Professional Documents

Culture Documents

Articol ICATE2018 Dinisfinal 2

Uploaded by

TurkogluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Articol ICATE2018 Dinisfinal 2

Uploaded by

TurkogluCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/329292021

Automation of a Pneumatic Cement Transport Installation Using PLC

Conference Paper · October 2018

DOI: 10.1109/ICATE.2018.8551374

CITATION READS

1 3,030

2 authors:

Corina Maria Dinis Gabriel Nicolae Popa

Polytechnic University of Timisoara Polytechnic University of Timisoara

81 PUBLICATIONS 185 CITATIONS 129 PUBLICATIONS 389 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Gabriel Nicolae Popa on 11 February 2019.

The user has requested enhancement of the downloaded file.

Automation of a Pneumatic Cement Transport

Installation Using PLC

Corina Maria Diniş Gabriel Nicolae Popa

Department of Electrical Engineering and Industrial Informatics Department of Electrical Engineering and Industrial Informatics

Politehnica University Timișoara Politehnica University Timișoara

Hunedoara, Romania Hunedoara, Romania

corina.dinis@fih.upt.ro gabriel.popa@fih.upt.ro

Abstract— The paper proposes the use of the PLC for the machine tools [9-14]. By connecting the system to PLCs and

automation of a pneumatic cement transport installation. This CPUs process, being a result of rapid technological progress,

type of installation is used inside cement plants as part of the most complex operations were solved. These PLCs besides

cement production process and other products derived from it. connections to instrumentation and sensors in the automation

PLCs control installation replaces a classical control installation, process, should allow control of the whole process and to

less reliable, with contacts and relays. For the control of the communicate to the operator the process states by visual and

pneumatic transport of the cement was using Zelio PLC and one sounds signals and/or through a communications network to a

extension module, to increase the numbers of digital inputs and

local computer. The PLCs feature allow automation operation

outputs, connected to PLC. The program was developed in

of the control unit to a high degree of flexibility by changing

function block diagram. Using PLC's controls, the installation

has been considerably simplified, and troubleshoot installations

and more convenient monitoring of basic parameters of the

are much easier. process [15-17].

PLCs are structures for control of industrial process, whose

Keywords—PLC, FBD, control, pneumatic transport, level sensors, implementation was used to eliminate the wired logical

cement structures and to replace them with programmable logical

structures. The majority of PLCs can be programmed via PC,

I. INTRODUCTION but it is possible to be programmed manually with the console,

The cement business has been a rush of expansions, or in case of low capacity PLCs, using the buttons and display

acquisitions, and automations over the last decades. As in other on the front of them. The best method of reprogramming the

industries, the quality control standards have to be met in the PLCs is using the PC, thanks to the possibility of building,

cement industry. The most important technological saving and debugging the programs. Intelligence of the PLCs

developments in the cement industry took place in the last consist in the ability to detect different types of sensors, input

century through technological improvements in various areas: and/or output devices [6,18-20].

bagging, palletizing and packing automation, high efficiency Zelio Logic smart relays (low capacity PLCs) - Schneider

cooling technology, milling developments, high efficiency Electric product - are use in small automation systems

separators, the bulk load facility, installation of roll press, comprising 10 to 40 inputs/outputs (digital and/or analogue).

modern control algorithms with applications in cement These relays can be used both in domestic (light installations,

industry, and so on [1-4]. alarm, etc.), industrial applications (small machinery, irrigation,

Pneumatic transport systems can be used for charging, pumping stations, etc.), and in the commercial (management of

transporting, and unloading powders. These systems are lighting, ensuring the heating, air conditioning, etc.).

common in the cement industry because they are reliable and Programming can be done directly using the buttons on the

less polluting. There are still control systems made with relays or on a PC using Zelio Soft with a programming cable,

contacts and relays (wired logic) that control such systems. with the possibility of programming in Function Block

Most often used in practice there are automation systems Diagram (FBD) or in Ladder Diagram (LD) [21-23].

containing both wired logic and programmed logic [5]. The paper presents the automation, made in a cement plant,

In the last century a new approach was design to for the pneumatic transport of cement between the sectors of

automation systems using programmable logic controllers the factory. Automation was done with a low capacity PLC and

(PLCs) that operate with a code write into a program memory. an extension module to increase the numbers of digital inputs

Various sensors can be connected to PLCs inputs and different and outputs.

actuators at their outputs, so that they can be implemented in

most industries, including the cement industry [6-8]. II. CEMENT PNEUMATIC TRANSPORT INSTALLATION

In industry, automated process control systems are a This type of installation is used inside cement plants as part

conglomeration of electronic devices that provides stability, of the cement production process and other products derived

accuracy, and, not least, performance. Operating systems can from it (Fig.1). The pneumatic cement transport installation has

have different implementations from power supplies to the following main components presented in Fig.2.

XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEE

Fig. 1. Positioning in the production plant of the pneumatic transport of

cement.

• Silo for storage of the material to be transported;

• Pressurised container;

• Electro-pneumatic devices;

• Cabinet with electric control devices.

Fig. 3. The detailed components of the cement pneumatic transport system.

• Fluid valve/bleeder - this components are used only

when the charging valve is open, by injecting

compressed air into the bottom of the silo cone in the

area between the silo and the pump, bubbling the

material from the bottom of the silo, making it flow

more fluidly, inside the pump;

• High pressure sensor - this is set to a 1.2 - 2 bar

threshold, during this time the electrical contact of this

sensor is closed, signaling the PLC that there is pressure

Fig. 2. The main components of the cement pneumatic transport system. in the pump (cylinder);

• Low pressure sensor - set between 0.2-0.1 bar, for

In Fig.3, the components of the pneumatic transport

example 0.2 bar. It closes the contact only when the

installation of the cement are described. The main features and

pressure inside the pressure pump drops below 0.2 bar,

roles of the components of the pneumatic cement transport

indicating the PLC that there is no pressure inside the

system and the functional description of these components are

cylinder;

presented below:

• Pressure pump - the cylinder of the installation, which is

• The silo of the installation - it has the role of storing the

pressurized for pneumatic transport, the pressure inside

material that comes from the production stream, to be

it, pushing the material from the pump to the bottom,

transferred to the pressurized cylinder (pressure pump)

which is discharged through the drawer at the bottom;

for transportation;

• Maximum pump level sensor - is designed to signal to

• The maximum and minimum level sensors of the silo

the PLC that the pressure pump (cylinder) is full with

are designed to signal the PLC, the level of material in

material;

the silo, signals used for the automatic or manual

loading of the pressure pump with material; • Minimum pump level sensor – it’s the role of signaling

the PLC, that the pressure pump is empty, there is no

• Pump decompression pipe - is designed to allow the air

material inside it;

pressure to be exhausted inside the pressure pump at the

top of the silo when the pump is depressurized if the • Pump Pressure Pump - it has the role of allowing the

transport cycle stops or the pressure pump is compressed air to enter inside the cylinder (pressure

depressurized to reload the material; pump), which stands at the top of the pump, making the

internal working pressure of the installation (for

• Decompression valve - to maintain or release the

example 1.7 bar);

pressure inside the pneumatically pressurized pump;

• Air Pneumatic Valve - it is a pneumatic assembly with

• Pneumatic valve for filling the pump, by opening it,

four electro-valves that allows proportional opening of

filling/refilling the pressure pump with silo material;

the drawer between 0 and 100% in four steps (25%,

50%, 75%, and 100%) and, of course, the closed

position;

• The pneumatic drawer - is a mechanical assembly with a

drawer plate that slides on two runways, depending on

the PLC prescription, which controls the four

compressed air suction valves, the drawer has the

following positions: closed, open 25%, open 50%, open

75% or 100% open.

III. AUTOMATION OF CEMENT PNEUMATIC TRANSPORT

INSTALLATION WITH ZELIO PLC

The present application requires a large number of digital

inputs and outputs, so it was chose a Zelio SR3B261BD PLC,

24V DC type, with 10 digital inputs (1 logic, 24V DC) and 10

digital relay outputs, and SR3XT141BD extension module,

which has 8 digital inputs, 24 V DC, and 6 relay digital output,

24 V DC. To programming PLC was used FBD (Function

Block Diagram) language [24].

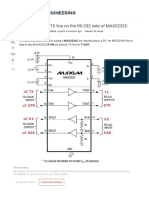

Using PLC type it will use hardware configuration from the

software (Zelio Soft 2). In application, it was choose from

Zelio 2 software, Zelio SR3B261BD PLC, SR3XT141BD

module extension (Fig.4), and FBD the programming language

(Fig.5).

Fig. 7. The digital inputs of the PLC and extension module.

Fig. 4. Configuring PLC and PLC extension in the software.

Fig. 5. Information regarding final hardware configuration PLC.

Fig. 6. Programmable buttons of the PLC.

In the Figs. 6-8 are shown programmable buttons, input and

output variables of the PLC used in the program. In the Fig.9 is

shown programming functions displayed information on the

PLC. Fig. 8. The digital outputs of the PLC and extension module.

position, the “Automatic” message will appear on the PLC

display, so that the user knows the operating mode of the

installation (Fig.10).

