Professional Documents

Culture Documents

318 - 10,480 Yds - FK Textile

318 - 10,480 Yds - FK Textile

Uploaded by

Soyeb Hassan0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

318_10,480 Yds- FK Textile

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pages318 - 10,480 Yds - FK Textile

318 - 10,480 Yds - FK Textile

Uploaded by

Soyeb HassanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

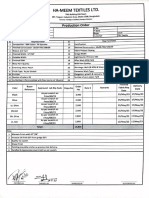

HA-MEEM TEXTILES LTD.

‘TML Building (5th floor)

387, Tejgaon Industrial Area, Ohaka-1208, Bangladesh

Factory: Faridpur,Telihati Sreepur, Gazipur

Production Order

[BPO No Loc-22-01-318 PIN

[BPO Date [3/20/2022 PrDate

[Millon Buyer Local

[Local/i0 [Customer__|FK Textiles

Req Parameter Req Parameter

1. [Composition: 98% Cotton 2% Spandex 13 _ Certification:

2_ [Finished Construction: 10x10+70D/72x42 14 [Declared Constrction: 10x10+70D/72x42

3 Weave: 3/1 $ Twil 15 _ [Fabric Process: Reactive

4 [Finished width: 53/54" 16 _[Greige width:

'S_[Cuttable Width: 52” 17_|Ught Source: Primary: D65

6 |Finished GSM: 28125 18 _[After Wash GSM: N/A

7_|Warp Yarn Quality: 19 [Weft Yarn Quality:

8 _[Emarizing: Lt. Peach (As Swatch) 20_|Shrinkage: Warp: 4% Weft: 8%

9) [Finish Type: AS Swatch 21 [Garments Wash Type:

10 [End Use: 22_|Elongation: N/A

11 [Number of colors: 03 23_ [Number of yarn colors:

12 [ins Method: 4 Point method with Pass barrier of 18 point 24 [Others

Finished

Approved Lab Value aor, | Steige Fabric] 1 E | Delivery

Dip Code i Req Date Date

Date

2150609, OT

peek 86,460 3/27/2022 | 1/27/2022

2180608, OT

29.12.2022

"B" 2150622, DT

14.12.2023

140,580 3/27/2022 | 1/27/2022

118,800 3/27/2022 | 1/27/2022

345,840

1. |Clean Fabric surface have to be maintained by avoiding Neps, Foreign Yarn, Knots, Thick & Thin Yarns & Unwanted Slubs.

2_ [Fabric Width have to be 52" Cuttable so maintain accordingly; Wastage Allowance 8%

3_ [Fabric GSM have to be maintained in before wash condition,

6 [Any fabric roll below 40¥ds won't be accepted during delivery.

7_ inspection report, Dye-Lot & Shade blanket has to be prepared before 1 day of delivery.

&

9

[Color Fastness should be checked

Fabric surface should be glossy

[Handfeel should be soft

[Quality = As Swatch

of wv

on

PREPARED BY CHECKED BY APPROVED BY AUTHORIZED BY

Costing - HTL

our? (3:18:53 PM

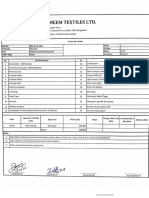

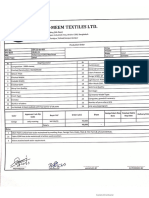

Style No: [construction : _[10x40+700/72x42

[cmts/auyer _ [Fx Textile fanty (ves) 35000

Prod Fin dt ‘Avg delay party/Bank

Price Validity [Conversion Rate 86

ISLNo Particular Basic Information Bor

Finished E1/PPI 2 a

2 |width(Greige/Finishea) 8 64

'3__|[GsM/oz/Constant(23.50-26.50) 281 8 26:50

Standard

4 Machine wise (OH/chem) on cant cia

Singing/ Desa (02/01) 002, 0.01 0.03)

[Scouring/Bleaching ((04/.03) (0.04) 0.03) 0.07

[Mercerizing (.03/.05) 0.03) 0.05 0.08)

IThermasol 03/07) 003) 0.07, 0.10)

(crs. 1.03/07) ° 0 0.00)

[pad Steam ((02/.03) 002 0.01 0.03)

stenter ((03/.08) 0.03) 0.04) 0.07

\Sanforizer (03/02) 008 0.02, 0.03)

