Professional Documents

Culture Documents

3ML Syringe Validation Report CR - BL.06

3ML Syringe Validation Report CR - BL.06

Uploaded by

Musyoka Urbanus0 ratings0% found this document useful (0 votes)

13 views8 pagesOriginal Title

3ML SYRINGE VALIDATION REPORT CR.BL.06

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views8 pages3ML Syringe Validation Report CR - BL.06

3ML Syringe Validation Report CR - BL.06

Uploaded by

Musyoka UrbanusCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

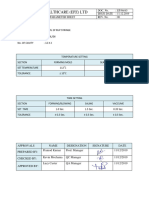

REVITAL HEALTHCARE (EPZ) LTD [Peaiment No. | 27706720 al

Revision No | 02

‘VALIDATION FOR BUSTER PACKING PROCESS

Effective Date: | 01083019

Validation of Blister Packing Process

Senet PATA —,

icpaedb ‘oot ga Oe

Gramed Lumen | Pred. Manager) ee) — eal

Rapper 7 Tob Titer Signature Date: |

sie Nlochoma | Gee , 05 (23/2019 |

Ta Tab Te Samar Bai

Lecten | @> roman) ter 5/69/2019 |

Page 10f8

REVITAL HEALTHCARE (EPZ) LTD | Document No. | 2106/20

Revision No | Or

[ WaLibaTiOn FoR BUSTER PACKING PROCESS

Contents

+ Introduction

+ Responsibilities

+ Equipment details

+ Validation

+ Packaging Equipment Qualification details

+ Installation qualification

+ Operational Qualification

+ Performance Qualification

+ Critical Parameters or steps

+ Sampling Inspection

+ Observation

+ Summary

+ Next validation due

+ Declaration

Page 2 of

REVITAL HEALTHCARE (EPZ) LTD | Becument No. | 7/06/20

1. Introduction

This Validation process describes in detall the activities required to execute the Validation phase

‘of quaication of REVITAL HEALTHCARE (EPZ) LTD. manufacturing facity of Mecca

Devices

2. Responsibilities

For this validation below persons are responsible forthe afferent tasks

+ QaManager Final Approval

+ QC Manager -Final Inspection

+ inspector “Inspection during trail

+ Production Manager “Process Verification

*+ Production Supervisor Process setting

Machine Setting

Mold Setting

+ Plant Engineer(Electrician) ‘Machine installation

Machine Fitness Check

Maintenance of the machine

Power connection of the machine

Persons responsible ofthis Validation are confirming compliance withthe Infermation below:

> Preparer

‘The preparer shal be the primary author ofthe document, or a delegate with an eppropriate

level of understanding ofthe technical content ofthe document, The preparer signs to confirm

‘tha, to their knowledge, the document is complete, comples with the validation plan and is

‘ree fom erors.

> Verifier

“The verifier shal be the system owner or a delegate with an appropriate level of understanding

‘ofthe functionality ofthe equipment/system. The verifier signs o confirm tha, to ther

knowledge, the document fufs all relevant testing requirements, is logical and executable and

Is free from errors.

> Quality Approval

‘The qually approver shall be the Qualty Manager ora delegate with an appropiate level of

understanding ofthe qualty systems relevant to ths protocol. The quality approver signs to

‘confirm that the document complies with relevant quality systems can be adequately resourced

in the time frame anticipated for execution and is free from errors.

Page 30f8

| REVITAL HEALTHCARE (EPZ) LTD [Peeument wo. |zin6720

Revision Nox | 0%

{ WaonTion FoR aUSTER PACKING PROCESS [ tfectve Dates | 01097035

3. Equipment Details .

[Machine Name CHL Jeb

‘Machine Model — ax ~ eo

[Total Load go Ew

Machine Serial Number "5 2006701

[PowerRequired TS

‘Ait Consumption baa C/rin

Mould Used EME SYRING

4, Validation

Packaging validation is establishing documented evidence, which provide high

degree of assurance that a specific packaging process performed, will

consistently produce a pack, which meets predetermined specication,

> Validation must be performed by person with the necessary education,

background, training experience and qualification.

> Validation program must be documented and approved.

5. Packaging Equipment Qualification details:-

> Commissioned By REVITAL HEALTHCARE (EPZ) LTD.

