Professional Documents

Culture Documents

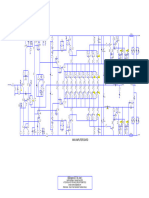

D150B - Esquema Hidráulico

D150B - Esquema Hidráulico

Uploaded by

Pedro Lucas Rodrigues QueirozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D150B - Esquema Hidráulico

D150B - Esquema Hidráulico

Uploaded by

Pedro Lucas Rodrigues QueirozCopyright:

Available Formats

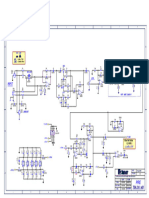

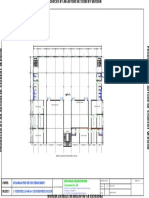

MAIN HYDRAULIC PUMP AND RESERVOIR EQUIPMENT VALVE EQUIPMENT VALVE CYLINDERS LEFT-HAND HYDROSTATIC PUMP ASSEMBLY

C5 F4-C2 C7 F4-C6 C2 F4-C3 C4 F4-C2

C1 F2-C4

C3 F3-C5 C4 F4-C1 C6 F4-C5 C1 F4-C4 C3 F4-C1 C5 F2-C3

C2 F2-C5

14

9 10 11

L1 LS A1 B1 A2 B2 A3 B3 A4 B4

8 8-05 8-06 8-05 8-07 9-01 9-02 10-01 10-02

F11-C5 C6

MLS MP

Ø0.8

F2-C1 C2 P Ø0.8 18-01

C6 F10-C2

C2 F1-C1 C5 F7-C3

F5-C1 C7

F8-C4 C3 8-01 8-03 PST

C6 F2-C7 C4 F10-C1

C1 F2-C2 15 C3 F7-C2

C5 F2-C6 F11-C4 C7

5 7 L

I

3 12

R T2 PS Fa Fe MB

4 18

5-01 F6-C3 C8

7-01 8-02 13 B

P T1

8-08

18-02

13-02

8-04 11-01 18-04

7-02

T C C4 F3-C1

T 16 18-03 18-04 18-06

C1 F1-C2 AC C3 F3-C2

18-07

6

18-05 A

P1 P2 F6-C1 C9

8-09 8-09 8-09 8-09 9-03 9-03 10-03 10-03

1 X1 X2 G G1 MH S MA

MPST

°C

2 C2 F11-C6 F11-C3 C10

L C1 F3-C7

C2 F3-C4

2 17 2 2

C1 F3-C3

19

2-01 2-01

FRAME 1 FRAME 2 FRAME 3 FRAME 4 FRAME 5

BC07K690-01A BC07K690-02A BC07K690-03A BC07K690-04A BC07K690-05A

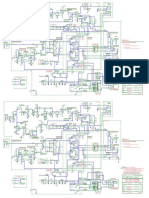

LEFT-HAND HYDROSTATIC MOTOR RIGHT-HAND HYDROSTATIC PUMP ASSEMBLY RIGHT-HAND HYDROSTATIC MOTOR BRAKES HYDROSTATIC FILTER TEST PORT PANEL

