Professional Documents

Culture Documents

Ficha Tecnica PTFE 25 Fibra Vidrio - ACP

Uploaded by

Diegofresneda54 Fresneda0 ratings0% found this document useful (0 votes)

6 views1 pagePTFE + 25% glass fibers is a composite material with the following key properties:

1. It has improved compression and wear resistance as well as excellent chemical stability.

2. Typical applications include dynamic seal parts in pneumatic, hydraulic, and mechanical systems where both rotating and alternating movements occur.

3. The material has a service temperature range of -200°C to +260°C and is stable over 20 years of exposure. Radiation resistance decreases mechanical properties but not electrical properties.

Original Description:

Original Title

Ficha Tecnica PTFE 25 Fibra Vidrio_ACP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPTFE + 25% glass fibers is a composite material with the following key properties:

1. It has improved compression and wear resistance as well as excellent chemical stability.

2. Typical applications include dynamic seal parts in pneumatic, hydraulic, and mechanical systems where both rotating and alternating movements occur.

3. The material has a service temperature range of -200°C to +260°C and is stable over 20 years of exposure. Radiation resistance decreases mechanical properties but not electrical properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageFicha Tecnica PTFE 25 Fibra Vidrio - ACP

Uploaded by

Diegofresneda54 FresnedaPTFE + 25% glass fibers is a composite material with the following key properties:

1. It has improved compression and wear resistance as well as excellent chemical stability.

2. Typical applications include dynamic seal parts in pneumatic, hydraulic, and mechanical systems where both rotating and alternating movements occur.

3. The material has a service temperature range of -200°C to +260°C and is stable over 20 years of exposure. Radiation resistance decreases mechanical properties but not electrical properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

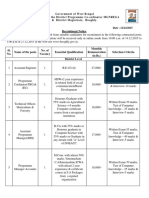

ACP MATERIALS S.L.

TECHNICAL DATA SHEET

Aluminios, Bronces, Casquillos autolubricados, Plásticos técnicos, Estratificados, etc.

PTFE + 25% Glass fibres

General properties

Test method Product characteristics

• Improved compression and wear

resistance.

Specific gravity ASTM D792 g/cm3 2,230 - 2.260 • Excellent chemical stability.

• Better thermal conductivity and

coefficient of friction when

combined with Mos2 or

Tensile strength ASTM D4894 MPa ≤ 13 Graphite.

Typical field of application

Elongation ASTM D4894 % ≤ 180 • It is the most commonly used

filler for dynamic seal

applications where both rotating

and alternating movements are

Hardness ASTM D2240 Shore D ≤ 60

involved, pneumatic, hydraulic

and mechanical parts.

Compression strength at 1% deformation MPa ≤9

Deformation under load (140Kg/cm2 for 24 hrs.

ASTM D621 % 09 - 11

at 23ªC)

Permanent deformation (after for 24 hrs.

ASTM D621 % 5,0 - 6,5

Relaxation at 23ªC)

Permanent deformation (after 24 hrs.

10-5 /ºC

Relaxation at 23ªC)

Coefficient of static friction 7,7 - 11-2

Coefficient of dynamic friction 8,5

Volume resistivity ASTM D257 Ohm*cm 104

Ageing and weatherability stable over 20 years of exposure

The data stated above are average

values ascertained by statistical tests

on a regular basis. They are in

Electrical properties unchanged, mechanical

Radiations resistance (gamma rays) LOW: properties decreased accordance with DIN EN 15860. The

data above are provided purely for

information and shall not be regarded

as binding unless expressly agreed in a

Service temperature ºC -200 / +260 contract of sale.

ACP MATERIALS S.L. Tel.: +34 96 140 05 56

Pol. Ind. del Mediterraneo Fax: +34 96 141 70 65

C/ Jaime I, Naves 10-11-14 Mail: info@acpmaterials.es

46560 MASSALFASAR - VALENCIA - ESPAÑA

You might also like

- Cynthia A. Young - Soul Power - Culture, Radicalism and The Making of A U.S. Third World Le PDFDocument314 pagesCynthia A. Young - Soul Power - Culture, Radicalism and The Making of A U.S. Third World Le PDFmi101No ratings yet

- Bollard Pull CalculationsDocument16 pagesBollard Pull CalculationsLuis Sierra100% (1)

- Manual Bomba KoomeyDocument95 pagesManual Bomba KoomeyDiego De JesusNo ratings yet

- Method Statement For InstallationDocument5 pagesMethod Statement For Installationsamsul maarifNo ratings yet

- Review Related Literature (0115)Document5 pagesReview Related Literature (0115)Nesty SarsateNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- Data Sheet - Polyfelt® Alidrain AD130 (300 603-td-10-18) PDFDocument1 pageData Sheet - Polyfelt® Alidrain AD130 (300 603-td-10-18) PDFErnie ErnieNo ratings yet

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDocument1 page3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNo ratings yet

- Data Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFDocument1 pageData Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFErnie ErnieNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Ptfe - G400Document1 pagePtfe - G400Alessio Di BellaNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Estane Skythane S190A TPU: TypeDocument2 pagesEstane Skythane S190A TPU: Typejuliushasan2No ratings yet

- Tech Data - PF Alidrain AD230 - 250Document1 pageTech Data - PF Alidrain AD230 - 250BinSayeed100% (1)

- Pps DatasheetDocument3 pagesPps Datasheetawdhesh ChaudharyNo ratings yet

- Tikidan TDS - Selfdan Ipe Plus, R3Document3 pagesTikidan TDS - Selfdan Ipe Plus, R3sandeepNo ratings yet

