Professional Documents

Culture Documents

7 Ed 50 F

7 Ed 50 F

Uploaded by

kimba worth0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

7ed50f_635a166c66364dde80a97ede5f0c9346

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pages7 Ed 50 F

7 Ed 50 F

Uploaded by

kimba worthCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

How to install your a”

Ultralift Hydraulic Mount urTraer We

Cover Lifter Hydraulic Mount Hot Tub Cover Lifter

This is your step by step guide to installing the Ultralift Hydraulic Mount Cover Lifter on to your hot tub or spa.

Begin by opening the box your cover liter came in and check the contents against the installation guide to

ensure you have all the components required.

PARTS LIST:

© % Bot Pins o

@ 20X No.10-1 inch Cross Slot

or Phillips Wood Screws

© 26X No.10- 5/8 inch Cross Slot

or Phillips Setf-Tapping Screws

46X Black Plastic Screw Head Caps

© 4X 5/16 inch NYLON Lock Nuts

© 4X NYLON Washers

@ 4X Ball Studs

© 2X Round Black Plastic Caps

© 2 Square Black Plastic Caps

© 1X "J" Hook Pin

® 2X Mounting Bracket Assemblies

{including the Slim Top Bracket)

® & Sliding Pivot Brackets

® 1X Center Pole

® 2X Cover Hooks.

© 2 Pivot Arms w/ Ball Stud Bracket

© 2 Foam Grips

® 2 Hydraulic Arm

© 2X Comer Support Arms

© 2X Short Support Arms

® X Clevis (Cotter) Pins

TOOLS LIST:

#6 Foot Tape Measure

© Ratchet Wrench

# 5/16” Socket Bit

# 5/16” Open End Wrench CORN

* Cordless Power Screwdriver or drill SURPORT

© A number of Cross Slot or Philips

screw driver bits.

« Needle Nose Pliers

«Small Flat Head Screwdriver

6-00

Diagram of

Finished Assembly

End View

To view the easy to follow Installation

Video that pertains to this Cover Lifter,

please go to:

www.ultrapoolandspa.com/videos

PIVOT ARM,

Now you are set to start

the install of your new

Cover Lifter...

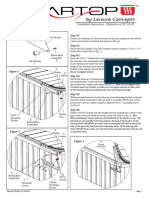

Step One: » Wid)

18) Ensure thatthe hot ubis 6 nones oF mere out rom any wal, obstustn or fnce this

prowdas ample leaance for your cover fo skinto cnc You cover ere nsalod

1b) Place your hot tub cover squarely over the hot tub and in the position you would lke it to

open, We rsonmand fet you have your ove" open om he oulsmant pa Tapes

Cento en, Ts ensues that you are not mouringbrackots to doors or Banos ta ay —

rood tbe ronoved to acuaas hoatr and pups Tan Y

1c) Now begn by nsertng th two (2) Roun Plastic Caos @ into the open ends ofthe *

found Bot Ame.

14) Then insert the two (2) Plastic Square Caps @ nto the open ends of the Sider Plot Brackets,

416) Than instal the Foam Grips (D onto the corner suport arms, frst Mbricating the interior of

the Foam Grips for easier appscation, Installation Tip: Ri the inside rim of the foarn grips

with dish soap to lubvicate thom making ft casio o side thom into piace.

‘Mf Assemble the Corner Support Arm inserting into the Short

‘Support Arm @ using too (3) No, 10 5/8 Sal Tapeng Sows

peat this assembly and create a second complete arm

Step Two:

\With your cover inthe closed postion begin the next step.

2a) Assamie the two piace Mounting Bracket @ using

‘wo 8/16 ch NOW Lock Nuts @ as shown,

2b) Piace the Mounting Bracket Assembly @) at the adge of wrere the comer radius begins

‘and at the fap odgo of your cove. Thon tll tho Mounting Brackst Assombly to the

Cabinet using the supplied 1" inch No. 10 Weed Pepeat the same

process on the opposte sic.

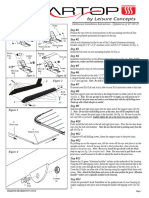

Step Three:

3) Insert the Siding Pot Bracket @ arm into the Mounting Bracket Assembly @® and postion

it s0 the back of the Sider Pivot Bracket Ines up with the back edge of the Pot tb.

Installation Tip: Use the Center Post (© as a straight edge to mark the back edge ofthe hot tub

and side the Sicing Pwot Bracket @ back tl touches the Center Post - now Ish positon.

Now secure both Siding Pwot Brackets using the No.10 6/8 inch Salt Tapping Screws

3b) Install the Ball Studs @ on to the Slider Pot Brackets ( ensuring that thay face away

‘fom the hot tub as shown,

5c) Its time ta slike the Cover Hooks (as shown hereon tothe long arm of the Comer Support

‘Arm Assombly (EXD. Make sure the Gover Hooks are facing in on each side ofthe hol tub.

