Professional Documents

Culture Documents

Tubo TMM

Tubo TMM

Uploaded by

joey catotoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tubo TMM

Tubo TMM

Uploaded by

joey catotoCopyright:

Available Formats

Plan

Training

Session

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Name: John Lucas Date: ______________

Sample Data Gathering Instrument for Trainee’s

Characteristics

Please answer the following instrument according to the

characteristics described below. Encircle the letter of your choice that best

describes you as a learner. Blank spaces are provided for some data that

need your response.

Characteristics of learners

Language, Average grade in: Average grade in:

literacy and English Math

numeracy (LL&N)

a. 95 and above a. 95 and above

b. 90 to 94 b. 90 to 94

c. 85 to 89 c. 85 to 89

d. 80 to 84 d. 80 to 84

a. 75 to 79 e. 75 to 79

Cultural and Ethnicity/culture:

language a. Ifugao

background

b. Igorot

c. Ibanag

d. Gaddang

e. Muslim

f. Ibaloy

g. Others (please specify) Illonggo

Education & Highest Educational Attainment:

general a. High School Level

knowledge

b. High School Graduate

c. College Level

d. College Graduate

e. with units in Master’s degree

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Characteristics of learners

f. Masteral Graduate

g. With units in Doctoral Level

h. Doctoral Graduate

Sex a. Male

b. Female

Age Your age: _____

Physical ability 1. Disabilities(if any)_____________________

2. Existing Health Conditions (Existing illness

if any)

a. None

b. Asthma

c. Heart disease

d. Anemia

e. Hypertension

f. Diabetes

g. Others(please specify) ___________________

Number of years as a competency trainer

Previous

experience with ______

the topic

Previous List down trainings related to your

learning qualification

experience ___________________________

___________________________

___________________________

National Certificates acquired and NC level

Training Level

completed ___________________________

___________________________

Special courses Other courses related to your qualification

a. Units in education

b. Master’s degree units in education

c. Others(please specify)

_________________________

Learning styles a. Visual - The visual learner takes mental

pictures of information given, so in order

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Characteristics of learners

for this kind of learner to retain

information, oral or written, presentations

of new information must contain diagrams

and drawings, preferably in color. The

visual learner can't concentrate with a lot

of activity around him and will focus better

and learn faster in a quiet study

environment.

b. Kinesthetic - described as the students in

the classroom, who have problems sitting

still and who often bounce their legs while

tapping their fingers on the desks. They are

often referred to as hyperactive students

with concentration issues.

c. Auditory- a learner who has the ability to

remember speeches and lectures in detail

but has a hard time with written text.

Having to read long texts is pointless and

will not be retained by the auditory learner

unless it is read aloud.

d. Activist - Learns by having a go

e. Reflector - Learns most from activities

where they can watch, listen and then

review what has happened.

f. Theorist - Learns most when ideas are

linked to existing theories and concepts.

g. Pragmatist - Learns most from learning

activities that are directly relevant to their

situation.

Other needs a. Financially challenged

b. Working student

c. Solo parent

d. Others(please specify)

___________________________

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

FORM 1.1 SELF-ASSESSMENT CHECK

INSTRUCTIONS: This Self-Check Instrument will give the trainer necessary

data or information which is essential in planning training

sessions. Please check the appropriate box of your answer

to the questions below.

