0% found this document useful (0 votes)

52 views4 pagesFire Safety Risk Assessment for Yas Marina

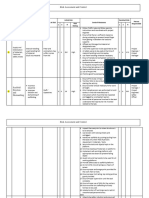

The document provides a task risk assessment for fire alarm system maintenance work at the Yas Marina Circuit in Abu Dhabi. It identifies 9 main hazards: 1) Exposure to Corona, 2) Unauthorized access, 3) Electricity, 4) Slips, trips and falls, 5) Slippery surfaces, 6) Dust, 7) Fire alarm activation, 8) Working on ladders, 9) Noise and vibration. For each hazard, it lists control measures to mitigate the risks and the risk rating is reduced from "High" or "Medium" to "Low" with the control measures in place. Site supervisors and engineers will monitor to ensure the control measures are followed.

Uploaded by

kidangilarjunCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

52 views4 pagesFire Safety Risk Assessment for Yas Marina

The document provides a task risk assessment for fire alarm system maintenance work at the Yas Marina Circuit in Abu Dhabi. It identifies 9 main hazards: 1) Exposure to Corona, 2) Unauthorized access, 3) Electricity, 4) Slips, trips and falls, 5) Slippery surfaces, 6) Dust, 7) Fire alarm activation, 8) Working on ladders, 9) Noise and vibration. For each hazard, it lists control measures to mitigate the risks and the risk rating is reduced from "High" or "Medium" to "Low" with the control measures in place. Site supervisors and engineers will monitor to ensure the control measures are followed.

Uploaded by

kidangilarjunCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd