Professional Documents

Culture Documents

Incinera

Incinera

Uploaded by

ambiental.yacopi3dOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Incinera

Incinera

Uploaded by

ambiental.yacopi3dCopyright:

Available Formats

United States Office of Water EPA 832-F-99-072

Environmental Protection Washington, D.C. September 1999

Agency

Water Efficiency

Technology Fact Sheet

Incinerating Toilets

DESCRIPTION C In areas where water is scarce due to drought

or other environmental conditions and the

Incinerating toilets are self-contained units need to conserve water motivates

consisting of a traditional commode-type seat consideration of alternative, water-free toilet

connected to a holding tank and a gas-fired or systems.

electric heating system to incinerate waste products

deposited in the holding tank. The incineration C Where community, environmental, and health

products are primarily water and a fine, non- organizations have concerns regarding

hazardous ash that can be disposed of easily and existing sewage disposal practices, especially

without infection hazard. seepage of contaminants into local water

supplies from improperly functioning septic or

APPLICABILITY other treatment systems, or exposure of

residents to improperly dumped waste

Though traditional water-flushing toilets are widely products from rudimentary collection pails

used throughout developed regions of the world, called “honey buckets.”

their use is not always feasible. For example:

All of these situations are potentially suited to the

C In rural areas where no municipal sewage use of incinerating toilets which are portable, water-

system exists, or where installation of septic free, and sanitizing.

systems is impractical or prohibitively

expensive due to shallow soils, steep slopes,

high groundwater levels, or extreme cold ADVANTAGES AND DISADVANTAGES

weather conditions.

Often touted as a “pollution-free” technology,

C For remotely located roadside rest areas, incinerating toilets have some clear advantages over

where connection to a piped sanitary system many traditional methods of sewage disposal. There

is impractical and the cost unjustifiable. are also disadvantages that should be considered.

C For work crews operating in areas where Advantages

permanent toilets are not available.

C Uses no water.

C In marine vessels, for which discharge of

untreated waste into bodies of water is C Incineration cycle produces a fine, sterile ash

prohibited; human wastes must either be that can be thrown in the trash.

stored in tanks while at sea or be treated prior

to discharge. C Ash is space-saving; as little as one

tablespoon of ash is generated on average per

use.

C Incinerating toilet systems are portable, system. Not all units can be used during the

simple to install, and easy to use. Can be incinerating cycle. Some units require initiation of

installed in remote areas, either for temporary an incinerating cycle after each use while others

or permanent use. Can be installed in allow for multiple uses before an incineration cycle

unheated shelters, even in freezing takes place.

temperatures.

Electric Incinerating Toilets

C Relatively odorless in comparison to more

commonly used storage-in-disinfectant The Incinolet electric incinerating toilet

portable toilets. (Blankenship/Research Products, 1999) is designed

with a paper-lined upper bowl that collects newly

C In most areas, can be used in unheated deposited waste. To “flush,” a foot pedal is pressed

shelters without fear of freezing. causing an insulated chamber cover to lift and swing

to the side while the bowl halves separate, dropping

Disadvantages the paper liner and its contents into the chamber.

When the foot pedal is released, the chamber is

C Incinerating process destroys nutrients in the resealed and the bowl halves return to normal

waste; ash is inadequate for replenishing soil position.

nutrients.

Incineration is initiated by pressing a “start” button

C Incinerating requires energy, resulting in after each use of the toilet. The manufacturer does

higher average energy costs for users. not recommend using the toilet multiple times

between incineration cycles. The toilet can continue

C Units are not entirely pollution-free; both to be used while incineration is in progress. Once

portable electric generation (for remote the “start” button is pressed, an electric heating unit

locations) and propane fuel burning produce cycles on-and-off for 60 minutes while a blower

some air pollutants. motor draws air from the chamber over a heat-

activated catalyst bed designed to remove odor

C Anti-foam agents, catalysts or other additives components. Upon leaving the catalyst bed, the air

are typically required for use. is forced out through a vent line. Makeup air for

the chamber is drawn from the room in which the

C Some models cannot be used while the toilet is operating. The blower motor continues to

incineration cycle is in progress. operate after the heating cycle to cool the unit. A

complete cycle takes from 1.5 to 1.75 hours.