BASIC COMPETENCIES

CAN I…? YES NO

1. Participate in workplace communication ✓

1.1 Obtain and convey workplace information ✓

1.2 Perform duties following workplace instructions ✓

1.3 Complete relevant work-related documents ✓

2. Work in team environment

2.1 Describe team role and scope ✓

2.2 Identify own role and responsibility within team ✓

2.3 Work as a team member ✓

3. Solve/Address general workplace problems

3.1 Identify routine problems ✓

3.2 Look for solutions to routine problems ✓

3.3 Recommend solutions to problems ✓

4. Develop career and life decisions

4.1 Manage one’s emotion ✓

4.2 Develop reflective practice ✓

4.3 Boost self-confidence and develop self-regulation ✓

5. Contribute to workplace innovation

5.1 Identify opportunities to do things better ✓

5.2 Discuss and develop ideas with others ✓

5.3 Integrate ideas for change in the workplace ✓

6. Present relevant information

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

6.1 Gather data/ information ✓

6.2 Assess gathered data/ information ✓

6.3 Record and present information ✓

7. Practice occupational safety and health

7.1 Identify OSH compliance requirements ✓

7.2 Prepare OSH compliance requirements ✓

7.3 Perform tasks in accordance with relevant OSH ✓

policies and procedures

8. Exercise efficient and effective sustainable practices

in the workplace

8.1 Identify the efficiency and effectiveness of ✓

resource utilization

8.2 Determine causes of inefficiency and/or ✓

ineffectiveness of resource utilization

8.3 Convey inefficient and ineffective environmental ✓

practices

9. Practice entrepreneurial skills in the workplace

9.1 Apply entrepreneurial workplace best practices ✓

9.2 Communicate entrepreneurial workplace best ✓

practices

9.3 Implement costeffective operations ✓

COMMON COMPETENCIES

CAN I...? YES NO

1. Validate vehicle specification

1.1 Check body type of the vehicle ✓

1.2 Check vehicle engine type ✓

1.3 Check vehicle specifications ✓

1.4 Complete validation of vehicle specification ✓

2. Move and position vehicle

2.1 Prepare vehicle for operatio ✓

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

2.2 Position vehicle ✓

2.3 Park and stop the vehicle

3. Utilize automotive tools

3.1 Prepare automotive tools ✓

3.2 Use automotive tools ✓

3.3 Maintain automotive tools ✓

4. Perform mensuration and calculation

4.1 Select measuring instruments ✓

4.2 Carry out measurements and calculation ✓

4.3 Maintain measuring instruments ✓

5. Utilize workshop and facilities and equipment

5.1 Perform pre-operation activities ✓

5.2 Use facilities and equipment ✓

5.3 Conduct post-operation activities ✓

6. Prepare servicing parts and consumables

6.1 Identify parts and consumables ✓

6.2 Retrieve and withdraw parts and consumables ✓

6.3 Complete work process ✓

7. Prepare vehicle for servicing and releasing

7.1 Receive vehicle ✓

7.2 Prepare vehicle for servicing ✓

7.3 Prepare vehicle for releasing ✓

CORE COMPETENCIES

CAN I…? YES NO

1. Diagnose and repair drive lines

1.1 Prepare to diagnose and repair drive lines ✓

1.2 Diagnose drive lines ✓

1.3 Repair drive lines ✓

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

1.4 Complete work processes ✓

2. Diagnose and repair clutch system

2.1 Prepare to diagnose and repair clutch system ✓

2.2. Diagnose clutch system ✓

2.3. Repair clutch system ✓

2.4 Complete work processes ✓

3. Diagnose and overhaul manual

3.1 Prepare to diagnose and overhaul manual ✓

transmission/ transaxle

3.2 Diagnose manual transmission/ transaxle ✓

3.3. Disassemble and evaluate manual transmission/ ✓

transaxle and components

3.4 Assemble manual transmission/ transaxle and ✓

components

3.5 Complete work processes ✓

4. Diagnose and overhaul differential

4.1 Prepare to diagnose differential assembly ✓

4.2 Diagnose differential assembly ✓

4.3. Disassemble and evaluate differential assembly ✓

and components

4.4. Assemble differential assembly and components ✓

4.5 Complete work processes ✓

5. Diagnose and repair brake system

5. Prepare to diagnose and repair brake system ✓

5.2 Diagnose brake system ✓

5.3 Repair brake system ✓

5.4 Complete work processes ✓

6. Diagnose and repair steering system

6.1 Prepare to diagnose and repair steering system ✓

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

6.2 Prepare to diagnose and repair steering system ✓

6.3 Repair steering system ✓

6.4 Complete work processes ✓

7. Diagnose and repair suspension system

7.1 Diagnose and repair steering ✓

7.2 Diagnose and repair steering ✓

7.3 Repair suspension system ✓

7.4Complete work processes ✓

Note: In making the Self-Check for your Qualification, all required competencies

should be specified. It is therefore required of a Trainer to be well- versed

of the CBC or TR of the program qualification he is teaching.