When the plant is in automatic mode, the cement powder

transport air is not set. In order to be able to start the

installation in automatic mode, it is necessary to set the

transport air flow beforehand. The transport air flow is set by

briefly pressing the four buttons of the PLC (Fig.11).

To start the pump, press the “Start automatically” button,

assuming all the conditions are met, the cement pumping cycle

will start automatically, turning on the automatic lamp on the

electric panel.

Fig. 10. Automatic operation of the pneumatic transport installation.

The air flow rate must be set before starting the installation

in automatic mode (before pressing the “Start Auto” button),

otherwise the button does not start, and the display of the PLC

shows “Transport air unset“. Once the transport air flow rate

has been set, the installation can be switched on automatically

mode and the air flow rate setting can be changed during

operation.

Fig. 11. Adjusting the air flow rate.

Considering that there is material in the pressure pump, so

the minimum level sensor is not activated, the transport air flow

rate has been set, then it will engage the pressurized air

pressure cylinder to the working pressure of 1.7 bar. When the

pressure inside the pump reaches 1.7 bar, the maximum

pressure sensor will close the ignition, the PLC deactivate the

pressure pump valve, and the internal pressure remains at 1.7

Fig. 9. Programming functions displayed information on the front of PLC.

bar.

During the operation of the pump, due to the fact that the

IV. DESCRIPTION OF THE PROGRAM IMPLEMENTED IN THE level of material inside it decreases, it is evacuated from the

ZELIO PLC pump to achieve the transport, the pressure will also decrease.

With the pressure drop below 1.7 bar in the pump, the pressure

A. Operation in Automatic and Manual Modes sensor contact will open and the PLC will command again the

For the automatic mode of the pneumatic transport system, opening of the compressed air valve to pressurize the pump,

the mode selection key must be in the “Automatic” position thus keeping the pressure inside the pump constant, in the range

(Fig.10). When the mode key is moved to the “Automatic” 1.6-1.7 bar.

When the installation is started automatically, the transport silo and will display the message “Min. pump”. At this point

air being set (25%, 50%, 75%, or 100%), the pneumatic drawer we will have the “Fault” light on and two indications on the

of the pressure pump will open, leaving the cement in the form screen of the PLC: “Min. silo“ and “Min. pump“, the operator

of powder to fall into the transport pipe pneumatically, being being informed about the situation. Having these two failures,

transported to the next destination within the cement plant. the cement pumping cycle in automatic mode is disabled.

Opening the pneumatic drawer for evacuating the material from

the pressure pump will be proportional to the air flow rate After reloading the material silo, pump filling can be done

setting, for example if the transport air has been set to 75%, the either manually by pressing the “ Start filling pump” button or

drawer will open to 75%, so it is regulated by the amount of by pressing the “ Automatic start” button, the PLC checks the

pumped material (pneumatically carried) in the unit of time. information from the system sensors, and because there is no

material in the pump and in silos, it will make the decision to

If during automatic transport, the material inside the start the pump filling cycle and then resume the pumping cycle

pressure pump ends (the minimum level sensor in the pump is manually.

activated), the “Min. pump” is displayed. At this time it is

necessary to automatically recharge the pressure pump. This In the manual material loading mode of pressure pump, the

load is as follows: mode selection key must be in the “ Manual” position, and the

minimum material level sensor in the silo must not be

• Close the pneumatic drawer at the bottom of the pump; activated. Manual pump loading can be done even if the pump

level has not reached the minimum level, but if the maximum

• The pressure pump is depressurized by activating the level sensor or the minimum level sensor is activated during

decompression electro-valve at the top of the pump, the charging, the charging stops automatically.

pressure inside the pump being discharged through a

pipe into the silo of the installation; All electro-pneumatic valves and electro-valves of the

installation can be handled manually, taking into account some

• When the pump is depressurized, the pressure inside it conditions such as:

will drop to 0 bar, at this moment the low pressure

sensor will close the contact by giving the pump load • The key to select the operating mode of the installation

condition (0.2 bar); must be in the “Manual” position;

• After the pressure inside the pump has dropped below • For the opening of the truck loading valve, between the

0.2 bar and if there is material in the upper silo, the silo and the pump, the pressure inside the pump must be

pneumatic valve opens between the silo of the below 0.2 bar, etc.

installation and the pump, leaving the material to

descend from the silo in the pump; B. Treating failures

• During charging with the pump material, the charge At the start of the installation, the exhaust system of the

valve fluid is activated intermittently. This air is blown installation and the loading valve between the silo and the

inside the connecting piece between the silo and the pump must be in the “closed” position. After the installation

pump by means of three jets mounted around it at an has been started, the drawer must be in the “open” position,

angle of 120°; between 25% and 100%, depending on the air transport setting.

In the 0% position, the drawer is considered to be in the closed

• During filling, the material level inside the pump position, and between the 25% and 100% positions it is

increases until it reaches the maximum level sensor, the considered open, so the limiting (position sensors) of the

pump load is considered to be completed and the PLC drawer are adjusted according to these physical values of the

stops charging automatically. drawer stroke. The position sensors for these two elements are

connected to the digital inputs of the PLC and the signalling of

After the pump is again pressurized to 1.7 bar, the operating

the physical state of these sensors is made directly to the

cycle will be resumed automatically, i.e. the pneumatic drawer

signalling lamps at the 24 V DC voltage on the cabinet door

at the bottom of the pump will open and the transport air flow

due to the low number of PLC digital outputs.

will increase to the set value, thus continuing automatic

transport. The emergency stop button stops the automatic operation of

the installation, automatically depressurizing the pressure

If during pump loading, either in automatic or manual

bottle. Also, the loading cycle in automatic and manual mode is

mode, the minimum material level in the silo is reached, the

interrupted if the emergency stop button is pressed.

pump charging cycle will be interrupted even if the pump is not

fully charged. The operator will know of the anomaly, due to

the “Fault” lamp illuminated on the control panel and the “Min.

silo “displayed on the PLC display.

If the end of the material in the silo is done during the

pump's automatic recharging and if the level in the pump is

above the minimum level sensor, the pumping cycle will be

restarted automatically until the material inside the pump. At

this point, the PLC will not initialize the pump recharge cycle, Fig. 12. Display of the fault condition due to the load limiting position limiters

because it has the information that there is no material in the and the installation drawer and display the emergency stop message.

When the emergency stop button is pressed, the emergency REFERENCES

stop message (Fig.12) is displayed on the PLC display. The

[1] N. Sutherland and R. Anbari, “High Efficiency Cement Cooling”,

program created in the PLC uses all the inputs and all digital Cement Industry Technical Conference (CIC), 2014 IEEE-IAS/PCA, 13-

outputs of the PLC (Fig.13). The program was made in FBD 17 April 2014, National Harbor, MD, USA, pp.1-6.

and are shows in Fig.14. [2] J. Knabbe, “Technical Advancements in Automation of Cement

Dispatch Terminals”, Cement Industry Technical Conference, 2000

IEEE-IAS/PCA, 7-12 May 2000, Salt Lake City, UT, USA, pp.1-6.

[3] L. Rice, “Automated Cement Loadout-Technology and Experience”,

Cement Industry Technical Conference, 2003. Conference Record.

IEEE-IAS/PCA 2003, 4-9 May 2003, Dallas, TX, USA, USA, pp.1-6.

[4] A.K. Swain, “Material Mix Control in Cement Plant Automation”, IEEE

Control Systems, Vol.15 (4), pp.23 – 27, 1995.

[5] F. Wuertele, “Equipment and Design Considerations for

Environmentally Safe Cement Distribution Terminals”, Cement Ind.

Fig. 13. Zelio SR3B261BD PLC and SR3XT141BD extension module. Tech. Conf., 35th IEEE, 23-27 May 1993,Toronto, Ont., Canada, pp.1-6.

[6] W. Bolton, Programmable Logic Controllers, Elsevier, 2006.

[7] I. Mărgineanu, PLCs, Albastră Publishing House, Cluj-Napoca, Romania

(in Romanian), 2005.

[8] G. N. Popa, I. Popa and S. I. Deaconu, PLCs in Applications, Mirton

Publishing House, Timișoara, Romania (in Romanian), 2006.

[9] V. P. Nelson and H. T. Nagle, Digital Logic Circuit Analysis and

Design, Prentice Hall, NJ, USA, 1995.

[10] J. Hugh, Automating Manufacturing Systems with PLCs, Version 5.0,

May 4, 2007.

[11] P. De Larminat, Automatique Appliquée, Hermès – Lavoisier, Février,

France, 2007.

[12] K. Bhujbal and A. Barve, “Automation of Scrap Disposal System Using

PLC,” Advance In Electronic And Electric Engineering, Vol.3 (1), pp.

107-112, 2013.

[13] I. Baciu and C.D. Cunțan, “Operation Analysis of a Frequency Converter

with Control Realized in LabView,” IEEE International Conference on

Industrial Technology, Athens, Greece, March 19-21, pp.432-437, 2012.

[14] C.D. Cunțan, I. Baciu and M. Osaci, “Operational Study of a Frequency

Converter with a Control Sequence, Utilizing Xilinx Software,” Acta

Polytechnica Hungarica, Vol.12 (6), pp. 201-212, 2015.

Fig. 14. The sequences of program (in FBD) implemented in PLC. [15] L. Popa and V. Popa, “An Innovative Approach for Modeling and

Simulation of an Automated Industrial Robotic Arm Operated Electro-

Pneumatically,” IOP Conf. Series: Materials Science and Engineering,

V. CONCLUSIONS 227, 012097, 2017.

[16] ***, Industrial Automation, Efficient and Robust Semiconductor

PLCs are often found in industrial applications and, even, in Sollutions, Infineon, 2013.

home applications. Due to the implementation in program of [17] L. Keviczky, “Automation and Control in Cement Industries”,

the command logic, programs that can be performed in Control Systems, Robotics, And Automation, Vol. XIX, 2012, pp.1-8.

different programming languages (instruction lists or graphics), [18] Y. N. Burali, “PLC Based Industrial Crane Automation and

control diagrams can be created, debug, and test quickly Monitoring”, Int. Journal of Eng. and Sci., Vol.1 (3), pp. 01-04, 2012.

compared to old command systems (wiring diagrams) that [19] M.G. Ioannides, “Design and Implementation of PLC-Based Monitoring

involved a considerable number conductors, electrical, and Control System for Induction Motor,” IEEE Transactions on Energy

electronic devices. Conversion, Vol.19 (3), pp. 469-476, 2004.

[20] C. Illes, G. N. Popa, and I. Filip, “Water Level Control System Using

Although low-capacity PLCs have been designed to PLC and Wireless Sensors,” IEEE 9th Int. Conference on Computational

monitor and control relatively independent applications (no Cybernetics (ICCC), Tihany, Hungary, July 8-10, pp.1-6, 2013.

communications with other monitoring equipment), they have [21] S. Sumardi, “Room Temperature Control System Prototype Industry

now found applications in various industrial areas, such as the Based Programmable Logic Controller Zelio SR2 B121 BD,” Innovative

cement industry. By using low-capacity PLCs, easy monitoring Systems Design and Engineering, Vol.6 (4), pp. 52-58, 2015.

and convenient control of the pneumatic transport installation [22] M. Aziz Muslim, N. Goegoes Dwi and A. Mahkrus, “Zelio PLC – based

automation of coffee roasting process,” The 6th – Electrical Power,

for cement is made. Electronics, Communications, Controls, and Informatics International

In cement industry the process control system is use to Seminar, Brawijaya University, Malang, Indonesia, May 30-31, pp.102-

106, 2012.

improve operational and energy efficiency. Using PLCs in

[23] C.M. Diniș, G.N. Popa and A. Iagăr, “Automation Heating and Pumping

control of cement industry the energy efficiency can be for Water Using Zelio PLC,” The 10th International Symposium on

improve since it is a big consumer of electricity, oil, coal, and Advanced Topics in Electrical Engineering, Bucharest, Romania, March

natural gas. Also, the air pollution is diminished in condition 23-25, pp.903-908, 2017.

the cement industry is the third largest emitter of greenhouse [24] ***, Zelio PLC. User’s Manual, Zelio Schneider Electric, 2007.

gases globally.

View publication stats

You might also like

- Wet Well Tech ReportDocument46 pagesWet Well Tech ReportGabrielGrecoNo ratings yet

- Meteorology Konu Konu Ayrılmış SorularDocument278 pagesMeteorology Konu Konu Ayrılmış Sorularjames100% (1)

- PLC Scada Training ReportDocument31 pagesPLC Scada Training ReportÄkshãy SaçhånNo ratings yet

- National Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byDocument31 pagesNational Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byÄkshãy SaçhånNo ratings yet

- Project SCADA Kel 1Document28 pagesProject SCADA Kel 1Muhammad KhairuddinNo ratings yet

- VecchiDocument4 pagesVecchiAnonymous 1n5HpBjNo ratings yet

- Pesa 2009 K210509077Document5 pagesPesa 2009 K210509077Lilamala LilavelikaNo ratings yet

- Automation FileDocument56 pagesAutomation FileLoveable ShubhamNo ratings yet

- July Univ - 375Document7 pagesJuly Univ - 375Nils BickelNo ratings yet

- Automatic Bottle Filling System Using PLC Conveyor ModelDocument71 pagesAutomatic Bottle Filling System Using PLC Conveyor ModelRanjith Kumar67% (3)

