Professional Documents

Culture Documents

Iarjset 4

Uploaded by

1DC20AT025 Ganesh AkshayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iarjset 4

Uploaded by

1DC20AT025 Ganesh AkshayCopyright:

Available Formats

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

Post-Tensioned Building Analysis and Design

– A Case Study

Rahul Singh1, Amarjeet Chauhan1, Yash Chonkar1, Apurva Rati1, Arbaz Kazi 2

Student, Civil Engineering Department, Vidyavardhini’s College of Engineering & Technology, Vasai (W) 1

Asst. Prof., Civil Engineering Department, Vidyavardhini’s College of Engineering & Technology, Vasai (W) 2

Abstract: In this fast-paced and competitive world, building sector is at the apex of the growth of any country. High-

rise buildings are admired by every human being. Traditionally the construction of a building is done by RCC but in

present world, construction of high rise buildings is done by Post-Tensioning. In RCC, the economic expenditure is

very high in commercial and institutional buildings because of more material required in construction and hence, Post

Tensioned building proves to be more economic and durable. Post-Tensioned building saves quantity of steel and

concrete as compared to RCC and increases clear span in rooms. Through this paper, the emphasis is to design a post-

tensioned building using ETABS and SAFE. ETABS stand for Extended Three-Dimensional Analysis of a building

systems. The main purpose of this software is to design multi-storeyed building in a systematic process which will be

in accordance with Indian Standard design codes.

Keywords: Post Tensioning, Multi-storeyed, SAFE, ETABS.

A. INTRODUCTION

The history of post-tensioning concrete stretches back to the 1930's, where a Frenchman named Eugene Freyssinet,

realized that placing concrete under compression greatly increases its strength. It includes laying sheathed cables and

pouring concrete around them and allowing it to set up, then stretching the cables and locking them into place.

Post World War II, post-tensioned concrete became a popular building method as there was a shortage of steel and there

was a need to replace damaged and war-torn bridges. The design and use of this method diminished until the mid-1960,

when much of its utilization was in the area of ground-supported slabs for warehouse, apartment, and residential floors.

In 1976, PTI (Post Tensioning Institute), which realised the future potential of PT, was formed.

A concrete when being placed under compression is known as Pre-stressed concrete. This is done before the

application of supporting any loads beyond its dead weight. This compression which is produced by the tensioning of

high-strength "tendons" is located within or adjacent to the concrete volume, and this in turn improves the performance

of the concrete in service. The tendons which are used in post-tensioning consists of single, multi-wire strands or

threaded bars which are made from tensile steels, carbon and aramid fiber. The quintessence of prestressed concrete is

that once the initial compression has been applied, the resulting material has the characteristics of high-strength

concrete when subjected to subsequent compression forces and high-strength steel when subject to tension forces.

Increased structural capacity and/or serviceability compared to conventionally reinforced concrete is noticed in many

situations.

Prestressed concrete is used in a wide range of building and civil structures where its improved performance can allow

longer spans, reduced structural thicknesses, and material savings compared to simple reinforced concrete. Typical

applications include high-rise buildings, residential slabs, foundation systems, bridge and dam structures, silos and

tanks, industrial pavements and nuclear containment structures.

First used in the late-nineteenth century, prestressed concrete has developed beyond pre-tensioning to include post-

tensioning, which occurs after the concrete is cast. Tensioning systems may be classed as either monostrand, where

each tendon's strand or wire is stressed individually, or multi-strand, where all strands or wires in a tendon are stressed

simultaneously. Tendons may be located either within the concrete volume (internal prestressing), or wholly outside of

it (external prestressing). Whereas pre-tensioned concrete uses tendons directly bonded to the concrete, post-tensioned

concrete can use either bonded or unbonded tendons.