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Evidences/Proof of Current Competencies

Form 1.2: Evidence of Current Competencies acquired related to

Job/Occupation

Current Proof/Evidence Means of validating

competencies

BASIC COMPETENCIES

1. Participate in workplace communication

1.1 Obtain and

convey workplace

information

Certificate of training Authenticated

1.2 Perform duties

Certificate of achievement certificate with dry

following

workplace seal.

instructions Written test

1.3 Complete Interview

relevant work-

related documents

2. Work in team environment

2.1 Describe team

role and scope

Authenticated

2.2 Identify own Certificate of training certificate with dry

role and Certificate of achievement seal.

responsibility

within team Written test

2.3 Work as a Interview

team member

3. Solve/Address general workplace problems

3.1 Identify

routine problems

Authenticated

3.2 Look for Certificate of training certificate with dry

solutions to Certificate of achievement seal.

routine problems

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

3.3 Recommend Written test

solutions to

Interview

problems

4. Develop career and life decisions

4.1 Manage one’s

emotion

Authenticated

4.2 Develop Certificate of training certificate with dry

reflective practice Certificate of achievement seal.

4.3 Boost self- Written test

confidence and

develop self- Interview

regulation

5. Contribute to workplace innovation

5.1 Identify

opportunities to

Authenticated

do things better Certificate of training certificate with dry

5.2 Discuss and Certificate of achievement seal.

develop ideas with

others Written test

5.3 Integrate ideas Interview

for change in the

workplace

6. Present relevant information

6.1 Gather

data/ information

Authenticated

6.2 Assess Certificate of training certificate with dry

gathered data/ Certificate of achievement seal.

information

Written test

6.3 Record and

present Interview

information

7. Practice occupational safety and health

7.1 Identify OSH

compliance

Authenticated

requirements Certificate of training certificate with dry

7.2 Prepare OSH

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

compliance Certificate of achievement seal.

requirements

Written test

7.3 Perform tasks

Interview

in accordance

with relevant OSH

policies and

procedures

8. Exercise efficient and effective sustainable practices in the

workplace

8.1 Identify the

efficiency and

effectiveness of

resource Certificate of training Authenticated

utilization Certificate of achievement certificate with dry

8.2 Determine seal.

causes of Written test

inefficiency

and/or Interview

ineffectiveness of

resource

utilization

8.3 Convey

inefficient and

ineffective

environmental

practices

9. Practice entrepreneurial skills in the workplace

9.1 Apply

entrepreneurial

workplace best

practices Certificate of training Authenticated

Certificate of achievement certificate with dry

9.2 Communicate

entrepreneurial seal.

workplace best Written test

practices

Interview

9.3 Implement

cost-effective

operations

COMMON COMPETENCIES

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

1. Validate vehicle specification

1.1 Check body

type of the vehicle

1.2 Check vehicle

engine type

Certificate of training Authenticated

1.3 Check vehicle Certificate of achievement

specifications certificate with dry

seal.

1.4 Complete

validation of Written test

vehicle Interview

specification

2. Move and position vehicle

2.1 Prepare

vehicle for

Authenticated

operation Certificate of training certificate with dry

2.2 Position Certificate of achievement seal.

vehicle

Written test

2.3 Park and stop

the vehicle Interview

3. Utilize automotive tools

3.1 Prepare

automotive tools

Authenticated

3.2 Use Certificate of training certificate with dry

automotive tools Certificate of achievement seal.

3.3 Maintain Written test

automotive tools

Interview

4. Perform mensuration and calculation

4.1 Select

measuring

Authenticated

instruments Certificate of training certificate with dry

4.2 Carry out Certificate of achievement seal.

measurements

and calculation Written test

4.3 Maintain Interview

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

measuring

instruments

5. Utilize workshop and facilities and equipment

5.1 Perform pre-

operation

activities

Certificate of training Authenticated

5.2 Use facilities Certificate of achievement

and equipment certificate with dry

seal.