DESIGN CRITERIA

Five models of the Incinolet electric toilet are

Specific design criteria depend on the type of energy available: two for fixed locations (one four-person

used for incineration. Incinerating toilets are capacity and one eight-person capacity); two

designed with a chamber that receives and stores mobile- location units for motor homes, trailers and

human wastes until ready for incineration. The boats (one four-person and one eight-person); and

incinerating chamber is typically composed of a urinal (eight-person). The smaller capacity units

stainless steel or a cast nickel alloy. The chamber is are designed for 120 volt service, while the larger

accessed through a toilet seat support—part of a units require 240 volts. All models retain the same

housing made of non-corroding fiberglass reinforced fundamental design principles described above.

plastic or similar material—having a sealable

receiving opening for introduction of wastes into the Gas-Fired Incinerating Toilets

chamber. Vapor and products of combustion are

fed by blower fan to a venting system which may be Propane or natural gas-burning incinerating toilets

as simple as an exhaust pipe, or which may also are manufactured by Storburn International, Inc.

incorporate an afterburner or other odor control (Storburn, 1999; Lake Geneva A&C Corp, 1977.)

These units are equipped with a three gallon storage months. The second household used the Incinolet

chamber which can accommodate 40 to 60 uses for approximately three years; however, toilet use

before initiation of an incinerating cycle. To initiate was intermittent over this period and the outdoor

the cycle, an anti-foaming agent is manually added privy was preferred because of incomplete

to the chamber, a pilot is lit using a built-in piezo- incineration of waste products. The second

electric igniter, and the burner is activated. This household installed a septic system to replace both

procedure automatically locks down the unit so it the Incinolet and the privy. The study

cannot be used while the burner is in operation. A acknowledges that the Incinolet manufacturer

complete incineration cycle takes approximately 4.5 subsequently added catalyst as an incineration aid,

hours for a full chamber. but notes that the basic configuration of the unit was

unchanged.

PERFORMANCE

Evaluation of 19 On-Site Waste Treatment

Systems in Southeastern Kentucky. Cold Weather Operation Study of a Storburn

Propane Combustion Toilet

A comparative “blackwater” (human excrement

waste) treatment study, known as the Appalachian Researchers from the Alaska Area Native Health

Environmental Health Demonstration Project Service and from the University of Alaska,

(AEHDP), was conducted in southeastern Kentucky Anchorage, conducted an examination of Storburn

during the 1970s (U.S. EPA 1980.) As part of the propane combustion toilets whereby honey bucket

year study, twenty prototype systems representing waste was collected over nearly a month and

several alternative treatment technologies were burned in a Storburn toilet using various batch sizes

installed in private residences in southeastern and burn cycle times (Ritz and Schroeder, 1994.)

Kentucky during 1970 and 1971, including six All burn cycles were conducted while the toilet and

incinerating toilets. The region used for the study propane fuel tank were located outdoors, with

was mountainous, characterized by shallow soils, ambient temperatures reaching as low as -11°C.

steep slopes and high groundwater, having a Anti-foam reagent was added to the contents of the

demonstrated need for alternative treatment combustion chamber before each cycle to prevent

methods. Further, the study was performed in a boil-over of liquid waste.

low-income area where cost of installation and

operation was a critical consideration. The Storburn was found to effectively reduce

human wastes to ash, even at low ambient

Two of the six toilets used in the study were temperatures. On the coldest day tested, the

Incinolet brand units and the remaining four were exhaust temperature was measured going from -

Destroilet brand propane-fired toilets. Since the 11°C to 100°C (the boiling point of water) only one

Destroilet is no longer on the market, and was minute after ignition. On average, the ash remaining

significantly different in design from propane-fired after incineration amounted to 2.23 percent of the

toilets available today, findings related to the total weight of waste treated in the Storburn.

