Professional Documents

Culture Documents

Basf - C 218 v30 Black

Uploaded by

fernandoincesaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basf - C 218 v30 Black

Uploaded by

fernandoincesaCopyright:

Available Formats

TECHNYL C 218 V30 BLACK 21N

TECHNICAL DATA SHEET Revised: September, 2018

TECHNYL® C 218 V30 Black 21N is a polyamide 6, reinforced with 30% of glass fiber, heat stabilized, for injection

moulding. The product offers an excellent combination between thermal and mechanical properties.

GENERAL

Material Status • Commercial: Active

• Africa & Middle East

• Latin America

Availability • Asia Pacific

• North America

• Europe

Filler / Reinforcement • Glass Fiber, 30% Filler by Weight

Additive • Heat Stabilizer

• Good Dimensional Stability • Heat Stabilized (Inorganic)

Key Benefits

• Good Flow • Good Mold Release

• Air intake manifolds • Electrical/Electronic Applications

Applications • Automotive applications • Fans and shrouds

• Connectors • Interior trims and switches

Certification/Compliance • EC 1907/2006 (REACH) • UL QMFZ2

RoHS Compliance • RoHS Compliant

Colors Available • Black • Natural Color

Forms • Pellets

Processing Method • Injection Molding

Resin ID (ISO 1043) • PA6-GF30

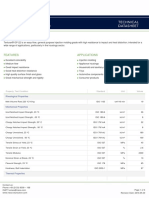

PROPERTIES

Typical values of properties are for Black grades

Physical Dry Conditioned Unit Test Method

Molding Shrinkage ISO 294-4

Across Flow 0.75 %

Flow 0.30 %

Water Absorption ISO 62

24 hr, 23°C 1.1 %

Equilibrium, 23°C, 50% RH 2.2 %

Density 1.36 g/cm³ ISO 1183/A

Mechanical Dry Conditioned Unit Test Method

Tensile Modulus (23°C) 10000 6000 MPa ISO 527-2/1A

Tensile Strength

Break, 23°C 170 MPa ASTM D638

Break, 23°C 180 115 MPa ISO 527-2/1A

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 1 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

Mechanical Dry Conditioned Unit Test Method

Tensile Elongation

Break, 23°C 3.5 % ASTM D638

Break, 23°C 3.2 6.5 % ISO 527-2

Flexural Modulus

23°C 8900 MPa ASTM D790

23°C 8500 5100 MPa ISO 178

Flexural Strength

23°C 255 MPa ASTM D790

23°C 250 160 MPa ISO 178

Charpy Notched Impact Strength ISO 179/1eA

-30°C 8.0 kJ/m²

23°C 10 18 kJ/m²

Charpy Unnotched Impact Strength

-30°C 60 kJ/m² ISO 179/1eU

23°C 75 90 kJ/m² ISO 179/1eU

23°C 70 kJ/m² ISO 179/1fU

Notched Izod Impact

23°C 130 J/m ASTM D256

-30°C 8.5 kJ/m² ISO 180/1A

23°C 11 19 kJ/m² ISO 180/1A

Thermal Dry Conditioned Unit Test Method

Heat Deflection Temperature

0.45 MPa, Unannealed 218 °C ISO 75-2/Bf

1.8 MPa, Unannealed 205 °C ASTM D648

1.8 MPa, Unannealed 208 °C ISO 75-2/Af

Melting Temperature 222 °C ISO 11357-3

Electrical Dry Conditioned Unit Test Method

Surface Resistivity 1.0E+14 1.0E+12 ohms IEC 60093

Volume Resistivity 1.0E+15 1.0E+13 ohms·cm IEC 60093

Electric Strength (2.00 mm) 22 kV/mm IEC 60243-1

Relative Permittivity

2.50 IEC 60250

(23°C, 2.00 mm, 1 MHz)