Cleaned, in routine operation : By REVITAL HEALTHCARE (EPZ) LTD.

> The type of testing Labeling, lubrication, Power in-put et:

> Number of people involved: 6 Nos

> Purpose of Equipment to Pack the medical device

> Target production rate 10-12 cyce/min.

> location of equipment CClean Room (Blister Packing Aree)

> Safety Consideration Emergency stop switch

> Type of maintenance required :Preventive & Breakdown (Unfortunate)

. Installation Qualification:

> IQ protocol is checklist to ensure that the system or equipment is

properly installed.

> In this engineering drawing should be checked and updated as

appropriate.

7. Operational Qualification:-

> 0Q protocol will challenge to system to demonstrate that it can

operate within specified parameters,

> Challenge the upper and lower operating limits, to test the arocess

and system.

8, Performance Qualification

Page 4 of

REVITAL HEALTHCARE (EPZ) LTD | Socument No.: | 2/F106/20 “|

PQ should performed in normal daily operation

> Testing of each piece of equipment

> Testing interaction between different pieces of equipment

> Test all critical steps

DELIVERY OF BLISTER FILM

HEAT TREATMENT OF BLISTER FIM

BLISTER FORMING FROM BLISTER FILM

PRODUCT FILLING TO BLISTER

L

UNWINDING OF COATED PAPER PLAIN 360GSM

tH

PRINTING OF BATCH NUMBER, MFG. & EXP.

SEALING OF BLISTER BY COATED PAPER

PUNCHING/CUTTING FOR WASTAGE REMOVAL

L

‘SECONDARY AND FINAL PACKAGING

Page Sof 8

REVITAL HEALTHCARE (EPZ) LTD | Secument No. | 206720

| Revision No.) | Ot

| WAUoaTiON FoR BUSTER PACKING PROCESS Effective Date: | 01082015

BLISTER PACKAGING OPERTION LINE DIAGRAM

4 my

Pea

Page 60f8

[REVITAL HEALTHCARE (EPZ) LTD [Becimentos J2fiosz0

Revision No.

-VAIORTON FOR BUSTER PACKING PROCESS Effective Date 0.092055

9. CRITICAL PARAMETERS OR STEPS

‘VALIDATION ATE: 2 .4).281-2.

aE |_ TEMPERATURE (°C) 1] TIME (SEC)

FORMING | SEALING | FORMING/BLOWING | SEALING | VACUUME

I 90 | 145 od janes ee

|_ Io! 00 tor | 1¥o os ie =

2.00 Es 190 fa Ve og

14.00 | 122 [200 1S 23 [00

16100 12/7 [aos] 22 [zs [ro

10. SAMPLING INSPECTION.

TIME QTY CHECKED ~_avRBEcT

G08 200 22

Looe 200 Niel

(2.00 Zoo We

[1H o° 200 wi

LU 00 | 200 28

11. OBSERVATION

‘Time | FORMING | SEALING | PRINTING | CUTTING | REMARK

[geo | weroe| Note [oe ek [Failed

10.00 ole ole on ok Passed.

v2.00 | ok ek oe ek | Passed

(uioo | ee | of | oe | based

16.00] NoteEp ok [Wet eK Caled

Page 7 of

[REVITAL HEALTHCARE (EPZ) LTD [Beeumert No: [2706/20

Revision Wo 101

‘VALIDATION FOR BUSTER PACKING PROCESS Effective Date: | 0:08.2019

11, SUMMARY: THE FOLLOWING PROCESS FOUND SUITABLE FOR

THIS PRODUCT

sy TEMPERATURE co TIME (SEC)

| FORMING | SEALING) FORMINGTBLOWING | SEALING |

[-tereo | re2 | Ivo] 65 iss

rzio0 | U 2 | 196 ty Le

[eseetedse ngcaeoee | | ee osama

12. Next validation due: after one year or prior to change the exiting

paper, film or machine

13. Declaration: we all here declared that we have checked and verified the

validation process and approving the above report to carry out regular’

process.