BP

27

21-01 C3 F5-C5 25 27-01 F5-C2 C6

C3 F7-C5

C3 F5-C8 C2 F6-C2

C2 F5-C3

C4 F8-C5 F11-C2 C4 C5 F6-C4

C2 F8-C2 C4 F1-C3

27-02 F3-C6 C5

B M1 U R T2 PS Fa Fe MB B M1 U 26

BP

20 21 F8-C3 C5

22

B 24 B

20-01 T1 22-01 23 26-01 27-03 F5-C7 C4

20-03 20-05 22-03 22-05

20-06 21-02 22-06 P

21-04 27-04 F5-C10 C3

21-03 21-04 21-06 26-02

21-07

20-02 22-02

27-05 F7-C4 C2

20-04 22-04 P T G P2 P1 P3

21-05 A

F8-C1 C6

C1 F7-C1

27-06 F7-C7 C1

A G T2 X1 X2 G G1 MH S MA A G T2 C1 F5-C4 C2 F5-C6

C1 F5-C9 C1 F9-C1 F11-C1 C7 C1 F7-C6

2 2 2

2 2

2-01

FRAME 6 FRAME 7 FRAME 8 FRAME 9 FRAME 10 FRAME 11

BC07K690-06A BC07K690-07A BC07K690-08A BC07K690-09A BC07K690-10A BC07K690-11A

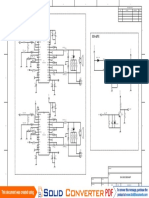

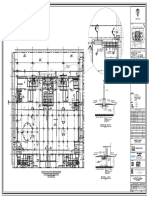

COMPONENTS

FRAME - COMPONENT NUMBERS FRAME - COMPONENT NUMBERS FRAME - COMPONENT NUMBERS FRAME - COMPONENT NUMBERS

FRAME 1 COMPONENTS FRAME 3 COMPONENTS FRAME 5 COMPONENTS

1- 1. Hydraulic Temperature Sending 3- 2. Hydraulic Reservoir 5- 2. Hydraulic Reservoir FRAME 8 COMPONENTS

Unit 3- 9. Angle Section 5- 2-01 Screen 8- 2. Hydraulic Reservoir

1- 2. Hydraulic Reservoir 3- 9-01. Flow Compensator Spool 5- 18. Left-Hand Track Pump 8- 22. Right-Hand Track Motor

1- 2-01. Screen 3- 9-02. Angle Spool 5- 18-01. Proportional Solenoids and Spool 8- 22-01 Speed Sensor

1- 3. Hydraulic Reservoir Vent 3- 9-03. Circuit Relief Valve with 5- 18-02. Hydrostatic Pump 8- 22-02. Hydrostatic Motor

Pressure: 1.3 Bar / 20 psi Anti-cavitation 5- 18-03. Servo Pistion 8- 22-03. Positioning Piston

Vacuum: 0.06 198 Bar / 2872 psi 5- 18-04. Main Pressure Relief 8- 22-04. Proportional Solenoid

Filter: 10 Micron 3- 10. Ripper Section (Optional) 450 Bar / 6527 psi 8- 22-05. Flushing Valve

1- 4. Equipment Hydraulic Pump 3- 10-01. Flow Compensator Spool 5- 18-05. Charge Pump Pressure Relief 8- 22-06. Flushing Orifice

64.5 cc / 4 Cubic Inch 3- 10-02. Ripper Spool 30 Bar / 435 psi

1- 5. Hydraulic Cooler Bypass Valve 3- 10-03. Circuit Relief Valve with 5- 18-06. Override Pressure Relief FRAME 9 COMPONENTS

1- 5-01. 13.8 Bar / 200 psi Anti-cavitation Blocked 9- 2. Hydraulic Reservoir

1- 6. Oil Cooler 198 Bar / 2872 psi 5- 18-07. Charge Pressure Pump 9- 23. Brake Pressure Switch

1- 7. Hydraulic Filter 3- 11. End Cover 19.6 cc / 1.2 Cubic Inch Normally Open (NO)

1- 7-01. Filter Bypass Switch 3- 11-01. ON/OFF Solenoid 5- 19 Charge Pressure Switch Closes at: 11-12.5 Bar / 164-184 psi

1- 7-02. 3.5 Bar / 50 psi 3- 12. Pilot Accumulator Normally Closed (NC) 9- 24. Brake Solenoid

3- 13. Accumulator Charge Valve Opens at 9- 25. Brake Cylinders

FRAME 2 COMPONENTS 17.5-19.5 Bar / 253-281 PSI

2- 8. Equipment Valve FRAME 4 COMPONENTS FRAME 10 COMPONENTS

2- 8-01. Unloading Valve 4- 14. Tilt Cylinder FRAME 6 COMPONENTS 10 - 2. Hydraulic Reservoir

138 liters per minute Bore:125 mm 6- 2. Hydraulic Reservoir 10 - 26. Filter

10-16 Bar / 145-232 psi Rod: 63 mm Diameter 6- 20. Left-Hand Track Motor 10 - 26-01. By-pass Switch

2- 8-02. Main Pressure Relief Stroke: 135 mm 6- 20-01 Speed Sensor 10 - 26-02. 3.5 Bar / 50 psi

185 Bar / 2683 psi 4- 15. Lift Cylinders 6- 20-02. Hydrostatic Motor

2- 8-03. Load Sense Relief Bore: 90 mm 6- 20-03. Positioning Piston FRAME 11 COMPONENTS

163 Bar / 2364 psi Rod: 50 mm Diameter 6- 20-04. Proportional Solenoid 11 - 27. Test Port Panel

2- 8-04. Load Sense Bleed Down Orifice Stroke 826 mm 6- 20-05. Flushing Valve 11 - 27-01. Charge / Pilot Pressure

0.4 liters per minute / 0.1 gpm 4- 16. Angle Cylinders 6- 20-06. Flushing Orifice 11 - 27-02. Equipment Valve Pressure

2- 8-05. Flow Compensator Spool Bore: 110 mm 11 - 27-03. Travel Pressure -Left-Forward

2- 8-06. Tilt Spool Rod: 55 mm Diameter FRAME 7 COMPONENTS 11 - 27-04. Travel Pressure -Left-Reverse

2- 8-07. Lift Spool Stroke: 509 mm 7- 2. Hydraulic Reservoir 11 - 27-05. Travel Pressure -Right-Forward

2- 8-08. Pre-charge Valve 4- 17. Ripper Cylinders (Optional) 7- 2-01 Screen 11 - 27-06. Travel Pressure -Right-Reverse

16 Bar / 232 psi Bore: 125 mm Cylinder 7- 21. Right-Hand Track Pump

2.- 8-09. Circuit Relief Valve with Rod: 70 mm Diameter 7- 21-01. Proportional Solenoids and Spool

Anti-cavitation Stroke: 275 mm 7- 21-02. Hydrostatic Pump

198 Bar / 2872 psi 7- 21-03. Servo Piston

7- 21-04. Main Pressure Relief

450 Bar / 6527 psi

7- 21-05. Charge Pump Pressure Relief

30 Bar / 435 psi

7- 21-06. Override Pressure Relief

Blocked

7- 21-07. Charge Pressure Pump

19.6 cc / 1.2 Cubic Inch

HYDRAULIC SYMBOLS CIRCUIT CONTINUATION NOTES

NOTE: All Pressures and Flows are at Operating RPM.

54

Frame Number and Circuit

Number where Circuit

CIRCUIT TAGS

F4-C3 C10

HYDRAULIC SCHEMATIC

continues.

CHECK VALVE FILTER OR SCREEN CIRCUIT PRESSURE

C6 F1-C3

D150B CRAWLER

20-01 FRAME - CIRCUIT CIRCUIT

SHOWS CIRCUIT SHOWS COMPONENT LOAD SENSE

COMPONENT CROSSING CIRCUIT

RESTRICTOR Circuit Number assigned to Circuit in Frame.

NUMBER NOT CONNECTED CONNECTED OIL COOLER DIRECTION OF FLOW LINE TYPES

Copyright © 2007. CNH Italia S.p.A. All Rights Reserved. BC07K690-00A

You might also like

- 32E391 Power Supply Service ManualDocument1 page32E391 Power Supply Service Manualies837No ratings yet

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- AD15 - 30VT Vox AmplifierDocument11 pagesAD15 - 30VT Vox AmplifierKenn FerroNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Input Jack PCB To Power PCBDocument2 pagesInput Jack PCB To Power PCBPablo Rodrigo Nazario Perez100% (2)

- 002 - DrivetrainDocument88 pages002 - DrivetrainCarlos PinedaNo ratings yet

- 006 - Fault CodesDocument36 pages006 - Fault CodesCarlos Pineda100% (2)

- Amplificador Ucd Hasta 1250w RmsDocument12 pagesAmplificador Ucd Hasta 1250w RmsAnonymous vl1q0B0% (1)

- 004 - Instrument Cluster NavigationDocument17 pages004 - Instrument Cluster NavigationCarlos PinedaNo ratings yet

- EQA00048 Jetstream 4200 PDFDocument151 pagesEQA00048 Jetstream 4200 PDFNam TruongNo ratings yet

- Docker Inc Docker Fundamentals Course PDFDocument193 pagesDocker Inc Docker Fundamentals Course PDFJavier MoralesNo ratings yet

- Research II Q4 Module 1Document12 pagesResearch II Q4 Module 1Mhelet Dequito Pacheco100% (1)

- Prepare Hand Tools and Equipment in Technical DraftingDocument8 pagesPrepare Hand Tools and Equipment in Technical DraftingClemenda TuscanoNo ratings yet

- 003 - 1150K-1650L HydraulicsDocument38 pages003 - 1150K-1650L HydraulicsCarlos PinedaNo ratings yet

- HYD Companies - Varun2Document124 pagesHYD Companies - Varun2api-19837551No ratings yet

- Instalaciones ElectricasDocument1 pageInstalaciones ElectricasVictor CantuNo ratings yet

- Sd-Ec-Cgc-St-P2a-B3-100 Rev-2Document1 pageSd-Ec-Cgc-St-P2a-B3-100 Rev-2Ahmed Salah El DinNo ratings yet

- Sd-Ec-Cgc-St-P2a-B2-100 Rev-1Document1 pageSd-Ec-Cgc-St-P2a-B2-100 Rev-1Ahmed Salah El DinNo ratings yet

- VC 4406Document4 pagesVC 4406Владимир БуклинNo ratings yet

- Plano ElectricoDocument1 pagePlano ElectricoCarlos Arturo Capacho MoralesNo ratings yet

- 3.residential StrutureDocument1 page3.residential Struturesakshikindre7No ratings yet

- Skyworth 168p-p42ttf-00 Fan7530 Fsfr1700 Str-A6159m SCHDocument1 pageSkyworth 168p-p42ttf-00 Fan7530 Fsfr1700 Str-A6159m SCH62eugenNo ratings yet

- Skyworth 168p-l5l01f-00 Psu SCHDocument2 pagesSkyworth 168p-l5l01f-00 Psu SCHTitán SotoNo ratings yet

- New ARCDocument1 pageNew ARCanoopgupta52No ratings yet

- Max10 SchematicDocument1 pageMax10 Schematicmarcelow2014No ratings yet

- Oneal Op7502Document5 pagesOneal Op7502LUIZ COELHO PWTNo ratings yet

- PID501 PID501: PSU: 50 To 100 VDocument4 pagesPID501 PID501: PSU: 50 To 100 VAgiga GigaNo ratings yet

- DR.L H Bidari Bungalow First Floor Center Line PlanDocument1 pageDR.L H Bidari Bungalow First Floor Center Line PlanRaj ChaughuleNo ratings yet

- VA DO How-To FloneDocument1 pageVA DO How-To FlonettNo ratings yet

- Crate BT15 - PWA Bass Amplifier PCB Layout (848PWA - A)Document1 pageCrate BT15 - PWA Bass Amplifier PCB Layout (848PWA - A)Guim EloyNo ratings yet

- AD100VT Service ManualDocument7 pagesAD100VT Service ManualKyleRBNo ratings yet

- CricketDocument4 pagesCricketPhạm Quốc ViệtNo ratings yet

- AD50VT1Document8 pagesAD50VT1Pablo RodriguezNo ratings yet

- Centre Line Plan: All Dimensions in MMDocument1 pageCentre Line Plan: All Dimensions in MMRHUTI NAIKNo ratings yet

- EEEngine G77-XL Ver.1aDocument3 pagesEEEngine G77-XL Ver.1aLanang DangiranNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 110001 - CDocument1 page07 522213 4800000612 WSP SLT DRG 110001 - CMOHD NAZEEF KHANNo ratings yet

- 25w 1250wDocument1 page25w 1250wneko1212121515123001No ratings yet

- A2 ME011542-SCHEM C: Chassis Harness, Ue6, Mk2.1 Harn SchemDocument1 pageA2 ME011542-SCHEM C: Chassis Harness, Ue6, Mk2.1 Harn SchemLuis ChaconNo ratings yet

- HV65T 100T Preamp - REVEDocument1 pageHV65T 100T Preamp - REVESzabo Mihai-PaulNo ratings yet

- Capsule MCUDocument1 pageCapsule MCUDavid duranNo ratings yet

- Samson - EX30Document4 pagesSamson - EX30IRAWAN SURYANATANo ratings yet

- F E D C B A: Pre Amplificador Eq 2 ViasDocument4 pagesF E D C B A: Pre Amplificador Eq 2 ViassugedaNo ratings yet

- Pre Tsa 420Document1 pagePre Tsa 420Antonio Fernandes de JesusNo ratings yet

- 21 C 1348 Preamp 2Document1 page21 C 1348 Preamp 2GökhanNo ratings yet

- Carvin Mts 3200 SCHDocument2 pagesCarvin Mts 3200 SCHAngel BacaNo ratings yet

- WWW - Teknisi Indonesia - Com.x260 NM A531R10 SILK BOT BVDocument1 pageWWW - Teknisi Indonesia - Com.x260 NM A531R10 SILK BOT BVodemontealtoNo ratings yet

- BK 3600/3800ampDocument1 pageBK 3600/3800ampAveriguaçoes Perigosas (Detetive)No ratings yet

- PROYECTO PROPIO-90x60Document1 pagePROYECTO PROPIO-90x60Caro MendezNo ratings yet

- Myanmar Fire Service Department 2-STOREYED (120'x80'x26') DIVISION FIRE STATIONDocument1 pageMyanmar Fire Service Department 2-STOREYED (120'x80'x26') DIVISION FIRE STATIONTun AungNo ratings yet

- Airport GuideDocument2 pagesAirport Guidearno limNo ratings yet

- Freemont Precision Travas PortasDocument1 pageFreemont Precision Travas PortasfabiogynNo ratings yet

- BC-5600&5800 OldDocument20 pagesBC-5600&5800 Oldsamuel debebeNo ratings yet

- Immulite Automated Immunoassay System: Assembly and Schematic DrawingsDocument36 pagesImmulite Automated Immunoassay System: Assembly and Schematic Drawingsşaban günerNo ratings yet

- Ci TP 01 04 016Document1 pageCi TP 01 04 016harihfclNo ratings yet

- Ci TP 01 04 016Document1 pageCi TP 01 04 016harihfclNo ratings yet

- Linear Psu SchematicDocument1 pageLinear Psu SchematicDelcu MarinicaNo ratings yet

- Jtag CPLD PDFDocument1 pageJtag CPLD PDFDeilyn RivasNo ratings yet

- New Kitchen (13!11!23Document1 pageNew Kitchen (13!11!23Vicky simplemanNo ratings yet

- Sd-Ec-Cgc-St-Sk-B3-033 Rev-00Document1 pageSd-Ec-Cgc-St-Sk-B3-033 Rev-00Ahmed Salah El DinNo ratings yet

- Delta Eadp-45bf-A Psu SCHDocument6 pagesDelta Eadp-45bf-A Psu SCHOscar Caetano FontNo ratings yet

- Electrical Schematic 1650L Crawler: V M P TDocument1 pageElectrical Schematic 1650L Crawler: V M P TCarlos PinedaNo ratings yet

- 12th International Conference On Magnesium Alloys and Their Applications (MG 2021) Meyer StoneDocument10 pages12th International Conference On Magnesium Alloys and Their Applications (MG 2021) Meyer Stonea stoneNo ratings yet

- Contact Tachometer: Model: DT-2235BDocument2 pagesContact Tachometer: Model: DT-2235Bnisne0730No ratings yet

- Ib Question OnlyDocument2 pagesIb Question Onlyapi-529669983No ratings yet

- Manjari Bahety CMBA2Y3-1926Document9 pagesManjari Bahety CMBA2Y3-1926Siddharth ChoudheryNo ratings yet

- LDA CreditCardDefault Code NDocument11 pagesLDA CreditCardDefault Code NSHEKHAR SWAMINo ratings yet

- Iec TS 61000-5-8-2009Document32 pagesIec TS 61000-5-8-2009Venkataramanan SNo ratings yet

- Appendix: Competencies and Performance Indicators (Pis) Computer Science & Engineering/Information Technology ProgramsDocument5 pagesAppendix: Competencies and Performance Indicators (Pis) Computer Science & Engineering/Information Technology ProgramsNitai PaityaNo ratings yet

- FG Wilson PerkinsDocument4 pagesFG Wilson PerkinsAemyNo ratings yet

- HeartviewDocument2 pagesHeartviewIsrael ExporterNo ratings yet

- Volume 19 Issue 3: International Journal of Virtual RealityDocument16 pagesVolume 19 Issue 3: International Journal of Virtual RealityMARYAMNo ratings yet

- Legrand Price List 2014Document44 pagesLegrand Price List 2014rajabharath12100% (1)

- Lesson 5: Selecting Event Venue and SiteDocument3 pagesLesson 5: Selecting Event Venue and SiteChavez RechelleNo ratings yet

- Assignment On Python 1Document6 pagesAssignment On Python 1Herton FotsingNo ratings yet

- Practical No - 01: Aim: Data Collection, Data Curation and Management For Unstructured Data (Nosql) Using Apache CouchdbDocument79 pagesPractical No - 01: Aim: Data Collection, Data Curation and Management For Unstructured Data (Nosql) Using Apache Couchdbyagyesh trivediNo ratings yet

- Oki C9650-C9850 - MM - Rev1 PDFDocument246 pagesOki C9650-C9850 - MM - Rev1 PDFzaika174No ratings yet

- Installation Manual: EM 710 Multibeam Echo SounderDocument155 pagesInstallation Manual: EM 710 Multibeam Echo SounderEvelyn HerediaNo ratings yet

- Principles and Practices of Robust, Photography-Based Digital Imaging Techniques For MuseumsDocument27 pagesPrinciples and Practices of Robust, Photography-Based Digital Imaging Techniques For MuseumsLegatus_PraetorianNo ratings yet

- 1.3 - Thermal Waves Propagation Study On SiC - MaSa - ST - V3Document27 pages1.3 - Thermal Waves Propagation Study On SiC - MaSa - ST - V3moyinglong1126No ratings yet

- LogDocument24 pagesLogcintapuspita2003No ratings yet

- Code - Aster: Macro-Order CREA - LIB - MFRONTDocument2 pagesCode - Aster: Macro-Order CREA - LIB - MFRONTStefano MilaniNo ratings yet

- 6wind Vrouter Provides Bgp-Based Border Routing For Isps: Solution BriefDocument4 pages6wind Vrouter Provides Bgp-Based Border Routing For Isps: Solution BriefwfawfwafNo ratings yet

- Blog - Next - Js 12 - Next - JsDocument12 pagesBlog - Next - Js 12 - Next - JsJulianIgnacioApazaCcoaNo ratings yet

- Feb 2013Document16 pagesFeb 2013api-209049915No ratings yet

- 710, Barton Centre, M G Road, Bangalore 560 001: A.O: Against Order Tax (Vat) 5% ExtraDocument11 pages710, Barton Centre, M G Road, Bangalore 560 001: A.O: Against Order Tax (Vat) 5% ExtraKumar NagarajNo ratings yet

- FSUIPC Offsets StatusDocument70 pagesFSUIPC Offsets StatusKAPTAN XNo ratings yet