Professional Documents

Culture Documents

M 57-80 (2004) Materials For Embankments & Subgrades

M 57-80 (2004) Materials For Embankments & Subgrades

Uploaded by

Franz Richard Sardinas MallcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M 57-80 (2004) Materials For Embankments & Subgrades

M 57-80 (2004) Materials For Embankments & Subgrades

Uploaded by

Franz Richard Sardinas MallcoCopyright:

Available Formats

Standard Specification for

and Subgrades

AASHTO Designation: M 57-80 (2004)

1. SCOPE

1.1. This specification covers materials for use in the construction of embankments and subgrades.

1.2. The values stated in S1 units are to be regarded as the standard.

2. REFERENCED DOCUMENTS

AASHTO Standards:

M 145, Classification of Soils and Soil-Aggregate Mixtures for Highway Construction

Purposes

M 146, Terms Relating to Subgrade, Soil-Aggregate, and Fill Materials

T 11, Materials Finer Than 75-pm (No. 200) Sieve in Mineral Aggregates by Washing

T 27, Sieve Analysis of Fine and Coarse Aggregates

T 87, Dry Preparation of Disturbed Soil and Soil Aggregate Samples for Test

T 88, Particle Size Analysis of Soils

T 90, Determining the Plastic Limit and Plasticity Index of Soils

T 99, Moisture-Density Relations of Soils using a 2.5-kg (5.5-lb) Rammer and a 305-mm

(12-in.) Drop

T 180, Moisture-Density Relations of Soils using a 4.54-kg (10-lb) Rammer and a 457-mm

(I 8-in.) Drop

T 191, Density of Soil In-Place by the Sand-Cone Method

T 224, Correction for Coarse Particles in the Soil Compaction Test

3. DEFINI'I'IONS

3.1. Definitions of these materials are given in M 146.

4. GENERAL REQUIREMENTS

4.1. Materials shall be free from detrimental quantities of organic material, such as leaves, grass, roots,

and sewage.

4.2. Materials obtained from cuts or borrow areas shall conform to one of the following requirements:

Note 1-See M 145.

TS-I b M 57-1 AASHTO

4.2.1. In Embankments-Materials classified in the A- 1 , A-2-4, A-2-5, or A-3 groups as in M 145 shall

be used when available and shall be compacted to the depth specified to not less than 95 percent of

the maximum density per T 99. If material of this character is not available and materials from the

A-2-6, A-2-7, A-4, A-5, A-6, or A-7 groups must be used, special attention should be given to the

design and construction of the embankment. Materials from these groups shall be compacted to

not less than 95 percent of the maximum density and within two percentage points of the optimum

moisture content per T 99.

4.2.2. In Slrbgrades-Materials classified in the A-1, A-2-4, A-2-5, or A-3, groups as shown in M 145

shall be used when available and shall be compacted to the depth specified to not less than 95

percent of the maximum density per T 99. Materials in the A-2-6, A-2-7, A-4, A-5, A-6, or A-7

groups may be used if compacted to the depth specified to not less than 95 percent of the

maximum density and within two percentage points of the optimum moisture content per T 99.

4.3. Local shale may be used in embankment or subgrade construction if the condition of existing

pavements and embankments indicate satisfactory results. Appropriate special specifications shall

be prepared for such material.

5. DENSITY REQUIREMENTS

5.1. Density percentage requirements may be specified in terms of T 180, if the resultant density and

optimum moisture content are comparable with T 99 under the above conditions.

6. METHODS OF TES'I'ING

6.1. Methods of testing materials for embankments and subgrades shall be in accordance with the

standard methods of the American Association of State Highway and Transportation Officials.

(See Table 1 .)

Table 1-AASHTO Standard Methods

Soil preparation (dry method)

Soil preparation (wet method)

Material passing 0.075-mm (No. 200) sieve

Sieve Analysis

Mechanical analysis of soils

Liquid limit

Plastic limit

Moisture-density relationship [4.54-kg (10-lb) hammer]

Moisture-density relationship [2.5-kg (5.5-lb) hammer]

Density of soil in place

Moisture in place by nuclear methods

Coarse particle correction

Note 2-Use either T 88 or T 11 and T 27 to determine the particle size distribution as a basis

for classification.

