Professional Documents

Culture Documents

Cátalogo de Productos DANA

Uploaded by

cesardario900 ratings0% found this document useful (0 votes)

5 views61 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views61 pagesCátalogo de Productos DANA

Uploaded by

cesardario90Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 61

=

LLL) b

Be

DANAZHA

(ee NENTS

Vision Measuring Instrument

Universal Testing Machine

Hydra

Horizontal Testing Machine

lic Universal Te:

ing Machine

Ultrasonic Flaw Detector

DANALUSIO;DANA-U820

X-ray Flaw Detector

‘Magnetic Yoke Flaw Detector

YANG

Handheld UV LED lamp.

‘S31201UV286nm

Surface Roughness Tester

[DANA-S220/DANA-S200/DANA-S360/DANA-S520

Portable Hardness Tester

DANA-HT10/DANA-H130/DANA-H1201DANA-H140

Webster Hardness Tester

\W-20)W-20NW-208)M1-875)-B92

Barcol Hardness Tester

Rockwell Hardness Tester

HR-IS0AHRS-1S0/HRSS-150,

ell Hardness Tester

HB-3000B/HB-3000MHBS-3000MD

Vickers Hardness Tester

‘Metallographic Grinding and Polishing Machine

UMP. 2B1JMP- 26

Metallographic Sample Mounting Machine

IM-2BWIN-2S

High and Low Temperature Test Chamber

Salt Spray Test Chamber

DANA-60L901/1201.

Fluorescence Spectrometer

HiVS-10008/HVS-1000BZ/HV 10008/HV 1000MBZIHV-SBZ/1082/30BZ/50BZ

Ultrasonic Hardness Tester

DANA-SUt00

Ultrasonic Thickness Gauge

DANA-1210/DANA-T220/DANA-T230/DANA-T240

Coating Thickness Gauge

DANA-C330/DANA-C320/DANA-C310

Metallographic Cutting Machine

IMC3-TAMCS-L

AISA 8949 Company Introduction

We are a manufacturer integrating R&D, production and sales. Products mainly including

universal testing machine, vision measuring machine, ultrasonic flaw detector.ultrasonic thickness

gauge ,leeb hardness tester,coating thickness gauge, surface roughness tester, and so on. We have

two factories which are located in Huzhou, Zhejiang Province, and Dongguan, Guangdong

Pr Je have advanced state of the art technique, perfect production process, accomplished

thod and ability of developing new products.

recruiting global agents if anybody is interested, please contact with us directly

DANA) Our Certifications

DANAES:

(Pp)

DANA Series f

Manual Vision Measuring Machine

, A

in =

8 Technical Specification

‘The vision measuring machine isa high-precision optical measuring instrument integrating ight, mechanls,

elect and cleiation, which fs developed onthe basis of ractionel optical instruments and combined withthe most aavanced medem image

processing and computer sofware technology

Itt mainy used for two-dimensional measurement and asits tree-dimensional measurement. can perform ecient, fast, accurate and

batch measurement of plane geometric elements suchas workpieces, pons, ines, les, acs, elipees rectangles, distances, and angles, and

some tvee-dimensional geomet elements such as cyinders, cones, spheres, ane neigh.

\

@ Product Characteristics

© Auto calibration uncon

«© Automatic edge finding measurement function,

‘© Users can impart the AUTO CAD workpiece fil into the measurement software in OXF format, and then can. easly realize the

Intuve comparison between the age and the drawing

© TEOCCO Camera,

DANA series manual vision measuring machine

oz) Eee ed Ee

Eectve Xm) 200 300 “00 00

a Yim) 10 200 sto 0

Zim) 200 20 20 20

Marble Courteop Size(mm 20260 460°380 0460 0-610

able hss Countertop ster) 9129 9-79 9509 nasr9

Workbench Weitea) 150 200 2=0 0

Site) eo"se0* 970 Ten"se0°sTO——860"TED"3T0 160 “8103020,

Powe OVAC-220¥C} 50H2 Total power SOW

Dighal Resolution XY coorinate measuring ination err < 31/200 um

enone maser au yzavésmanual

stem

Resolution ‘.901mm

conor Syste Act#z0 letrniecontolsstemidepending onthe mod)

Grating er Sinpo brand grating sesoltion:um

camera Comat Gigabit highspeed digital camera

Motor Precision serv intepated eto unit

Guide Rats “Thea uses paral precson al oss guide ras, and the Z xs ses sven ude als

Lens Pomeas gta z00m objective lens

Software INSPEC nteligent measurement software supports multil angunges

DANARS#

y

DANASemi-automatic Vision Measuring Machine

Ee ed

fective Xiom 200 30 0 500

ed Yoo) 100 20 200 ao

Zim) 20 200 200 200

acbe Countertop Size(mm) seo260 00 560° 460 0" 610

Ae ‘lass Countertop sie rm) nen8 mone 9-28 520709

workbench Weight) 150 20 280 80

Size(mm) ea"eeo*s7 ——Tea"680°9T0 ———BGO"TED"STO 1160" 101020

Power 1OVAC-220W1AC) S0H2 Total power

ight Resolution “coordinate measuringincication ear < 3+1/200) um

Leer 2 as utomati conto. as manual contol

sytem

Resolution (001mm

onto stern Acr#20Etectvoriccontrlsytemidependingo the model)

Gratinger Sinpo brand grating eslutin- um

camera Const Ggsbithih-speed egal camera

Meroe Preaion serve nterated motor unt

Guide Rats “The axis uses poral precsion bal ross guide il, andthe ais uses siverner guide ais

Lens Pomeas digtal zoom objecte lens

Sofware INSPEC ineligent measurement softwar supports multiple languegss

DANA Automatic Vision Measuring Machine

Co) SEC eg 5040

fective Xiom) 20 0 0 500

ca Yon 100 20 300 ey

Zim 200 200 200 200

Marble countertop Size(mm) seo260 0360 560° 460 0" 610

ert lass Countertop sie rm) nern8 wane 9-28 509

weribanch Wight) 150 20 20 20

Size(mm) Teareeo*970 —T60"680"9T0 ——_—6GO"TEN"STO 1160" 9101020

Power OVAC}-220WAC) SOH2 Total power

Digha Resolution “coordinate measuringingication ear < 3+1/200) um

Image measurement Image measurement sytemxy2 ans automate conto

sem

Resolution ‘901mm

Controle Sytem Acr#20 tector control systemidependingo the adel)

Gatingruler Sinpo brand grating eslutin- um

camera Comet Gigabit highspeed distal camera

Motor Praion serve nterated motor unt

Guide ais “The axis uses parallel precision bal ross guide ils, andthe ais uses siverlner guide ris

lens Forms gt zm objective lens

INSPEC ineligent measurement software supports mule languegss

Sotare

DANALS

DANA-UTMS5000

Universal Testing Machine

Standard Configuration

“Main rane

oor nyt researah and cone of stepping mor

al see pa

Load eer 5M

‘Standard ate

Tester standard version

8 Introduction

‘This test measurement an control system is designed for electronic universal testing machine matching set measurement,

contro in one ofthe measurement and contol instrument. Can be tensile, compression, bending, shear, tear, peel and other tests

© Features

‘© This machine adopts single-arm structure, lower space compression, beam stepless iting.