5.3 Conduct post-

operation Written test

activities Interview

6. Prepare servicing parts and consumables

6.1 Identify parts

and consumables

Authenticated

6.2 Retrieve and Certificate of training certificate with dry

withdraw parts Certificate of achievement seal.

and consumables

Written test

6.3 Complete

work process Interview

7. Prepare vehicle for servicing and releasing

7.1 Receive

vehicle

Authenticated

7.2 Prepare Certificate of training certificate with dry

vehicle for Certificate of achievement seal.

servicing

Written test

7.3 Prepare

vehicle for Interview

releasing

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Identifying Training Gaps

From the accomplished Self-Assessment Check (Form 1.1) and the

evidences of current competencies (Form 1.2), the Trainer will be able to

identify what the training needs of the prospective trainee are.

Form 1.3 Summary of Current Competencies Versus Required

Competencies

Required Units of Current Training

Competency/Learning Competencies Gaps/Requirement

Outcomes based on CBC s

BASIC COMPETENCIES

1. Participate in 1. Participate in

workplace workplace

communication communication

1.1 Obtain and convey 1.1 Obtain and

workplace information convey workplace

information

1.2 Perform duties 1.2 Perform duties

following workplace following workplace

instructions instructions

1.3 Complete relevant 1.3 Complete

work-related documents relevant work-

related documents

2. Work in team 2. Work in team

environment environment

2.1 Describe team role and 2.1 Describe team

scope role and scope

2.2 Identify own role and 2.2 Identify own role

responsibility within team and responsibility

within team

2.3 Work as a team 2.3 Work as a team

member member

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

3. Solve/Address 3. Solve/Address

general workplace general workplace

problems problems

3.1 Identify routine 3.1 Identify routine

problems problems

3.2 Look for solutions to 3.2 Look for

routine problems solutions to routine

problems

3.3 Recommend solutions 3.3 Recommend

to problems solutions to

problems

4. Develop career and 4. Develop career

life decisions and life decisions

4.1 Manage one’s emotion 4.1 Manage one’s

emotion

4.2 Develop reflective 4.2 Develop

practice reflective practice

4.3 Boost self-confidence 4.3 Boost self-

and develop self- confidence and

regulation develop self-

regulation

5. Contribute to 5. Contribute to

workplace innovation workplace

innovation

5.1 Identify opportunities 5.1 Identify

to do things better opportunities to do

things better

5.2 Discuss and develop 5.2 Discuss and

ideas with others develop ideas with

others

5.3 Integrate ideas for 5.3 Integrate ideas

change in the workplace for change in the

workplace

6. Present relevant 6. Present relevant

information information

6.1 Gather data/ 6.1 Gather data/

information information

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

6.2 Assess gathered data/ 6.2 Assess gathered

information data/ information

6.3 Record and present 6.3 Record and

information present information

7. Practice occupational 7. Practice

safety and health occupational safety

and health

7.1 Identify OSH 7.1 Identify OSH

compliance requirements compliance

requirements

7.2 Prepare OSH 7.2 Prepare OSH

compliance requirements compliance

requirements

7.3 Perform tasks in 7.3 Perform tasks in

accordance with relevant accordance with

OSH policies and relevant OSH

procedures policies and

procedures

8. Exercise efficient and 8. Exercise

effective sustainable efficient and

practices in the effective

workplace sustainable

practices in the

workplace

8.1 Identify the efficiency 8.1 Identify the

and effectiveness of efficiency and

resource utilization effectiveness of

resource utilization

8.2 Determine causes of 8.2 Determine

inefficiency and/or causes of

ineffectiveness of resource inefficiency and/or

utilization ineffectiveness of

resource utilization

8.3 Convey inefficient and 8.3 Convey

ineffective environmental inefficient and

practices ineffective

environmental

practices