Page Bf

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Operation and Maintenance of Microscope: Revital Healthcare (Epz) LTDDocument5 pagesOperation and Maintenance of Microscope: Revital Healthcare (Epz) LTDMusyoka UrbanusNo ratings yet

- Justification Sample For Biocompatibility SampleDocument1 pageJustification Sample For Biocompatibility SampleMusyoka UrbanusNo ratings yet

- ProtocolDocument7 pagesProtocolMusyoka UrbanusNo ratings yet

- VTM Box ArtworkDocument1 pageVTM Box ArtworkMusyoka UrbanusNo ratings yet

- Process Paramater 0.5ML MC-06Document1 pageProcess Paramater 0.5ML MC-06Musyoka UrbanusNo ratings yet

- Quality Manual Policy ObjectivesDocument5 pagesQuality Manual Policy ObjectivesMusyoka UrbanusNo ratings yet

- Packaging Validation For Iv SetDocument39 pagesPackaging Validation For Iv SetMusyoka UrbanusNo ratings yet

- Tertiary Packaging Material SpecificationDocument3 pagesTertiary Packaging Material SpecificationMusyoka UrbanusNo ratings yet

- Primary Packaging Material SpecificationDocument3 pagesPrimary Packaging Material SpecificationMusyoka UrbanusNo ratings yet

- Lorry DescriptionDocument3 pagesLorry DescriptionMusyoka UrbanusNo ratings yet

- Christina BradleyDocument37 pagesChristina BradleyMusyoka UrbanusNo ratings yet

- BT SetDocument3 pagesBT SetMusyoka UrbanusNo ratings yet

- Meeting Held On 15.05.21 With ChairmanDocument1 pageMeeting Held On 15.05.21 With ChairmanMusyoka UrbanusNo ratings yet

- CE Marking RulesDocument46 pagesCE Marking RulesMusyoka UrbanusNo ratings yet

- PQ Report Ver. 01Document15 pagesPQ Report Ver. 01Musyoka UrbanusNo ratings yet

- 11 Sop For Accident ReportingDocument10 pages11 Sop For Accident ReportingMusyoka UrbanusNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- Doctor Pack India PVT LTD Sop Title: Management ReviewDocument5 pagesDoctor Pack India PVT LTD Sop Title: Management ReviewMusyoka UrbanusNo ratings yet

- 04 Sop For Objectives, Targets & EnvtalDocument7 pages04 Sop For Objectives, Targets & EnvtalMusyoka UrbanusNo ratings yet

- 07 Sop For Compliance of Air Pollution Guidelines of NemaDocument5 pages07 Sop For Compliance of Air Pollution Guidelines of NemaMusyoka UrbanusNo ratings yet

- 05 Sop For Competence, Awareness & TrainingDocument6 pages05 Sop For Competence, Awareness & TrainingMusyoka UrbanusNo ratings yet

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- General Cleaning Procedure: Revital Healthcare (Epz) LimitedDocument4 pagesGeneral Cleaning Procedure: Revital Healthcare (Epz) LimitedMusyoka UrbanusNo ratings yet

- Corrective Action and Preventive Action Procedure: Revital Healthcare (Epz) Ltd. Standard Operating ProcedureDocument7 pagesCorrective Action and Preventive Action Procedure: Revital Healthcare (Epz) Ltd. Standard Operating ProcedureMusyoka Urbanus100% (1)

- Sop For Customer ServiceDocument4 pagesSop For Customer ServiceMusyoka UrbanusNo ratings yet

- 08 Sop For Compliance of Water Pollution Guidelines of NemaDocument5 pages08 Sop For Compliance of Water Pollution Guidelines of NemaMusyoka UrbanusNo ratings yet

- Iso 6710-BCTDocument9 pagesIso 6710-BCTMusyoka Urbanus100% (1)

- Schedule 1: List of Raw Materials Exempted From PVOCDocument5 pagesSchedule 1: List of Raw Materials Exempted From PVOCMusyoka UrbanusNo ratings yet

- Change Control Form RevisedDocument5 pagesChange Control Form RevisedMusyoka UrbanusNo ratings yet

- (EN ISO 13485 &ISO 9001 Certified Company) Quality Control DepartmentDocument4 pages(EN ISO 13485 &ISO 9001 Certified Company) Quality Control DepartmentMusyoka UrbanusNo ratings yet