Destroilet are not relevant to this Fact Sheet. Moreover, microbiological examination of the

Results pertaining to the Incinolet electric toilet, resulting ash revealed no fecal contamination. The

however, are still pertinent. coldest temperatures tested did adversely impact

incineration, however, because the contents of the

The two users of Incinolet toilets complained of propane tank could not vaporize properly. To

incomplete waste incineration. Scraping of partly maintain an optimal fuel supply to the toilet, the

burned feces from the walls of the incinerating authors of the study recommend keeping propane

chamber was periodically necessary. One household tanks sheltered or heated when used in sub-zero

using the Incinolet deemed the operating cost conditions.

excessive, and abandoned the incinerating toilet in

favor of their outdoor privy after approximately six

OPERATION AND MAINTENANCE h, this amounts to $160.00 per month or $1,920

annually.

Incinerating toilets are generally simple to operate,

either involving the press of a button to begin the According to the manufacturer, maintenance costs

operating cycle or the activation of a burner. The for the Incinolet include $0.08 per bowl liner used

degree of maintenance required depends on the (one per use), a new heating coil every one to three

model used. Storburn gas-fired toilets have no years ($89.10 each), and a new blower fan every

moving parts and routine maintenance involves two years ($8.95 each). Using the same

periodic cleaning of the burner and regular removal assumptions for frequency of use and replacing parts

of ash. every two years, the annual maintenance cost is

approximately $828.

Maintenance for the electric incinerating toilet

involves: Assuming a total purchase and installation cost of

$4,000, for a 10-year service life, the average annual

C Regular emptying of the ash collection pan. cost (including purchase, installation, operation and

maintenance averaged over 10 years) is $3,148 in

C Cleaning of the outer stainless steel surfaces 1999 dollars for the Incinolet electric toilet.

including the bowl halves.

Ritz and Schroeder performed a life-cycle cost

C Periodic (every 90 days) cleaning of the analysis for the Storburn propane toilet (Ritz and

blower motor with occasional replacement of Schroeder, 1994.) The authors calculated the

the blower wheel. annual operational cost per adult to be $233.60 and

the average annual maintenance cost to be $150.

C Cleaning and lubrication of the foot pedal Assuming a purchase and installation price of

mechanism. $4,000, the annual cost for four adult users

averaged over a 10-year service life is $1,484 in

C Removal of bits of paper and dust from the 1994 dollars. In 1999 dollars (assuming 5 percent

combustion chamber. inflation per year), this figure is equivalent to

$1,894. Since this estimate reflects unit operation

C Annual inspection of the catalyst. under cold-weather conditions, it may be assumed

that this represents the high end of the cost range;

COSTS the unit would require less energy for each burn

cycle when used indoors or in warmer climates, with

According to Incinolet product literature (Research correspondingly lower energy costs.

Products/Blankenship), a four-user electric

incinerating toilet costs $2,300; an eight-user toilet

costs $2,700. The purchase cost of a propane-

burning Storburn is $2,550; a natural gas-burning

unit costs is $2,590. Vent kits for both types of

toilet are not included in these costs.

The cost of electricity varies widely according to the

location of service. Domestic retail energy prices

can vary from $0.05 to $0.15 per kilowatt-hour.

The Incinolet electric toilet is claimed by the

manufacturer to use 2 kw-h per cycle. Assuming

four users, each using the toilet every 1.5 hours for

a use period of 10 hours, the electric toilet would

consume approximately 53 kw-h of energy per day,

or about 1,600 kw-h per month. At $0.10 per kw-

REFERENCES The mention of trade names or commercial products

does not constitute endorsement or recommendation

1. Lake Geneva A & C Corp, 1977. Store and for use by the U.S. Environmental Protection

Burn Incinerating Toilet and Method. Agency.

United States Patent US4051561.

2. Research Products/Blankenship. Incinolet

Electric Incinerating Toilet product ADDITIONAL INFORMATION

literature. Internet site at http:/www.

incinolet.com, accessed June 1999. Storburn International, Inc.