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

9. Practice 9. Practice

entrepreneurial skills in entrepreneurial

the workplace skills in the

workplace

9.1 Apply entrepreneurial 9.1 Apply

workplace best practices entrepreneurial

workplace best

practices

9.2 Communicate 9.2 Communicate

entrepreneurial workplace entrepreneurial

best practices workplace best

practices

9.3 Implement cost- 9.3 Implement cost-

effective operations effective operations

Required Units of Current Training

Competency/Learning Competencies Gaps/Requirement

Outcomes based on CBC s

COMMON

COMPETENCIES

1. Validate vehicle 1. Validate vehicle

specification specification

1.1 Check body type of the 1.1 Check body type

vehicle of the vehicle

1.2 Check vehicle engine 1.2 Check vehicle

type engine type

1.3 Check vehicle 1.3 Check vehicle

specifications specifications

1.4 Complete validation of 1.4 Complete

vehicle specification validation of vehicle

specification

2. Move and position 2. Move and

vehicle position vehicle

2.1 Prepare vehicle for 2.1 Prepare vehicle

operation for operation

2.2 Position vehicle 2.2 Position vehicle

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

2.3 Park and stop the 2.3 Park and stop

vehicle the vehicle

3. Utilize automotive 3. Utilize

tools automotive tools

3.1 Prepare automotive 3.1 Prepare

tools automotive tools

3.2 Use automotive tools 3.2 Use automotive

tools

3.3 Maintain automotive 3.3 Maintain

tools automotive tools

4. Perform 4. Perform

mensuration and mensuration and

calculation calculation

4.1 Select measuring 4.1 Select measuring

instruments instruments

4.2 Carry out 4.2 Carry out

measurements and measurements and

calculation calculation

4.3 Maintain measuring 4.3 Maintain

instruments measuring

instruments

5. Utilize workshop and 5. Utilize

facilities and equipment workshop and

facilities and

equipment

5.1 Perform pre-operation 5.1 Perform pre-

activities operation activities

5.2 Use facilities and 5.2 Use facilities and

equipment equipment

5.3 Conduct post- 5.3 Conduct post-

operation activities operation activities

6. Prepare servicing 6. Prepare

parts and consumables servicing parts and

consumables

6.1 Identify parts and 6.1 Identify parts

consumables and consumables

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

6.2 Retrieve and withdraw 6.2 Retrieve and

parts and consumables withdraw parts and

consumables

6.3 Complete work 6.3 Complete work

process process

7. Prepare vehicle for 7. Prepare vehicle

servicing and releasing for servicing and

releasing

7.1 Receive vehicle 7.1 Receive vehicle

7.2 Prepare vehicle for 7.2 Prepare vehicle

servicing for servicing

7.3 Prepare vehicle for 7.3 Prepare vehicle

releasing for releasing

Required Units of Current Training

Competency/Learning Competencies Gaps/Requirement

Outcomes based on CBC s

CORE COMPETENCIES

1.Diagnose and repair 1.Diagnose and

drive lines repair drive lines

1.1 Prepare to diagnose 1.1 Prepare to

and repair drive lines diagnose and repair

drive lines

1.2 Diagnose drive lines 1.2 Diagnose drive

lines

1.3 Repair drive lines 1.3 Repair drive

lines

1.4 Complete work 1.4 Complete work

processes processes

2.Diagnose and repair 2.Diagnose and

clutch system repair clutch

system

2.1 Prepare to diagnose 2.1 Prepare to

and repair clutch system diagnose and repair

clutch system

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

2.2. Diagnose clutch 2.2. Diagnose

system clutch system

2.3. Repair clutch system 2.3. Repair

clutch system

2.4 Complete work 2.4 Complete work

processes processes

3.Diagnose and overhaul 3.Diagnose and

manual overhaul manual

3.1 Prepare to diagnose 3.1 Prepare to

and overhaul manual diagnose and

transmission/ transaxle overhaul manual

transmission/

transaxle

3.2 Diagnose manual 3.2 Diagnose

transmission/ transaxle manual

transmission/

transaxle

3.3. Disassemble and 3.3. Disassemble

evaluate manual and evaluate manual

transmission/ transaxle transmission/

and components transaxle and

components

3.4 Assemble manual 3.4 Assemble

