0% found this document useful (0 votes)

3K views7 pages01-Sieve Analysis Coarse and Fine Aggregate.

The document provides the standard operating procedure for sieve analysis of coarse and fine aggregates according to IS:2386 (Part-1)-1963. It describes the process of testing aggregate samples through a series of sieves to determine particle size distribution. Key steps include drying the sample, nesting sieves in order of decreasing size, shaking the sample for 10 minutes, weighing retained material on each sieve, and calculating the percentage passing and retained to determine if the aggregate meets specifications. The purpose is to ensure the aggregate has a gradation that will produce strong, workable concrete.

Uploaded by

gsv988Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views7 pages01-Sieve Analysis Coarse and Fine Aggregate.

The document provides the standard operating procedure for sieve analysis of coarse and fine aggregates according to IS:2386 (Part-1)-1963. It describes the process of testing aggregate samples through a series of sieves to determine particle size distribution. Key steps include drying the sample, nesting sieves in order of decreasing size, shaking the sample for 10 minutes, weighing retained material on each sieve, and calculating the percentage passing and retained to determine if the aggregate meets specifications. The purpose is to ensure the aggregate has a gradation that will produce strong, workable concrete.

Uploaded by

gsv988Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Sieve Analysis of Coarse and Fine Aggregates: Defines the methods and purpose for determining the properties of coarse and fine aggregates.

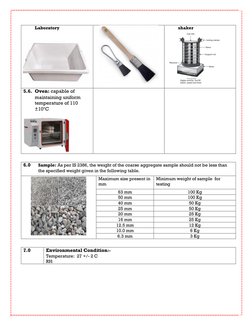

- Sample and Equipment: Lists the equipment required for testing, including sieves and balances, and sample preparation protocols.

- Test Procedure for Coarse Aggregate: Details the step-by-step procedure for conducting a sieve analysis on coarse aggregates.

- Test Procedure for Fine Aggregate: Provides a detailed process for executing sieve analysis specific to fine aggregates.

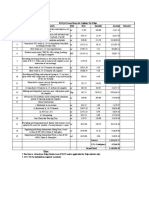

- Analysis and Reporting: Instructions for recording observations and calculating results in the lab report format.