To meet the architecturally challenging applications of this modern world, while still providing a durable concrete

structure, designers specify cast-in-place construction. Cast-in-place construction allows the engineer the flexibility to

meet any geometric floor plan and to use varying section dimensions. This results in the most economical solution for

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 17

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

the concrete application. Using post-tensioned reinforcement in cast-in-place construction helps the engineer in even

more improved economical solution by reducing the depth of the structural elements. Reduction in depth optimizes the

quantity of concrete required and can reduce the overall weight of a structure which saves foundation costs and can

reduce the overall height of a building saving in exterior cladding costs. A post-tensioned cast-in-place concrete

solution for a slab-on-ground application or a high-rise building floor system affords the owner, architect, and engineer

the most cost-effective solution to meet today’s challenging construction environment. The model work is carried out to

analyse and design of hospital building.

Both these methods are used specifically in the construction of bridges and storage tanks for many decades due to its

decisive technical and economic advantages. The focus of this paper is on applications of post-tensioning in building

sector.

The most important advantages offered by post-tensioning briefly are:

There is a considerable percentage saving in concrete and steel, due to the participation of the entire concrete

cross-section, more slender designs are possible.

Smaller deflections compared to structural members with steel and reinforced concrete.

Good crack behaviour and therefore better protection of the steel against corrosion.

There is constant serviceability even under considerable overload, since temporary cracks close again after the

removal of overload.

High fatigue strength, since the amplitude of the stress changes in the prestressing steel under alternating loads

are quite small.

For the above listed reasons, post-tensioned construction has also come to be used in many situations in buildings. The

following advantages of post-tensioned slabs over reinforced concrete slabs may be listed:

More economical structures resulting from the use of prestressing steels with a very high tensile strength

instead of normal reinforcing steels.

Larger spans and greater slenderness. The condition of greater slenderness results in reduced - dead load,

which also has a beneficial effect upon the columns and foundations and reduces the overall height of buildings or

enables additional floors to be incorporated in buildings of a given height.

Under permanent load, very good behaviour in respect of deflections and cracking.

Higher punching shear strength is achieved by appropriate layout of tendons

There is considerable reduction in construction time because of earlier striking of slab formwork.

The real development took place in the USA and Australia. The First post-tensioned slabs was constructed of higher

strength steel, better attachment hardware, better construction techniques, and simplified design methods, the use of P-T

to reinforce structures became more popular. In the next decade numerous post-tensioned slabs were designed and

constructed in connection with the lift slab method. Post-tensioning enabled the lifting weight to be reduced and the

deflection and cracking performance to be improved. Attempts were made to gain in depth knowledge by theoretical

studies and experiments on posttensioned plates. By the early 1990s the mystery of P-T subsided with further

refinements to the tensioning process, the development of more corrosion resistant anchorages, and the widespread

dissemination of design software.

Due to these factors, P-T has become a preferred method for reinforcing concrete today even in building sector [1].

B. LITERATURE REVIEW

1. Dr Manmohan R Kalgal explained through his paper the need for post-tensioning in our

Building sector. The major advantages of post-tensioning is that it is economic, considerable saving of concrete and

steel can be achieved. The Post-tensioned slabs result in larger spans and greater slenderness. There is reduction in

construction time as a result of earlier striking of formwork. Dr Kalgal also explained us bonded and unbonded tendons.

Advantages and disadvantages of both tendons are explained. An effort is made through this paper that will help post-

tensoning to be familiar among more and more people.

2. V.G.Kiran Kumar et al. (2014) explained through their paper the use of ETABS for a High Rise Building.

Load calculation, wind load calculation, seismic load calculation and the design of a post-tensioned slab can be studied.

With the use of post-tensioning method, thickness of the slab is reduced. If thickness of slab is reduced, this creates a

chain reaction i.e number of columns and beams is reducing which leads to the structure being more economic and eco-

friendly.

3. B.Anjaneyulu et al. (2016) explained the importance of flat slab in India as this construction is a developing

technology. It has many advantages over conventional slabs and can be used this modern world where every building

needs to have a high degree of structural stability and it should have an eye-catching look to it. Flat slab can be built by

both conventional reinforced concrete as well as post-tensioning. However, for span up to 10 metres conventional

concrete design is used in India.

