Professional Documents

Culture Documents

Ds Te6517 en Co

Uploaded by

Vaibhav PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds Te6517 en Co

Uploaded by

Vaibhav PatilCopyright:

Available Formats

Temperature

Process thermocouple

For additional thermowell or basic module

Models TC12-B, TC12-M

WIKA data sheet TE 65.17

for further approvals

see page 2

Applications

■■ Chemical industry

■■ Petrochemical industry

■■ Offshore

■■ Plant and vessel construction

Special features

■■ Sensor ranges from -40 ... +1,200 °C (-40 ... +2,192 °F)

■■ For many variants of temperature transmitters including

field transmitter

■■ For mounting in all standard thermowell designs

■■ Spring-loaded measuring insert (replaceable)

■■ Explosion-protected versions

Description

Thermocouples in this series can be combined with a large

number of thermowell designs. The replaceable, centrically

spring-loaded measuring insert and its extended spring travel Fig. left: Process thermocouple model TC12-B

enable combination with the widest range of connection head Fig. right: Basic module model TC12-M

designs.

A wide variety of possible combinations of sensor,

connection head, insertion length, neck length, connection to

thermowell etc. are available for the thermometers; suitable

for any thermowell dimension and any application.

Operation without thermowell is only recommended in certain

applications.

WIKA data sheet TE 65.17 ∙ 04/2019 Page 1 of 9

Data sheets showing similar products:

Process resistance thermometer; model TR12; see data sheet TE 60.17

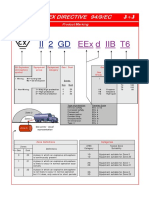

Explosion protection (option)

For application in hazardous areas, corresponding versions The permissible power Pmax as well as the permissible

are available. ambient temperature for the respective category can been

seen on the EC-type examination certificate or else the

Intrinsic safety IECEx certificate or the operating instructions.

These instruments comply with the requirements of the ATEX

directive or IECEx for gas. Built-in transmitters have their own EC-type examination

certificate. The permissible ambient temperature ranges of

Flameproof enclosure the built-in transmitters can be taken from the corresponding

These instruments comply with the requirements of the ATEX transmitter approval.

directive or IECEx for gas.

Approvals (explosion protection, further approvals)

Logo Description Country

EU declaration of conformity European Union

EMC directive 1)

EN 61326 emission (group 1, class B) and interference immunity (industrial application)

■■ RoHS directive

■■ ATEX directive (option)

Hazardous areas

- Ex i Zone 0 gas [II 1G Ex ia IIC T1 ... T6 Ga]

Zone 1 mounting to zone 0 gas [II 1/2G Ex ia IIC T1 ... T6 Ga/Gb]

Zone 1 gas [II 2G Ex ia IIC T1 ... T6 Gb]

- Ex d Zone 1 mounting to zone 0 gas [II 1/2D Ex db IIC T1 ... T6]

Zone 1 gas [II 2G Ex db IIC T1 ... T6]

IECEx (option) International

(in conjunction with ATEX)

Hazardous areas

- Ex i Zone 0 gas [Ex ia IIC T1 ... T6 Ga]

Zone 1 mounting to zone 0 gas [Ex ia IIC T1 ... T6 Ga/Gb]

Zone 1 gas [Ex ia IIC T1 ... T6 Gb]

- Ex d Zone 1 mounting to zone 0 gas [Ex db IIC T1 ... T6 Ga/Gb]

Zone 1 gas [Ex dbIIC T1 ... T6 Gb]

EAC (option) Eurasian Economic

Hazardous areas Community

- Ex i Zone 0 gas [0 Ex ia IIC T3/T4/T5/T6]

Zone 1 gas [1 Ex ib IIC T3/T4/T5/T6]

Zone 20 dust 2) [DIP A20 Ta 65 °C/Ta 95 °C/Ta 125 °C]

Zone 21 dust 2) [DIP A21 Ta 65 °C/Ta 95 °C/Ta 125 °C]

- Ex d Zone 1 gas [1 Ex d IIC T6 ... T1]

INMETRO (option) Brazil

Hazardous areas

- Ex i Zone 0 gas [Ex ia IIC T3 ... T6 Ga]

Zone 1 mounting to zone 0 gas [Ex ib IIC T3 ... T6 Ga/Gb]

Zone 1 gas [Ex ib IIC T3 ... T6 Gb]

Zone 20 dust 2) [Ex ia IIIC T125 ... T65 °C Da]

Zone 21 mounting to zone 20 dust 2) [Ex ib IIIC T125 ... T65 °C Da/Db]

Zone 21 dust 2) [Ex ib IIIC T125 ... T65 °C Db]

- Ex d Zone 1 mounting to zone 0 gas [Ex d IIC T* Ga/Gb]

Zone 1 gas [Ex d IIC T* Gb]

WIKA data sheet TE 65.17 ∙ 04/2019 Page 2 of 9

Logo Description Country

NEPSI (option) China

Hazardous areas

- Ex i Zone 0 gas [Ex ia IIC T1 ~ T6 Ga]

Zone 1 mounting to zone 0 gas [Ex ia IIC T1 ~ T6 Ga/Gb]

Zone 1 gas [Ex ia IIC T1 ~ T6 Gb]

KCs - KOSHA (option) South Korea

Hazardous areas

- Ex i Zone 0 gas [Ex ia IIC T4 ... T6]

Zone 1 gas [Ex ib IIC T4 ... T6]

- PESO (option) India

Hazardous areas

- Ex i Zone 0 gas [Ex ia IIC T1 ... T6 Ga]

Zone 1 mounting to zone 0 gas [Ex ib IIC T3 ... T6 Ga/Gb]

Zone 1 gas [Ex ib IIC T3 ... T6 Gb]

- Ex d Zone 1 gas [Ex d IIC T1 ... T6 Gb]

DNOP - MakNII (option) Ukraine

Hazardous areas

- Ex i Zone 0 gas 2) [II 1G Ex ia IIC T3 ...T6 Ga]

Zone 1 mounting to zone 0 gas 2) [II 1/2G Ex ia IIC T3 ...T6 Ga/Gb]

Zone 1 gas 2) [II 2G Ex ia IIC T3 ...T6 Gb]

Zone 20 dust 2) [II 1D Ex ia IIIC T125 ... T65 °C Da]

Zone 21 mounting to zone 20 dust 2) [II 1/2D Ex ia IIIC T125 ... T65 °C Da/Db]

Zone 21 dust 2) [II 2D Ex ia IIIC T125 ... T65 °C Db]

GOST (option) Russia

Metrology, measurement technology

KazInMetr (option) Kazakhstan

Metrology, measurement technology

- MTSCHS (option) Kazakhstan

Permission for commissioning

BelGIM (option) Belarus

Metrology, measurement technology

Uzstandard (option) Uzbekistan

Metrology, measurement technology

Manufacturer‘s information and certificates

Logo Description

SIL 2

Functional safety

1) Only for built-in transmitter

2) Only for model TC12-B

Instruments marked with “ia” may also be used in areas only requiring instruments marked with “ib” or “ic”.

If an instrument with “ia” marking has been used in an area with requirements in accordance with “ib” or “ic”, it can no longer be operated in

areas with requirements in accordance with “ia” afterwards.

Approvals and certificates, see website

WIKA data sheet TE 65.17 ∙ 04/2019 Page 3 of 9

Specifications

Output signal thermocouple

Temperature range Measuring range see page 5

Thermocouple per IEC 60584-1 Types K, J, E, N, T

Measuring point ■■ Ungrounded welded (ungrounded)

■■ Welded at the bottom (grounded)

Tolerance value of the measuring element

■■ per IEC 60584-1 Class 1

Class 2

■■ per ASTM E230 Standard

Special

Output signal 4 ... 20 mA, HART® protocol, FOUNDATION™ Fieldbus and PROFIBUS® PA

Transmitter (selectable versions) Model T16 Model T32 Model T53 Models TIF50, TIF52

Data sheet TE 16.01 TE 32.04 TE 53.01 TE 62.01

Output

■■ 4 ... 20 mA x x x

■■ HART® protocol x x

■■ FOUNDATION™ Fieldbus and PROFIBUS® PA x

Galvanic isolation yes yes yes yes

Measuring insert (replaceable)

Material Ni alloy: alloy 600, others on request

Diameter Standard: 3 mm, 4.5 mm, 6 mm, 8 mm

Option (on request): 1/8 inch (3.17 mm), 1/4 inch (6.35 mm), 3/8 inch (9.53 mm)

Spring travel approx. 20 mm

Response time t50 < 5 s t90 < 10 s (measuring insert diameter 6 mm: The thermowell required for operation

(in water, per EN 60751) increases the response time dependent upon the actual parameters for the thermowell and the

process.)

Neck tube

Material Stainless steel 1.4571, 316, 316L

Connection thread to the thermowell ■■ G 1/2 B ■■ M14 x 1.5

■■ G 3/4 B ■■ M18 x 1.5

■■ 1/2 NPT ■■ M20 x 1.5

■■ 3/4 NPT ■■ M27 x 2

Connection thread to the head ■■ M20 x 1.5 with counter nut

■■ 1/2 NPT

Neck length ■■ min. 150 mm, standard neck length

■■ 200 mm

■■ 250 mm

other neck lengths on request

Ambient conditions

Ambient and storage temperature -60 1) / -40 ... +80 °C

Ingress protection IP66 per IEC/EN 60529

The specified ingress protection only applies for TC12-B with corresponding thermowell,

connection head, cable gland and appropriate cable dimensions.

Vibration resistance 50 g, peak-to-peak

Use thermocouples with shielded cable, and ground the shield on at least one end of the lead.

For a correct determination of the overall measuring deviation, both sensor and transmitter measuring deviations have to be considered.

1) Special version on request (only available with selected approvals), other ambient and storage temperature on request

WIKA data sheet TE 65.17 ∙ 04/2019 Page 4 of 9

Sensor Measuring insert

Sensor types The replaceable measuring insert is made of a vibration-

resistant, sheathed measuring cable (MI cable).

Model Operating temperatures per

The measuring insert diameter should be approx. 1 mm

IEC 60584-1 ASTM E230

smaller than the bore diameter of the thermowell.

Class 2 Class 1 Standard Special Gaps of more than 0.5 mm between thermowell and the

K -40 ... +1,200 °C -40 ... +1,000 °C 0 ... 1,260 °C measuring insert will have a negative effect on the heat

J -40 ... +750 °C -40 ... +750 °C 0 ... 760 °C transfer, and they will result in unfavourable response

E -40 ... +900 °C -40 ... +800 °C 0 ... 870 °C behaviour of the thermometer.

N -40 ... +1,200 °C -40 ... +1,000 °C 0 ... 1,260 °C

T -40 ... +350 °C 0 ... 370 °C When fitting the measuring insert into a thermowell, it is

very important to determine the correct insertion length

(= thermowell length for bottom thicknesses of ≤ 5.5 mm). In

Sheath material and sheath diameter may limit the maximum

order to ensure that the measuring insert is firmly pressed

operating temperature.

down onto the bottom of the thermowell, the insert must be

spring-loaded (spring travel: 0 ... 20 mm).

The actual operating temperature of the thermometers

is limited both by the maximum permissible working

Calculation of the measuring insert length in the event

temperature and the diameter of the thermocouple and the

of replacement

MI cable, as well as by the maximum permissible working

temperature of the thermowell material. Thread to connection head Measuring insert length l5

1/2 NPT NL + 12 mm

For detailed specifications for thermocouples, see M20 x 1.5 NL + 18 mm

IEC 60584-1 or ASTM E230 and Technical information

IN 00.23 at www.wika.com. NL = Nominal length of the TC12-B or TC12-M

Tolerance value

For the tolerance value of thermocouples, a cold junction

temperature of 0 °C has been taken as the basis.