‘© Transmission part adopts circular are synchronous tooth bet, lead sorew pair transmission, stable transmission, low noise.

‘© The specially designed synchronous gear belt deceleration system and precision ball screw pair dive the moving beam of the

testing machine to realize the non-clearance transmission,

8 Technical Specification

Model Ped

Testmachinelevel 0S lee Tene tke 60mm

uma AN Host parameters Compression stoke ren

rcttorce index sa: fest wih: Een

oss: han +1 oft deta aloe Force contol alent aes < 2.055%, te wna et val

a aa Gone precision Rat SB6 0.0548 within 08% ot wae

Deformation index epost Deformation rate adustment range 002 SNS

Maximum valie 10mm Acguraoy ot wanna rate <5, le win 1% a6 ve

deformation rate — i

ey on ale BBB 0 000RFS, win 20.5% ot vale

‘ccuraey Taterthan £0.85 of ind van “Accuracy of when th rie = O00 Trin, twin 41% oe

Gdeplacerent—Setatuc When be spoud a> 2dr

Meseig secu baer than 25% ote cad vale fate contd” wild 2% et ae

‘The deplacement

" Reeokton: 000mm Constant fre, constant csplacement. constant deformation

aa ea vaanan Somfol range. Osve-fOO% FS securay. hen he set vou

a oe = inate pee eguton SOG, ig tno fhe avi Whante sped te = 10%

posure: tater han +1 of th nde alos FSvaie erate setvae

Working environment room tpt 10-35 aiiy 20-60% Host ize bout 600 490% 160m

Force contol rate adjustment range _0cos=wFSS

DANRARS#

DANA-UTM2TM/STM/10TM

Computerized Universal Testing Machine

Standard Configuration

Wain rae

ators yet research and conta sett steping mie

Bat screw pat

Load sero 204N/SOKN HOOKNOierent mods wh fret oa senso

andar nes

Tact standard vrzon

‘Compsr industry computer ,

Random os, andom eran instalation marl y

@ Introduction

‘This test measurement and contol system is designed for electronic universal tasting machine matching set measurement,

‘control in one of the measurement and contol instrument. Can be tensile, compression, bending, shear, tear, peel and other test.

@ Features

‘© This machine adopis twin column structure, lower space compression, beam stepess iting

‘© Transmission part adops circular are synchronous tooth belt, lead sorew pair transmission, stable transmission, low noise.

‘© The specially designed synchronous gear belt deceleration system and precision ball screw pair drive the moving beam of the

testing machine to realize the non-clearance transmission.

{

DANAES

8 Technical Specification

Model Eater Pate

820 470 1650 mm 605601900 {#80 550 1900 mm

or) Os tee 05teal

Maxum valve 206N aks ‘90

ee Measuring range 21005

‘Accuracy eter han 3 ote inde vale

Resoluton 120000 yas

optional opto

Deformation index —Mazamumvalve _tone

Measuring range 254300%

Accuracy betethan 20.5% of te indested vate

Measuring accuracy beterthan 20.5% of ta indoatd vale

‘The clsplacement

Resolution a00Irm

pees ange ‘renin = ori stapes ep roguaon

Accuracy tartan #1 oft nated abe

Teneie stoke oom em Tain

ost parameters [Compression stoke 006mm ‘oo ‘100mm

Test with ‘mm ‘100m “nm

Wirkng environment room tmperatie 1036, hamity 20% — 20%

Force conto ale adjustment range 0005- 54F

Foros conta ate conto precision when teal i < OSES, tis witn 21 va; Rate BBB 00 054FS win 20.5% savas

Deformation rate adustment range on eKFSS

‘Accuracy f deformation rate contol enteral ie < OOSHFS, ie wihin a8 a vale Rate BEB OOUENFS, wh a0 5 sl vale

Accuracy of eeplacerment rate conto!

han the rien <0 ri, whine valu When the ped» DSi win 0 2% vale

{Constant ferce, constant cplacement, constant deformation contol range _0%-100% FS

constant fore, constant elisplacement, constant deformation contol accuracy

when the sat vals = 1S, twin 0.1% ofthe st vai; When th pode < OMFS, Rie oft seve

Various Fixtures

DANAR#

Standard Configuration

Nan fame

so an sytm research an conta et of stepping mot

al screw pir

Loa sensor 200KN | 00KN /COOKN Diront mods wih eertlond sensors)

Stand ture

Tester standard erin

Computer nasty compute

Randel anon fle mania taiaion man,

@ Introduction

‘This machine isan important equipment fr testing the physical properties, mechanical properties, process properties, structural

properties and intemal and external defects of various materials and ther produc. It can realze the tensile, compression, bending,

‘shear and other tests of metal or non-metallic materials, aulomatically obtain the tensile strength, yield strength, specified non

proportional extension strength, elastic modulus and other performance indexes of the measured materials,

Mos En) Eon) ie)

Max Testload (iN) 300 600 1000

Displacement Resolution 2.01mm

“estore resolution ‘vs00000

Test Load Indicating Accuracy =20%

Deformation measuring range 86 t00FS

Deformation Tet Accuracy <105%

Load Measuring Range 2m-I00WF.S

Displacement Test Accuracy <20,.5%

Deformation Reson “200000

No Of clu 6

Ditanoe between Wo column (mn) 0 540 co

Diameter of column (rm) « 75

Sie of workbench (ram) aor aeons 735°550°78, 225762006

Depth of workbench (mm) 580 160 a5

Max. Stroke of piston (rm) 250

eee ‘About 160 200 20

adjustment (mmimin)

Motor power for

crossbeam moverent (KW) a

Load Frame Dimension (mn) ‘40°590"1900 735°S50°1950 25'620°2300

Ol source contled cabinet (ran) -200"680"750

Load Frame Weight (ka) About 1450, ‘About 750 ‘Roout2750

Power (ki) 275

DANARSA

Horizontal Tensile

Testing Machine

@ Introduction

Horizontal tensile testing machine is suitable for tensile test of long material Ike wire rope, cable, nylon rope, sulalors sting and.

chain et. It applies the ful cigital controller, servo control system along with the standard analytic sofware, soit can realize close oop

contro for load and displacement, cigitaly setting zero, sofwarefhardware digitally calibrating, protection, limit postion signal input,

thus the machine posses user’ programming function Its widely used in some plants who produce longer materia

@ Features

*Itadopts electro-hycraulic servo automatic contol technology to automatically control two cylinders’ propulsion speed to complete

the pull test with simple operations.

‘© The high-precision load cel, calbrated by a national-level metrology institute, has measurement accuracy better than 1%,

‘© The tension tests controled by computer, with simple operation interface and complete functions, The test can be completed by

‘simply operating the mouse for selection It can display data and corresponded curves in real time.

‘= The computer vill directly fish data acquisition and analysis after the pul test, and then print test report and line chart.

‘© Itcan be configured witha high-precision camera to make you easily grasp the whole tension process and capture photos inthe

process.

‘© The equipment can complete various forms test, such as static tension test, breaking tension test, displacement test, and fatigue

test, ete

@ Standards

(981727 10-2005 measuring leather’ expansion and he rate of elongaton.