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 18

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

4. Jnanesh Reddy et al. (2017) gave us a comparison between post tensioned and RCC Flat Slab in a multi-storey

post tensioned building. The need of concrete in a RCC Flat Slab is comparatively more than a PT slab. Cost of steel

required is also more than the combined price of steel and tendons in PT slab construction. Stiffness and strength of the

structure will also be more than that of the RCC Flat Slab. As thickness is reduced in PT slab aesthetic look can be

increased and also the structure is lighter as the dead load gets reduced.

5. Sreenivasa Prasad Joshi explained the qualitative and quantitative analysis of a Post Tensioned Slab through

manual calculations. The primary advantages of Post-Tensioned Floors is longer spans, overall economic structural cost,

reduced floor to floor height, waterproof and deflection free slab, early formwork stripping and material handling. The

comparison result of RCC and PT Slab shows us that there is 67% saving of concrete in PT, also the comparison

between RCC and PT Beam shows us that there is 79% saving of concrete in PT. The rate analysis between the two

shows us that there is 48% saving of cost in PT. However post-tensioning is rejected in buildings due to lack of

knowledge and flexibility.

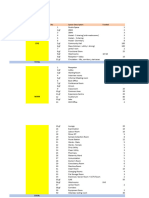

C. DESCRIPTION OF STUDY MODEL

A. Project Details

1. Purpose of building: Institutional

2. Shape of building: Regular (rectangular)

3. No of stories: (G+18)

4. Type of wall: Masonry

5. Height of stories: 4.8m (similar)

B. General conditions of area of construction

1. Area: Mumbai

2. Zone: III

3. Soil Type: Moderate

4. Zone factor:0.16

5. Response Reduction Factor, R=5.0

6. A eighteen floor institutional building of asymmetrical plan.

C. Material Properties

To carry out the work in ETABS software, the properties of the material such as concrete and steel should be defined,

similarly the loads should be defined such as live load, dead load, seismic load, wind load.

1. Grade of concrete and steel: M40 and Fe500

2. LL=4kN/m2

3. FF= 1.5kN/m2

4. Beam size = 300*500 mm2

5. Column size = 500*500 mm2

D. Properties of Tendon used in designing

a. Type of tendon- Cold drawn steel.

b. Modulus of elasticity- 210000 N/mm2.

c. Diameter of one wire in a strand- 2.5mm.

d. No. of wire in one strand-7

e. Yield stress of tendon-1865 N/mm2.

f. Tendon jacking stress- 1488 N/mm2.

D. METHODOLOGY

All the process which was carried out while designing the structure is represented in form of flowchart given below:

• ARCHITECTURAL PLAN

1. A plan was selected and proposed.

2. Plan was of G+18 floors of hospital building.

3. Built-up area of one slab was 47300 ft2.

4. Plan consists of different levels having non-typical type.

• MODELLING IN ETABS

1. Centre line plan was prepared in autocad to simplify the work in etabs.

2. Grids was laid in ETABS.

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 19

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

3. Structure was modelled according to the plan selected in ETABS.

4. Modelling of structural members is given below .

• ASSIGNING OF VARIOUS LOADS

1. Reinforcing bars of desirable diameter was allowed.

2. Loads of various types was defined along with mass source for seismic loaing.

3. Loads like live load, seismic load, wind load was assigned to structure according to IS 875 and IS 1893.

• ANALYSIS OF STRUCTURE

1. Model was locked in ETABS.

2. Model was checked before analysis for the errors in modelling.

3. Errors was rectified.

4. Analysis of structure was carried out with the help of software.

• DESIGN OF STRUCTURE

1. Design of different members was carried out with the help of software.

2. Detailing preferances was selected.

3. Rebar selection rules was applied.

4. Detailing was also done by same software.

5. Report generation was also done in software.

Fig.1. Autocad center line plan

Fig.2. Columns placed

Fig.3. Beams placed

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 20

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

Fig. 4. Slabs placed

Fig. 5. Walls placed

Fig. 6. Tendons placed

Fig. 7. Bending moment diagram

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 21

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

Fig. 8. Deflection in mm

Fig. 9. Cage view of beam

Fig. 10. Cage view of column

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 22

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 5, Issue 3, March 2018

Fig. 11. Reactions on column in kN

E. CONCLUSION

I. Our project deals with provision of earthquake and wind resistance structure.

II. Minimum sizes of column and beam provided was C500*500 and B300*500.

III. Seismic analysis was done by using ETABS software.

IV. All the members were passed in design.

V. As building is post tensioned one, it proves to be economical.

REFERENCES

[1] Dr. Manmohan R kalgal, “Post-Tensioned Concrete in Building Sector”.

[2] Jnanesh reddy , “Comparative study of post tensioned and RCC flat slab in multi storey commercial building” ,2017

[3] V.G.Kiran Kumar and N.Lokeshwar Reddy, “Design and analysis of a commercial complex by using post tensioned method”, 2014

[4] Srenivasa Prasad Joshi, “Evaluation of post tensioned slabs – qualitative and quantitative analysis”, 2016

[5] B.Anjaneyulu , “Analysis and design of flat slab by using ETABS software” , 2016

[6] IS 1893:2000, Part 1, Criteria for Earthquake resistant design of structures- General provision for buildings, Bureau of Indian standards, New

Delhi

[7] IS 875:1987, Part 2-3, Code of Practice for design loads(other than earthquake loads) for Buildings and Structures, Bureau of Indian standards,

New Delhi

[8] IS 1343:2012, Prestressed concrete- Code of Practice, Bureau of Indian standards, New Delhi

Copyright to IARJSET DOI 10.17148/IARJSET.2018.534 23

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Assessment of Prestressed Concrete Aplications in NigeriaDocument5 pagesAssessment of Prestressed Concrete Aplications in NigeriaonyejekweNo ratings yet

- Volume 12 Construction Management PlanDocument21 pagesVolume 12 Construction Management PlansreenNo ratings yet

- 20 0650 Demolition Method StatementDocument23 pages20 0650 Demolition Method StatementFazrin inasNo ratings yet

- R.Aparna Shetty 1Document13 pagesR.Aparna Shetty 1Samiullah MohammedNo ratings yet

- Feasibility Analysis of Post-Tensioned Beam For Industrial Building A ReviewDocument10 pagesFeasibility Analysis of Post-Tensioned Beam For Industrial Building A ReviewIJRASETPublicationsNo ratings yet

- Comparative Study of Diagrid Structures Over Braced Tube StructuresDocument9 pagesComparative Study of Diagrid Structures Over Braced Tube StructuresNguyễn Trúc LâmNo ratings yet

- 143 Manoj Journal MB PDFDocument12 pages143 Manoj Journal MB PDFAnonymous ELujOV3No ratings yet

- Analysis and Design of Prestressed Concrete Flat SlabDocument8 pagesAnalysis and Design of Prestressed Concrete Flat SlabPRAVEENKUMAR HIREMATHNo ratings yet

- Analysis and Design of Prestressed Concrete Flat SlabDocument8 pagesAnalysis and Design of Prestressed Concrete Flat SlabPRAVEENKUMAR HIREMATHNo ratings yet

- 107 7 BuildingDocument8 pages107 7 BuildingRamkumar KumaresanNo ratings yet

- Post Tension StructuresDocument10 pagesPost Tension Structurestwinkle4545No ratings yet

- Behaviour of Concrete Deck Slab Using Shear Connectors: A ReviewDocument10 pagesBehaviour of Concrete Deck Slab Using Shear Connectors: A ReviewRambo d sNo ratings yet

- PROJECT Sewage TreatmentDocument16 pagesPROJECT Sewage TreatmentKaushiki KambojNo ratings yet

- 135 Transverse BoxDocument7 pages135 Transverse BoxAnonymous b9fkTYfEoRNo ratings yet

- Overview of Pre-Engineered BuildingsDocument6 pagesOverview of Pre-Engineered BuildingsGhaneshwar ThangjamNo ratings yet