[Emerizing/ Peach (02/01) (0.02) 0.01, 0.03

[Brushing {.02/:01) 0 0 0.00)

inspection (03/=.) 008 o 0.08)

lothers 0.00

[Dyeing Cost (Std) O21 024) 0.45)

[Dyeing cost for this style/Vds $ o2t 0.24) 0.46

[Over Price/vds $ 0.00)

[Total Cost/Vds $ 0.46) 39

Selling Price/Yds $ oat 35

5_|Warp count Ratio GSM

io] 100% 169

alow 0

a] om 0

% 0

6 ____|Weft Count

io] 100% in

a] o% 0

ao 0

fesvel nt) "AGM (Accounts), ‘GM/Sr GM (M4) wo

ee"

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 139 - 15,000 Yds-Headwind-Rev-04Document2 pages139 - 15,000 Yds-Headwind-Rev-04Soyeb HassanNo ratings yet

- 301 - 1,50,000 Yds-Nice Denim-R1Document1 page301 - 1,50,000 Yds-Nice Denim-R1Soyeb HassanNo ratings yet

- 325 - 55,712 Yds-Aman GraphicsDocument1 page325 - 55,712 Yds-Aman GraphicsSoyeb HassanNo ratings yet

- 335 - 2300 Yds-Era FashionDocument2 pages335 - 2300 Yds-Era FashionSoyeb HassanNo ratings yet

- 329 - 1,07,426 Yds-UnifillDocument2 pages329 - 1,07,426 Yds-UnifillSoyeb HassanNo ratings yet

- 337 - 639 Yds-Debonair PadingDocument1 page337 - 639 Yds-Debonair PadingSoyeb HassanNo ratings yet

- 334 - 13,000 Yds-FR TextileDocument2 pages334 - 13,000 Yds-FR TextileSoyeb HassanNo ratings yet

- 139 - 15,000 Yds-Headwind-Rev-01Document1 page139 - 15,000 Yds-Headwind-Rev-01Soyeb HassanNo ratings yet

- 338 - 12,125 Yds-FK TextileDocument1 page338 - 12,125 Yds-FK TextileSoyeb HassanNo ratings yet

- 0081 - 13,800 Yds-F.RDocument1 page0081 - 13,800 Yds-F.RSoyeb HassanNo ratings yet

- 340 - 11,425 Yds-Anika FabricDocument1 page340 - 11,425 Yds-Anika FabricSoyeb HassanNo ratings yet

- 004 4,000 Yds-ParamountDocument2 pages004 4,000 Yds-ParamountSoyeb HassanNo ratings yet

- 146 - 28,500 Yds-FRDocument1 page146 - 28,500 Yds-FRSoyeb HassanNo ratings yet

- Bpo 447 PDFDocument1 pageBpo 447 PDFSoyeb HassanNo ratings yet

- 309 - 16,385 Yds-FK TextileDocument1 page309 - 16,385 Yds-FK TextileSoyeb HassanNo ratings yet

- 144 - 14,000 Yds-F.R TexDocument1 page144 - 14,000 Yds-F.R TexSoyeb HassanNo ratings yet

- TYDFL Marketing ProfileDocument1 pageTYDFL Marketing ProfileSoyeb HassanNo ratings yet

- Offer APRNO-22-05027 1Document1 pageOffer APRNO-22-05027 1Soyeb HassanNo ratings yet

- 006 - 1,26,000 Yds-SanjanaDocument2 pages006 - 1,26,000 Yds-SanjanaSoyeb HassanNo ratings yet

- BCI Membership FormDocument13 pagesBCI Membership FormSoyeb Hassan100% (1)

- Monthly Delivery PlanDocument1 pageMonthly Delivery PlanSoyeb HassanNo ratings yet

- 007 - 46,000 Yds-Sanzana LocalDocument2 pages007 - 46,000 Yds-Sanzana LocalSoyeb HassanNo ratings yet

- GSM Calculation For Woven FabricDocument3 pagesGSM Calculation For Woven FabricSoyeb HassanNo ratings yet

- 21SS Fabric Lead Time Chart-HoorainDocument4 pages21SS Fabric Lead Time Chart-HoorainSoyeb HassanNo ratings yet

- Calculate Crimp Percentage of Woven FabricDocument2 pagesCalculate Crimp Percentage of Woven FabricSoyeb HassanNo ratings yet

- Basf Sharontan 101216215349 Phpapp01Document29 pagesBasf Sharontan 101216215349 Phpapp01Soyeb HassanNo ratings yet