(98172711-2005 measuring tea force of eather axes fice ) S040, 0K, 2008, 00K, SCAN

(0872712-2005 measuring leather’ strength and sirech of spherical cack test, Rangeaftt ore 100%

ISO 13054 Test Machines for Grab and Sp Tests of Fab, err Toten = ag

‘ASTM D76 Tense Textes Test Machine

[ASTM D751 Coated Fabrics Rainivea: Test Equipment eset creas we

[ASTM D168 Seun Seams of Woven Fabric “ni sig Space ‘on, fOr astonced)

‘ASTM 4964 Tension and Elongation of Esto Fabris. Tipit 700mm Cane stories)

STM DED Cab Tea Wt Tethe enten Testing Saed (00min (can econ)

‘ASTM D50NS Breaking Force and Elongation of Teste Fabris by tip Method

[ASTM 6775 Break strength and Elongation Test Equpmentfor Tertle Webbing THe ei et cents

Tape and Braiced Materia

[ASTM D7260 Tensile Testing of Aramid Yarn,

otra (eae steed)

DANA-US10

‘Standard Configuration

Seal probe 4 | Prose Carfone

ral pre 1) Inston manu

probe someting sable 2 | Softuare ,

Power dope + | Insrunertcase 1

8 Introduction

applied for electric power, petrochemi

Digital ultrasonic flaw detector is advanced type, can quicky, easily and without damage, accurately detec, locate, evaluate

‘and diagnose various defects inside the work-piece such as cracks, welds, pores, sand holes, inclusions, folding, etc. It has been

boller and pressure vessel, steel structure, military, aerospace, railway transportation,

‘automobile, machinery and other feds, Its an essential instrument forthe non-destructive testing industry.

8

Features

Measurement cisplay mode: positive wave,negatve wav-

full wave and RF wave,

Ithas a tinear suppression function, the maximum inibit-

Jon is 80% ofthe sereen height.

Itcan switch between single crystal probe, double crystal

probe and two inspection modes.

Ithas a gate setting and alarm function. The position and

Width ofthe gate can be arbitaily sat on the seven, and

‘an incoming wave alarm can be set.

‘500 independent detection channels, each channel seta

separate set of testing parameters,

‘Two display mades with angle and K value

“The DAC curve is generated automaticaly, and up to 10

points can be recorded, with four adltional adjustable

offset curves.

‘AVG curve is generated automatically, and two types of

defects can be customized

‘Automatic probe calibration function

\With storage function, it ean store 100A sean graphic,

parameters and DAC curve

Has a storage graphics playback function, the stored A

sean graphies from the storage area and displayed on the

Has a delete function to delete the specitied content (rep-

resented by the storage group number) from the storage

Peak memory function,

Freeze and thaw functions with waveform and inspection

parameters.

|with sound path measurement and echo frequency anal

ysis function,

Realtime power status indication function.

Support USB communication interface.

LL-battery low pawer consumption, can continuous work

rng move than ten hours

‘Can set up buzzer alarm during operation.

Light, convenient, easy to operate,

DANARSA

DANARS:

8 Technical Specification

rt

‘Sean range (mm)

Puls shit (us)

‘Sean range (ra 0-10000|

‘Grades:255,1072 3040500708090, 10,1020, 250, 200,360,400, 450 00,

£0, 700.00 200, 0002003000 4000500 00, 7000500 000, 0000

‘Aji op tance

Puasa (s}-7 +6568

‘rae: 20,10, 0.0, 10,20, 5,10, 10, 200,250, 0, 380,40, 0, 00, 600,70,

00.0100 60020002500 0003400

Ajmer ep (e9868)5)

Probe zero points)

Probe apa. 00-6000,

Aust ne tp: 001

tel sound sped 1000-12000

Mate sound spoedins) Td sunspots 22602790 20805230, 4700 500 6300,

‘Agus be tpt

‘Wecing methods ‘Shige pobe (eee aed sn, ul probes (one freaking ener snag)

Frequency Range(Wz) os-20

Gain adjustment) O-120 Adustinesop:02.124,58 102080

Linear inhibition ‘Seren hight 10 80% op ze: 1%

Vertclinearty enor

‘ere nes er, oon an 3

Horizontal near eor

tint ean ange, no mare han 02%

Flaw detection sensity margin e208

Dynamic Range 2208

‘Alarm Incr wave alae

Display screen Depa: Hehrignoes lr 57 delay

Scan display area Fusion of heat /AScan shows eeze a thaw A Sean fs

Flaw detecton channel m0

Data storage 500 Sean gaps

PC communication terface standard se

Unis of measurement vim

Power Adon ener COV 240BoH BOM 13.5

Baty ium 0) Bair 000A

“Working temperature C) =0-s0'e

Working humic (RH) 20-00%

Intertace Type exc

Dimensions (rm) aaa

Weightco)

10

DANA-US20

Digital Ultrasonic Flaw Detector

‘Standard Configuration

a iit 4 | Waray ord 1

‘Sih pre 4. | Prose contests 1

angle probe 4 estueion manual

2 | Sotware aa

4

@ Introduction

Digital ultrasonic aw detector is advanced type, whichis touch screen, can quickly, easly and without damage, accurately

detect, locate

‘evaluate and diagnose various defects inside the work-piece such as cracks, welds, pores,

1d holes, inclusions,

folding, tc. thas been applied for electric power, petrochemical, boler and pressure vessel, stool structure, military, aerospace,

railway transportation, automobile, machinery and other lds. Its an essential instrument for the non-destructive testing industy.

6 Features

‘© High-precision quantification and positioning to meet the

requirements of near and far distance detection.

'¢ The near-field blind zone is small, can meet the detecting

requirements for small-diameter and thin-walled pipe.

‘© Auto calibration funcion:one-button auto calibration.easy

to operate, automatic test probe "P Delay'"K value',"X

value” and the velocity.

‘= Automatic cisplay the defect echo position(Depttd,

Horizontap,Distance:s, Amplitude, 8,¢ )

‘= Auto gain, peak envelope, peak memory functions, which

can improve the detection efficiency.

‘© Automatically record the flaw detection process and dyna

mic playback

' @value calculation: Forging law detection by straight pro-

be, can find the highest wave to conversion @ value auto-

matically

‘+ 500 independent channels(can be expandable), which can

input and store the detection standards of any industries,

‘realy, do not need to carry the standard blocks for on-site

inspection,

Store, playback 500 A-scan waves and data freely.

The DAC, AVG, and TCG cures (depth compensation)

fate automatically generated and can be segmented. The

‘sampling points are unrestricted and can be corrected and

compensated,

Pulse width and strength can adjustable.

B scan and B color scan function.

(Can communicate with the computer, and export word

Fie, also the detection report

IPBS ABS plastic case, sturdy and durable, water-proof and

dust proof, and excellent ant-nterference ability,

High performance lithium battery, can work continuously

for 8-10 hours.

Real-time clock recording: realtime flaw detection date,

time tracking record, and storage

ower-down protection, storage data can not lost.

Digital reject, does not affect gain and lineaiy

Gain compensation: Db attenuation can be corrected for

surface roughness, curved surfaces, long-range law del

lection of thick workpieces, ete

DANAHSA

DANARS:

6 Technical Specification

ope TeTFTeurscon, Or Atgerpover

pwn mde Ry. Thon Oa sirage so swat)

over sippy iain ay am ‘

Bana cpcty son ting Tempe 0c

Powe votie tv Store Tempera a =006

rowerganey de we

orig ine thon meron Poms

Acad 0c OC est ii eda

Acne oh ___K tv

ee)

ree mes ope robe pe She, Da Tes one

Chal ype ge ded Fer ‘irene ae

hart han Sg ea Onions Neer

Pulse Tine 9 Faje tp

Tran Vane 8-38, pA Hel veoaly ame

are 00 Pe dpc 180m

Gan 8, ap POEAY Oa

an eau AL J

roe ampere Aa Rw ue Ye St erin

ting Faerey 06a Tesing Poni Pet

Tesing Ringe =n, a iy mp

(cate Amputee a vam. anges Hoan dalarce, Vtcal dance, The

Measurement ference ake btveen Aan 8 Gate

‘cursor: 2 ose curses can teste Rrra an verzal dance, nde dance Between

cserstunder 8 sean ony

Gate

Cate vt: 10-80%, p16

DAG simu ive, et to NBT A7OYR,GB/T 1345 7 20712 and her ears

curve 06, maxim sb aves

NG

Ful soon, cursor sutchrngeightorzon singletons at air{12-T00X, sap 10%), eho compare

other functons eho fi peak nls peak menoras sancutsio made seenshet

Peak eszelrack dphiate expansion sree moist sania wel saionioo

Alarm Sound ight

Sensitivity Leavings 2926/2000 0arH42 50020)

Hozontalneaty eer 30.3%

Vertical inearty eror 3%

‘Ampltude ineatty eror <2%

Attenuator accuracy 2048 +1 a

Dynami range 2218

Distantresoluion —_=2id

Noise Level #00100

DANAHSA

XXG Seri

Directional Ceramic Tube X-ray Detector

XXG-1005 XXG-1605 XXG-2005,

XXG-2506,XX6-3005,XXG-5205,XXG-3605

6 Introduction

‘The Gas-filed X-Ray Flaw Detector is an advanoed non-destructive testng equipment, which is widely used in machinery

‘manufacturing, petroleum, chemical, textle, aviation, boiler, pressure vessel, metallurgy, shipbuilding, national defense industry, etc.

‘The portable X-ray flaw detector uses an advanced controle. The controller integrates the strengths of domestic and foreign similar

Instruments, and adopts advanced single-chip microcomputer control system and advanced electronic circuits such as thyristor

voltage reguiation and thyristor frequency conversion and steady current. This series of flaw detectors has the advantages of small

‘ize, light weight, easy operation, stable operation and high reliability.

© Technical Specification

Input

Poms

cca

WAG=1005 > antoo— AOR aT HOH ONAN 5, 2

WHG—1605__>4_——omtoo «ROG YBNI 8 =

YAG=2005 98 _——w0-a00—~20320 SCS 2

HG=2505°5 aso) «20x20 at =O DAD _—_—S « =

WiG—305 56s tm-g0 2828S _—8 =

wiG—m05°7—eo-say 29429 YS % ”

G—3505_ +7 mas _——20x20 at SS AOTD 98 ©

DANARS:

@ Technical Specification

tem co

AC power ACz20V=10% SHE

Tate eurenovege) Son

Outpt

Hin vote ranstemerinpt votape ctuston a

celia tod Frond cooing

ray generator ulation eth ‘SF5 Ga ian

‘Saf ering pessuro20C) 036-0480

\Werking conditions olive Hurity 088

rite 1000n

Sts 30m)

‘ocatlerath cr

pone somAin

Max penetation condton

am Doses nl senizston

pts costy peo

‘The controler wah on

Wirking way Work and etn: made tha maximum pon me can stp 1 8 mins

8 Optional Accessories

Darkroom timer Darkroom red light Fim storage bag

Image quality indicators Pull ring magnet Lead markers

>

mn of

Leather bag X-RAY warning rope Plast bag

fF

Groove test block

2

e

XRAY Film viewers

Lead markers tape Sticer

or

Patch frame Cleaning sheet shelf

$3120/UV365nm

Handheld UV LED lamps

‘Standard Configuration

Main unit

‘Adoptive charger

Gogoles

Wiranty card

Produc Corieate

Inert manual

8 Introduction

DANAHSA

LUV lamp for aw detection, has two kinds of thermal ght source and cold ight source. Itis an indispensable auxliary tool in

fluorescent testing (Ruorescent magnetic particle testing, fuorescent penetrant testing and fluorescent leakage testing), and is

\Widely used inthe fild of fluorescent testing, With the rapid development of UV LED technology, more and mare thermal black lights

‘are replaced by LED black lights

© Technical specification

Intensity range

Incensty adjustable Intensity range

Intensity range

Uviighe Fx

Valle ight

Coverage area

Power

‘output

Wavelength

Size

Weight

Battery Capacy |

Chaeging Time

Diameter sou 00m

1ar72"780m

4963

eaoavnto0070006m*

2 sooo yn?

2 Toon

LUV LED-OVA Ugh vA

366menUVA)

965

DANAE

V-A/Y-2/Y-8

Magnetic Yoke Flaw Detector

‘Standard Configuration

an gin 1 | Power coonadarwie (128 ¥8)

Inet box 4 wants

cr conser 4.) Prost Ceres

8) 4) Inseucion mara

[DC memnezed power suply (2) 1. |_Insrunent ass

"AC magnazed pone euply (8) 1

© Introduction

With the characteristics of compact structure, reasonable layout, compact size, ight weight and easy to cary, this kind of

detector can be directly plugged into AC, as well as be equipped with AC magnetized power supply (AC battery pack) and DC

‘magnelized power supply (DC battery pack, which is of high efficiency and compactness, Besides, iis applicable for inspection of

hull welds, high-altitude steel structure welds and internal operation of pressi

vessels. Moreover,

is suitable for magnetic powder

inspection of surface and near surface defects for various steel structures, boilers, pressure vessels, pressure pipes and welding

structures in electric power, metallurgy, petrochemical, machinery and ather industries.

@ Features

Three power supply modes can be selected freely:

‘© Be directly connected to AC power supply for place with

irectinsert AC power supply.

‘© For place without direct insert AC power supply, AC

‘magnetized power supply (AC battery pack) can be used

to realize AC magnetization inspection function

DC magnetized power supply (OC battery pack) also can

be selected to realize function of DC magnetization.

‘© AC magnetized power supply (AC battery pack) has the

Protection function of stable votage output, over-charge,

over-curent, over-dscharge,

‘© Automatic power off will be started when the iting force

Is insufficient, so as to ensure the detection sensitivity.

‘= Power display function, which can cisplay current battery

capacity, 26 well as with sounel-ght alarm function.

‘© Builtin microcomputer chip, stable output voltage to

ensure detection sensitivity

‘© Adjustable magnetization intensity

‘© Special working pockets,

6 Technical Specification

Elocrode 210mm

“Maximum current 284 28k

Weight 220 22a

"YY AC magneton deel sa pov)

Main function ¥2 BO magneton MIO)

"Y= AC magretenionwth 7-000)

Wiring temp. 0-40 Strapetomp.———ad-s0

Felatvehumity No canfensngst05.