- TDS UBE NYLON 1024B, CastDocument1 pageTDS UBE NYLON 1024B, CastAlexander ShvetsNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- PVDC Coated Nylon Film Nxo: Technical InformationDocument1 pagePVDC Coated Nylon Film Nxo: Technical InformationIvan TedjaNo ratings yet

- PP11280 SpecificationDocument2 pagesPP11280 Specificationudummy552No ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- Heat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesDocument2 pagesHeat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesCarlos Berrospi ChacaNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Technical Datasheet 2102TX00: 1) Product DescriptionDocument1 pageTechnical Datasheet 2102TX00: 1) Product DescriptionjavadmohammadiNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- UK NatureFlex NPFDocument2 pagesUK NatureFlex NPFHavir GhteuNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Iocl PPCP Injection Molding 11 Mfi 4100mhDocument1 pageIocl PPCP Injection Molding 11 Mfi 4100mhAparesh GantaitNo ratings yet

- Virgin PTFE G400 Extruded - Rev.06Document1 pageVirgin PTFE G400 Extruded - Rev.06Alessio Di BellaNo ratings yet

- Datenblatt Rohstoff Torlon 4301Document4 pagesDatenblatt Rohstoff Torlon 4301DarkedgeNo ratings yet

- FKM 95 Compound 514162Document1 pageFKM 95 Compound 514162heningputriNo ratings yet

- TDS Conbextra EP160 Saudi ArabiaDocument4 pagesTDS Conbextra EP160 Saudi ArabiajasonNo ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- Aramco PP HP30EGDocument2 pagesAramco PP HP30EGSayed FathyNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- OPTIMASTIC PU1K 50 Prod Tech InfoDocument2 pagesOPTIMASTIC PU1K 50 Prod Tech InfoMel GarciaNo ratings yet

- Conbextra EP150: Constructive SolutionsDocument4 pagesConbextra EP150: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- High Barrier & High Metal Adhesion Metallized PET Film - KZMBDocument1 pageHigh Barrier & High Metal Adhesion Metallized PET Film - KZMBAngga PrasetyoNo ratings yet

- BPC - BG HD 7000fDocument1 pageBPC - BG HD 7000fSLKM Engineering & ConsultantsNo ratings yet

- Polyester: Data SheetDocument1 pagePolyester: Data SheetñeNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- AC410Document1 pageAC410P Singh KarkiNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- l3n71b l4n71b E4n71b PDFDocument10 pagesl3n71b l4n71b E4n71b PDFHectorNo ratings yet

- Writing A Close Analysis and Critical InterpretationDocument11 pagesWriting A Close Analysis and Critical InterpretationJALBEE MARIE ABDULRADZAKNo ratings yet

- A Guide To Face Detection in Python - Towards Data ScienceDocument26 pagesA Guide To Face Detection in Python - Towards Data ScienceerivandoramosNo ratings yet

- CV Adinda Putri MDocument1 pageCV Adinda Putri MVeena GamingNo ratings yet

- Nature of Inquiry and ResearchDocument20 pagesNature of Inquiry and ResearchJewelrhey Radcliffe MiddletonNo ratings yet

- Gea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFDocument2 pagesGea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFJorge A. TorresNo ratings yet

- WbnotDocument2 pagesWbnotJeshiNo ratings yet

- Taf - Fepa Safety Leaflet Flap Discs EnglishDocument2 pagesTaf - Fepa Safety Leaflet Flap Discs EnglishkerolcarrollNo ratings yet

- Mindful Recovery: A Case Study of A Burned-Out Elite ShooterDocument12 pagesMindful Recovery: A Case Study of A Burned-Out Elite ShooterRandy HoweNo ratings yet

- Solucionario Capitulo 23 Paul e TippensDocument18 pagesSolucionario Capitulo 23 Paul e TippensALICIA MARIE SABILLON RAMOSNo ratings yet

- Ignou Thesis FormatDocument8 pagesIgnou Thesis Formatdnr8hw9w100% (2)

- Minesweepers 2019 Rule Book v5.4Document48 pagesMinesweepers 2019 Rule Book v5.4JOSE DAVID VALDA PEÑARANDANo ratings yet

- Nursing InformaticsDocument4 pagesNursing InformaticsRandy AminolaNo ratings yet

- Defining Submission PhasesDocument1 pageDefining Submission Phasesmohan krishnaNo ratings yet

- ThesisDocument153 pagesThesisMarius BrătanNo ratings yet

- The Translation of Serious Literature & Authoritative Statements - Poetry - Patricia Iris v. RazonDocument20 pagesThe Translation of Serious Literature & Authoritative Statements - Poetry - Patricia Iris v. RazonPatricia Iris Villafuerte RazonNo ratings yet

- Is Higher Education Making Students Dumb and Dumber?Document29 pagesIs Higher Education Making Students Dumb and Dumber?RubRafNo ratings yet

- Rear FrameDocument24 pagesRear FrameYuriPasenkoNo ratings yet

- Literature ReviewDocument4 pagesLiterature Reviewapi-608950669No ratings yet

- Exercise Solution - I Software Testing Chapter 4Document4 pagesExercise Solution - I Software Testing Chapter 4Fatima AsadNo ratings yet

- HFSS Datasheet WebDocument2 pagesHFSS Datasheet Webbecool_bcn75No ratings yet

- Project Report On Business Eco Magazine - Vivek Kumar ShawDocument36 pagesProject Report On Business Eco Magazine - Vivek Kumar ShawAnand shawNo ratings yet

- CSS 211Document173 pagesCSS 211Adikwu Anyebe OwoichoNo ratings yet

- Arduino YunDocument1 pageArduino YunTerrance MasterNo ratings yet

- Carlson 2016Document11 pagesCarlson 2016A. MungalNo ratings yet