Neck tube

Listed models are available both as single or dual

The neck tube is screwed into the connection head or the

thermocouples. The thermocouple will be delivered with

case. The neck length depends on the intended use. Usually

an ungrounded measuring point, unless explicitly specified

an isolation is bridged by the neck tube. Also, in many cases,

otherwise.

the neck tube serves as a cooling extension between the

connection head and the medium, in order to protect any

possible built-in transmitter from high medium temperatures.

In the Ex d version the flameproof joint is integrated in the

neck tube.

WIKA data sheet TE 65.17 ∙ 04/2019 Page 5 of 9

Components model TC12

Model TC12-M Model TC12-B Model TC12-B Model TC12-B

Module Variant 1 Variant 2 Variant 3

14039769.01

Thread T4

T3

T1

Thread Thread Thread Thread

Tundefined

Legend:

Connection head Terminal block A (U2) Insertion length

Neck tube Transmitter (option) NL Nominal length

Connection to thermowell Field transmitter N (MH) Neck length

Measuring insert

Neck tube versions

Neck tube “Nipple-union-nipple” Tapered Parallel thread with

(neck tube welded) neck tube thread counter nut

14013854.02

Legend:

Neck tube

Thread to the thermowell

Measuring insert

Thread to the connection head

A(U2) Insertion length

(tapered thread)

A(L1) Insertion length

(parallel thread)

Parallel Tapered Parallel Tapered

NL Nominal length

thread thread thread thread N(MH) Neck length

WIKA data sheet TE 65.17 ∙ 04/2019 Page 6 of 9

Thermowell selection

TW10 TW15 TW20 TW25 TW31 TW50 TW55

Data sheets: Data sheet: Data sheet: Data sheet: Data sheet: Data sheet: Data sheet:

TW 95.10 TW 95.15 TW 95.20 TW 95.25 TW 95.31 TW 95.50 TW 95.55

TW 95.11

TW 95.12

Special thermowells on request

Connection head

A B

00

1/4000

1/4000

5/6000

5/6000

7/8000

5/6000

7/8000

7/8000

7/8000 DIH50

other connection

7/8000

andere DIH50

Anschlussgehäuse KN4-P

andere Anschlussgehäuse KN4-P

BVC BVC

housings

Model Material Cable outlet Ingress Explosion protection Cap Surface

protection

1/4000 F Aluminium ½ NPT, ¾ NPT, M20 x 1.5 IP66 1) Without, Ex i, Ex d Screw-on lid Blue, lacquered 2)

1/4000 S Stainless ½ NPT, ¾ NPT, M20 x 1.5 IP66 1) Without, Ex i, Ex d Screw-on lid Blank

steel

5/6000 Aluminium 2 x ½ NPT, 2 x ¾ NPT, IP66 1) Without, Ex i, Ex d Screw-on lid Blue, lacquered 2)

2 x M20 x 1.5

7/8000 W Aluminium ½ NPT, ¾ NPT, M20 x 1.5 IP66 1) Without, Ex i, Ex d Screw-on lid Blue, lacquered 2)

7/8000 S Stainless ½ NPT, ¾ NPT, M20 x 1.5 IP66 1) Without, Ex i, Ex d Screw-on lid Blank

steel

1) The specified ingress protection only applies for TC12-B with corresponding cable gland, appropriate cable dimensions and mounted thermowell.

2) RAL 5022

Field temperature transmitter with digital

display (option)

Field temperature transmitters models TIF50, TIF52

As an alternative to the standard connection head the

thermometer can be fitted with an optional model TIF50 or

TIF52 field temperature transmitter.

The field temperature transmitter comprises a 4 ... 20 mA/

HART® protocol output and is equipped with an LCD

indication module.

Model TIF50: HART® slave

Model TIF52: HART® master Field temperature transmitters models TIF50, TIF52

WIKA data sheet TE 65.17 ∙ 04/2019 Page 7 of 9

Transmitter (option)

As an option, WIKA transmitters can be installed in the

TC12-B connection head.

Model Description Explosion protection Data sheet

T16 Digital transmitter, PC configurable Optional TE 16.01

T32 Digital transmitter, HART® protocol Optional TE 32.04

T53 Digital transmitter FOUNDATION™ Fieldbus and PROFIBUS® PA Standard TE 53.01

TIF50 Digital field temperature transmitter, HART® protocol (slave) Optional TE 62.01

TIF52 Digital field temperature transmitter, HART® protocol (master) Optional TE 62.01

Other transmitters on request.

