Professional Documents

Culture Documents

Console Remote Control Installation Instructions

Uploaded by

Joswyn LopesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Console Remote Control Installation Instructions

Uploaded by

Joswyn LopesCopyright:

Available Formats

CONSOLE REMOTE CONTROL

INSTALLATION INSTRUCTIONS

IMPORTANT: This document is written to aid our dealers, boatbuilders, and company service personnel in the proper

installation or service of our products. Persons who are not familiar with these or similar products produced by Mercury

Marine, and who have not been trained in the recommended servicing or installation procedures should have the work

performed by an authorized Mercury Marine dealer technician. Improper installation or servicing of the Mercury product could

result in damage to the product or personal injury to the installer or persons operating the product.

NOTE: After completing installation, place these instructions with the product for the owner's future use.

Console Remote Control

48822

Notice to Installer

Throughout this publication, Warnings and Cautions (accompanied by the International Hazard Symbol) are used to alert the

installer to special instructions concerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully.

These "Safety Alerts," alone, cannot eliminate the hazards that they signal. Strict compliance to these special instructions

when performing the service, plus common sense operation, are major accident prevention measures.

! WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

! CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, could result in engine or major component failure.

IMPORTANT: Indicates information or instructions that are necessary for a particular step or action.

NOTE: Indicates information that helps in the understanding of a particular step or action.

This instruction sheet has been written and published by the service department of Mercury Marine to aid installers when

installing the products described herein.

It is assumed that these personnel are familiar with the installation procedures of these products, or like or similar products

manufactured and marketed by Mercury Marine. Also, that they have been trained in the recommended installation

procedures of these products, which includes the use of mechanics’ common hand tools and the special Mercury Marine or

recommended tools from other suppliers.

90-8M0103112 FEBRUARY 2015 © 2015 Mercury Marine Page 1 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

We could not possibly know of and advise the marine trade of all conceivable procedures by which an installation might be

performed and of the possible hazards and/or results of each method. We have not undertaken any such wide evaluation.

Therefore, anyone who uses an installation procedure or tool that is not recommended by the manufacturer must first

completely satisfy himself that neither his nor the product’s safety will be endangered by the installation procedure selected.

All information, illustrations, and specifications contained in this manual are based on the latest product information available

at time of publication. As required, revisions to this manual will be sent to all OEM boat companies.

Selecting GEN ll Remote Control Cables

Mercury ‑ Mariner ‑ Force ‑ Mercury MerCruiser

Refer to the Mercury Precision Parts Accessories Guide for the available shift and throttle cables for your application. This

control requires the use of Mercury/Quicksilver GEN II shift and throttle cables.

IMPORTANT: Remote control cables must be the correct length. Sharp bends on too‑short of cables result in kinks. Too‑long

of cables require unnecessary bends and/or loops. Both conditions place extra stress on the cables.

IMPORTANT: Use 2‑4‑C with PTFE to lubricate the shift cable and throttle cable.

a - Remote control end

b - Engine end

95 c

b 95 c - Adjusting barrel

95 95 17431

Tube Ref No. Description Where Used Part No.

95 2-4-C with PTFE Shift cable/throttle cable lubrication points 92-802859A 1

NOTE: Allow for clearance of the cables directly behind the remote control. Cable radius at any one point must not be less

than 305 mm (12 in.).

General Installation Information

IMPORTANT: The control handle friction adjustment must be made prior to installation.

Control Handle Friction Adjustment

The control handle friction is preset from the factory. However, it can be adjusted.

• Use an 11/32 in. nut driver or socket wrench to carefully adjust the control handle friction. To increase friction, turn the

adjusting nut clockwise. To decrease friction, turn the adjusting nut counterclockwise.

IMPORTANT: Control handle friction is necessary for proper mechanical control operation. Insufficient friction may cause

undesirable control arm operation.

21553

Page 2 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Reinstallation of Control Handle

! WARNING

Improper installation can result in sudden, unexpected loss of throttle and shift control, resulting in serious injury or death.

Install all control components properly.

1. If the control handle is removed and reinstalled for any reason, apply Loctite 271 Threadlocker on the threads of the

control handle retaining screw.

2. Tighten the control handle retaining screw to the specified torque.

Tube Ref No. Description Where Used Part No.

7 Loctite 271 Threadlocker Control handle retaining screw threads 92-809819

Description Nm lb‑in. lb‑ft

Control handle retaining screw 17 150 –

Control Module Mounting

IMPORTANT: The control handle friction adjustment must be made prior to the installation of the remote control.

NOTE: The gasket and mounting base must be placed over the console control mount opening prior to installing the shift and

throttle cables to the control module.