- BBR Post-Tensioning en Rev1 0510Document16 pagesBBR Post-Tensioning en Rev1 0510jasamnajNo ratings yet

- Financial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabDocument6 pagesFinancial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabtienaicvnNo ratings yet

- Prestressed T-Beam PDFDocument6 pagesPrestressed T-Beam PDFAbhilash KumarNo ratings yet

- Predicting Axial Shortening of Vertical Elements in High Rise Buildings by Using Pca MethodDocument8 pagesPredicting Axial Shortening of Vertical Elements in High Rise Buildings by Using Pca MethodOscar Zúñiga CuevasNo ratings yet

- A Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansDocument6 pagesA Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansHabeeb ShaikNo ratings yet

- 278 EarthquakeDocument22 pages278 EarthquakeTarek AbulailNo ratings yet

- Precast SystemsDocument13 pagesPrecast Systemsparamarthasom1974No ratings yet

- IJCRT2106637Document8 pagesIJCRT2106637jrcruzpogi0242424No ratings yet

- The Evolution of Composite Flooring Systems: Applications, Testing, Modelling and Eurocode Design ApproachesDocument30 pagesThe Evolution of Composite Flooring Systems: Applications, Testing, Modelling and Eurocode Design ApproachesPaloma ValeNo ratings yet

- Low Loss Precast Concrete Frame BuildingsDocument13 pagesLow Loss Precast Concrete Frame BuildingsGuntara Muria AdityawarmanNo ratings yet

- Conceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsDocument13 pagesConceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsSiti Aisyah NurjannahNo ratings yet

- Conceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsDocument13 pagesConceptual Development: Low Loss Precast Concrete Frame Buildings With Steel ConnectionsZvonimir MajićNo ratings yet

- 7 V May 2019Document9 pages7 V May 2019Rishika DixitNo ratings yet

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 pagesCE 416 Prestressed Concrete Sessional (Lab Manual)julesNo ratings yet

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 pagesCE 416 Prestressed Concrete Sessional (Lab Manual)RahulKikaniNo ratings yet

- Behaviour of Flat Slab, Waffle Slab, Ribbed & Secondary Beam in A Multistorey Building Under Seismic Response: A ReviewDocument9 pagesBehaviour of Flat Slab, Waffle Slab, Ribbed & Secondary Beam in A Multistorey Building Under Seismic Response: A ReviewIJRASETPublicationsNo ratings yet

- Cost-Effectiveness of Pre-Engineered and Conventional Steel FramesDocument7 pagesCost-Effectiveness of Pre-Engineered and Conventional Steel FramesBiswajit SahooNo ratings yet

- Post Tensioning in Building StructuresDocument21 pagesPost Tensioning in Building StructuresLuan Truong VanNo ratings yet

- RI - 3 EngineeringStructures32 2010Document16 pagesRI - 3 EngineeringStructures32 2010Bahaa HussainNo ratings yet

- IJCRT2303651Document4 pagesIJCRT2303651pankaj645924No ratings yet

- Post Tension IngDocument25 pagesPost Tension IngakhilbmittalNo ratings yet

- Seminar Report - B-213Document34 pagesSeminar Report - B-213Sharvari PatilNo ratings yet

- Design of PrestressedDocument7 pagesDesign of PrestressedManish AryalNo ratings yet

- Advanced Prestressed Concrete StructuresDocument27 pagesAdvanced Prestressed Concrete StructuresAravindNo ratings yet

- Comparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument6 pagesComparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySyed Abdul RawoofNo ratings yet

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument5 pagesPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignLIZA MARIE QUINDAONo ratings yet

- Vibration Serviceability of Long-Span Concrete BuiDocument82 pagesVibration Serviceability of Long-Span Concrete BuiDaniel A. FlorêncioNo ratings yet

- A Review Paper On Comparative Analysis On RCC Structure With Energy Dissipation Device and Composite StructureDocument8 pagesA Review Paper On Comparative Analysis On RCC Structure With Energy Dissipation Device and Composite StructureIJRASETPublicationsNo ratings yet