Operation temp. nse <18¢ Dayo 0%

Sens ef

Minimum AC boost —>45g(4§),manimam AC boos 7h (63.0%)

Minnum DC boast

218 gl 17M} maxmum DC best 249 225N)

a

Model ‘MT-e00 MT-500

Battery capacity HOOmARACUMUnZA) S0ONANCCLIMUNZA)

Detection time Aout sh a

(Overall dimensions $5-95+180mm) $6061)

DANARS#

DANA-S220

Surface Roughness Tester

‘Standard Configuration

@ Introduction

DANA-S220 is a new generation of Surface Roughness Tester Series. It features high accuracy, wide application, simple

‘operation, portability and stable performance. The tester is widely used in measuring the surface roughness of various metals and

non-metal. Is integrated structure of sensor and main body and hand-held design make it suitable to be used in production sites.

6 Features

‘© Shell used to pull aluminum mold design, durable, anti-

electromagnetic interference abiity significantly in ine with

the design ofthe new tend,

«© Using high-speed DSP processor for data processing and

calculation, measurement and computation speed is great

ly improved.

+ Using a decicated charger or computer USB por for char-

ging, convenient and quick

8 Technical Specification

«© Lcuid crystal display wide temperature using OLED color Tsing pcanters a Re Ra Rt

splay, popular high bighiness,no visual angle, sutable Nasi ge Ra, R:005150 Ra E0500

for various occasions. Saleen 026,080,280

‘© The lithium ion rechargeable battery, can work for along “Bsdustonlengiimn) 128A

time, no memory effect, can while charging, charging time Stok gh (rm) *

Is shor, long battery ie

‘Automatic shutdown function and low power design of so-

Inder ssray

Ineaon err

fivare and hardvare ofthe instrument with lng werking Eero ec

hours, suitable for feld use. Powe acaba

The surface roughness of metal and non-metal. aaa anal

'» Pocket-size & economically price. “Fone measuingriedfchage s00Nm

«Large measuring range suitable for most mateals a

‘© Optimized electric circuit design with transducer structure- rc

design high integrate power

Woo atet Ee

«# oould test ex-cle, at surface, conical surface andalso ese

See 16am xr

test groove larger than 80°30mm

DANAES

DANA-S360

Surface Roughness Tester

‘Standard Configuration

‘Standard Sensor 1 | Adjustable support 1

Clean boc 1 Operating manual 1

bracket 1 waranty ert 1

Charger 1 corieats of prt :

ss cing cable 1 tnstument see 1

© Introduction

Portable surface roughness tester allows surface roughness measurement both on metal and non-metal workpieces. It is

suitable for machining and manufacturing, quality conto, inspection departments, especialy for measurement on lage and heavy

‘workpiece, assembly line, onsite

8 Features

‘© Electromechanical integration design, small volume, ight ‘s Can be connected toa computer and printer.

weight, easy fo use. ‘* Bluetooth function; Can acquire, manage data by APP.

‘© Using DSP chip to control and data processing, high speed,

low power consumption,

(© 128 x 64 OLED dot matrix display, cigtal/ graphic display, 6 Technical Spacttiention

hightght no perspective. Model Eon

«Intuitive and rich display information, can display al the

=r aR RFR Ry

parameters and graphics. Heer) Rau, Rsk, Rhu, Rm, Rin, Ric

+ Compatible wih ISO, OIN, ANS, JIS national standards Measuring rage (um) Ra 001618000 Re 0.020000

«Residual quant ion, prompting the user to charge. Sanglelengh (rm) 02,000,250

«Continuous working time more than 20 hours Gaurianleghian) Wan

4 Reaktme clock settings and csplay, convenient data anid nTona

recording and storage Ideaton accuracy 0001

+ With automatic dormancy, automatic shutdown and power puraugr roy sous

‘saving function. Varaity oe

‘+ Relale contol motor to go dead cru and software ae =

design Power actress any

«+ Measurement infomation display, menu promptinfomation ae ae

false information and switch machine and other tips that asian oe

information y

ze ‘tn xm nm

‘+ Optional diferent sensor, measuring platform, mini

vt mee Weight of Host 9.3kg

printer, extension rod and other accessories.

DANA-S520

Portable Surface Roughness Tester

‘Standard Configuration

Host 4) Aust sppot

‘Sanda Sever 1 opecing rau 4

(alban 1 wanantyews

rt 5 corteasof peut 4

Cae 1) tunantcase 4

cna 1 ussetarigeate 4

Tush po 1

@ Introduction

Portable surface roughness tester DANA-5520 allows surface roughness measurement both on metal and non-metal workpie-

ces, Itcan be used on variety of machining parts and operates on various surfaces, not only flat but also outer cone, outer cylinder,

curved, pinholes, grooves, recesses grooves and axle et. It's suitable for machining and manufacturing, quality conta, inspection

departments, especialy for measurement on large and heavy workpiece, assembly line on site, TheDANA-S520is a non destructive

testing instrument, damage won't caused to testing piece.

Features

Mechatronics and ergonomics design, small size, ight

weight, easy to operation

‘The stylus crive unit can be stored within the main unit for

‘standard measurement, or separated from the display unit

by using the supplied cable which allows more flexible me-

‘surement in any orientation. The diver can be separated

‘and reattached in one simple step.

DSP chip control and data processing, high speed, ow

power consumption

22 Parameters: Ra Rz, Ra, Rt, Rp Ry, R&z, R2y, Rs, Rsk

Re(JIS), Rsm, Riu, Rr, Ry(ulS), Rmax Re, Rk, Rpk,

Fk, Met, M2

Measurement range up to 160um (can be optional to 320

bm)

35 inches color graphic TFT touch sereen, wide viewing

angle, excellent readabilty and an intuit rich display, it

includes a backlight to improve visibility in dark,

Environments.

‘Can be operated using buttons or touch screen.

It provide Bluetooth Capability, support wireless

‘connection with mobile and mini printer.

Builtin lithium-ion rechargeable battery and contol circu,

high capacity, no memory effect, it works over 50 hours

‘while fully charged, and there is remaining charge indicat-

or, charging hint.

Large capacity data storage, 100 item of raw data and cu-

‘ves can be stored.

Real-time clock setting and display for easy dala recording

‘and storage,

Reliable crcut and software design to preventing the mot

cor stuck

‘All parameters or any ofthe parameters which set by users

‘can be printed

(Optional accessories: Bluetooth capabilty, curved sensor,

pinholes sensors, measurement, stand, extension rod,

printer,

Portable Surface Roughness Tester complies with interna-

tional standards ISO, DIN, ANSI, JIS,

DANARS#

DANAE

@ Technical Specification

Mod Ee

Neauuenent Range T2808 ea) 3205 60um)

“The Xai (Transverse) 750

024m 25m

Resolaon The Zax (vera) eed

‘20080.