Dissipation Factor (1 MHz) 0.023 IEC 60250

Comparative Tracking Index (Solution A) 400 400 V IEC 60112

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 2 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

Flammability Dry Conditioned Unit Test Method

Flame Rating (0.40 mm) HB UL 94

IEC

Glow Wire Flammability Index (1.6 mm) 650 °C

60695-2-12

Oxygen Index 23 % ISO 4589-2

PROCESSING

Injection Dry Unit

Drying Temperature 80 °C

Suggested Max Moisture 0.20 %

Rear Temperature 230 to 235 °C

Middle Temperature 235 to 240 °C

Front Temperature 240 to 250 °C

Mold Temperature 60 to 90 °C

Injection Notes

The material is supplied in airtight bags, ready for use. In case that the virgin material has absorbed moisture, it must be

dried with a dehumidified air drying equipment, dew point mini -20°C. Recommended time 2-4h

Injection Advice:

• For reinforced polyamides, Solvay recommends the use of steel with a high content of carbon, and purified for

polishing, to avoid or limit the abrasion. For example: X38CrMoV5-1 (EN Norm) - 1.2367 /1.2343 (DIN Norm) or

X160CrMoV12 (EN Norm) - 1.2601 /1.2379 (DIN Norm). In the case of high requirements on surface quality a mould

temperature of up to 120°C can be considered.

• The processing parameters like processing temperatures are a recommendation and can be adjusted in function of

injection machine size, part geometry / design

DISCLAIMER

The information contained in this document is given in good faith based on our current knowledge. It is only an indication

and it is in no way binding. This information must on no account be used as a substitutive for necessary prior tests which

alone can ensure that a product is suitable for a given use. ANY WARRANTY OF PRODUCT PERFORMANCE,

MERCHANDABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS EXPRESSLY EXCLUDED. Users are responsible for

ensuring compliance with local legislation and for obtaining the necessary certifications and authorizations. Users are

requested to check that they are in possession of the latest version of this document, and Solvay is at their disposal to

supply any additional information.

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 3 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

SAFETY INFORMATION

Detailed information regarding safety are available on the safety data sheet (SDS). SDS is sent with the first material order

or available by contacting our customer services

REGULATIONS COMPLIANCE

This product is not intended to be used for the following regulated market: food contact, drinking water, toys, cosmetics or

medical devices.

This grade complies with ROHS Directive 2011/65/EU and 2015/863 as amended.

Grades produced or imported in Europe comply with REACH directive 1907/2006/EC as amended.

CUSTOMER SERVICES

Our customer services are not only concerned with manufacturing and supply of Engineering Plastics products. We are

available to assist our customers in finding technical solutions that meet their requirements. Specific support is in particular

offered on:

- Material selection

- Material testing

- Parts design advice, training for design engineers

- Part testing

- Design simulation

- Processing through different technologies

- Assembly and post-processing technology expertise

- Parts optimization through Computer Aided Design

You can find more information on Solvay Product range on our internet product finder at the following address: http://

www.technyl.com

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 4 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

MULTIPOINT DATA

Isothermal Stress vs. Strain (ISO 11403-1)

240

Dry: 23°C

220

Dry: 80°C

200 Dry: 120°C

Dry: -30°C

180 Dry: 200°C

Dry: 150°C

160

Dry: 180°C

140 Conditioned: 23°C

Stress (MPa)

Conditioned: 80°C

120 Conditioned: 120°C

100 Conditioned: 180°C

Conditioned: 150°C

80

60

40

20

0

0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14

Strain (mm/mm)

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 5 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

Viscosity vs. Shear Rate (ISO 11403-2)

2000

Dry: 270°C, 0.070%

Dry: 250°C, 0.070%

1000

Viscosity (Pa·s)

500

200

100

10 100 1000 10000

Shear Rate (sec^-1)

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 6 of 7

technyl-americas@solvay.com - Americas

TECHNICAL DATA SHEET

TECHNYL® C 218 V30 BLACK 21N

Revised: September, 2018

Notes

Typical properties: these are not to be construed as specifications.

Solvay Engineering Plastics

www.solvay.com - www.technyl.com

Tel: 00 800 55 400 600

technyl-emea@solvay.com - Europe, Middle East, Africa

technyl-apac@solvay.com - Asia Pacific

Page: 7 of 7

technyl-americas@solvay.com - Americas

You might also like

- Basics of Mole ConceptDocument31 pagesBasics of Mole Conceptptjain02100% (11)

- Gabion Wall Typical Design Sheet-Front-19-8-2008Document8 pagesGabion Wall Typical Design Sheet-Front-19-8-2008jfejfe100% (1)

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Photochemistry-Ppt 7422144 PowerpointDocument10 pagesPhotochemistry-Ppt 7422144 PowerpointArangaNo ratings yet

- Axial behavior of large-scale rectangular concrete columns confined with FRPDocument10 pagesAxial behavior of large-scale rectangular concrete columns confined with FRPTariqueNo ratings yet

- ISO-9963-1-1994 Alkalinity in WaterDocument9 pagesISO-9963-1-1994 Alkalinity in WaterJOSEPH OMONDINo ratings yet

- Technyl - A 218GV30 Natural - J20005Document6 pagesTechnyl - A 218GV30 Natural - J20005Leandro LacerdaNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Technyl Star® A 205F Natural SDocument3 pagesTechnyl Star® A 205F Natural STiago GalloNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- Datasheet CX02-81Document2 pagesDatasheet CX02-81jprodriguezNo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Grivory GVX 5h Nat - Mds - enDocument5 pagesGrivory GVX 5h Nat - Mds - enJohn KingNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Amilan® CM3001G30Document3 pagesAmilan® CM3001G30agungNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- Sabic® Pmma 20HRDocument2 pagesSabic® Pmma 20HRNguyễn Hồng NamNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Sabic® Ppcompound 31T1010: PP Compound Mineral FilledDocument2 pagesSabic® Ppcompound 31T1010: PP Compound Mineral Filledmohamed sabryNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Durethan BKV240H2.0XCP properties guideDocument3 pagesDurethan BKV240H2.0XCP properties guideshahin_723No ratings yet

- PC Makrolon 2458 - 2006Document4 pagesPC Makrolon 2458 - 2006countzeroaslNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- ABS Technical Data SheetDocument1 pageABS Technical Data SheetarmandoNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Ultramid B3WG6 NYLON PDFDocument3 pagesUltramid B3WG6 NYLON PDFrenebbNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- Technical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Document2 pagesTechnical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Priyalakshmi NarasimhanNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- Technical Sheet Extruded AcrylicDocument1 pageTechnical Sheet Extruded AcrylicG GutierrezNo ratings yet

- LANXESS_Durethan_BKV35H2.0_901510_ISO_ENDocument3 pagesLANXESS_Durethan_BKV35H2.0_901510_ISO_ENcristinamss33No ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- POLYFLAM_RABS_90000_UV5_LS_(E128762)Document3 pagesPOLYFLAM_RABS_90000_UV5_LS_(E128762)simonNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Mechanical, Thermal and Electrical Properties of Durethan BKV130H2.0Document3 pagesMechanical, Thermal and Electrical Properties of Durethan BKV130H2.0RICARDONo ratings yet

- SE-316 Parts Data sheetDocument27 pagesSE-316 Parts Data sheetElnBEKKARYNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Pla - FC 60025 Cristal - ErtDocument2 pagesPla - FC 60025 Cristal - ErtfernandoincesaNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Makrolon 2405 ISO enDocument4 pagesMakrolon 2405 ISO enJuan Daniel Ledezma Alonso100% (1)

- 05 Parafuso Fenda Rev. 02Document1 page05 Parafuso Fenda Rev. 02fernandoincesaNo ratings yet