TS-I b M 57-2 AASHTO

You might also like

- Materials For Embankments and SubgradesDocument2 pagesMaterials For Embankments and Subgradesمنير أحمد100% (2)

- AASHTO R-18 QA For Testing LabsDocument27 pagesAASHTO R-18 QA For Testing LabsMike FeistNo ratings yet

- Standard Specification For Aggregate For Masonry MortarDocument3 pagesStandard Specification For Aggregate For Masonry MortarAlbertto GuardadoNo ratings yet

- ASTM D3910 - Design, Testing, and Construction of Slurry Seal PDFDocument8 pagesASTM D3910 - Design, Testing, and Construction of Slurry Seal PDFLahcenLakdim100% (1)

- M147Document1 pageM147FRANZ RICHARD SARDINAS MALLCONo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- AASHTO M-57 (Año 2008)Document2 pagesAASHTO M-57 (Año 2008)Roberto VasquezNo ratings yet

- Materials For Embankments and SubgradesDocument1 pageMaterials For Embankments and SubgradesEvert Rivera50% (2)

- ADQCC-Earthworks-Embankments Specs (Extraction)Document8 pagesADQCC-Earthworks-Embankments Specs (Extraction)Abdullah MansoorNo ratings yet

- The Classification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesDocument4 pagesThe Classification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesEvert RiveraNo ratings yet

- Materials For Embankments and SubgradesDocument2 pagesMaterials For Embankments and SubgradesJORGE ENCALADA CARREÑONo ratings yet

- Aashto M145-91Document5 pagesAashto M145-91KkNo ratings yet

- M 147Document2 pagesM 147Katerin HernandezNo ratings yet

- B. Compacting Earth Embankments: Tandard Onstruction PecificationsDocument2 pagesB. Compacting Earth Embankments: Tandard Onstruction PecificationsAbdullah MansoorNo ratings yet

- Aashto T224Document5 pagesAashto T224Alex100% (2)

- AASHTO M-145-2003 Soil ClassificationDocument4 pagesAASHTO M-145-2003 Soil Classificationbrooters RamosNo ratings yet

- Aashto M145-95Document5 pagesAashto M145-95Samuel EsparteroNo ratings yet

- Aashto T 87-1986 R2004Document4 pagesAashto T 87-1986 R2004Nikolay Drumev0% (1)

- Materials Laboratory ManualDocument120 pagesMaterials Laboratory ManualAbdul KaderNo ratings yet

- Aashto t86-70 Recoleccion de MuestraDocument4 pagesAashto t86-70 Recoleccion de Muestraridel mermaNo ratings yet

- CivilDocument182 pagesCivilnaveed ahmedNo ratings yet

- R 5-03 Selection & Use of Emulsified Asphalts PDFDocument5 pagesR 5-03 Selection & Use of Emulsified Asphalts PDFWalticoZegarraHerreraNo ratings yet

- Paving Uses and Application Temperatures For Road TarsDocument2 pagesPaving Uses and Application Temperatures For Road TarsfabulosofigueroaNo ratings yet

- Gallivan - Pre Final Edits - Superpave Volumetric Mix DesignDocument16 pagesGallivan - Pre Final Edits - Superpave Volumetric Mix DesignWail Osman MukhtarNo ratings yet

- Bedding Sand Cable TrenchDocument3 pagesBedding Sand Cable TrenchScott NewtonNo ratings yet

- Correction For Coarse Particle in The Soil Compaction Test AASHTO T-224 (1996) (Modified)Document2 pagesCorrection For Coarse Particle in The Soil Compaction Test AASHTO T-224 (1996) (Modified)Julio César ChávezNo ratings yet

- King Salman Airbase Project Royal Saudi Air Force: Page ofDocument2 pagesKing Salman Airbase Project Royal Saudi Air Force: Page ofAnonymous NR3qZ30No ratings yet

- Materials Laboratory ManualDocument120 pagesMaterials Laboratory ManualKamel FedaouiNo ratings yet

- ROADSTONE SR-21-Brochure-V3Document12 pagesROADSTONE SR-21-Brochure-V3John LiebermanNo ratings yet

- M 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCDocument3 pagesM 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCFranz Richard Sardinas MallcoNo ratings yet

- Laboratory Manual of Test Procedures February 2021Document120 pagesLaboratory Manual of Test Procedures February 2021Lencho KebedeNo ratings yet

- SR 21 Annex E 2016 1Document12 pagesSR 21 Annex E 2016 1joebriffa100% (1)

- Aashto T 182-84 (2002)Document2 pagesAashto T 182-84 (2002)latifjandawoodzai888No ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Aastho 2011 1b Spec 622Document1 pageAastho 2011 1b Spec 622Albertto GuardadoNo ratings yet

- ASTM D6114 - 97 Standar Specification For Asphalt Rubber BinderDocument4 pagesASTM D6114 - 97 Standar Specification For Asphalt Rubber BinderVanessa Melgarejo Avila100% (1)

- Jenkins Et Al Foamed Mix Perform ISAP 2002 1Document16 pagesJenkins Et Al Foamed Mix Perform ISAP 2002 1Louistelson MoreiraNo ratings yet

- Engineering GuideDocument4 pagesEngineering GuidePhoukham PHILAVONGNo ratings yet

- Department of Public Works and Highways: - "V" .//-.U N Republic of The PhilippinesDocument4 pagesDepartment of Public Works and Highways: - "V" .//-.U N Republic of The PhilippinesFaustino AbadNo ratings yet

- SR 21 Brochure NOV 17Document12 pagesSR 21 Brochure NOV 17jav ezdNo ratings yet

- Nanyang Technological University School of Civil and Structural EngineeringDocument44 pagesNanyang Technological University School of Civil and Structural EngineeringZhwan AnwarNo ratings yet

- IRC 95-1987 Specifications For Semi Dense Bituminous ConcreteDocument13 pagesIRC 95-1987 Specifications For Semi Dense Bituminous Concretearunmani2679100% (2)

- Networks Business Unit: SUBDIVISION DESIGN GUIDELINE - NUMBER 4, (Revision 0, 04/01/06)Document3 pagesNetworks Business Unit: SUBDIVISION DESIGN GUIDELINE - NUMBER 4, (Revision 0, 04/01/06)MAZReeNo ratings yet

- Materials Laboratory ManualDocument145 pagesMaterials Laboratory Manualrsoasadigmoniem2023No ratings yet

- Topic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005Document56 pagesTopic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005vinay rodeNo ratings yet

- Aashto Pp-14 (2018) Diseño OgfcDocument9 pagesAashto Pp-14 (2018) Diseño OgfcMario Esteban Solano RodriguezNo ratings yet

- SOil Clasification Mexico TEchnicianDocument5 pagesSOil Clasification Mexico TEchnicianCollin LegaspinaNo ratings yet

- Standard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowDocument13 pagesStandard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowrajibchattarajNo ratings yet

- Paving Uses and Application Temperatures For Road TarsDocument2 pagesPaving Uses and Application Temperatures For Road TarsCarlos RosasNo ratings yet

- Technical Info PDFDocument159 pagesTechnical Info PDFEngr RakNo ratings yet

- Cement Pavement Aeronautics - P-304 - 282161 - 7Document5 pagesCement Pavement Aeronautics - P-304 - 282161 - 7Mog GomNo ratings yet

- D 3282 - 93 r97 - RdmyoditotnsotdfmqDocument6 pagesD 3282 - 93 r97 - RdmyoditotnsotdfmqninaNo ratings yet

- Classification of Soil and Soil-Aggregate AASHTO M-145Document4 pagesClassification of Soil and Soil-Aggregate AASHTO M-145caballerolang0% (1)

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- BS 4987-1-2005Document38 pagesBS 4987-1-2005Salma AlzwayNo ratings yet

- BS 598-104-2005Document22 pagesBS 598-104-2005Salma AlzwayNo ratings yet

- Gypsum and Related Building Materials and Systems: Standard Terminology Relating ToDocument5 pagesGypsum and Related Building Materials and Systems: Standard Terminology Relating ToSalma AlzwayNo ratings yet

- Standard Specification For: 1. ScopeDocument3 pagesStandard Specification For: 1. ScopeSalma AlzwayNo ratings yet

- Standard Specification For: 1. ScopeDocument2 pagesStandard Specification For: 1. ScopeSalma AlzwayNo ratings yet

- Standard Specification For: 1. ScopeDocument3 pagesStandard Specification For: 1. ScopeSalma AlzwayNo ratings yet

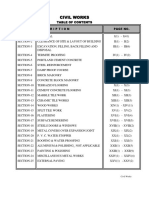

- Libyan Technical Consultancy Company: LNA Construction Trading J.S. Company Benghazi Soccer StadiumDocument1 pageLibyan Technical Consultancy Company: LNA Construction Trading J.S. Company Benghazi Soccer StadiumSalma AlzwayNo ratings yet

- Standard Specification For: 1. ScopeDocument5 pagesStandard Specification For: 1. ScopeSalma AlzwayNo ratings yet