10

paaneter apa, ROR AAS A oI

Neasurementitem Standard ISOANSLONIS

Graphic Boul area cave Roughness ple Pray oe

Fite ROPC-RC Gown OP

“The sampling eat aaeam

‘Assessment ngth a) Loon net6

Measuring method shies

styus te Damon $0 ene ale Sun

Force aon

_— Shi part a ay i af crate: ren

025, VO 36mm

108, V0 Sonve

Traversing sped —

Retin _ Veins

‘ecacy Lose 0%

Repeattity Loss

Power spply itn Lis ion btn Chr DESVSE0GnA

Cut dimension ain 525 Bren ae 347 tien

‘Weight (main unt) ‘nd

‘workng Envronment Tenperte-200 = 40 iy «00% RA

Store ae Transportation Teperte:-400 = 60€ iy: «60% RH

© Measuring Range

DANARS#

Optional configuration of roughness meter

a

k DANAGD -Rontange

rmeasuig mechanism

DANAI00 standard sensor

meme an sa ner ute of erie, dp 80 eam >i >

Misimam 44 suport fy a 280 Seen ee aha

FMP Need oupingtohiy c0s20 fo omen Og 05-29

Min thknesofsample coupling tahy Erm fom ‘9 100m om

in depth oflayerthicknessfrsuroce 3080 sa0m 20200 a0 nm

8 Size of tip indentation

Vessco eit dar Oka arm ae 100m oom

Depot néertaon hm 28m ‘am sm 20m

irinwsezoay stan danse Okan assem sn 00m ‘sm

Dephotnéertaon Wir om um am tm

urinesesooy iin dar 03m asm ase : ase

Depth oft Ayn ‘ym Tum = 10m

‘DANA-H130

Portable Hardness Tester

‘Standard Configuration

Dipeeetense 1 Mm ‘

‘myc *

6 Introduction

DDANAI30Paatle Lee harcnes ser, host ang pier regs desig, convent for users opt test ests, especiay

‘uli ar hrdness testing ots, igh est perlomance

Theinsturent aon sveaminedergonorc stu design equpped wih tarda bracket alge color sreen 320240

pty, ich convene er eperaton and readin,

© Features

| Lage sxe0n 240320 TF pay, showing ncn

ans parameters.

“estat ay arg, een upside down,

Support Yorgd see (Stal? materi, when usng the

| DIDG impect eves test “orga” sample, can read HB

salu set whoa he nae for mana checking le

“+ Wide measuing age. ean measure te harness fa

metalic mtorals. Orel pay of hrc scales HR,

HRC, HRA, HV, HB, HS, HL and tee Qe of eng

lues nme.

“Seven impact doves ae svi for speci applesion,

‘Aulomateay erty he ype of pact eves

{+ Large capac merry cou sir 600 groups (Raabe

to average trs32~1)lomaton cing sees.

‘sued alu, mean vale, testng data, pact recon,

‘pact mee mate! and harass coal to

| Upper and owe nt ean be preset twist som

‘aly when the est value exceeding the int

“Baton nomatoninsaes th rst capaty fhe tary

ans he chge sas

Crigna! mooted igh speed thermal intr suppect the

‘eed printing Kirstin Ican eave dia permanent

rechargeable try as te power source, Charge cre

Uitte sige the instant. Cantruous wong

period ane estan 50 hers (EL of an no pining)

‘to power ao seve energy

Industiazse housing osgn trey, comet potatia,

igh relay stale er hrs operating envtenmen,

rt, shock and eecomagnetererence,

Excl ates serves system or high pay prot

cts-two years quant and allie mantanance

Easy to buy ad confortable tse.

DANARE:-

8 Main Application

i cavity of mots

. Boatings and ctor pats

Testing suse smal hotow space

‘he nt maciet an permanent assonbles pars. ete erteaton mntewarhause ct mee maar

Faure anaiysis of pressure vessel, seam generator and apd tein in ge range ard ut-measurng areas fr

cher eaupment lage sede work pee,

rae

Tene eh Seoatatn’

Wage

woo oe

DANARS

DANA-H140

Pen Type Leeb Hardness Tester

‘Standard Configuration

amit 4 Manat 1

‘Stand et Bock 4 Prete Cettete 1

leaning brs) 4) Waray Cre 1

‘Sia supporting 4 Communication cable

try Charger 1 Package ese 1

8 Introduction

‘The portable hardness testing instruments, which integrated the smartest NDT technology and the smallest dimension. The

hardness tester is @ revolutionary product that can test most of the metal objects. With the pen type design and innovative D/OL

Impacting probes, it provide convenient and reliable experience of testing,

With ts smal size, impressive design, competitive pice, convenient using experience, It can wildly be used in various

situations

6 Features

+ Inteligent operation

‘© Easy operation wth several buttons, magnitude and Rockwell values displayed.

‘© Industrial bright OLED display.

© Good performance of OLED display, even i

© Accurate measurement value.

‘+ High accuracy shown value eror + 0.3% (HLD=800), showing the value of repeatabilty of 0.5%,

Supports a variety of hardness standards,

@ HL. HV. HRA. HRC. HRB. HB. HV. HS.

‘Technical Specification

the sunshine,

Messutog range HLD(70 960) RC(17 9.69.5), HE(1-689) 60-1082) HS (06 02S.) HR (135-1017)

Impex rections Up. down, Poraorta staré up, saning down

Messing sorts ‘Sto anos, yt t, saies tal pay atiron, nocla cast on

cast auiinun lo. copper ills as) a aly of npr and tn capper ben) xed oo

‘Stare ASTINASSE. ONEOIS.1. GAT73N4-1008

eco) Huoy05% coH0)

Dspiay 12864 LED day

Raposo ve Huo: 08% econo

Power seo Recharges ium btry

mensone 148" 40° 30ne fost).

Woe 03g (ox.

Conincuswanngpetod aout hows

DANARS:

DANA-H120

Portable Hardness Tester

‘standard Configuration

6 Features

© LOD display of 128x64 matric is used.

Converts to all common hardness scales(H\.HB,HRC,HR-

* BHRAHS)

‘ Hermeticaly sealed metal shell, solid and curable, has:

cellent resistance to vibration, shock and electomagnetic,

interference ably.

‘With USB2.0 interface, multiple communication mades are

adopted to meet customized requirements of various users.

‘Equipped with a data processing software, through the

USB interface, can exchange data with computer printing

and parameter setting.

* Equipped with 7 types of impact devices which need not

tobe recalbrated when changing them, the system can

entity the type of impact device automaticaly

‘© Max 600 groups (impact times:32~1) of data can be

stored at internal non volatile data storage,

‘Upper and lower limit of hardness can be preset; When

the tested value exceeds the limits, alarm will send out

‘automaticaly to make convenient for the requirements of

batch measurements,

* Back light display has been used to make convenient for

the use in poor light.

* Test values software calibration function

© Material of cast stee!is added; HB values can be read

‘ut directly when DIDC impact device is used to measure

“cast steel work pee

© Failure analysis of pressure vessel, steam turbo ge

set and other equipment.

tor

8 Main Application

‘© The assembled machinery and permanenty installed parts

‘© Die cavity of molds.

Heavy work piece.

Bearings and other pats

(Cases which require the test result wth normalized original

recording.

‘Material identifation ofthe metal material warehouse.

(Quick tests of large range and mulipoint measuring posi.

tions for heavy Workpiece.