‘3d) Now sli the Long Arm of the Comes Support Arm Assemby (@XDinto the Center Post

‘and repeat this on the apposte end ofthe Canter Post using the ather Gomer Support Army

Aesomby.

Step Four:

42) Then algn the sacond hoe up rom the bottom ofthe Pot Arm &B withthe top hole

inthe Sling Pwo! Brack

4b) Postion he Nyon Washers © on he ie ofthe pivot arm anc bracket. Than sear them

ino place by sing trough the Bat Pr

42) Secure the Bot Pin @ into place using the Cavs Pn @ (Colter Pri, Repeat this step on

she cpocste sido othe hot ub.

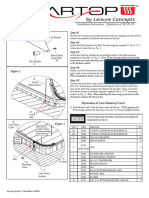

Step Five:

58) Once tis complte check o make sure thatthe Center Poi @ that ecsses over he

Cover 1 inst hack o the carer fling seam on te tr seo ath the Pvt Ams

tro 1.5 Phos oat fom the cabnot on oth ss of thot tb.

'5) Then on the side of the hot ub see the Pot Arm (B wth tres (3)No.10 5/8" nch

Sel Tapaing Sores

'5e) Than stop back and make sug thatthe Pot Arms (B ave sil 1Sinches out rm the

hot ub and the Conor Pole) i tng 1 inch acs ofthe canto sea Iso fa Seeing

‘the Pwot Am eB on the opposte side a he hot

54) Now pace a rctac yer of ard bom nc the Conte Pol an eat tho Cantor

Polo tt the screw hace ae ir to sare your het ub -rot ont lope he oatom

fhe poe once n poston secure heer sing trae No.10 9/8" non Se Teping

Screws @. Ropoat ts sop onthe cpooste onda he Cntr Pak.

Step Si:

68) Now open the Hot Tub Cover tothe up right position an attach tho argo ona he

Hydraulic Arm €@ to the Ball Stud @ now instaled on the Slider Pivot Bracket ( by

pressing the fting over tho ond of tho Bal Stud iso

1) Then move up so that the opoosto end of the Hycrausc Aum moet the Bal Stl @

‘iso now instaled on the Sider Pivot Arm «@). Repeat these steps on the opposite se of

‘honor

“Tipe you ovr nocd to ramvo the Hyeraule Am €B gonty pry the ha cle coe to rleaso

the ping fom the pal te

Ox

7 Boron

/

'

t ‘nro At —

—S

HS

== 1B

Step Seven:

You are almost there,

7a) Cow the Sot Tapong Sores @ anc Wood Sores @ wih the Black Paste Covers that

neo ovr ths head of each sre finishing the ok

7h) Then ntl the Joo ® into te Sing Pot Bracket @ inthe open ooston hole ith the

cava opts ercrcs some adieu saat and whos tho covers down mow the v Hos tO

‘he Closer” poston ho.

You have now installed your Ultrali

Mount Cover Lifter.

Remember... Remember to aways fold back your cover before using

the Cover Lifter to lft the cover into its final resting place - this ensures a

longer lfe for your cover and Cover Lifter extending your enjoyment of

your hot tub,

Hydraulic

Ultralift Hydraulic Mount ura We

Cover Lifter Warranty Hydraulic Mount Hot Tub Cover Lifter

‘THE WARRANTY:

‘SMP Specialty Metal Products Inc. warrants to you (the orignal purchaser] forthe statad warranty term of LIFETIME

‘fom the orginal date of purchase, to be fre fom defects in material and workmanship

Utrat Cover Liters wil be fee from defects in mataials or workmanship that would causa the iter to be inoperable in

normal working conditions. Ary clrn mada within these tam fo Litetime ofthe product ftom the data of purcnasa wil be repakedt

‘or replaced at the option ofthe Manufacture

This isa 100% Non-Prorated Warranty on all pars for the ifelme of the product

gas springs which include a 100% One Year Warranty

EXCLUSIONS To WARRANTY

« Liter has been subjected to altration, misuse or tapas by anyone other than an authorzad representatve

ofthe Manctacture, unless written approval is provided

(Only parts excluded for the warranty are the:

‘© Damage causad by improper instalation or during transportation from the salle tothe purchaser

«Any damage resutng tom any misuse, abuse, negigence, accident or aration, environmental,

lor use during high winds.

‘The warranty covers the operational uss o the lite but does not cover scratches, abrasions, rusting o any defects to the

{nish of the material caused by or resulting fom the exposure to the environmental factors; sun, rain, chemicals or any

detect resulting fom narma fading or miner deterioration.