- Key Words: Rammed Earth (Pisé), Formwork, Energy Performance, Durability, Local MaterialDocument41 pagesKey Words: Rammed Earth (Pisé), Formwork, Energy Performance, Durability, Local MaterialLionel TebonNo ratings yet

- Cacml-001844-00-Qac-Do-0010 Document Internal Acces RoadDocument107 pagesCacml-001844-00-Qac-Do-0010 Document Internal Acces Roadtiote moussaNo ratings yet

- Earth Science SHS Unit 8 Soil Resources Study GuideDocument52 pagesEarth Science SHS Unit 8 Soil Resources Study GuideSpicychicken NuggetssNo ratings yet

- Chapter - 3 - Geologic ResourcesDocument173 pagesChapter - 3 - Geologic ResourcesvhiergouNo ratings yet

- Bharat PlywoodDocument25 pagesBharat PlywoodpmyilsamyNo ratings yet

- 2022.08.30 Presentation Sinarmas Land (Benowo) ReviewDocument74 pages2022.08.30 Presentation Sinarmas Land (Benowo) ReviewTeddy SusantoNo ratings yet

- The Geotechnical Properties of Jamshoro Soil (Shale) With CementDocument6 pagesThe Geotechnical Properties of Jamshoro Soil (Shale) With CementijmremNo ratings yet

- Ijiwet Vol (3) No (1) 6Document8 pagesIjiwet Vol (3) No (1) 6Stevaldy SutantoNo ratings yet

- MarrsDocument3 pagesMarrsRohit PatilNo ratings yet

- Settlement Part DDocument7 pagesSettlement Part DHardik GajjarNo ratings yet

- Crushed Stone ReportDocument13 pagesCrushed Stone ReportJavier Enrique Diaz ChacinNo ratings yet

- Bristish Columbia, SodiumDocument2 pagesBristish Columbia, SodiumCláudiá Fióréllá H CNo ratings yet

- Navaron Satkhira Bhomra SamplesDocument9 pagesNavaron Satkhira Bhomra SamplesSreenivasula Reddy KandulaNo ratings yet

- Rank - M25 &M40 Mix Design With GGBS & FlyashDocument8 pagesRank - M25 &M40 Mix Design With GGBS & FlyashNaresh CharyNo ratings yet

- Work Forms Cw-006aDocument1 pageWork Forms Cw-006arichieNo ratings yet

- Geotechnics DataDocument31 pagesGeotechnics DataDid DdeNo ratings yet

- Lecture 2 - Basics of GeologyDocument86 pagesLecture 2 - Basics of GeologyNick jamesNo ratings yet

- Soil - FillingDocument6 pagesSoil - FillingGiora RozmarinNo ratings yet

- The Carbonate-Hosted ZN-PB San Gregorio Deposit (Colquijirca District, Central Peru) As Part of A High Sulfidation Epithermal SystemDocument5 pagesThe Carbonate-Hosted ZN-PB San Gregorio Deposit (Colquijirca District, Central Peru) As Part of A High Sulfidation Epithermal SystemGino Asencio AlvaradoNo ratings yet

- Overview of Cover CropsDocument16 pagesOverview of Cover Cropslaraworden100% (1)

- Longwall MiningDocument2 pagesLongwall MiningRiswan RiswanNo ratings yet

- Water and Sediment ControlDocument5 pagesWater and Sediment ControlAmalina YaniNo ratings yet

- Sive AnalysisDocument15 pagesSive AnalysisRhiky Irvanjas JanultullohNo ratings yet

- Tabriz-Final PaperDocument15 pagesTabriz-Final Paperwaleed shahidNo ratings yet

- Principles of Water Resources Engineering: Version 2 CE IIT, KharagpurDocument15 pagesPrinciples of Water Resources Engineering: Version 2 CE IIT, KharagpurVivekChaudharyNo ratings yet

- Stabilization of Expansive SoilDocument4 pagesStabilization of Expansive SoilSamara LujanNo ratings yet

- Economic Geology - Supergene Ore Deposits: January 2017Document48 pagesEconomic Geology - Supergene Ore Deposits: January 2017daren rodriguezNo ratings yet

- SOIL 101 SYllabusDocument6 pagesSOIL 101 SYllabusSeprida HalogNo ratings yet

- Geotechnical Final For WebDocument193 pagesGeotechnical Final For Webkesharinaresh100% (1)

- 1 s2.0 S0038080620318011 MainDocument9 pages1 s2.0 S0038080620318011 MainSiddhant ShuklaNo ratings yet