- Reinforced jet-grouted piles analysis and designDocument11 pagesReinforced jet-grouted piles analysis and designHüseyin EkiciNo ratings yet

- A Review On Analysis and Design of Prestressed Concrete Bridge by CSiBridge SoftwareDocument7 pagesA Review On Analysis and Design of Prestressed Concrete Bridge by CSiBridge SoftwareIJRASETPublicationsNo ratings yet

- Paper 222Document12 pagesPaper 222dheerajbhawar786No ratings yet

- 65 7 SeismicDocument9 pages65 7 SeismicRahmi NurahimNo ratings yet

- Hoi - Thao T11-03 LuuDocument22 pagesHoi - Thao T11-03 LuuvuhachauNo ratings yet

- Wind Analysis of RCC Tube in Tube Structure Using ETABS SoftwareDocument13 pagesWind Analysis of RCC Tube in Tube Structure Using ETABS SoftwareIJRASETPublicationsNo ratings yet

- CE 416 Prestressed Concrete Lab ManualDocument47 pagesCE 416 Prestressed Concrete Lab Manualkorosh75No ratings yet

- Sustainable Design of Deconstructable Steel-ConcreDocument9 pagesSustainable Design of Deconstructable Steel-ConcreUsha EngineeringNo ratings yet

- Paper 8889Document5 pagesPaper 8889IJARSCT JournalNo ratings yet

- A Review Paper On Flexible FormworkDocument3 pagesA Review Paper On Flexible FormworkIJARSCT JournalNo ratings yet

- Advantages and Benefits of Unbonded Post-TensioningDocument2 pagesAdvantages and Benefits of Unbonded Post-TensioningJc OndoNo ratings yet

- Saint Louis College: BT3 (AR A315D)Document9 pagesSaint Louis College: BT3 (AR A315D)Dennis Roel T. DulayNo ratings yet

- Comparative Study On Fixed Base and Base Isolated Buildings On Sloping GroundDocument17 pagesComparative Study On Fixed Base and Base Isolated Buildings On Sloping GroundHanni Zaw OoNo ratings yet

- Toowoomba Full Paper02Document7 pagesToowoomba Full Paper02Nuno FerreiraNo ratings yet

- Retrofitting of Deteriorated With Carbon Wrapping & Steel Plate JacketingDocument13 pagesRetrofitting of Deteriorated With Carbon Wrapping & Steel Plate JacketingIJRASETPublicationsNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Behavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesFrom EverandBehavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesNo ratings yet

- A Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteDocument6 pagesA Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteSHEKHARNo ratings yet

- Adobe Scan 17 Sept 2023Document4 pagesAdobe Scan 17 Sept 20231DC20AT025 Ganesh AkshayNo ratings yet

- Kenan Omer GhassanJJCEDocument10 pagesKenan Omer GhassanJJCE1DC20AT025 Ganesh AkshayNo ratings yet

- Application of 3D Printing Technology in The Construction Industry and Its Development ProspectsDocument7 pagesApplication of 3D Printing Technology in The Construction Industry and Its Development Prospects2JH19CV015 Mohammedasjadraza MullaNo ratings yet

- AREA PROGRAM PDocument7 pagesAREA PROGRAM P1DC20AT025 Ganesh AkshayNo ratings yet

- Akshay Ferrocement WardrobeDocument1 pageAkshay Ferrocement Wardrobe1DC20AT025 Ganesh AkshayNo ratings yet

- Sabaramati Riverfront Development ProjectDocument81 pagesSabaramati Riverfront Development Project1DC20AT025 Ganesh AkshayNo ratings yet

- Sabarmathi Riverfront RedevelopmentDocument13 pagesSabarmathi Riverfront Redevelopment1DC20AT025 Ganesh AkshayNo ratings yet

- BS-IV Acoustics - Module 4 & 5 - 03-11-23Document50 pagesBS-IV Acoustics - Module 4 & 5 - 03-11-231DC20AT025 Ganesh AkshayNo ratings yet