- ProceedingsofCERIE2011Screw 1Document6 pagesProceedingsofCERIE2011Screw 1abuthahirNo ratings yet

- PLC Based Automatic Liquid Filling System For Different Sized BottlesDocument6 pagesPLC Based Automatic Liquid Filling System For Different Sized BottlesRodel GamaleNo ratings yet

- Distributed Control Systems: Process Control in The Chemical IndustriesDocument14 pagesDistributed Control Systems: Process Control in The Chemical IndustriesAhmad HamoudaNo ratings yet

- Automation Summer Training ReportDocument45 pagesAutomation Summer Training ReportLaxman GautamNo ratings yet

- Implementation of Communication System Between Siemens PLC S7-1200 With Omron PLC CP1L-EL20DT1-D For Induction Motor Speed ControllerDocument9 pagesImplementation of Communication System Between Siemens PLC S7-1200 With Omron PLC CP1L-EL20DT1-D For Induction Motor Speed ControllerDuy KhổngNo ratings yet

- Automation of Tank Level by Using PLC and SCADA / HMI: ISSN: 2454-132X Impact Factor: 4.295Document9 pagesAutomation of Tank Level by Using PLC and SCADA / HMI: ISSN: 2454-132X Impact Factor: 4.295Nils BickelNo ratings yet

- The PLC in Automation TechnologyDocument22 pagesThe PLC in Automation TechnologyAthira AnandNo ratings yet

- Honeywell Dcs ArchitectureDocument14 pagesHoneywell Dcs ArchitectureVanama MalaiNo ratings yet

- Implementation of Home Automation Safety Control Using Programmable Logic ControllerDocument10 pagesImplementation of Home Automation Safety Control Using Programmable Logic ControllerAnjaneyulu NaikNo ratings yet

- Application of PLC in The Wind Power IndustryDocument1 pageApplication of PLC in The Wind Power IndustryjyothimidhunaNo ratings yet

- Boiler Application Using Wireless Bridge Between PLC and ScadaDocument6 pagesBoiler Application Using Wireless Bridge Between PLC and ScadaDhaval MehtaNo ratings yet

- Automatic Liquid Filling To Bottles of Different Height Using Programmable Logic ControllerDocument3 pagesAutomatic Liquid Filling To Bottles of Different Height Using Programmable Logic ControllerVishwa DissanayakeNo ratings yet

- Automation & ControlDocument41 pagesAutomation & Controlkaushal2442No ratings yet

- Report AcknowledgmentDocument45 pagesReport Acknowledgmentrajubhati41No ratings yet

- Programable Logic Control (PLC) As A Smart Services in Industry With Internet of Things (Iot)Document23 pagesProgramable Logic Control (PLC) As A Smart Services in Industry With Internet of Things (Iot)Vishal kaushikNo ratings yet

- Design and Implementation of A Configurable Programmable Logic Controller Using Microchip PICDocument5 pagesDesign and Implementation of A Configurable Programmable Logic Controller Using Microchip PICPallavi GuptaNo ratings yet

- Indraprastha Gas Limited (Igl)Document51 pagesIndraprastha Gas Limited (Igl)shyamNo ratings yet

- Programmable Logic ControllerDocument74 pagesProgrammable Logic ControllerNaga RajanNo ratings yet

- Lec - 5-Introduction To PLCDocument60 pagesLec - 5-Introduction To PLCNurhussen NureNo ratings yet

- Review PaperDocument7 pagesReview PaperRoch RonaldoNo ratings yet

- Refrigeration Unit DesignDocument4 pagesRefrigeration Unit Designosvaldo350No ratings yet

- Automation of Captive Power Plant Using PLC and DcsDocument3 pagesAutomation of Captive Power Plant Using PLC and DcsAnju JacobNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- PLC AutomationDocument47 pagesPLC AutomationAman AJNo ratings yet

- PLC Based Automatic Liquid Filling Syste PDFDocument5 pagesPLC Based Automatic Liquid Filling Syste PDFAzhis MaulanaNo ratings yet

- PLC Manual - 1803096 - Mayank Shahabadee - FINALDocument72 pagesPLC Manual - 1803096 - Mayank Shahabadee - FINALMayank Shahabadee67% (3)

- 563 2046 1 PB PDFDocument11 pages563 2046 1 PB PDFWaleed AliNo ratings yet

- Automatic Filling Management System For Industries Saubhagya Tandon, Shreya Srivastava, Sandeep Pal Srji Vol 3 Issue 2 Year 2014Document6 pagesAutomatic Filling Management System For Industries Saubhagya Tandon, Shreya Srivastava, Sandeep Pal Srji Vol 3 Issue 2 Year 2014Dr. Krishna N. SharmaNo ratings yet

- Paper Mill Operation and TheoryDocument85 pagesPaper Mill Operation and TheoryS Bharadwaj Reddy50% (2)

- Application of Industrial PLC For Controlling Intelligent Traffic LightsDocument4 pagesApplication of Industrial PLC For Controlling Intelligent Traffic LightsAFAFNo ratings yet

- Boiler Automation PDFDocument5 pagesBoiler Automation PDFHarshada DeokateNo ratings yet

- Automated and Monitored Liquid Filling System Using PLC TechnologyDocument5 pagesAutomated and Monitored Liquid Filling System Using PLC TechnologyKun DikiNo ratings yet

- Application of PLC's For Automation of Processes in IndustriesDocument7 pagesApplication of PLC's For Automation of Processes in IndustriesMHMDNo ratings yet

- Efficient Automation of Concrete Batching Plant Using PLC & Scada Project Reference No: 38S0193Document4 pagesEfficient Automation of Concrete Batching Plant Using PLC & Scada Project Reference No: 38S0193Gangadhar PradhanNo ratings yet

- Efficient Automation of Concrete Batching Plant Using PLC & Scada Project Reference No: 38S0193Document4 pagesEfficient Automation of Concrete Batching Plant Using PLC & Scada Project Reference No: 38S0193Gangadhar PradhanNo ratings yet

- PLC Based Liquid Filling and Mixing-1227Document5 pagesPLC Based Liquid Filling and Mixing-1227Castellani SolisNo ratings yet

- Summer TrainingDocument42 pagesSummer TrainingAman yadavNo ratings yet

- Control of Boiler Operation Using Plc-ScadaDocument4 pagesControl of Boiler Operation Using Plc-ScadaSiddhantNo ratings yet

- Unit II Course MaterialDocument11 pagesUnit II Course MaterialKumaresan ElectronicsNo ratings yet

- Automatizirano Upravljanje Crpnom Stanicom: Automation of Sewage Pumping StationDocument5 pagesAutomatizirano Upravljanje Crpnom Stanicom: Automation of Sewage Pumping StationMartin PervanNo ratings yet

- Chapter 4 FinalDocument11 pagesChapter 4 Finalmuhaba muhamedNo ratings yet

- Cost Effective Monitoring and Automation of Concrete Plant Using PLCDocument10 pagesCost Effective Monitoring and Automation of Concrete Plant Using PLCmelad yousefNo ratings yet

- Industrial Training Report: Sri.B.SharanappaDocument40 pagesIndustrial Training Report: Sri.B.SharanappaKollu dhruvaNo ratings yet

- Control System Design of The Pumping StationDocument6 pagesControl System Design of The Pumping StationblackbriaruyjvhvjNo ratings yet

- Air Supply For Industrial Process (PLC, SCADA & DCS) - The Start of Industrial Automation Systems EvolutionDocument55 pagesAir Supply For Industrial Process (PLC, SCADA & DCS) - The Start of Industrial Automation Systems EvolutionDhiraj PrakashNo ratings yet

- PLC SCADA Training ReportDocument37 pagesPLC SCADA Training ReportAarif HussainNo ratings yet

- Simulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIDocument6 pagesSimulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIEditor IJTSRDNo ratings yet

- PLCDocument11 pagesPLCJohn Larrence Carpio OrigenesNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Building Automation: Communication systems with EIB/KNX, LON and BACnetFrom EverandBuilding Automation: Communication systems with EIB/KNX, LON and BACnetNo ratings yet

- 13.8V 20A Linear Power SupplyDocument4 pages13.8V 20A Linear Power Supplymyemail1964100% (1)

- Noctua PWM Specifications White PaperDocument8 pagesNoctua PWM Specifications White PaperTurkogluNo ratings yet

- AVRJTAG Clone in Action - Do It Easy With ScienceProgDocument13 pagesAVRJTAG Clone in Action - Do It Easy With ScienceProgTurkogluNo ratings yet

- CYD277Document4 pagesCYD277TurkogluNo ratings yet

- RS232-TTL Module MAX3232 (4691) Sunrom ElectronicsDocument5 pagesRS232-TTL Module MAX3232 (4691) Sunrom ElectronicsTurkogluNo ratings yet