The waranty does not cover damage resutng from abuse or accidents, including but not limited tothe folowing damage:

«Use of abrasive or unapproved cleaners that coud cause surface damage

«© Subjection to solvents or other chemicals which could dateriorate painted surfaces

«© Use for any othar pumose than as a Spa or Hot tub cover Iter

MAKING A CLAIM:

To make a warranty claim: in the event of a defect covered by this warranty for Utvalit, contact the original etal soler and

provile orginal purchase receipt, any photo(s) ceatly showing the defects) and an explanation, NO RETURNS OF

MERCHANDISE WILL BE ACCEPTED UNTIL A “RETURN AUTHORIZATION NUMBER” HAS BEEN ISSUED.

‘The Far willbe repared or replaced at the ciseration of the Manufactura. I necessary, the purchasar is response to

Ship any sai parts back to the manufacturer. The waranty includes al Labor costs performed a the manufacture’ facity

[but not labor inthe fie. SMP will cover the cost(s) to repair and/or replacement of the items back tothe retailer or salle:

FREIGHT DAMAGE:

‘Any materials damaged in freight willbe replaced by SMP Speciaty Metal Products provided the purchaser fles the

appropriate clams form with the carrer, and submits copies to the manudacturer within five (5) business days of recehing

the damaged merchandise. Al calms should also be reported to the sell

‘Consequential Damages:

‘SMP Specialty Metal Products Inc. wil not be lable for any loss, expense, or damage other than to Uva, that may result

‘tom a defect in materials or workmanship. This wananty does not cover incidental damages including damage to property or

injury arising fom the use or inablity to use this product. Manufacturer or Selle shal in no event be lable for any amount

‘excess ofthe orginal purchased amount, (Some Provinces / States do not allow the excision or mtation of incidental or

Cconsequertial damages, so the above mentioned keitaton may not apply te you.

itis important that you report to the Retailer from whom you purchased Uttalit, any defacts as soon as they are

detected. tits impractical to report any detects tothe Reale,

CONTACT SMP Specialty Metal Products Inc. 326 Watline Avenue, Mississauga, Ontario Canada, L4Z 1X2;

Phone: 1-800-597-1243, Ema: info@theUltalit.com

Patent No. 2,482,883, Us Patent No. 729028782 Made in Canada

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Woodsman Installation InstructionsDocument14 pagesWoodsman Installation Instructionskimba worthNo ratings yet

- 18013430825c23b492c10f39.63464022 - Shooting Bench PlansDocument10 pages18013430825c23b492c10f39.63464022 - Shooting Bench Planskimba worthNo ratings yet

- Smartop Upright 3.0 Installation Instructions 7-14-20Document2 pagesSmartop Upright 3.0 Installation Instructions 7-14-20kimba worthNo ratings yet

- Smartop Upright 2.0 Installation Instructions 4-30-19Document2 pagesSmartop Upright 2.0 Installation Instructions 4-30-19kimba worthNo ratings yet

- Smartop Upright Deckmount Installation Instructions 7-30-19Document4 pagesSmartop Upright Deckmount Installation Instructions 7-30-19kimba worthNo ratings yet

- MillerDocument88 pagesMillerkimba worthNo ratings yet

- Smartop Upright 3.0 DeckMount Installation Instructions 4-29-20Document1 pageSmartop Upright 3.0 DeckMount Installation Instructions 4-29-20kimba worthNo ratings yet

- 2020 Leisure Concepts Dealer Brochure 1Document40 pages2020 Leisure Concepts Dealer Brochure 1kimba worthNo ratings yet

- Alpina B3 Flash DIY With Winkfp - BMW 3-Series (E90 E92) ForumDocument7 pagesAlpina B3 Flash DIY With Winkfp - BMW 3-Series (E90 E92) Forumkimba worthNo ratings yet

- 639 Tippmann Tippmann Tank Regulator Manual ENGDocument2 pages639 Tippmann Tippmann Tank Regulator Manual ENGkimba worthNo ratings yet

- Catapultscrossbows ManualDocument36 pagesCatapultscrossbows Manualkimba worthNo ratings yet

- MOJ0601 Large Print Lawyers Working With ChildrenDocument5 pagesMOJ0601 Large Print Lawyers Working With Childrenkimba worthNo ratings yet

- Discrimination Against People With Experiences of Mental Illness July 97Document49 pagesDiscrimination Against People With Experiences of Mental Illness July 97kimba worthNo ratings yet

- MOJ0504 Large Print Parenting Plan Workbook FillableDocument33 pagesMOJ0504 Large Print Parenting Plan Workbook Fillablekimba worthNo ratings yet