- Ijirt152909 PaperDocument6 pagesIjirt152909 Paper1DC20AT025 Ganesh AkshayNo ratings yet

- Penebar SW55 PDSDocument2 pagesPenebar SW55 PDSAristya DhaneswaraNo ratings yet

- Contoh Report Final Year Projek PoliteknikDocument60 pagesContoh Report Final Year Projek PoliteknikSyfull musicNo ratings yet

- Architecture During AkbarDocument2 pagesArchitecture During AkbarShruti ParikhNo ratings yet

- Tunneling and TBM MethodDocument27 pagesTunneling and TBM MethodHuseyin OzturkNo ratings yet

- PROPOSED INTERIOR RENOVATION WORK FOR STATE BANK OF INDIADocument50 pagesPROPOSED INTERIOR RENOVATION WORK FOR STATE BANK OF INDIAMaulik ShahNo ratings yet

- Concrete Technology - Lecture 1Document11 pagesConcrete Technology - Lecture 1Taha Buğra ÖzdemirNo ratings yet

- Technical Specification 1Document73 pagesTechnical Specification 1mudassir mNo ratings yet

- 2018 Code Conforming Wood Design Updated ICCDocument54 pages2018 Code Conforming Wood Design Updated ICCVinícius Da Cunha FerreiraNo ratings yet

- Earthquake Resistant BuildingDocument36 pagesEarthquake Resistant Buildingsai projectNo ratings yet

- JSW PL 0522 Ing-NtcDocument3 pagesJSW PL 0522 Ing-NtcHuzefa RangwalaNo ratings yet

- 3D Printing in Construction: Best Practices for PrefabricationDocument8 pages3D Printing in Construction: Best Practices for PrefabricationAslıNo ratings yet

- 2020 - MIDAS - Lite VersionDocument1 page2020 - MIDAS - Lite VersionniteshNo ratings yet

- Lightweight Foam ConcreteDocument14 pagesLightweight Foam Concretegopi100% (4)

- Datasheet Cofraplus 60Document2 pagesDatasheet Cofraplus 60Giulia AlzettaNo ratings yet

- Network DiagramDocument7 pagesNetwork DiagramNemo SecretNo ratings yet

- General Notes 1 Steel WorkDocument18 pagesGeneral Notes 1 Steel Workmaga2292No ratings yet

- DT PracticeDocument20 pagesDT PracticeGeorge GruschowNo ratings yet

- Sedc RefresherDocument56 pagesSedc RefresherHarold GarciaNo ratings yet

- Shrike Build ManualDocument29 pagesShrike Build Manualvelok71No ratings yet

- Zach & Diane Jan 11Document16 pagesZach & Diane Jan 11Alexia E GuerraNo ratings yet

- 5-1940-8040 Rev. 05Document15 pages5-1940-8040 Rev. 05Mathi Vinoth PillaiNo ratings yet

- D317 - Illustration Second Sem. SY 2020 - 21 By: Arnedo O. SantosDocument82 pagesD317 - Illustration Second Sem. SY 2020 - 21 By: Arnedo O. SantosArchi HarraNo ratings yet

- Suitability of GFRG Panel For Residential BuildingDocument53 pagesSuitability of GFRG Panel For Residential BuildingPraveen KumarNo ratings yet

- Cist Graves in Macedonia and Their DecorDocument111 pagesCist Graves in Macedonia and Their DecorSadık TuğrulNo ratings yet

- Install HVAC Ductwork EfficientlyDocument5 pagesInstall HVAC Ductwork EfficientlyBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Orn401 BSL Tube and Clamp Product BrochureDocument8 pagesOrn401 BSL Tube and Clamp Product Brochuremarchus09No ratings yet

- Broadmeadow Estuary Bridge: Integration of Design and ConstructionDocument27 pagesBroadmeadow Estuary Bridge: Integration of Design and ConstructionRavi GuptaNo ratings yet

- Manpower DistributionDocument9 pagesManpower DistributionRyanNo ratings yet