47 Copernicus Blvd., Unit #3

3. Ritz, P. and Schroeder, H.P., 1994. “Life Brantford, Ontario, Canada N3P 1N4.

Cycle Cost Analysis of a Storburn Propane Contact: David Gabriel, Owner

Combustion Toilet.” Paper presented at the Contact: Julie-Ann Friedrich

8th International Cold Regions Conference,

Fairbanks, Alaska. Research Products/Blankenship (Incinolet)

2639 Andjon Dr.

4. Storburn International. Storburn Dallas, TX 75220

International Inc. Gas-Fired Incinerating Contact: Carol McFarland

Toilet product literature. Internet site at

http://www3.sympatico.ca/storburn/, Dr. Herbert Schroeder

accessed June 1999. Associate Professor of Civil Engineering

University of Alaska

5. U.S. Congress, Office of Technology 3211 Providence Dr.

Assessment,1994. An Alaskan Challenge: Anchorage, AK 99508

Native Village Sanitation. OTA-ENV-591,

U.S. Government Printing Office,

Washington, DC.

6. U.S. EPA, 1980. Evaluation of 19 On-Site

Waste Treatment Systems in Southeastern

Kentucky. EPA 600/2-80-101, U.S. EPA,

Washington, DC.

For more information contact:

Municipal Technology Branch

U.S. EPA

Mail Code 4204

401 M St., S.W.

Washington, D.C., 20460

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Demineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsFrom EverandDemineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsRating: 4 out of 5 stars4/5 (2)

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Safe Energy Forever: + Pure water for the world and a cure for cancerFrom EverandSafe Energy Forever: + Pure water for the world and a cure for cancerNo ratings yet

- Rainwater Harvesting: Understanding the Basics of Rainwater Harvesting (Transform Your Home and Farm With Rainwater to Uncover Self-sufficiency Secrets)From EverandRainwater Harvesting: Understanding the Basics of Rainwater Harvesting (Transform Your Home and Farm With Rainwater to Uncover Self-sufficiency Secrets)No ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Drip Irrigation : Efficient Water Delivery for Crop GrowthFrom EverandDrip Irrigation : Efficient Water Delivery for Crop GrowthNo ratings yet

- No-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingFrom EverandNo-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingNo ratings yet

- Good Stoves Facilitation: How to Innovate and Change the WorldFrom EverandGood Stoves Facilitation: How to Innovate and Change the WorldNo ratings yet

- The Control of Indoor Climate: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandThe Control of Indoor Climate: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Eco-Friendly Plumbing Solutions: Sustainable Practices and Innovative Technologies for the Green Homeowner: Homeowner Plumbing Help, #5From EverandEco-Friendly Plumbing Solutions: Sustainable Practices and Innovative Technologies for the Green Homeowner: Homeowner Plumbing Help, #5No ratings yet

- From cleanup of fossil energy to space exploration without fuels and nuclear energyFrom EverandFrom cleanup of fossil energy to space exploration without fuels and nuclear energyNo ratings yet

- How to Be Self Sufficient for Survival Prepping, Sustainable Living and Surviving off the GridFrom EverandHow to Be Self Sufficient for Survival Prepping, Sustainable Living and Surviving off the GridNo ratings yet

- Garden Ponds, Fountains & Waterfalls for Your HomeFrom EverandGarden Ponds, Fountains & Waterfalls for Your HomeRating: 4.5 out of 5 stars4.5/5 (3)

- Environmental Fluid Dynamics: Flow Processes, Scaling, Equations of Motion, and Solutions to Environmental FlowsFrom EverandEnvironmental Fluid Dynamics: Flow Processes, Scaling, Equations of Motion, and Solutions to Environmental FlowsNo ratings yet

- Central Heating: A Design and Installation ManualFrom EverandCentral Heating: A Design and Installation ManualRating: 2 out of 5 stars2/5 (1)