8 Technical Specification

Model Boone

(TORO FLD (196518, (13-1004RB,

Messuring range (TS 5HRC, (5985)HRA, 0975}

(onrtonis

Impact directions amor UN

Tensile stenght S740 2562 Nr

Harness scales HL HORE HR HRA HVS

Display 12064 din atic LCO

Memory OOHRS? every 4p)

Inerace port sao

Dimensions 1250" 2

Weight oaKe

Continuous working period 200 haus ith backabt)

‘Messuring materials tes! ana stee ly ol ston, sti,

79/28, roar cation, est akin ally cope lore

{eas} an lo of expper ann, copper (wor) rgd oe

Webster Hardness Tester

‘W-20/W-208/W-20B/W-B92/W-B75,

‘Standard Configuration

Man pat 1 | Sma sooner 1

Standard arses beck 1 Marval 1

Spare needs 1 | Product coieats 1

Clbration wrench + | Canyin case 1

6 Introduction

—— —

° — =

fa

sis

Webster Hardness Tester is an instrument that can promptly on-site test the hardness of aluminum alloy material, including

section bartubes plates aluminum parts and hardness of other soft mental. tis such an instrument convenient in usage, wth a sim-

ple ‘clamp" and direct result-reading, that it alvays receives good feedback of high efficiency and strong stabil

Especially suitable in production site sales site or construction site for quicky testing on bulk products with non-destructive

‘quality inspection piece by piece Besides aluminum alloy material, itis also suitable to test red copper, brass, soft copper ete

®

Main Application

‘© Indenter:Re-engineerred with advanced material and new

production technology manufactured, higher hardness,

long service life, good interchangeabilly.

'» Incicator Hand: High strength indicator hand, less ikaly to

be bent by long-term using or mis-operaton,

‘» Dial Glass: High strength, high toughness, uneasy to be

broken or scratched,

‘* Handle: Forged aluminum alloy handle with fine anodized

finishing, high esistance to abrasion and stain,

‘* Hardness Blocks: Tested by standard Rockwell hardness

tester, attached with test report

‘© Good Stabiity: Stable full scale point, stable calibration

point, indieator never glides

‘» Easy Conversion; Results can be converted to Vickers,

Rockwell and Briel

© Using Scope

‘+ W20: General Mode, suitable for common aluminum

materials

‘W208: Suitable for aluminum materials with thickness <

‘mm,

«+ W208: Suitable for aluminum tube with ner cia 26mm.

‘+ W-892: Sutable for sof stainless see, colaolled stip,

+ W#B75; Sutabe for brass tube, brass stip,

© Technical Specification

oz

Tesingarge (equivalent to 20 ~ 110 HRE,.SB-13THRV),

) atv (5= 17H)

Repeat st (5-17 a)

-epeton AmhunAey

Sut spine Set ‘Tks 046 i >

‘meson St 22a tent WH)

cng weight 20K

DANA

DANAS#:

DANA SERIES

Barcol Hardness Tester

‘Standard Configuration

Tear

‘Stacard harsss block

‘Spare inderters

Cateatn wench

Caryn ese

@ Introduction

‘Barcol Hardness Tester Impressor is an indentation hardness tester. The operation is easy, quick and almost non-cestructve.

The testis as simple as one press. Its @ convenient tool for testing the hardness of aluminum, aluminum alloys and fiber reinforced

plastics, which conforms to American Standard ASTM B648.

Barcol Hardness Testers mainly used to test the hardness of aluminum and aluminum alloys, to test the hardness of other soft

‘metals and glass fore reinforced plastic producs.Itcan also be used to test the hardness of extra large, extra wide, extra thick work

pieces, and to test the hardness of boards, bet materials, section materials, forgings and castings et.

Batool Hardness Tester is commonly used as supplement of Webster Hardness Testers. It is usually used when test the

hardness of pure aluminum, lw hard aluminum alloys and extra large, extra thick materials.

6 Features

‘Single hand operation, operating experience required can

test any operating experience which is reachable in any site

Wide vali testing range equivalent to Brnell hardness 25-

‘1SOHBW, used to test the hardness of allkinds of alumin-

Lum from very soft aluminum to very hard alloys.

BarcolImpressor has a wide range of application. Mode!

{984-1 can be used to tet aluminum and aluminum alloys,

‘copper andl copper alloys, glass fiber reinforced plastics,

Tigi plastics, etc. The improved type can be used to test

lead, tn and other soft metal, and flexible plastics, rubber,

fel, eather, and so on,

\with 100 scales, our Barcolimpressoris of higher sensi.

ty than commonly used Webster hardness testers in lumi

‘rum alloy industry.

By use ofthe conversion table, the test results can be easily

converted to HB, HR, HV and HW.

* Itcould finish the testing work on one side ofthe workpiece

‘without rouble of moving or supporting the workpiece. Due

to this feature, the hardness tester can be used to test ext-

rallarge, extra thick workpleces and assembly parts

® Technical Specification

Model E

Teaing Range 10046 (25-1804)

Inder 25 pan adore, heed face ante OT

Ene 1-248

‘niente arose ange A5-SSHBa 2a

Horaoss range SHB tH

“eoccppun tree _Natessrange45-S6HBa225H8a

Revesby Ener — res range 8-B8H 1 2HBa

esoion 0548 Weaht 059

DARA

HR-150A

Rockwell Hardness Tester

© Introduction

Determination of Rockwell hardness of ferrous, non-ferrous and non-metallic materials; Wide range of applications, suitable

for Rockwell hardness measurement of heat-treated materials such as quenching, quenching and tempering, and cemented

carbide,

6 Features

Easy to use, anc the test force can be applied and unloaded by a handle

Dial direct reading, HRA, HRB, HRC scale

(ther scales of Rockwell are optional

High precision of indication, easy installation and low fallre rate

8 Technical specifi

Measuring ange 2 SeHRA20 BHAA, 20-00HRB 20-7

ETOH DARA TE BBHRAC 1

Reslution 2ASHRG: 84S SOHRE 1S

ETOHRC: 18

estore 5864 S007 147IN (60 100 ¥5Okg)

Maximum hight of specimen ‘en

Distance between the center ofthe ram andthe machine wall oo

Hardness rezoition| fen

Experimental fore loading Maral

Value display Di

size 405238 60mm

Weight ke

DANAZS#

HRS-150

Rockwell Hardness Tester

‘Standard Configuration

ion Roche Inder

Haris tock (@ HRC high and low HR 1 bc)

Ineo ana

(91 875m tal net

Darel pase

[San ieee

Nae Unt

Wage (A: 8)

‘Tot ble (age, smal, shaped)

© Introduction

Its suitable for determining the Rockwell hardness of ferrous metals, non-ferrous meals and non-metalic materials. tis widely

Used in quenched steel, quenched and tempered steel, annealed steel, chiled castings, malleable castings, hard alloy steel,

‘luminum alloy, copper, bearing steel

@ Features

High-precision digital display

"Meru structure, hardness value automatic calculation and display

‘Automatic conversion of various hardness values,

‘The shell adopts the perfect casting process and special hole surface processing

‘The one-cut plane processing technology ensures the fatness of each plane:

The screw rod also uses a fine grinding process to ensure thal the machine rises and falls smoothly and without eccentricity

‘This machine ensures higher precsion and more stably forthe whole machine for special processing