- PC400TDocument4 pagesPC400TTurkogluNo ratings yet

- Crosstalk From RX To TX Line On The RS-232 Side of MAX3232CDocument4 pagesCrosstalk From RX To TX Line On The RS-232 Side of MAX3232CTurkogluNo ratings yet

- ADUM1301 Datasheet and Product Info Analog DevicesDocument1 pageADUM1301 Datasheet and Product Info Analog DevicesTurkogluNo ratings yet

- Web Solar Gune Sen Erji ArduinoDocument1 pageWeb Solar Gune Sen Erji ArduinoTurkogluNo ratings yet

- TX 1Document14 pagesTX 1TurkogluNo ratings yet

- Samsung C100 Dataflash AllPinoutsDocument3 pagesSamsung C100 Dataflash AllPinoutsTurkogluNo ratings yet

- Manual DGT V2 ENGDocument51 pagesManual DGT V2 ENGTurkogluNo ratings yet

- aTQ229 5V PanasonicDocument11 pagesaTQ229 5V PanasonicTurkogluNo ratings yet

- NLSF595Document15 pagesNLSF595TurkogluNo ratings yet

- Lecture 8cDocument29 pagesLecture 8cs_paraisoNo ratings yet

- X-Plane Mobile ManualDocument66 pagesX-Plane Mobile ManualRafael MunizNo ratings yet

- NATCO Presentation - Desalters PDFDocument12 pagesNATCO Presentation - Desalters PDFshahmkamalNo ratings yet

- Life Processes: Science Unit 1Document19 pagesLife Processes: Science Unit 1patil pratikNo ratings yet

- Motionless Electromagnetic GeneratorDocument8 pagesMotionless Electromagnetic Generatorraja100% (1)

- Power Electronics Circuits Devices and Applications by Muhammad H RashidDocument602 pagesPower Electronics Circuits Devices and Applications by Muhammad H Rashidkartik balojiNo ratings yet

- List of GHS Hazard Statement & PictogramsDocument33 pagesList of GHS Hazard Statement & PictogramsKhairul BarsriNo ratings yet

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Document4 pagesSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNo ratings yet

- OK Flux 231 (F7AZ-EL12) PDFDocument2 pagesOK Flux 231 (F7AZ-EL12) PDFborovniskiNo ratings yet

- Mathematics in The Modern World ReviewerDocument2 pagesMathematics in The Modern World ReviewerVince Luigi ZepedaNo ratings yet

- Thermocouple: Seeback EffectDocument8 pagesThermocouple: Seeback EffectMuhammadHadiNo ratings yet

- Typeset EquationsDocument26 pagesTypeset EquationsEpic WinNo ratings yet

- Varargout Tugas - GUI (Varargin) : FunctionDocument7 pagesVarargout Tugas - GUI (Varargin) : FunctionDwi Lestari dwi375ft.2019No ratings yet

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDocument24 pagesCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuNo ratings yet

- Famous MathematicianDocument116 pagesFamous MathematicianAngelyn MontibolaNo ratings yet

- L4 Subdivision of PlotsDocument20 pagesL4 Subdivision of PlotsKenny BoatNo ratings yet

- The Library of Babel - WikipediaDocument35 pagesThe Library of Babel - WikipediaNeethu JosephNo ratings yet

- 3 DB RDMDocument49 pages3 DB RDMfaisal shahzadNo ratings yet

- 7PA30121AA000 Datasheet enDocument2 pages7PA30121AA000 Datasheet enMirko DjukanovicNo ratings yet

- EConsole1 Quick Start Guide ENGDocument21 pagesEConsole1 Quick Start Guide ENGManuel Casais TajesNo ratings yet

- Sewage: Vag Hade Flap ValveDocument4 pagesSewage: Vag Hade Flap ValveAhmedRamadanNo ratings yet

- Test ElectrolysisDocument3 pagesTest ElectrolysisNatalia WhyteNo ratings yet

- PPF CalculatorDocument2 pagesPPF CalculatorshashanamouliNo ratings yet

- Synthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesDocument6 pagesSynthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesAnonymous yNMZplPbVNo ratings yet

- PistonDocument7 pagesPistongauravarora93100% (1)

- GMS60CSDocument6 pagesGMS60CSAustinNo ratings yet

- Georgi Lecture Notes On Weak Interactions Physics Harvard Web Draft 1998Document167 pagesGeorgi Lecture Notes On Weak Interactions Physics Harvard Web Draft 1998manosmagicas7340No ratings yet

- TMT Boron CoatingDocument6 pagesTMT Boron Coatingcvolkan1100% (2)