Electrical connection

Colour code of cable strands

Sensor IEC 60584-1 ASTM E230

Single type

3171966.01

Positive Negative Positive Negative

thermocouple

K Green White Yellow Red

J Black White White Red

E Violet White Violet Red

N Pink White Orange Red

T Brown White Blue Red

Dual

thermocouple

For the electrical connections of built-in temperature transmitters see the corresponding data sheets or operating instructions.

WIKA data sheet TE 65.17 ∙ 04/2019 Page 8 of 9

Functional safety (option)

In safety-critical applications, the entire measuring chain

must be taken into consideration in terms of the safety

parameters. The SIL classification allows the assessment of

the risk reduction reached by the safety installations.

Selected TC12 process thermocouples in combination with

an appropriate temperature transmitter (e.g. model T32.1S)

are suitable as sensors for safety functions up to SIL 2.

Matched thermowells allow easy dismounting of the

measuring insert for calibration. The optimally matched

measuring point consists of a thermowell, a TC12

thermometer and a T32.1S transmitter developed in

accordance with IEC 61508. Thus, the measuring point

provides maximum reliability and a long service life.

Certificates (option)

Certification type Measurement Material

accuracy certificate

2.2 test report x x

3.1 inspection certificate x x

DKD/DAkkS calibration x -

certificate

The different certifications can be combined with each other.

Approvals and certificates, see website

Ordering information

Model / Explosion protection / Ignition protection type / Sensor / Sensor specifications / Thermometer range of use / Measuring

point / Connection housing / Thread size at cable outlet / Cable outlet / Transmitter / Neck tube version / Connection to case,

connection head / Connection to thermowell / Neck tube length N(MH) / Insertion length A / Measuring insert / Options

© 04/2011 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet TE 65.17 ∙ 04/2019 Page 9 of 9

04/2019 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Thermowell PT 100Document17 pagesThermowell PT 100Muhammad darwisNo ratings yet

- Surface Thermocouple Temperature MonitoringDocument12 pagesSurface Thermocouple Temperature MonitoringMaryoly BlancoNo ratings yet

- Wika TC10-HDocument12 pagesWika TC10-HMS COPNo ratings yet

- Threaded Resistance Thermometer With Protection Tube Model TR10-CDocument18 pagesThreaded Resistance Thermometer With Protection Tube Model TR10-CAnubhav YadavNo ratings yet

- Wika Tc10-ADocument7 pagesWika Tc10-AMS COPNo ratings yet

- Safety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)Document9 pagesSafety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)shakouri1370_8902064No ratings yet

- HDA 4400 EXia dual approval hydrogen pressure transmitterDocument4 pagesHDA 4400 EXia dual approval hydrogen pressure transmitterExinspection anoafpsoNo ratings yet

- PRD Doc Buw 669835-00001 Sall Ain V10Document60 pagesPRD Doc Buw 669835-00001 Sall Ain V10Amer CajdricNo ratings yet

- Selecting Explosion Protected EquipmentDocument32 pagesSelecting Explosion Protected EquipmentSing Yew LamNo ratings yet

- FKP Pressure TransmitterDocument8 pagesFKP Pressure TransmitterTrần PhongNo ratings yet

- At ExDocument2 pagesAt ExMoustafa Ibrahim YehyaNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- Ii2Gexhiict6Gb: X-Cube Ex Project and Design SheetDocument4 pagesIi2Gexhiict6Gb: X-Cube Ex Project and Design SheetDerick LopesNo ratings yet

- Ex MotorDocument120 pagesEx Motormbdonek5252No ratings yet

- Explaining ATEX & IECEx Certifications NotesDocument3 pagesExplaining ATEX & IECEx Certifications Notes何吉飞No ratings yet

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- Selection of Explosion Protected Equipment For Hazardous LoctionsDocument32 pagesSelection of Explosion Protected Equipment For Hazardous Loctionsasex4uNo ratings yet

- Ex Selection - 5 Des 2022Document8 pagesEx Selection - 5 Des 2022Alex van dykNo ratings yet

- AI RTD TC ATEX Ex I en de FR Es 6309Document88 pagesAI RTD TC ATEX Ex I en de FR Es 6309jose luis juarezNo ratings yet

- dsmc0020 en Medc hd1 Heat DetectorDocument2 pagesdsmc0020 en Medc hd1 Heat DetectorAbdul Hakeem MohammedNo ratings yet

- SicmeDocument12 pagesSicmeTraian SerbanNo ratings yet

- DS51 Non Electrical Wallchart Iss5 0813Document1 pageDS51 Non Electrical Wallchart Iss5 0813perumal1312No ratings yet

- Types of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresDocument1 pageTypes of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresHimanshu ChichraNo ratings yet

- 986 07 1006 031 - ManDocument8 pages986 07 1006 031 - ManFernando Ledesma RamirezNo ratings yet

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDocument1 pageNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNo ratings yet

- Instruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust AtmospheresDocument4 pagesInstruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust Atmospheresgelustan2006No ratings yet

- CompEx GuideDocument22 pagesCompEx GuideFederico MaggiNo ratings yet

- HazLoc Guide To Zoned EquipmentDocument8 pagesHazLoc Guide To Zoned EquipmentDzeminSinNo ratings yet

- Flowserve NT3000 Electro-Pneumatic TransducerDocument20 pagesFlowserve NT3000 Electro-Pneumatic TransducerShahnawaz SalimNo ratings yet

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishJohnNo ratings yet

- Explosion-Protected Pressure Switches M.8: M.8 Druckschalter in ATEX-Ausführung - 0340-0341 / 0165Document6 pagesExplosion-Protected Pressure Switches M.8: M.8 Druckschalter in ATEX-Ausführung - 0340-0341 / 0165Rodica PuscauNo ratings yet

- Thames Side T34 Silo Data Sheet 09.2016Document4 pagesThames Side T34 Silo Data Sheet 09.2016Zakir MohyuddinNo ratings yet

- ATEX Enclosures: LabellingDocument2 pagesATEX Enclosures: LabellingKarthikeyan RNo ratings yet

- 05-Ejbx enDocument14 pages05-Ejbx enAmer CajdricNo ratings yet

- Catalogue - LT Type DP Transmitter - Azbil - JapanDocument24 pagesCatalogue - LT Type DP Transmitter - Azbil - JapanReza Pratama NugrahaNo ratings yet

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDave CNo ratings yet

- IECEx Certification Bodies for Explosive Atmospheres EquipmentDocument1 pageIECEx Certification Bodies for Explosive Atmospheres EquipmentMrudang MehtaNo ratings yet

- ATEX Samsung Best Buy Air Conditioner 1.1Document4 pagesATEX Samsung Best Buy Air Conditioner 1.1moosuhaibNo ratings yet

- Ex KodlariDocument1 pageEx KodlaridhnsekaranNo ratings yet

- Abb MT 5000Document12 pagesAbb MT 5000FIRMANSYAHNo ratings yet

- EN DE FR ES: Examples/Beispiele/Exemples/EjemplosDocument52 pagesEN DE FR ES: Examples/Beispiele/Exemples/Ejemplosjose luis juarezNo ratings yet

- UK ATEX IECEx Sensor CatalogueDocument26 pagesUK ATEX IECEx Sensor Cataloguedj22500No ratings yet

- Data AtexDocument4 pagesData AtexdursosonoNo ratings yet

- ΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑDocument1 pageΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑKonstantinos KantzavelosNo ratings yet

- Marking Electrical Equipment for Explosive AtmospheresDocument1 pageMarking Electrical Equipment for Explosive AtmospheressaiyedasadNo ratings yet

- Clasificacion de Enclosures Nema Ip AtexDocument5 pagesClasificacion de Enclosures Nema Ip AtexJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- SS2 GTX00D 0100 21 PDFDocument24 pagesSS2 GTX00D 0100 21 PDFtjahyo02No ratings yet

- Raychem Im Install039 T100 MLDocument36 pagesRaychem Im Install039 T100 MLsunny kumarNo ratings yet

- Atex PDFDocument115 pagesAtex PDFSanjay Kumar SinghNo ratings yet

- SWF Hoists and Crane Components Available EX-proof Versions ofDocument1 pageSWF Hoists and Crane Components Available EX-proof Versions ofOkanSukruNo ratings yet

- Productattachments Files 2 0 2015 07 Rag Atex-Equipment-Class-LabellingDocument1 pageProductattachments Files 2 0 2015 07 Rag Atex-Equipment-Class-LabellingDhananjay BhaldandNo ratings yet

- BASIC PRINCIPLES OF EXPLOSIVE PROTECTION IEC 60079Document18 pagesBASIC PRINCIPLES OF EXPLOSIVE PROTECTION IEC 60079Duong NguyenNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- XXIVth International Congress of Pure and Applied Chemistry: Plenary and Main Section Lectures Presented at Hamburg, Federal Republic of Germany, 2–8 September 1973From EverandXXIVth International Congress of Pure and Applied Chemistry: Plenary and Main Section Lectures Presented at Hamburg, Federal Republic of Germany, 2–8 September 1973No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Test PaperDocument12 pagesTest PaperVaibhav PatilNo ratings yet

- 10158676953506001Document2 pages10158676953506001LTHCB ITNo ratings yet

- Lecture Notes On Data AnalysisDocument118 pagesLecture Notes On Data AnalysisCharmaine BulawanNo ratings yet

- Income Tax Calculator For FY 2023-24 (Old & New Regime)Document1 pageIncome Tax Calculator For FY 2023-24 (Old & New Regime)Vaibhav PatilNo ratings yet

- Smartline: Std700 Smartline Differential Pressure Specification 34-St-03-121, March 2020Document15 pagesSmartline: Std700 Smartline Differential Pressure Specification 34-St-03-121, March 2020Vaibhav PatilNo ratings yet

- CAMS CKYC Application FormDocument4 pagesCAMS CKYC Application Formdibyaduti_20009197No ratings yet

- 5.5 KW 4p-Ds - EilDocument9 pages5.5 KW 4p-Ds - EilVaibhav PatilNo ratings yet

- Control NarrativeDocument7 pagesControl NarrativeVaibhav PatilNo ratings yet

- Plate and FrameDocument28 pagesPlate and FrameVaibhav PatilNo ratings yet

- Servo MotorDocument41 pagesServo MotorVaibhav Patil100% (1)

- Classification of Heat ExchangersDocument77 pagesClassification of Heat Exchangers4605566vivek100% (1)

- Article Hydrocarbon Engineering Feb 2011Document0 pagesArticle Hydrocarbon Engineering Feb 2011Sook Thiam LeeNo ratings yet

- Magnetic Resonance ImagingDocument20 pagesMagnetic Resonance ImagingVaibhav Patil50% (2)

- MRIDocument37 pagesMRIVaibhav PatilNo ratings yet

- Indian Power ScenarioDocument47 pagesIndian Power ScenarioVaibhav PatilNo ratings yet

- Indian Power ScenarioDocument47 pagesIndian Power ScenarioVaibhav PatilNo ratings yet

- Indian Power ScenarioDocument47 pagesIndian Power ScenarioVaibhav PatilNo ratings yet

- TRIO 50.0 TL OUTD US 480 - Rev.G PDFDocument4 pagesTRIO 50.0 TL OUTD US 480 - Rev.G PDFmarcosNo ratings yet

- Designing a Power Supply: A Project ReportDocument31 pagesDesigning a Power Supply: A Project Reportpriyanka sarmahNo ratings yet

- Engineering Division: FF/HART ConfigurationDocument34 pagesEngineering Division: FF/HART ConfigurationJorge Pérez FrisanchoNo ratings yet

- VI Lect - Notes#3 Btech Vii Sem Aug Dec2022Document164 pagesVI Lect - Notes#3 Btech Vii Sem Aug Dec2022NAAZNo ratings yet