1. Select the mounting area for the remote control. Select the template for the type of application. Follow the template

directions when cutting and drilling the mounting surface.

2. Connect the control cables and install the rear cover to the remote control. Refer to the Throttle and Shift Cable

Installation in this instruction sheet.

3. Install the remote control following the mounting instructions. Make necessary wiring connections by selecting the correct

wiring diagram for the remote control model installed.

4. Install and adjust the shift and throttle cables to the power package as outlined in the instructions which accompany the

power package or refer to the Product Service Manual.

Final Checks and Adjustments

1. Recheck the tightness of the control handle retaining screw. Tighten to the specified torque.

Description Nm lb‑in. lb‑ft

Control handle retaining screw 17 150 –

2. Before installing the back cover, recheck the throttle cable and shift cable retaining screws to ensure they are secure.

3. Ensure the back cover screws are securely tightened.

4. Before the remote control is securely fastened, verify the control cables and the control wiring harness are routed

correctly.

NOTICE

Failure to rotate the propeller shaft when shifting gears or forcing the shift mechanism while the engine is not operating can

result in product damage. If you must shift gears with the engine off, manually rotate the propeller shaft in the appropriate

direction.

5. Operate the control handle several times (see Notice preceding). Any binding or stiffness in the operation of the control

handle is usually caused by the following:

a. Bends or tension on the control cables near the control.

b. Excessive number of bends in the cables.

c. Bends are too small in the cables.

d. Tight engine linkage.

e. Cable ties strapped too close to the control module.

f. Control handle friction adjustment.

g. Improper adjustment at the engine.

90-8M0103112 FEBRUARY 2015 Page 3 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

! WARNING

Performing tests with the engine running may cause the propeller to rotate and result in serious injury or death. Use caution

when performing a test that requires the engine running, and remove the propeller to avoid injury.

6. Check the operation of the neutral start safety switch. The engine must only crank when the remote control is in the

neutral position.

Required Mounting Clearance for Single Handle Remote Control

IMPORTANT: Ensure the remote control has adequate clearance and does not contact other components. The cable path

should be free of obstructions. See shaded area.

184.4 mm

(7.25 in.) 125.1 mm

50.8 mm (4.92 in.)

(2.00 in.) a

UP

DN

R 203.2 mm

(8.00 in.) 245.1 mm

(9.65 in.)

117.8 mm

(4.63 in.)

456.6 mm

(17.98 in.)

23.4 mm

(0.92 in.)

a 211.5 mm

(8.33 in.)

40.6 mm

b (1.60 in.)

147.6 mm

(5.81 in.)

b

48812

a - Hand clearance

b - If the shift and throttle cables are not mounted in the same housing slot position, do not use cable ties to secure the

control cables ‑ an increase in the shift and throttle load will be noticed

Drilling Mounting Area Location

IMPORTANT: When selecting a mounting area for the remote control, the area directly behind the mounting panel must have

sufficient clearance for the control module, wiring harness, control cables, and control cable movement. Refer to the required

mounting clearances.

Page 4 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

IMPORTANT: Allow sufficient clearance for the handle movement to avoid interference with boat components or other

accessories. Ensure the control handle clears the dash, seats, steering wheel, and any other obstructions when rotating the

control handle.

1. Remove the cutout template page located at the end of these installation instructions.

2. Ensure the area of the boat where the remote control will be mounted is clear of obstructions and wiring prior to drilling

the mounting area.

3. Place the cutout template onto the control mounting surface. Secure the cutout template to the desired location with

adhesive tape.

IMPORTANT: Before drilling the mounting holes to 7 mm (5/16 in.) to accommodate the use of well nuts, ensure the

thickness of the mounting area does not exceed the gripping range of the well nuts used. If the thickness is beyond the

gripping range of the well nuts, drill the mounting holes to the correct diameter of a common flange head type screw.

4. Drill and cut the mounting area as directed on the cutout template.

88.9 mm

(3-1/2 in.)

67.3 mm 48857

(2-21/32 in.)

48858

5. The control module can be rotated 8° from perpendicular relative to the remote control mounting surface. An 8° undercut

must be made to the mounting location to allow for adequate clearance for the control module.

6. After cutting out the mounting area, remove all sharp edges with a suitable tool.

a 8 8

b

21603

a - Control mounting surface

b - 8° undercut

90-8M0103112 FEBRUARY 2015 Page 5 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Throttle and Shift Cable Installation

Control Cable Anchor Attaching Location

a 4 a - Shift arm

2

b - Throttle arm

1 b 3 17551

Starboard Mount Control Port Mount Control

Anchor Attaching Anchor Attaching

Outboard Models (U.S. and Belgium Models Only) Location Location

Throttle Throttle

Shift Cable Shift Cable

Cable Cable

Force outboards, except 9.9 and 15 hp 4 2 3 2

Mercury and Mariner outboards ‑ standard rotation models, all

models through 300 XS with pull throttle, includes 1994‑1/2 20/25 4 2 3 2

hp

Mercury and Mariner outboards ‑ 18 hp, 20 hp, and 25 hp of U.S.

4 1 3 1

origin, with push throttle cable

Mercury and Mariner outboards ‑ counterrotation gearcase, all

3 2 4 2

models through 300 XS, unless listed below

Mercury and Mariner outboards ‑ standard rotation gearcase, 250

3 2 4 2

hp/275 hp 3.4L

Mercury and Mariner outboards ‑ counterrotation gearcase, 250

4 2 3 2

hp/275 hp 3.4L

Mercury outboards ‑ standard rotation gearcase, 3.0L EFI,

4 2 3 2

OptiMax S/N 1B752547 and above

Mercury outboards ‑ counterrotation gearcase, 3.0L EFI, OptiMax

4 2 3 2

S/N 1B752547 and above

Mercury 3.0L outboards with Torque Master gearcase S/N

4 2 3 2

1B973743 and below

Mercury 3.0L outboards with Torque Master II gearcase S/N

4 2 3 2

1B973744 and above

Page 6 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

1. Remove the screws securing the back plate to the control module.

a c

b a - Back plate

b - Washer

c - Screw (5)

17557

IMPORTANT: Determine the type of drive unit rotation the cable is installed onto. The shift cable must be correctly

installed at the remote control assembly for the appropriate drive unit rotation; standard or counterrotation.

NOTE: For Bravo Three, Blackhawk Drive, and for 3.0 Liter EFI GEN ll and OptiMax GEN ll outboard models, refer to the

instructions for standard rotation control cable installation.

2. Mercury MerCruiser models standard rotation ‑ The control cable must be installed in the remote control so the cable

end will move in the direction of "X" when the shift handle is placed in the forward position.

3. Mercury MerCruiser models counterrotation ‑ The control cable must be installed in the remote control so the cable

end will move in the direction of "Y" when the shift handle is placed in the forward position.

Y

17576

Direction of arrow (viewed at shift plate)

Mercury MerCruiser Models Standard Rotation Counterrotation

Anchor Attaching Location Anchor Attaching Location

Starboard Mount Mechanical Control

Shift Cable Throttle Cable Shift Cable Throttle Cable

Direction of arrow X X Y X

Lever number 4 2 3 2

Typical Throttle and Shift Cable Installation, Outboard and Mercury MerCruiser

! WARNING

Improper installation can result in sudden, unexpected loss of throttle and shift control, resulting in serious injury or death.

Install all control components properly.

IMPORTANT: Threads of the control cable fastener screws contain a threadlocker. Additional threadlocker should not be

applied during the original installation. If the screws are installed and then removed for any reason, apply an appropriate

amount of Loctite 271 Threadlocker on the screw threads and tighten to the specified torque. Failure to apply Loctite 271

Threadlocker on the cable fastener screw threads, or to tighten screws to the specified torque, can lead to the screws

loosening, which could result in loss of throttle or shift control.

IMPORTANT: Applying too much Loctite can result in the locking agent contacting other moving parts of the control,

preventing or limiting proper operation.

Description Nm lb‑in. lb‑ft

Control throttle and shift cable screws 2.8 25 –

1. Apply Loctite 271 Threadlocker to the threads of the cable fastener screws.

2. Connect the control cables to the appropriate arm in the remote control module.

90-8M0103112 FEBRUARY 2015 Page 7 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

3. Tighten the cable fastener screws to the specified torque.

a- Small spacer

b- Screw

c- Shift cable

d- Throttle cable

e- Large spacer

7

e

d b d

c

c

a

c d 17555

Tube Ref No. Description Where Used Part No.

7 Loctite 271 Threadlocker Control cable fastener screw threads 92-809819

Description Nm lb‑in. lb‑ft

Control cable fastener screws 2.8 25 –

4. After installing the control cables, secure the back plate with five screws and the washer. Tighten the screws to the

specified torque.

a c

b a - Back plate

b - Washer

c - Screw (5)

17557

Description Nm lb‑in. lb‑ft

Back plate screws (5) 1.1 10 –

Page 8 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Mounting the Remote Control

Single Handle Console Control Models

NOTE: The gasket and mounting base must be placed over the console control mount opening prior to installing the shift and

throttle cables to the control module.

1. Place the gasket and mounting base over the console control mount opening prior to installing the shift and throttle

cables to the control module.

b a - Gasket

a b - Mounting base

48861

2. Install the mounting brackets to the control module with two 57 mm (2.0 in.) screws and locknuts. Do not tighten the

screws at this time.

a b b c a - Screw (2), 57 mm (2.0 in.)

b - Mounting bracket (2)

c - Locknut (2)

20463

3. Place the control module assembly in the mounting cutout and select the desired angle of the control handle relative to

the mounting surface. The maximum angle is 8° from perpendicular. After the angle of the handle is selected, secure the

mounting brackets with the screws and locknuts. Tighten the screws to the specified torque.

b a - Control handle in neutral detent

a b - Control module assembly mounted at 8° from

c perpendicular

c - Mounting bracket

d

d - Mounting panel

20465

Description Nm lb‑in. lb‑ft

Mounting bracket screws and locknuts 4 35 –

4. Adjust the control handle friction to the desired resistance.

• Turn the control friction adjustment nut clockwise to increase the resistance.

90-8M0103112 FEBRUARY 2015 Page 9 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

• Turn the control friction adjustment nut counterclockwise to decrease the resistance.

48826

5. Install a cable tie anchor onto the mounting screw located at the right side of the handle.

6. Secure the remote control module assembly to the console with four mounting screws 38 mm (1.5 in.). Tighten the

screws securely.

IMPORTANT: Ensure the trim switch wire harness has enough slack so that it will move freely with the full range of the

control handle.

7. Provide the needed slack in the trim switch wire harness and then fasten the trim switch wire harness to the cable tie

anchor with a cable tie.

a a- Screw (4)

b- Cable tie anchor

c- Cable tie

b c d- Trim switch wire harness

d

d

48827

8. Install the spacer on top of the remote control.

53652

Page 10 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

9. Hook the rear of the cover into the base and fasten the front of the cover to the base with a screw. Tighten the screw

securely.

a - Cover

b - Screw

48834

10. Connect the remote control neutral start safety switch leads to the correct wire connections. Refer to Wiring Diagrams.

! WARNING

Starting the engine with the drive in gear can cause serious injury or death. Never operate a boat that does not have a

neutral‑safety‑protection device.

a - Neutral start safety switch leads

b - Wire connections

a b

48849

Wire Color Code Abbreviations

Wire Color Abbreviations

BLK Black BLU Blue

BRN Brown GRA Gray

GRN Green ORN Orange

PNK Pink PPL Purple

RED Red TAN Tan

WHT White YEL Yellow

LT Light DK Dark

90-8M0103112 FEBRUARY 2015 Page 11 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Wiring Diagrams

Single Outboard

a

e

b

f

53721

a- 14‑pin connector

b- Ignition key switch

c- Lanyard connection for MCM models

d- Power trim connector

e- Neutral start safety switch leads

f- Analog gauge harness

Page 12 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Single Mercury MerCruiser ‑ Gasoline Models

b

e

a f

53722

a- 14‑pin connector

b- Ignition key switch

c- Lanyard connection for MCM models

d- Trim limit switch

e- Power trim harness connector

f- Neutral start safety switch leads

g- Analog gauge harness

90-8M0103112 FEBRUARY 2015 Page 13 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Single Mercury MerCruiser ‑ Diesel Models D3.0L/150, D3.6L/180, D4.2L/220

b

c

BLK/WHT

BLK/YEL

a d

PPL

RED/PPL

RED/PPL

PPL

YEL/RED

BLK/YEL PPL

YEL/RED e

PPL

f

BLK/YEL

YEL/RED

YEL/RED

n h

i

YEL/RED

YEL/RED

j

m k

GRN

BLU

RED

BLU

BLU

BLU

PPL PPL

l 48961

a- 12 volt source

b- Preheat

c- Alternator

d- Fuse

e- Ignition key switch

f- Stop switch

g- Light switch and audio test

h- Preheat indicator

i- Alternator indicator

j- Oil pressure indicator

k- Coolant temperature indicator

l- To trim limit switch

m- Power trim harness connector

n- Neutral start safety switch leads

Page 14 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Single Mercury MerCruiser ‑ Diesel Model D7.3L/270

BLK/WHT

BLK/YEL

a b

PPL

c

RED/PPL

YEL/RED

d

e

f

g

h

YEL/RED

n

RED/PPL

j

YEL/RED

YEL/RED YEL/RED

GRN

BLU

RED

m BLU

BLU BLU

k

PPL PPL 48963

a- 12 volt source

b- Lanyard stop switch leads

c- Lanyard stop switch

d- Water in fuel indicator

e- Coolant temperature indicator

f- Oil pressure indicator

g- Alternator indicator

h- Preheat indicator

i- Light switch and audio test

j- Ignition key switch

k- To trim limit switch

l- Power trim harness connector

m- Plastic connector

n- Neutral start safety switch leads

90-8M0103112 FEBRUARY 2015 Page 15 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

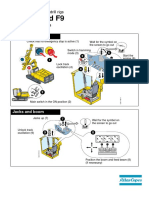

Features and Operation

1 2

4

5

48860

1. Power trim switch (if equipped) ‑ Used to trim or raise drive unit for trailering, launching, beaching, or shallow water

operation. Refer to the Operation and Maintenance Manual for detailed power trim/tilt operating procedures.

2. Trailer switch (if equipped) ‑ Used to raise the drive unit beyond the maximum trim position. Refer to the Operation

and Maintenance Manual for detailed trailer switch operation.

3. Control handle ‑ Operation of the shift and throttle are controlled by the movement of the control handle. Push the

control handle forward from neutral with a quick firm motion to the first detent for forward gear. Continue pushing forward

to increase speed. Pull the control handle back from neutral with a quick firm motion to the first detent for reverse gear.

Continue pulling back to increase speed.

NOTICE

Failure to rotate the propeller shaft when shifting gears or forcing the shift mechanism while the engine is not operating can

result in product damage. If you must shift gears with the engine off, manually rotate the propeller shaft in the appropriate

direction.

4. Throttle only button ‑ Allows the engine throttle advancement without shifting the engine. This is done by disengaging

the shift mechanism from the control handle. The throttle only button can be depressed only when the remote control

handle is in the neutral position and should only be used to assist in starting the engine. Refer to the Operation and

Maintenance Manual for correct throttle setting for starting the engine.

5. Control handle throttle friction adjustment nut ‑ This nut can be adjusted to increase or decrease the friction on the

control handle. This will help prevent creep of the remote control handle. Turn the nut clockwise to increase friction and

counterclockwise to decrease friction. Adjust to the desired friction.

Mechanical Remote Control Maintenance

! WARNING

Neglect or improper maintenance, repairs, or inspections of the power package can result in product damage or serious

injury or death. Perform all procedures as described in this manual. If you are not familiar with proper maintenance or

service procedures, consign the work to an authorized Mercury Marine dealer.

Maintenance and safety instructions are the owner’s responsibility and must be performed at the following specified intervals:

• After the first 25 hours of use, follow the instructions in 1, 2, and 3, below.

• A regular 100‑hour or yearly (whichever comes first) maintenance schedule should be followed, involving all of the

instructions listed below.

1. Check all fasteners which secure the control housing to the control module, and the control and module to the boat.

Tighten any loose fasteners to the specified torque listed in the installation instructions.

2. Check the control handle retaining screw to ensure that it is tightened to the specified torque. If the screw has been

removed for any reason, Loctite 271 Threadlocker should be applied to the screw threads before installation.

3. Check electrical connections to be sure that they are tight, free of corrosion, and that all harnesses are properly secured

and kept away from water.

4. Inspection and lubrication of the remote control assembly should be performed once each year by your authorized

dealer. Lubrication should also be performed if the remote control is disassembled, or if control operating effort has

increased. Lubricate with 2‑4‑C with PTFE or equivalent.

Page 16 / 18 90-8M0103112 FEBRUARY 2015

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

5. Yearly inspection of the cables for free‑play should coincide with the dealer inspection and lubrication. Cable ends should

be disconnected from both the engine and the control. Cable ends should be manually manipulated to feel for stiffness,

binding, or tightness affecting the cable core. Worn, pinched, or corroded cables should be replaced. Mercury/Quicksilver

GEN II throttle and shift cables are required for use in this remote control.

Tube Ref No. Description Where Used Part No.

7 Loctite 271 Threadlocker Control handle retaining screw threads 92-809819

95 2-4-C with PTFE Remote control internal moving parts and control cable ends 92-802859A 1

Description Nm lb‑in. lb‑ft

Control handle retaining screw 17 150 –

Single Handle Mounting Template

IMPORTANT: Due to printing variables, the image may have changed from the actual size. Check this template with the

mounting base before drilling or cutting the mounting surface, or use the mounting base as a guide to mark the mounting

surface.

90-8M0103112 FEBRUARY 2015 Page 17 / 18

CONSOLE REMOTE CONTROL INSTALLATION INSTRUCTIONS

Drill the holes and cutout the shaded area.

3 mm 3 mm

(1/8 in.) (1/8 in.)

b

3 mm

(1/8 in.)

88.9 mm

(3-1/2 in.)

3 mm

(1/8 in.)

3 mm 3 mm

(1/8 in.) (1/8 in.)

67.3 mm

48857

(2-21/32 in.)

a - Front of boat

b - Drill to the correct diameter for the fasteners used

Products of Mercury Marine © MERCURY MARINE. All rights reserved. Reproduction in whole or in part without permission is

prohibited. Alpha, Axius, Bravo One, Bravo Two, Bravo Three, Circle M with Waves Logo, K-planes,

W6250 Pioneer Road Mariner, MerCathode, MerCruiser, Mercury, Mercury with Waves Logo, Mercury Marine, Mercury

Precision Parts, Mercury Propellers, Mercury Racing, MotorGuide, OptiMax, Quicksilver, SeaCore,

Fond du Lac, WI 54936-1939 Skyhook, SmartCraft, Sport-Jet, Verado, VesselView, Zero Effort, Zeus, #1 On the Water and We're

Driven to Win are registered trademarks of Brunswick Corporation. Pro XS is a trademark of Brunswick

Corporation. Mercury Product Protection is a registered service mark of Brunswick Corporation.

Page 18 / 18 90-8M0103112 FEBRUARY 2015

You might also like

- Installation: EVC - C Electronic Vessel Control ACDocument92 pagesInstallation: EVC - C Electronic Vessel Control ACTiên Lê Trần MỹNo ratings yet

- BR33 Rotary Valve ManualDocument20 pagesBR33 Rotary Valve ManualHimozaesNo ratings yet

- Actuador Electrico RotorkDocument16 pagesActuador Electrico RotorkAriel AgueroNo ratings yet

- Binder1 PDFDocument454 pagesBinder1 PDFAniket KhotNo ratings yet

- Operation Manual: & Parts ListDocument62 pagesOperation Manual: & Parts ListanggieNo ratings yet

- Braden BG8A BG8B Installation Mainenance and Service ManualDocument31 pagesBraden BG8A BG8B Installation Mainenance and Service ManualAnibal Jose Cruz Larez100% (2)

- RT770E T3-T4i SM CTRL447-05 PDFDocument357 pagesRT770E T3-T4i SM CTRL447-05 PDFDmitryNo ratings yet

- S280906 Probar Baterias PDFDocument8 pagesS280906 Probar Baterias PDFrosasojedaNo ratings yet

- Voltage Regulators: Required ItemsDocument4 pagesVoltage Regulators: Required Itemssincos1983No ratings yet

- Braden CH330A ServiceDocument35 pagesBraden CH330A ServiceHarry Leonardy SihiteNo ratings yet

- FIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectDocument44 pagesFIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectEdgarNo ratings yet

- Owner'S Manual: Manual Do UsuárioDocument44 pagesOwner'S Manual: Manual Do Usuáriojuan c GimenoNo ratings yet

- 3043-PPV-001 Motor IomDocument22 pages3043-PPV-001 Motor IomMiguel Angel RodriguezNo ratings yet

- IM Rime 4000 CompleteDocument37 pagesIM Rime 4000 CompleteVivi Puspita SariNo ratings yet

- 40 60 PDFDocument547 pages40 60 PDFDiego Arcos100% (2)

- Mercury 40-50-55-60 Service Repair ManualDocument4 pagesMercury 40-50-55-60 Service Repair ManualRyan ActonNo ratings yet

- Service Manual NBT40Document220 pagesService Manual NBT40RICARDO BLANCONo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectionfrank1220uNo ratings yet

- Marine Products: SL-3 Engine ControlsDocument16 pagesMarine Products: SL-3 Engine ControlsPedro GuerraNo ratings yet

- Modular Collator Base: ManualDocument68 pagesModular Collator Base: ManualRobot 3TNo ratings yet

- SafeGear MCC IOMM Controller July 2017Document28 pagesSafeGear MCC IOMM Controller July 2017CARLOS LÓPEZNo ratings yet

- Bucket Elevator Maintenance ManualDocument26 pagesBucket Elevator Maintenance ManualJ Dany T. Delgado100% (1)

- Maintenance Manual - Actuator PDFDocument9 pagesMaintenance Manual - Actuator PDFParag PadoleNo ratings yet

- Altivar 71 Schneider ElectricDocument78 pagesAltivar 71 Schneider Electricchabane_148549No ratings yet

- CPVC Sprinkler Head Adapter FittingDocument2 pagesCPVC Sprinkler Head Adapter FittingValentin A.No ratings yet

- Pioneer VF5000Document97 pagesPioneer VF5000Fida HussainNo ratings yet

- Tms700e13 SM CTRL512-01 PDFDocument352 pagesTms700e13 SM CTRL512-01 PDFDanilo MarinNo ratings yet

- Merc Controls Newest ManualDocument659 pagesMerc Controls Newest ManualTom Bores90% (21)

- Instruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Document36 pagesInstruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Kluzu Formaggio100% (1)

- MHC 16 - 4-06Document40 pagesMHC 16 - 4-06Gary LeeNo ratings yet

- Greatork IOM ... MANUALDocument36 pagesGreatork IOM ... MANUALRAMESH RAMASAMY100% (1)

- Manual Markon NAC160 NAC190Document23 pagesManual Markon NAC160 NAC190Sajjad HussainNo ratings yet

- On Load Tap Changers Abb PDFDocument12 pagesOn Load Tap Changers Abb PDFKushtrim MalaNo ratings yet

- PLC ConnectionEDocument374 pagesPLC ConnectionEJennifer Urrutia Asela100% (1)

- Steering Mechanism: MaintenanceDocument16 pagesSteering Mechanism: MaintenanceZoltán RozinkaNo ratings yet

- H3N Series User Manual-No HD Logo-140812Document80 pagesH3N Series User Manual-No HD Logo-140812Luis Raul Diaz AviñaNo ratings yet

- Product Manual CANcockpitDocument174 pagesProduct Manual CANcockpitJoao Silva100% (2)

- Operations and Service Manual: MKT1723 Rev 4Document38 pagesOperations and Service Manual: MKT1723 Rev 4Percy RivaNo ratings yet

- Holland XL Ar452 Users Manual 565370Document8 pagesHolland XL Ar452 Users Manual 565370Angel FraustoNo ratings yet

- Cover PDFDocument3 pagesCover PDFJim LassNo ratings yet

- Grove Rt-880e-Service ManualDocument346 pagesGrove Rt-880e-Service Manualramiro serrano olliscoNo ratings yet

- Mercury 30 - 40hp Service OEM ManualDocument532 pagesMercury 30 - 40hp Service OEM ManualwboeremaNo ratings yet

- Operating Manual: Aligner Device-850Document15 pagesOperating Manual: Aligner Device-850atya ragabNo ratings yet

- Greatork AVA AVAM AVAT AVATM AVAMD Operating ManualDocument52 pagesGreatork AVA AVAM AVAT AVATM AVAMD Operating ManualWhat's UpNo ratings yet

- Constant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENDocument28 pagesConstant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENPanificados MarielaNo ratings yet

- Merc Service Manual 11 Bravo Stern DrivesDocument596 pagesMerc Service Manual 11 Bravo Stern DrivesHayduke them92% (13)

- 1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFDocument797 pages1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFRoberto Implatini100% (5)

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFDocument9 pagesDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFMozes SimataaNo ratings yet

- Mercruiser Service Manual Merc-Marine 4 Cyl 1985 To 1989Document274 pagesMercruiser Service Manual Merc-Marine 4 Cyl 1985 To 1989Osw Galati100% (3)

- Daewoo Doosan Forklift D20S-3 D25S-3 D30S-3 Service ManualDocument1,021 pagesDaewoo Doosan Forklift D20S-3 D25S-3 D30S-3 Service Manualrgcsadlerhotmail.comNo ratings yet

- Q' Range Electric Direct-Drive Quarter Turn Valve Actuators Instruction ManualDocument12 pagesQ' Range Electric Direct-Drive Quarter Turn Valve Actuators Instruction Manualravi_fdNo ratings yet

- Mercruiser D219 Service ManualDocument546 pagesMercruiser D219 Service ManualEerik (stnz)No ratings yet

- Manual de Servicio - Inglés PDFDocument2,148 pagesManual de Servicio - Inglés PDFzaidsantoyo50% (2)

- REMOTE-SENSE-JUMPER-LEAD-INSTALLATION-INSTRUCTIONS-34SI,-35SI,-36SIDocument3 pagesREMOTE-SENSE-JUMPER-LEAD-INSTALLATION-INSTRUCTIONS-34SI,-35SI,-36SIJose RoyNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mercruiser Diesel 4.2L CMD QSD 270 300 350Document129 pagesMercruiser Diesel 4.2L CMD QSD 270 300 350Joswyn LopesNo ratings yet

- Electrical: Section 2B - Charging & Starting SystemDocument51 pagesElectrical: Section 2B - Charging & Starting SystemJoswyn LopesNo ratings yet

- Maintain Outboard Engine EasilyDocument14 pagesMaintain Outboard Engine EasilyJoswyn LopesNo ratings yet

- General information on factors affecting boat engine performanceDocument20 pagesGeneral information on factors affecting boat engine performanceJoswyn LopesNo ratings yet

- Medium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?Document1 pageMedium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?OsniSoiNo ratings yet

- Start The Engine For ROC F6 and F9Document2 pagesStart The Engine For ROC F6 and F9aaronNo ratings yet

- M.tech Petroleum EngineeringDocument2 pagesM.tech Petroleum EngineeringAqinwandeNo ratings yet

- Asme Section Ii A Sa-426 PDFDocument6 pagesAsme Section Ii A Sa-426 PDFAnonymous GhPzn1xNo ratings yet

- Proportional Pressure Reducing Valve, Pilot Operated: RE 29176/04.05 Replaces: 11.02Document12 pagesProportional Pressure Reducing Valve, Pilot Operated: RE 29176/04.05 Replaces: 11.02Gytis MarkauskasNo ratings yet

- MAPs Limited Contention ProtocolsDocument60 pagesMAPs Limited Contention ProtocolsSahilPrabhakar100% (1)

- Why Vehicle Slip When It Is Travelling On A SlopeDocument12 pagesWhy Vehicle Slip When It Is Travelling On A SlopeRizwan Sheikh0% (1)

- Cellular manufacturing: a lean system for grouping similar machinesDocument4 pagesCellular manufacturing: a lean system for grouping similar machinesPrashant AroraNo ratings yet

- Présentation - Cnes - Icam - Materiaux - Structuraux - 2021 PDFDocument62 pagesPrésentation - Cnes - Icam - Materiaux - Structuraux - 2021 PDFJoshua VUITTENEZNo ratings yet

- The HACCP Plan Form The StepsDocument4 pagesThe HACCP Plan Form The StepsAnonymous qfCJwxib7No ratings yet

- Capital BudgetingDocument30 pagesCapital BudgetingNarasimhaPrasadNo ratings yet

- Application Engineering BulletinDocument2 pagesApplication Engineering BulletinCesar G.No ratings yet

- 1999 Ford Ranger Owner's ManualDocument216 pages1999 Ford Ranger Owner's Manualtacosoft100% (6)

- Bridge Deck BehaviourDocument327 pagesBridge Deck BehaviourJunwhan KimNo ratings yet

- Supply Chain Management in E-CommerceDocument9 pagesSupply Chain Management in E-CommerceAbhishek AgarwalNo ratings yet

- Air Outlets and Inlets PDFDocument7 pagesAir Outlets and Inlets PDFAdamNo ratings yet

- mx4gvr Ol eDocument111 pagesmx4gvr Ol eHector Cabrera GarciaNo ratings yet

- CHEMICAL BONDING typesDocument68 pagesCHEMICAL BONDING typesHarsh Tyagi100% (2)

- Computaion IntelligentDocument624 pagesComputaion IntelligentThaiHuynhNgocNo ratings yet

- Chapter 3 Cost Behavior Analysis and UseDocument45 pagesChapter 3 Cost Behavior Analysis and UseMarriel Fate Cullano100% (1)

- Interseal 547: Surface Tolerant EpoxyDocument4 pagesInterseal 547: Surface Tolerant EpoxyTài Đỗ VănNo ratings yet

- Rule of Thumb: Distillation and Gas AdsorptionDocument2 pagesRule of Thumb: Distillation and Gas AdsorptionChristina Joana GuzmanNo ratings yet

- Electrical Services Company Profile TemplateDocument1 pageElectrical Services Company Profile Template10K GOLDNo ratings yet

- Oryx, Salt-MsdsDocument6 pagesOryx, Salt-MsdsMarg ConveyorsNo ratings yet

- RainbowCrack tutorial guide for password crackingDocument5 pagesRainbowCrack tutorial guide for password crackingJunior SanzNo ratings yet

- Government of Chhattisgarh: Ublic Orks EpartmentDocument19 pagesGovernment of Chhattisgarh: Ublic Orks EpartmentLucky ChopraNo ratings yet

- Peering Grandstream Camera & IP Phone Door Open ConfigurationDocument12 pagesPeering Grandstream Camera & IP Phone Door Open ConfigurationJuliano Alves FernandesNo ratings yet

- Air Fin Cooler Optimisation For Offshore & Onshore Application PDFDocument3 pagesAir Fin Cooler Optimisation For Offshore & Onshore Application PDFDHAVAL PANCHALNo ratings yet

- Arduino Controlled 432 MHZ Wireless Power OutletsDocument12 pagesArduino Controlled 432 MHZ Wireless Power Outletsm01maiklerNo ratings yet

- Ieee Computer SDN Issue When Open Source Meets Network Control PlanesDocument9 pagesIeee Computer SDN Issue When Open Source Meets Network Control PlanesMysterio KnowerNo ratings yet