- Water Damage Restoration and Clean Up ChecklistFrom EverandWater Damage Restoration and Clean Up ChecklistRating: 1 out of 5 stars1/5 (1)

- Synthetic Membrane Process: Fundamentals and Water ApplicationsFrom EverandSynthetic Membrane Process: Fundamentals and Water ApplicationsGeorges BelfortRating: 4 out of 5 stars4/5 (1)

- RENEWABLE ENERGY: Solar, wind and other sources for a sustainable futureFrom EverandRENEWABLE ENERGY: Solar, wind and other sources for a sustainable futureRating: 4.5 out of 5 stars4.5/5 (3)

- College of Arts and Communication: University of Eastern PhilippinesDocument4 pagesCollege of Arts and Communication: University of Eastern PhilippinesMark Johnson San JuanNo ratings yet

- Republic of The Philippines University Town, Northern SamarDocument14 pagesRepublic of The Philippines University Town, Northern SamarMark Johnson San JuanNo ratings yet

- Additional ActivitiesDocument6 pagesAdditional ActivitiesMark Johnson San JuanNo ratings yet

- Directions: Select The Letter That Represents Your Best Answer. UseDocument23 pagesDirections: Select The Letter That Represents Your Best Answer. UseMark Johnson San JuanNo ratings yet

- Attendance Sheet For The Month of September 2020Document11 pagesAttendance Sheet For The Month of September 2020Mark Johnson San JuanNo ratings yet

- School Year: 2nd Semester (2019-2020) Subject Code: PE 4 - Swimming Student ID Full NameDocument38 pagesSchool Year: 2nd Semester (2019-2020) Subject Code: PE 4 - Swimming Student ID Full NameMark Johnson San JuanNo ratings yet

- Edited-Hope2 - q2 - MODULE 3Document31 pagesEdited-Hope2 - q2 - MODULE 3Mark Johnson San Juan100% (2)

- Basketball Module 1Document11 pagesBasketball Module 1Mark Johnson San JuanNo ratings yet

- Basketball Modeule 2Document25 pagesBasketball Modeule 2Mark Johnson San JuanNo ratings yet

- Impact Basketball 2017 Team Training ProgramDocument10 pagesImpact Basketball 2017 Team Training ProgramMark Johnson San JuanNo ratings yet

- Course Title: Self-Defense (ARNIS) Course Code: P.E. 2Document13 pagesCourse Title: Self-Defense (ARNIS) Course Code: P.E. 2Mark Johnson San JuanNo ratings yet

- TechniqueDocument1 pageTechniqueMark Johnson San JuanNo ratings yet

- Edited-Hope2 - q2 - MODULE 4-Moderate To Vigorous Physical Actvities - BadmintonDocument24 pagesEdited-Hope2 - q2 - MODULE 4-Moderate To Vigorous Physical Actvities - BadmintonMark Johnson San Juan100% (1)

- Historical Development of Physical EducaDocument37 pagesHistorical Development of Physical EducaMark Johnson San JuanNo ratings yet

- Mid Term Examination-BSNDocument5 pagesMid Term Examination-BSNMark Johnson San JuanNo ratings yet

- TechniqueDocument1 pageTechniqueMark Johnson San JuanNo ratings yet

- Tubular Vent BinderDocument12 pagesTubular Vent BinderbayuNo ratings yet

- (Massimiliano Montini, Slavko Bogdanovic) Environm (Book4You)Document261 pages(Massimiliano Montini, Slavko Bogdanovic) Environm (Book4You)memoNo ratings yet

- Characteristics of Collapsi AND BLE Prob Soils Lems: FebruaryDocument23 pagesCharacteristics of Collapsi AND BLE Prob Soils Lems: Februaryศิวาเวช อบมาNo ratings yet

- Memo Nzasa Point FinalDocument109 pagesMemo Nzasa Point FinalmercuskusenzaNo ratings yet

- Galvanic Corrosion Lecture2Document12 pagesGalvanic Corrosion Lecture2Hashem Mohamed HashemNo ratings yet