© Technical specification

Rexdngacacy on epoxy 205

eit ce 7) Twaltetforce ea) OHNO ND

Teale FR, HRC. HRD. HE RF. HR. HR

Terkange rates evteneo Hmcio foo "netsonis "wwatsons "irene

vane ee ec sand carn enna ova

coneienicle pce ik kn re dig La sn i ly

tout Bikini ARESEinethon Mixmag feces ate

Indnterouter wailditance 10mm Powers) Aca te

Size) 500240 720m Went a9

DARAESA

HRSS-150 Touch Screen

Full Scale Rockwell Hardness Tester

‘Standard Configuration

Diamond indenter 1

Tel HockHRE. HRC gh. HC HRIEN. HRSGN. HRSG) 6

@ Introduction

Itis used to determine the Rockwell hardness of ferrous metals, non-fertous metals and non-metalc materials Its widely used

in quenched steel, quenched and tempered, annealed steel, chiled castings, malleable castings, hard alloy steel, aluminum alloy,

‘copper, bearing steel, Hard plastic, hard rubber, aluminum, tin, copper, mild steel, synthetic resin and friction material hardness

measurement

6 Features

‘This machine is a high-precision large-screen display ful scale Rockwell harcness tester withthe hardness test ofall Rockwell,

scales such as Rockwell, surface Rockwell, and plastic Rockwell

‘This machine uses sensors. Closect-oop control technology, the indenter automatically drops, the initial est force is automaticaly

applied, the main test force is automatcally applied, the hardness value is automatically measured, the harcness value is

‘automatically displayed, the measurement error can be automaticaly corrected, the hardness is automatically converted, and the

buit.n printer can print the test results. Connect with the computer, can send the test data directly

«©The screw rod also adopts a fine grinding process to ensure the smooth ting and no eccentricity of the machine,

© Technical specification

Conversion Seales Reel Brnatend Vise Exscutive standard Aran! owT22 won?

welTime te Hardness reading Co diay

Inti test force Sg 20.4NVDiF (GEN) Date ouput Buin pcr 6 RS 252 taco

Totaltestorce {Shg47-N) 0kg@BK2N) SHG 441.3N) COKGISEBAN) TOOKHOTN) TSOGHETIN)

Ra 20.98 HRB: 1-100. HRC: 20-70_HRO-A0-77-WRE:TO-100 HAF; @D-00 HRG: 90.98 WEE 8-100

HR A0-100 “HAL SDS HRM SO15 HR 50-15

"HRN 70-94 HRION-42-06 RAEN 2077 -HRIST-OTSS HRGOT-2082 HRASTIOTZ

‘Maximum height of specimen 1850 Indenteruterwallditance 0mm

Slr) 202405 720m Powe supply oz

Weight ah

ardnesstestrange

DANAES:

HB-3000B

Brinell Hardness Tester

‘Standard Configuration

© Introduction

Ithas a wide range of applications, and is suitable forthe precision measurement of parallel plane, an the surface measure-

iment stable an reliable Determination of Brinellharcness of ferrous metals, nonferrous metals and bearing alloys

6 Features

Lever loading. easy to operate, stable, accurate, reliable, durable

Electronic reversing switch

High precision reading microscope measurement system

tis widely used in quality contro in production ste, and has strong adaptability to work environment

Measuring the Brinell hardness of unquenched steels, cast iron, non-ferrous metals and soft bearing-alloys etc

High testing precision, extensive testing range, automatic load system

High accuracy, wide measuring range

‘Automatic fore loading

8 Technical Specification

Messuing ange $0500

= 600 (187 eh, 2452 EDK, TEEN TG,

807 (100g, 204200 2000

atimum alowable eight of specimen 230m

Distance between the center ofthe am andthe machine wall _——_Y2nen|

Pome Supply ‘ACSEOWIZZOV EOF

see {8000 060mm

Weight 10K

DANAHSA

HB-3000M Touch

Screen Brinell Hardness Tester

‘Standard Configuration,

Man Unt

‘Standard harass lok

25.50 Orme nwa Ls

op eae pe ona

3

1

1

8 Introduction

Itis suitable for hardness measurement of cast ron, steel, nonferrous metals, soft alloy and other materials. It's also suitable

for hardness measurement of hard plastics, bakelite and other non-metallic materials,

6 Features

‘+The hardness tester removes the loading weight, adopts the electronic automatic loading system, has ten levels of test force,

\wider test range and higher precision

‘©The shells made of one-step molding casting by special sand turing process, with stable structure and no deformation

'» The closed1oop sensor loading microcomputer conrol system has high precision and stable performance

‘* This machine adopts electronic automatic loading and unloading, microcomputer control, and can automaticaly compensate the

test force, so as to ensure the accuracy ofthe test

'* The noise produced in the process of testing is very small, which is suitable for various laboratories

‘* This machine can cooperate with Brinell image measurement software, grealy improve work efficiency

8 Technical specification

eee ewiasee Wewioroen HBV" s00, MTOR

Conversion scale HRC, HRA, HRIGN, HROON, HRASN, HY

a 28612. 10h 607). 25 (120, 187 Be (160) 20h AEN)

20 (4503) TONG (73EON), 000g (07M), 00 (1471) 200K 254208)

Wardness reading Feary mioecore opnal wih porale ars rape meres)

Measuring ange co-680)8 Dimension 580210 750mm

Mininumunitofmessuement ——_0.0inm Weight 1209

“otal magaication 2x DwelTime sas

Macalloableheightofspecimen 200m Powersupply AGRE +, SOE He

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Formato FlujogramaDocument12 pagesFormato Flujogramacesardario90No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Caracterización Del ProcesoDocument3 pagesCaracterización Del Procesocesardario90No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Ejemplo de matriz legal de una empresa de serviciosDocument21 pagesEjemplo de matriz legal de una empresa de servicioscesardario90No ratings yet

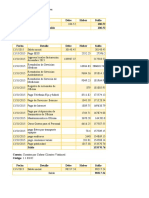

- MAYORIZACIONDocument13 pagesMAYORIZACIONcesardario90No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Beneficios de Tener Una Tienda OnlineDocument3 pagesBeneficios de Tener Una Tienda Onlinecesardario90No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Formulario TTDocument83 pagesFormulario TTcesardario90No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Notas A Los Estados FinancierosDocument2 pagesNotas A Los Estados Financieroscesardario90No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Estado Cambios PatrimonioDocument1 pageEstado Cambios Patrimoniocesardario90No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Estado de CostosDocument3 pagesEstado de Costoscesardario90No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Estado Flujo EfectivoDocument2 pagesEstado Flujo Efectivocesardario90No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- DANA-T230 Through Coating Ultrasonic Thickness GaugeDocument4 pagesDANA-T230 Through Coating Ultrasonic Thickness Gaugecesardario90No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Libro DiarioDocument23 pagesLibro Diariocesardario90No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Norma GM EspañolDocument9 pagesNorma GM Españolcesardario90100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- AWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFDocument28 pagesAWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFcesardario90100% (1)

- Inconel Alloy 718Document28 pagesInconel Alloy 718hosseinidokht86No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GMW14057 Aug 2011Document12 pagesGMW14057 Aug 2011cesardario90No ratings yet

- Snt-Tc-1a 2011Document42 pagesSnt-Tc-1a 2011cesardario90No ratings yet

- Tintas PenetrantesDocument6 pagesTintas Penetrantescesardario90No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)