Professional Documents

Culture Documents

Dme April-May2010 R04

Dme April-May2010 R04

Uploaded by

Senthil Mithul0 ratings0% found this document useful (0 votes)

7 views4 pagesOriginal Title

DME APRIL-MAY2010 R04

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesDme April-May2010 R04

Dme April-May2010 R04

Uploaded by

Senthil MithulCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

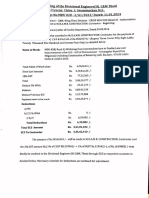

Reg. No. : |

Question Paper Code: D 2482

B.E/B.Tech. DEGREE EXAMINATION, APRIL/MAY 2010.

Fifth Semester

Mechanical Engineering

ME 1302 — DESIGN OF MACHINE ELEMENTS

(Regulation 2004)

(Common to B.E. (Part-Time) Fourth Semester ~ Regulation 2005)

‘Time : Three hours Maximum : 100 marks

Use of approved design data book is permitted.

Answer ALL questions.

PART A — (10 x 2 = 20 marks)

1. What are the steps in machine design process?

2. How will you account for stress concentration in design of the machine parts?

3. What is Jack shaft?

4, What is the critical speed of shaft?

5. What is threaded joint?

6. What are the advantages of welded joints compared with riveted joints?

7. What are the applications of concentric spring?

8. Two springs of stiffness K, and K, are connected in series. What is the stiffness

of connection?

9. What is a quill bearing?

10. What is cooling stress?

PART B — (5 x 16 = 80 marks)

11. (a) A shaft, as shown in fig. 11. (a) is subjected to a bending load of 3 KN,

pure torque of 1000 N-m and an axial pulling force of 15 KN. Calculate

the stresses at A and B.

3BKw

25000

Fig. 11. (a).

Or

(b) The C-frame of 100 KN capacity press is shown in fig. 11. (b). The

material of the frame is grey cast iron and the factor of safety is 3

Determine the dimensions of the frame.

Fig. 11. (b). All dimension in mm

12. (a) A shaft is supported by two bearings placed 1 m apart. A 600 mm

diameter pulley is mounted at a distance of 300 mm to the right of left

hand bearing and this drives a pulley directly below it with the help of

belt having maximum tension of 2.25 KN. Another pulley 400 mm

diameter is placed 200 mm to the left of right hand bearing and is driven

with the help of electric motor and belt, which is placed horizontally to

the right. The angle of contact for both the pulleys is 180° and .=0.24.

Determine the suitable diameter for a solid shaft, allowing working

stress of 60 MPa in tension and 40 MPa in shear for the material of shaft.

Assume that the torque on one pulley is equal to that on the other pulley.

Or

(b) Design a knuckle joint to connect two circular rods subjected to an axial

tensile force of 50 KN. The rods are co-axial and a small amount of

angular movements between their axes is permissible. Design the joint

and specify the dimensions of its components. Select suitable materials

for the parts. .

2 D 2482

13.

14,

(a)

(b)

(b)

ACME threads are used in a lead screw of a lathe. ACME threads have

50 mm outside diameter and 8 mm pitch. The axial pressure required

from lead screw is 2500N. The collar subjected to thrust in the carriage

has 110 mm outside diameter and 55 mm inside diameter and the lead

screw rotates at 30 r.p.m. Determine,

() The power required to drive the lead screw and

Gi) The efficiency of the lead screw. Take 4 for screw as 0.15 and that

for collar as 0.12.

Or

Determine the length of the weld run for a plate of size 120 mm wide and

15 mm thick to be welded to another plate by means of

Gi) A single transverse weld and

(ii) Double parallel fillet welds when the joint is subjected to variable

loads.

A concentric spring is used as a valve spring in a heavy duty diesel

engine. It consists of two helical compression springs having the same

free length and same solid length. The composite spring is subjected to a

maximum force of 6000 N and the corresponding deflection is 50 mm. The

maximum torsional shear stress induced in each spring is 800 N/mm?.

‘The spring index of each spring is 6. Assume same materials for two

springs and the modulus of rigidity of spring materials is 81370 N/m?.

The diametral clearance between the coils is equal to the difference

between their wire diameters. Calculate :

(i) The axial force transmitted by each spring.

Gi) Wire and mean coil diameters of each spring.

(iii) Number of active coils in each spring.

Or

A Belleville spring is made of silicon steel. The spring is compresses

completely flat when it is subjected to axial force of 4500 N. The

corresponding maximum stress is 1375 x 10° N/m’. Assume d, /d, = 1.75

and h/t = 1.5. Calculate :

(Thickness of washer

Free height of washer minus thickness(h)

iii) Outer diameter of washer and

(iv) Inner diameter of washer.

3 D 2482

15.

(a)

b)

‘A single-row deep-groove ball bearing is subjected to a radial force of

8 KN and a thrust force of 3 kN. The shaft rotates at 1200 rpm. The

expected life Ly, of the bearing is 20,000 hr. The minimum acceptable

diameter of the shaft is 75 mm. Select a suitable ball bearing for this

application.

Or

The turning moment diagram of a multi-cylinder engine is drawn with a

scale of (Imm = 1°) on the abscissa and (1 mm = 250 N-m) on the

ordinate. The intercepted areas between the torque developed by the

engine and the mean resisting torque developed by the engine and the

mean resisting torque of the machine, taken in order from one end are

350, +800, -600, +900, -550, +450 and -650 mm’. The engine is running

at a mean speed of 750 rpm and the coefficient of speed fluctuations is

limited to 0.02.A rimmed flywheel made of gray cast iron FG 200

(p = 7100 kg/m’) is provided. The spokes, hub and shaft are assumed to

contribute 10% of the required moment of inertia. The rim has

rectangular cross section and the ratio of width to thickness is 1.5.

Determine the dimensions of the rim.

4 D 2482

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 139 10 Tamil 1 Exercise QuestionsDocument23 pages139 10 Tamil 1 Exercise QuestionsSenthil MithulNo ratings yet

- Dom 2021 Bhavani 1Document26 pagesDom 2021 Bhavani 1Senthil MithulNo ratings yet

- Adobe Scan 30 Jan 2024Document1 pageAdobe Scan 30 Jan 2024Senthil MithulNo ratings yet

- Professional I Want To Be - 3 To 5 - QuestionareDocument1 pageProfessional I Want To Be - 3 To 5 - QuestionareSenthil MithulNo ratings yet

- DMS12012024 10224693835181492Document2 pagesDMS12012024 10224693835181492Senthil MithulNo ratings yet

- Itr1 English20-21Document2 pagesItr1 English20-21Senthil MithulNo ratings yet

- 02 12 2014 Mechanical EngineeringDocument30 pages02 12 2014 Mechanical EngineeringSenthil MithulNo ratings yet

- Dom Bha 2Document22 pagesDom Bha 2Senthil MithulNo ratings yet

- Austempering TreatmentDocument7 pagesAustempering TreatmentSenthil MithulNo ratings yet

- Iii Math Sep Unit TestDocument5 pagesIii Math Sep Unit TestSenthil MithulNo ratings yet

- SPF 2000 Calculation Sheet Rs 50Document10 pagesSPF 2000 Calculation Sheet Rs 50Senthil MithulNo ratings yet

- User Manual For Challan GenerationDocument12 pagesUser Manual For Challan GenerationSenthil MithulNo ratings yet

- ஜோதிடமலர் 8-2-24Document16 pagesஜோதிடமலர் 8-2-24Senthil MithulNo ratings yet