- Cómo Abrir Un Negocio de Cría de CerdosDocument18 pagesCómo Abrir Un Negocio de Cría de CerdosMaurys LongartNo ratings yet

- Ingenieria Civil ContinentalDocument1 pageIngenieria Civil ContinentalWilder Saravia PomaNo ratings yet

- Curso Fractura Hidraulica - Semana 4.1Document77 pagesCurso Fractura Hidraulica - Semana 4.1rubenNo ratings yet

- Estudio de Suelos - ChojñacotaDocument54 pagesEstudio de Suelos - ChojñacotaAntonio Angles TarquiNo ratings yet

- Civil Engineering Important 138 MCQs Irrigation EngineeringDocument28 pagesCivil Engineering Important 138 MCQs Irrigation EngineeringVenkat Macharla55% (11)

- Restauración de Jardines Historicos en Mexico Saul AlcantaraDocument21 pagesRestauración de Jardines Historicos en Mexico Saul AlcantaraEduardo Hinojosa100% (1)

- Tasa de Recirculacion Del Trietilenglicol para Deshidratacion Por Absorcion Del Gas NaturalDocument14 pagesTasa de Recirculacion Del Trietilenglicol para Deshidratacion Por Absorcion Del Gas NaturalLaurys Maita ZambranoNo ratings yet

- S 821 - 826 - Manual - 2006Document174 pagesS 821 - 826 - Manual - 2006Centrifugal SeparatorNo ratings yet

- Sulthan Seyed Trading and Contracting SPCDocument3 pagesSulthan Seyed Trading and Contracting SPCSEYED SULTHANNo ratings yet

- Rhodiasolv Rpde Na: Safety Data SheetDocument19 pagesRhodiasolv Rpde Na: Safety Data SheetFrancisco EspinosaNo ratings yet

- Sieve Analysis LabDocument7 pagesSieve Analysis LabTinotenda ZembeNo ratings yet

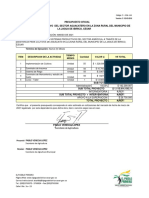

- Presupuesto Oficial Aguacate 2021Document9 pagesPresupuesto Oficial Aguacate 2021Shirley Mendez PalmaNo ratings yet

- DC Surface Solar SS PumpsDocument2 pagesDC Surface Solar SS Pumpsnairsangeet9No ratings yet

- Hoja IMPRESIONDocument2 pagesHoja IMPRESIONAdministración HWPNo ratings yet

- MINI PETA 1.2 Sample Script With InstructionDocument4 pagesMINI PETA 1.2 Sample Script With Instructioncristine venzonNo ratings yet

- Why The Need For The Clean Water Act?Document4 pagesWhy The Need For The Clean Water Act?Jerry Eduardo II BonaguaNo ratings yet

- Manta 01Document10 pagesManta 01hugisNo ratings yet

- Ecosistemas AcuaticosDocument13 pagesEcosistemas AcuaticoscarlosNo ratings yet

- Invertebrates: Rachel Reed & Erin BaxterDocument54 pagesInvertebrates: Rachel Reed & Erin BaxterJamesNo ratings yet

- 2 Planning PF Coastal Protection Measures Along Kerala CoastDocument209 pages2 Planning PF Coastal Protection Measures Along Kerala CoastVarsha RanganathaNo ratings yet

- Solucionario Examen Final de Construcción 1Document6 pagesSolucionario Examen Final de Construcción 1Elita Lucy Meza Sabino100% (1)

- App H - Evaluation of Sludge Dryer and Dewatering FacilitiesDocument77 pagesApp H - Evaluation of Sludge Dryer and Dewatering FacilitiesRajan BhosaleNo ratings yet

- Riego Por GravedadDocument21 pagesRiego Por GravedadSophia Angela ParedesNo ratings yet

- Ciudad-Imperial Terraza de PumapunkuDocument23 pagesCiudad-Imperial Terraza de PumapunkuyemoarequipaNo ratings yet

- Drainage SystemDocument2 pagesDrainage SystemAlbert Andrew FloresNo ratings yet