- AN118fb PDFDocument48 pagesAN118fb PDFLOLONo ratings yet

- PM4018MUDocument11 pagesPM4018MUaldo_suviNo ratings yet

- Forward Converter Design and AnalysisDocument56 pagesForward Converter Design and AnalysisJeanTsunaNo ratings yet

- Preface For The Power SystemsDocument16 pagesPreface For The Power SystemsSaket Tirpude20% (5)

- Addis Ababa University Addis Ababa Institute of TechnologyDocument56 pagesAddis Ababa University Addis Ababa Institute of TechnologyFìrœ Lōv MånNo ratings yet

- VHF FM Handheld Transceiver: 144 MHZ, Ultra-Rugged, 5 Watts!Document2 pagesVHF FM Handheld Transceiver: 144 MHZ, Ultra-Rugged, 5 Watts!Jc Sevillano AlejandroNo ratings yet

- Am DSBFC Systems (By Larry E. Gugle K4rfe)Document9 pagesAm DSBFC Systems (By Larry E. Gugle K4rfe)rascalangelNo ratings yet

- ST3PA, ST3PC Time Relay ManualDocument2 pagesST3PA, ST3PC Time Relay ManualMohamedNo ratings yet

- LTE FDD Cluster DT - Analysis ReportDocument23 pagesLTE FDD Cluster DT - Analysis ReportAnonymous 0d9mC0OaxENo ratings yet

- 1482267279amasadoras Univex Greenline FichaDocument2 pages1482267279amasadoras Univex Greenline FichaAdriana GalindoNo ratings yet

- Electric Circuit Fundamentals: Essential QuestionDocument15 pagesElectric Circuit Fundamentals: Essential QuestionMOBILEE CANCERERNo ratings yet

- Electrical Meter ConnectionDocument18 pagesElectrical Meter ConnectionMelinda PerezNo ratings yet

- UTCPanel+ Guide EDocument65 pagesUTCPanel+ Guide Ejroyal692974100% (1)

- Aalim Muhammed Salegh College of Engineering Digital Systems Design Lab RecordDocument67 pagesAalim Muhammed Salegh College of Engineering Digital Systems Design Lab Recordaafreen sadakNo ratings yet

- SA100 V 14 BulletinDocument8 pagesSA100 V 14 BulletinTeepoonsab somsaiNo ratings yet

- NNH4-65C-R6-V2: Electrical SpecificationsDocument4 pagesNNH4-65C-R6-V2: Electrical SpecificationsDavid Angulo EsguerraNo ratings yet

- Esure™ Rectifier Module: User ManualDocument26 pagesEsure™ Rectifier Module: User ManualBysNo ratings yet

- 3ek7 UsaDocument8 pages3ek7 UsaJuan Jose RodriguezNo ratings yet

- Danfoss Scroll Compressors in Parallel Installation SMSYSZDocument48 pagesDanfoss Scroll Compressors in Parallel Installation SMSYSZNikolas Chionas100% (1)

- At-CP1E CPU Unit SoftwareDocument450 pagesAt-CP1E CPU Unit SoftwareNikolas Kolasni Lakenir Ckerde DockosNo ratings yet

- Coax Connectors - RF TypesDocument6 pagesCoax Connectors - RF TypesMicah WilsonNo ratings yet

- JVC Car Stereo KD-S595 Service ManualDocument42 pagesJVC Car Stereo KD-S595 Service ManualAnonymous j5apk2AumNo ratings yet

- ESD5522E Generator Speed Control UnitDocument2 pagesESD5522E Generator Speed Control UnitKhaled KamelNo ratings yet

- LA210P Pro Loudspeaker CE-LVD Test ReportDocument73 pagesLA210P Pro Loudspeaker CE-LVD Test ReportJL EN CONCIERTONo ratings yet

- XEnergy Technical Guide en 158487Document88 pagesXEnergy Technical Guide en 158487Cris_eu09No ratings yet

- Recuperar Driver GhostDocument3 pagesRecuperar Driver GhostainhoazalaNo ratings yet