- DIN EN ISO 294-4 Corrigendum 1: September 2011Document2 pagesDIN EN ISO 294-4 Corrigendum 1: September 2011fernandoincesaNo ratings yet

- Norma Astm c1609Document5 pagesNorma Astm c1609Danny LiangNo ratings yet

- Correcting Configurations: Learning ObjectivesDocument3 pagesCorrecting Configurations: Learning ObjectivesZainab FahadNo ratings yet

- Checking Procedure Step by Step For SlabDocument11 pagesChecking Procedure Step by Step For Slabkmandar99100% (1)

- Probing The Fluxional Bonding Nature of Rapid Cope Rearrangements in Bullvalene C10H10 and Its Analogs C8H8, C9H10, and C8BH9Document8 pagesProbing The Fluxional Bonding Nature of Rapid Cope Rearrangements in Bullvalene C10H10 and Its Analogs C8H8, C9H10, and C8BH9PeterNo ratings yet

- Coa sm0441Document3 pagesCoa sm0441Abhishek MuleNo ratings yet

- NCERT Exemplar For Class 11 Chemistry Chapter 8 - Redox Reactions (Book Solutions)Document22 pagesNCERT Exemplar For Class 11 Chemistry Chapter 8 - Redox Reactions (Book Solutions)jackdish18No ratings yet

- Sd ArticleDocument44 pagesSd ArticleSimon ChovauNo ratings yet

- D Block Jeemain - GuruDocument7 pagesD Block Jeemain - GuruAbdelfattah oufNo ratings yet

- Energy Changes in Chemical ReactionsDocument32 pagesEnergy Changes in Chemical ReactionsRon allen ConconNo ratings yet

- 58 CitaDocument6 pages58 CitaKaren Alejandra López CastañosNo ratings yet

- Psfsiee ReviewDocument10 pagesPsfsiee Reviewlimichael000No ratings yet

- MSA and MAA by AutotitratorDocument4 pagesMSA and MAA by AutotitratorJeevan PradhanNo ratings yet

- TD Istra-40 enDocument2 pagesTD Istra-40 enAsmir SofticNo ratings yet

- Properties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistDocument4 pagesProperties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistPaul Schumann50% (2)

- Physical Science Q1 Module 6Document25 pagesPhysical Science Q1 Module 6Zeporah OrdonNo ratings yet

- Water Contents of A Fine-Grained Soil: Its Shrinkage LimitDocument9 pagesWater Contents of A Fine-Grained Soil: Its Shrinkage LimitmaaahiiNo ratings yet

- D 2251 - 96 R00 - RdiynteDocument2 pagesD 2251 - 96 R00 - RdiynteRuben YoungNo ratings yet

- خواص صخور المكمن رقم 7Document32 pagesخواص صخور المكمن رقم 7maamoun ramyNo ratings yet

- 88848003EN Manual 884 Professional VADocument198 pages88848003EN Manual 884 Professional VAPedroNo ratings yet

- Narasimlu PublicationDocument13 pagesNarasimlu Publicationsreedhar_vkNo ratings yet

- Yr 12 Chemistry Holiday HomeworkDocument8 pagesYr 12 Chemistry Holiday HomeworkEsam ELNOAMANYNo ratings yet

- USP-NF Acetazolamide TabletsDocument2 pagesUSP-NF Acetazolamide TabletsStalin VacaNo ratings yet

- Purification set of questionsDocument50 pagesPurification set of questionsSarbajit RoyNo ratings yet

- Slide Principles of Electrolysis in Aqueous SolutionDocument16 pagesSlide Principles of Electrolysis in Aqueous SolutionNur HasanudinNo ratings yet

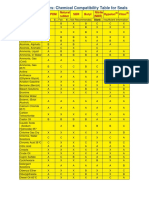

- Chemical Compatibility Table For SealsDocument3 pagesChemical Compatibility Table For SealsThanh Tuyên VõNo ratings yet