 2 - Part 1virk42000No ratings yet

- Production Planning and ControlDocument34 pagesProduction Planning and ControlAkanksha RanjanNo ratings yet

- CAPM NotesDocument15 pagesCAPM NotesRitvik kNo ratings yet

- Chapter I IntroductionDocument19 pagesChapter I IntroductionFathurNo ratings yet

- Group 3-PMS & Strategic Capacity ManagementDocument58 pagesGroup 3-PMS & Strategic Capacity Managementrezka_hapsariNo ratings yet

- Part IIIDocument21 pagesPart IIIGeoff HungryNo ratings yet

- Introduction To PP Sys, Lecture-4Document10 pagesIntroduction To PP Sys, Lecture-4Ahmed ButtNo ratings yet

- Chapter 3Document61 pagesChapter 3Caringal Christelle MaeNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Strengthening the Operational Pillar: The Building Blocks of World-Class Production Planning and Inventory Control SystemsFrom EverandStrengthening the Operational Pillar: The Building Blocks of World-Class Production Planning and Inventory Control SystemsNo ratings yet

- TOGAF® 10 Level 2 Enterprise Arch Part 2 Exam Wonder Guide Volume 2: TOGAF 10 Level 2 Scenario Strategies, #2From EverandTOGAF® 10 Level 2 Enterprise Arch Part 2 Exam Wonder Guide Volume 2: TOGAF 10 Level 2 Scenario Strategies, #2Rating: 5 out of 5 stars5/5 (1)

- Demand Forecasting: Simple Moving AverageDocument8 pagesDemand Forecasting: Simple Moving AverageSrinivas GowdaNo ratings yet

- Om Notes 1Document4 pagesOm Notes 1Srinivas GowdaNo ratings yet

- Week - 4 Session-2: Capacity and Aggregate PlanningDocument6 pagesWeek - 4 Session-2: Capacity and Aggregate PlanningSrinivas GowdaNo ratings yet

- Unit Ii Forgin Set of QuestionsDocument3 pagesUnit Ii Forgin Set of QuestionsSrinivas GowdaNo ratings yet

- Unit Ii Forging2Document15 pagesUnit Ii Forging2Srinivas GowdaNo ratings yet

- Unit I Sand CastingDocument36 pagesUnit I Sand CastingSrinivas Gowda100% (1)

- 67 - 2 - Lina Elsherif ThesisDocument94 pages67 - 2 - Lina Elsherif ThesisSrinivas GowdaNo ratings yet

- Unit I Sand Casting Set of QuestionsDocument4 pagesUnit I Sand Casting Set of QuestionsSrinivas GowdaNo ratings yet

- Journal of Loss Prevention in The Process Industries: Min-Soo Kim, Sang-Kwon LeeDocument5 pagesJournal of Loss Prevention in The Process Industries: Min-Soo Kim, Sang-Kwon LeeSrinivas GowdaNo ratings yet

- 2014 UP Agency and Partnership ReviewerDocument48 pages2014 UP Agency and Partnership ReviewerJohn Noldan AugustinNo ratings yet

- Agenda 21Document10 pagesAgenda 21aussienewsviews5302100% (1)

- Visa Application Form Kingdom of The Netherlands in The CaribbeanDocument9 pagesVisa Application Form Kingdom of The Netherlands in The CaribbeanUtkarsh Choudhary100% (1)

- Tbig LK TW Iv 2020Document150 pagesTbig LK TW Iv 2020Daniel R GoldmanNo ratings yet

- Business Law: Contract of Indemnity AND GuaranteeDocument20 pagesBusiness Law: Contract of Indemnity AND GuaranteeBharggav Shorthand ClassesNo ratings yet

- Sectoral MCG Lambunao SeptDocument8 pagesSectoral MCG Lambunao SeptRenjie AbaraiNo ratings yet

- School DRRM Plan 2021Document2 pagesSchool DRRM Plan 2021jarvinNo ratings yet

- Your Account Summary: Hno583 Sec 18 B Chandigarh 160018Document4 pagesYour Account Summary: Hno583 Sec 18 B Chandigarh 160018Gagan TandonNo ratings yet

- Role of Financial Institutions For Funding EnterpriseDocument2 pagesRole of Financial Institutions For Funding EnterpriseJahanzeb PashaNo ratings yet

- 401 05 01d Case - Fraud - Group 4 - WellsfargoDocument29 pages401 05 01d Case - Fraud - Group 4 - WellsfargoRhea BadanaNo ratings yet

- De Guzman Vs TumolvaDocument2 pagesDe Guzman Vs TumolvaBRYAN JAY NUIQUE100% (1)

- Gender Representation in The Media Lesson PlanDocument2 pagesGender Representation in The Media Lesson Planapi-250065413No ratings yet

- 3-Listado Defin. Puntuacion T. LaboratorioDocument52 pages3-Listado Defin. Puntuacion T. LaboratoriofNo ratings yet

- Unlawful Detainer PDFDocument2 pagesUnlawful Detainer PDFBIGBOYNo ratings yet

- Official Compromis 2016 - 6th JPNBIMCCDocument17 pagesOfficial Compromis 2016 - 6th JPNBIMCCLive LawNo ratings yet

- Religion and LawDocument34 pagesReligion and LawMitali KhatriNo ratings yet

- The Art of Modern Gunfighting ( - Reitz ScottDocument232 pagesThe Art of Modern Gunfighting ( - Reitz ScottNisic222100% (28)

- IELTS Reading Tips For TrueDocument16 pagesIELTS Reading Tips For Truefariha20020% (2)

- 2 Answer KeyDocument43 pages2 Answer Keyปาริฉัตร หล่องคำNo ratings yet

- 0510 Grade 10 British Online AssignmentDocument4 pages0510 Grade 10 British Online Assignmentknight.alfardanNo ratings yet

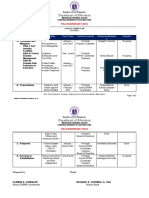

- Training Matrix MTB MLE 2023 InsetDocument2 pagesTraining Matrix MTB MLE 2023 InsetLG BaganiNo ratings yet

- 9004310134Document404 pages9004310134vladimir rosas ayalaNo ratings yet

- Tugas 1 - Public SpeakingDocument4 pagesTugas 1 - Public SpeakingNandi Ramdiansyah NoorNo ratings yet

- Global McDonald's Case AnswersDocument6 pagesGlobal McDonald's Case AnswersСвятослав КолыхаевNo ratings yet

- Vol 164 No. 46Document40 pagesVol 164 No. 46edelapolloNo ratings yet

- Information Security Literature ReviewDocument7 pagesInformation Security Literature Reviewfahynavakel2100% (1)

- Gender and Development: FMS II Arlene Gabayno Focal PersonDocument11 pagesGender and Development: FMS II Arlene Gabayno Focal PersonAnnelyanne Rufino100% (1)

- Technological Institute of The Philippines: Name ID NoDocument2 pagesTechnological Institute of The Philippines: Name ID NoJohn Cabrera PlacenteNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)