transmission/ transaxle manual

and components transmission/

transaxle and

components

3.5 Complete work 3.5 Complete work

processes processes

4.Diagnose and overhaul 4.Diagnose and

differential overhaul

differential

4.1 Prepare to diagnose 4.1 Prepare to

differential assembly diagnose differential

assembly

4.2 Diagnose differential 4.2 Diagnose

assembly differential assembly

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

4.3. Disassemble and 4.3. Disassemble

evaluate differential and evaluate

assembly and components differential assembly

and components

4.4.Assemble differential 4.4Assemble

assembly and components differential assembly

and components

4.5 Complete work 4.5 Complete work

processes processes

5. Diagnose and repair brake system

5.1 Prepare to diagnose 5.1 Prepare to

and repair brake system diagnose and repair

brake system

5.2 Diagnose brake 5.2 Diagnose brake

system system

5.3 Repair brake system 5.3 Repair brake

system

5.4 Complete work 5.4 Complete work

processes processes

6. Diagnose and repair steering system

6.1 Prepare to diagnose 6.1 Prepare to

and repair steering system diagnose and repair

steering system

6.2 Prepare to diagnose 6.2 Prepare to

and repair steering system diagnose and repair

steering system

6.3 Repair steering system 6.3 Repair steering

system

6.4 Repair steering system 6.4 Repair steering

system

7. Diagnose and repair suspension system

7.1 Diagnose and repair 7.1 Diagnose and

steering repair steering

7.2 Diagnose and repair 7.2 Diagnose and

steering repair steering

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

7.3 Repair suspension 7.3 Repair

system suspension system

7.4Complete work 7.4Complete work

processes processes

Using Form No.1.4, convert the Training Gaps into a Training Needs/

Requirements. Refer to the CBC in identifying the Module Title or Unit of

Competency of the training needs identified.

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

Form No. 1.4: Training Needs

Training Needs Module Duration

Title/Module of

(Learning Outcomes)

Instruction

Core Competencies

1.Diagnose and repair

drive lines

1.1 Prepare to diagnose Diagnosing and 24 Hrs

and repair drive lines repairing drive lines

1.2 Diagnose drive lines

1.3 Repair drive lines

1.4 Complete work

processes

2.Diagnose and repair

clutch system Diagnosing and 24 Hrs

2.1 Prepare to diagnose and repairing clutch

repair clutch system system

2.2. Diagnose clutch system

2.3. Repair clutch system

2.4 Complete work

processes

3. Diagnose and overhaul

manual Diagnosing and 24 Hrs

3.1 Prepare to diagnose overhauling manual

and overhaul manual

transmission/ transaxle

3.2 Diagnose manual

transmission/ transaxle

3.3. Disassemble and

evaluate manual

transmission/ transaxle

and

components

3.4 Assemble manual

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

transmission/ transaxle

and components

3.5 Complete work

processes

4. Diagnose and overhaul

differential Diagnose and 24 Hrs

4.1 Prepare to diagnose overhaul differential

differential assembly

4.2 Diagnose differential

assembly

4.3. Disassemble and

evaluate differential

assembly and components

4.4. Assemble differential

assembly and components

4.5 Complete work

processes

5. Diagnose and repair

brake system Diagnosing and 24 Hrs

5.1 Prepare to diagnose and repairing brake

repair brake system system

5.2 Diagnose brake system

5.3 Repair brake system

5.4 Complete work

processes

6. Diagnose and repair steering system

6.1 Prepare to diagnose and

repair steering system Diagnosing and 24 Hrs

6.2 Prepare to diagnose and repairing steering

repair steering system system

6.3 Repair steering system

6.4 Repair steering system

7. Diagnose and repair suspension system

7.1 Diagnose and repair

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

steering Diagnosing and 24 Hrs

repairing

7.2 Diagnose and repair

suspension system

steering

7.3 Repair suspension

system

7.4Complete work

processes

Date Developed: Document No. SCMCSTI-AT

Automotive

August 2023 2

Servicing NCII

Date Revised: Issued by:

August 2023

Diagnose and Page of

Developed by: BTVTED-AT

overhaul

John Tubo

differential Revision # 00

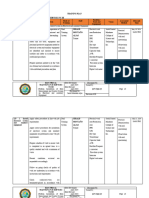

SESSION PLAN

Sector : Automotive and Land Transport Sector

Qualification Title : Automotive Servicing NCII

Unit of Competency : Diagnose and overhaul differential

Module Title : Diagnosing and overhauling differential

Learning Outcomes:

At the completion of the module the trainees/students should be able to:

1. Prepare to diagnose differential assembly

2. Diagnose differential assembly

3. Disassemble and evaluate differential assembly and components

4. Assemble differential assembly and components

5. Complete work processes

A. INTRODUCTION

This unit identifies the competence required to diagnose and overhaul the differential.

B. LEARNING ACTIVITIES

LO 1: Prepare to diagnose differential assembly

Learning Content Methods Presentation Practice Feedback Resources Time

Date Developed: Document No. SCMCSTI AT 2

Automotive Servicing NCII August 2023 Issued by:

Date Revised:

August 2023 Page of

Diagnose and overhaul BTVTED- AT

Developed by:

differential John Tubo

Revision # 00

1. Tools, equipment Self-paced The trainee will

and materials in Instructions read Information

diagnosing and Sheet 4.1-1 on

overhauling Tools, equipment

differential and materials in

diagnosing and

overhauling

differential

Demonstration The trainee will

demonstrate the

proper usage of

tools, utensils and

equipments

diagnosing and

overhauling

differential

2. Discuss Self-paced The trainee will

Occupational Safety Instructions read Information

and Health Standards Sheet 4.1-2 discuss

(OSHS) on Occupational

Safety and Health

Standards (OSHS)

Date Developed: Document No. SCMCSTI AT 2

Automotive Servicing NCII August 2023 Issued by:

Date Revised:

August 2023 Page of

Diagnose and overhaul BTVTED- AT

Developed by:

differential John Tubo

Revision # 00

LO 2:

1.

2.

LO 3:

1.

2.

LO 4:

1.

2.

C. ASSESSMENT PLAN

D. TEACHER’S SELF-REFLECTION OF THE SESSION

Date Developed: Document No. SCMCSTI AT 2

Automotive Servicing NCII August 2023 Issued by:

Date Revised:

August 2023 Page of

Diagnose and overhaul BTVTED- AT

Developed by:

differential John Tubo

Revision # 00

Food and Date Developed: Document No.

Beverage Services July 2010 Issued by:

Date Revised:

NCII February 2012 Page 30 of 61

Developed by:

Provide food and Marisol M.

beverage service Tandoy Revision # 01

to guests

Food and Date Developed: Document No.

Beverage Services July 2010 Issued by:

Date Revised:

NCII February 2012 Page 31 of 61

Developed by:

Provide food and Marisol M.

beverage service Tandoy Revision # 01

to guests

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GenovaDocument3 pagesGenovajoey catotoNo ratings yet

- CantongDocument3 pagesCantongjoey catotoNo ratings yet

- AljasDocument3 pagesAljasjoey catotoNo ratings yet

- GentisonDocument3 pagesGentisonjoey catotoNo ratings yet

- Erika AssessmentDocument4 pagesErika Assessmentjoey catotoNo ratings yet

- SESSION PLAN CatipayDocument8 pagesSESSION PLAN Catipayjoey catotoNo ratings yet

- Balasabas Session PlanDocument9 pagesBalasabas Session Planjoey catotoNo ratings yet

- TuboDocument9 pagesTubojoey catotoNo ratings yet

- Joey TM FinalDocument23 pagesJoey TM Finaljoey catotoNo ratings yet

- Jayden With Session PlanDocument38 pagesJayden With Session Planjoey catotoNo ratings yet