Professional Documents

Culture Documents

Algae As Biological Detoxificant of A Atoxin Produced by Aspergillus Avus Isolated From Sun Ower Seed

Uploaded by

kadek siwi0 ratings0% found this document useful (0 votes)

3 views6 pagesOriginal Title

AlgaeasbiologicaldetoxificantofaflatoxinproducedbyAspergillusflavusisolatedfromsunflowerseed.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views6 pagesAlgae As Biological Detoxificant of A Atoxin Produced by Aspergillus Avus Isolated From Sun Ower Seed

Uploaded by

kadek siwiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/286740784

Algae as biological detoxificant of aflatoxin produced by Aspergillus flavus

isolated from sunflower seed

Article in Indian Journal of Science and Technology · January 2008

DOI: 10.17485/ijst/2008/v1i3/29226

CITATIONS READS

13 421

4 authors, including:

Narasimhan Banu Sekaran Sridhar

Bharathi Womens College (Autonomous) Kalaignar Karunanidhi Government Arts College, Tiruvannamalai

51 PUBLICATIONS 351 CITATIONS 59 PUBLICATIONS 1,204 CITATIONS

SEE PROFILE SEE PROFILE

Muthumary Johnpaul

University of Madras

84 PUBLICATIONS 3,321 CITATIONS

SEE PROFILE

All content following this page was uploaded by Sekaran Sridhar on 29 July 2020.

The user has requested enhancement of the downloaded file.

1

Indian Journal of Science and Technology http://www.indjst.org Vol.1 No 3 (Aug. 2008)

Algae as biological detoxificant of aflatoxin produced by Aspergillus flavus isolated from sunflower seed

N. Banu1, S.Sridhar 2, J. Muthumary and R. Rengasamy

Centre for Advanced Studies in Botany,

University of Madras, Guindy Campus, Chennai – 600 025, India.

1

Vel’s college of science, Pallavaram; 2Pepsico India Ltd., Chennai

banunkl@yahoo.com

Abstract: Aspergillus flavus is the widely reported prescribed for appropriate implementation. To

food-borne fungus and the most important achieve such low levels,

mycotoxin source in the world’s food supplies. A decontamination/detoxification procedures are

new approach using algae- Spirulina platensis useful in order to recuperate mycotoxin-

(blue-green alga), Ulva faciata (green alga) and contaminated commodities. The ideal

Sargassum wightii (brown alga) was experimented decontamination procedure should be easy to use,

to control the growth of A. flavus and its aflatoxin inexpensive and should not lead to the formation of

B1 production. Among the three algae, S. wightii compounds that are still toxic or may reverse to

was found as most suitable biocontrolling agent. reform the parent mycotoxin or alter the nutritional

The optimum biomass concentration of the alga to and palatability propertied of the product. Hence

detoxify the aflatoxin B1 and inhibition of the fungal approaches involving physical, chemical and

mycelial growth was worked out in a controlled biological methods have been made to detoxify

condition. An algal biomass of 1.8% (in final aflatoxin in food and feedstuffs by many workers

concentration) of S. wightii effectively eliminated (Landers et al., 1967; Park, 1993; Shannaz &

(100%) aflatoxin B1 and total inhibition of the Ghaffar 1999; Namazi et al., 2002; Vilar et al.,

fungal growth of A. flavus was also achieved 2003).

concomitantly. The experimental results were In the present investigation, different

encouraging for possible application of algal concentrations of the algal biomass (in powder) of

biomass as biocontrolling agent to recuperate Spirulina platensis, Ulva faciata and Sargassum

aflatoxin contaminated food and feed commodities. wightii was tested to prevent the growth of A. flavus

Introduction and the aflatoxin B1 production by the fungus.

Aflatoxins are the potent toxic, mutagenic, Materials and methods

heterogenic and carcinogenic metabolites Spirulina platensis (blue-green alga), Ulva

produced by species of Aspergillus flavus and A. faciata (green alga) and Sargassum wightii (brown

parasiticus in food and feed, especially in the oil alga) were selected to assess their efficacy to

seeds and their products, both at pre- and post- detoxify aflatoxin B1 content produced by A. flavus.

harvest conditions. Their occurrence in food and Ten gram of each dry powder sample of the algae

feed materials has caused not only health hazards was obtained from algal culture collection of Centre

to animals and humans but also economic losses for Advanced Studies in Botany, University of

especially to the exporting countries. They are Madras. The above algal biomaterials were

initially classified as human carcinogens by the dissolved in distilled water to get 3% stock

International Agency on Research in Cancer in solutions.

1993 and further epidemiological experiments Five and ten milliliter of S. platensis and

continue to show a strong link

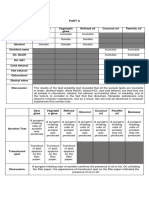

between aflatoxin exposure Table 1. Quantification of aflatoxin B1 by TLC and HPTLC

and Hepato Cellular

Carcinoma (HCC). The U.S. Mycelial Concentration of

FDA has currently established Algal aflatoxin B1 (ppm) as

dry

action levels (Max.) of Name of the algae biomass (ml) determined by

weight

aflatoxin to be 20 ppb for (3% solution)

(g) TLC HPTLC

human foods (except milk),

0.5 ppb for milk, 20 ppb for Spirulina platensis 5 3.3 12 14

animal feeds, except some S. platensis 10 2.3 28 22

cases of feeds meant for Ulva faciata 5 4.0 24 25

maturing and finishing of meat U. faciata 10 3.6 28 29

animals, which varied from Sargassum wightii 5 3.6 14 16

100 to 300ppb (Park, 1993). S. wightii 10 3.4 28 26

From the viewpoint of S. wightii 20 3.3 1.4 2.5

health and economics, it is S. wightii 40 1.6 0.33 0.65

imperative that such low S. wightii 60 1.6 - -

levels of aflatoxin are S. wightii 80 2.1 1.4 1.4

Control - 3.9 30 36

iSee© category: Research article “Algal decontamination of aflatoxin” by Banu et al.

Indian Society for Education and Environment

2

Indian Journal of Science and Technology http://www.indjst.org Vol.1 No 3 (Aug. 2008)

incubated for a period of 8 days at 30ºC up to the

Fig. 1 a - l. HPTLC Densitogramms stage of stationary culture. The fungus was

isolated earlier from the surface sterilized

sundered sunflower seed used for oil crushing.

a. Authentic After incubation, the culture was killed and the

culture filtrate was filtered through Whatmans No.

1 filter paper and the dry weight of the mycelium

was recorded. One hundred milliliter of culture

filtrate was extracted thrice with equal volume of

chloroform. The chloroform extract was dried

over rotary evaporator at 62 ºC. The final residue

was dissolved in 0.2 ml of chloroform. The same

procedure was followed for control without

adding algal suspension.

Quantification of aflatoxin B1 by TLC

Five, 10, 20 and 40 µl of the above

extracts were applied to pre-coated

TLC plates (Merck) along with the standard

aflatoxin B1. The plates were developed in a tank

containing chloroform: acetone in the ratio of

88:12. After the development, the plates were

b. Control viewed under long UV light at 365 nm. Blue-

fluorescence similar to standard aflatoxin B1

indicated the presence of aflatoxin B1.

Quantification of aflatoxin B1 was made by

evaluating on the plate itself using long UV light.

The role of algal suspension on detoxification

was determined by quantifying the intensity of

blue fluorescence of aflatoxin B1.

High Performance Thing layer chromatography

Twenty micro liter of the above sample

extracts were loaded onto pre-coated silica gel

plate. The plate was developed in a saturated

tank containing tertiary butyl methyl ether:

methanol: water in a ratio of 9.6:0.3:0.1. The

developing distance of the plate was up to 80

c. Aspergillus flavus with 5ml of mm. The developed plates were scanned in a

Spirulina platensis Camag TLC Scanner 3 at 366 nm. The presence

of blue-fluorescence indicated the presence of

aflatoxin and confirmed with authentic sample.

Results and discussion

The blue-green alga, Spirulina platensis

showed marked reduction of aflatoxin B1

(starting concentration was 30 ppm and 36 ppm

as per TLC and HPTLC methods, respectively) to

12 ppm as determined by TLC and 14 ppm by

HPTLC method. At the same time, addition of

higher concentration of the alga (10 ml stock

solution) poorly effected the aflatoxin B1

elimination; at the same time mycelial reduction

of A. flavus was observed. Thus the addition of 5

ml algal stock solution, the weight of the

U. faciata and 5, 10, 20, 40, 60 and 80 ml of S. mycelium was reduced to 3.3 g in comparison with

wightii stock solutions were added separately to a control (3.9 g). But at 10 ml concentration algal

final volume of 100 ml of Yeast Extract Sucrose biomass, the effect was only on the growth of the

medium (2% yeast, 20% sucrose) (Davis et al., mycelium and not inhibited the aflatoxin production

1966) and inoculated with a disc of A. flavus. It was (Table 1 & Fig. 1 a, b, c & d).

iSee© category: Research article “Algal decontamination of aflatoxin” by Banu et al.

Indian Society for Education and Environment

3

Indian Journal of Science and Technology http://www.indjst.org Vol.1 No 3 (Aug. 2008)

d. Aspergillus flavus with 10ml of Spirulina platensis ml concentration, the dry weight of the

mycelium was increased by 1 g compared

to control (Table 1 Fig. 1 e & f).

The brown alga S. wightii at 5 ml

concentrations effected reduction in the

production of aflatoxin B1 (to 14 ppm as

determined by TLC and 16 ppm by HPTLC

method) as well as in the growth of the

mycelium. But at 10 ml, not much effect

was noted both on the growth of the

fungus and in aflatoxin B1 production

(Table 1; Fig. 1g- h).

Among the 3 algae tested for their

efficacy on controlling the growth of A.

flavus and its aflatoxin B1 produciton, all

the three were found to be suitable in a

varying degree. Considering the variability,

Spirulina platensis and Sarassum wightii

were found to be better organisms to

decontaminate A. flavus and detoxify the

production of aflatoxin B1. However in the

present investigation, only Sargassum

wightii was selected for further study (at

20, 40, 60 and 80 ml stock solution).

At 20 ml concentration of S. wightii on

A. flavus, a marked reduction on the

growth of the mycelium (3.3 g) as well as

in aflatoxin B1 production was observed

(to 1.4 ppm as recorded by TLC and to 2.5

ppm as recorded by HPTLC method). At

40 ml concentration of the alga, the

mycelial weight was reduced to 3.6 g and

aflatoxin B1 was 0.33 ppm by TLC and

f. Aspergillus flavus with 10ml of Ulva faciata 0.65 ppm by HPTLC. At 60 ml of

concentration S. wightii, 100% elimination

of aflatoxin B1 was noted along with the

reduction of mycelial growth. But at 80 ml

concentration of the alga, mycelial growth

was observed along with the production of

aflatoxin B1 at a concentration of 1.4 ppm

as quantified both by TLC and by HPTLC

(Table I and Fig. 1 i, j, k & l).

Thus, among the different

concentrations (5, 10, 20, 40, 60 and 80

ml), 60 ml of S. wightii was found to be

suitable for 100% elimination of aflatoxin

B1 as well as total inhibition of the growth

of A. flavus. Hence the optimum biomass

concentration of S. wightii was found to be

The green alga U. faciata at both 5 and 10 ml 60 ml (1.8% biomass dry/wet in a 100 ml

concentrations had not showed any positive control of YES medium) to detoxify aflatoxin B1 and to

on aflatoxin B1 production compared with S. control fungal growth.

platensis. But the mycelial dry weight showed

reduction at 10 ml concentration of U. faciata. At 5

iSee© category: Research article “Algal decontamination of aflatoxin” by Banu et al.

Indian Society for Education and Environment

4

Indian Journal of Science and Technology http://www.indjst.org Vol.1 No 3 (Aug. 2008)

g. Aspergillus flavus with 5ml of Sargassum wightii aromatic compound including the potent

hepatocarinogen, aflatoxin B1 (Negishi et al.,

1989; Breinholt et al., 1995). Chlorophyllin

may block the absorption of carcinogens,

thereby reducing their bioavailability in target

tissues ultimately leading to reduced DNA

adduct formation and tumor burden (Egner et

al., 2003).

Conclusion

The preferential inhibition of aflatoxin B1

production and its mould growth by S. wightii

is significant. The investigation supports the

possible role of algae as biological control

agent over the mould and its toxin. Further

investigation on the safe use of algal biomass

to protect the food stuff from mould and

aflatoxin, may lead to an inexpensive and

safe approach to realize the public health

h. Aspergillus flavus with 10ml of Sargassum wightii

mandate.

Acknowledgements

We greatly acknowledge the Department

of Science and Technology, Govt. of India for

providing the financial support to carryout the

research work.

References

1. Breinholt V, Schimerlik M, Dashwood R

and Bailey G (1995) Mechanisms of

chlorophyllin anticarcinogenesis against

aflatoxin B1 complex formation with the

carcinogen. Chem. Res. Toxicol. 8, 506 –

514.

2. Davis ND, Diener UL and Eldridge DW

(1966) Production of aflatoxin B1 and G1

i. Aspergillus flavus with 20ml of Sargassum wightii by Aspergillus flavus in a semisynthetic

medium. Appl. Microbiol. 14, 378–380.

3. Egner PA, Muñoz A and Kensler TW

(2003) Chemoprevention with

clhlorophyllin in individuals exposed to

dietary aflatoxin . Mut. Res. 523- 524,

209– 216.

4. Kephart JC (1955) Chlorophyll derivative,

their chemistry, commercial preparation

and uses. Eco. Bot. 9, 3– 38.

5. Landers KE, Davis ND and Diener UL

(1967) Influence of atmospheric gases on

aflatoxin production by Aspergillus flavus

in peanuts. Phytopathol., 57, 1086–1090.

6. Namazi M, Allameh A, Aminshahidi M,

The capacity of the algal biomass to control and Nohee A and Malekzadeh F (2002)

elimination of toxins produced by A. flavus is Inhibitory effects of ammonia solution on

mainly due to the presence of algal chlorophyll- growth and aflatoxin production by Aspergillus

Chlorophyllin. It is basically a water-soluble mixture parasiticus NRRL – 2999. Acta Poloniae

of sodium-copper salts of chlorophyll formed from Toxicol. 10, 65–72.

the saponification of the relatively nonpolar, parent 7. Negishi T, Arimoto S, Nishizaki C and Hayatsu

compound (Kepart, 1955). It acts as an interceptor H (1989) Inhibitory effect of chlorophyll on the

forming tight molecular complexes with planar, genotoxicity of 3-amino-1-methyl-5H-pyrido

(4,3-b) indole (Trp-p-2). Carcino. 10, 145– 149.

iSee© category: Research article “Algal decontamination of aflatoxin” by Banu et al.

Indian Society for Education and Environment

5

Indian Journal of Science and Technology http://www.indjst.org Vol.1 No 3 (Aug. 2008)

j. Aspergillus flavus with 40ml of Sargassum wightii 8. Park DL (1993) Perspectives of

mycotoxin decontamination

procedures. Food Add. And Conta.

10, 49 – 60.

9. Shahnaz D and Ghaffar A (1999) Use

of ammonia gas in the control of

Aspergillus flavus infection and

aflatoxin production in sunflower

seeds. Pak.J. Bot. 31, 231– 235.

10. Vilar MS, Kuilman-Wahls MEM and

Fink-Gremmels J (2003) Inhibition of

aflatoxin B1 mutagenicity by

cyclopiazonic acid in the presence of

human liver preparations. Toxicol.

Let. 143, 291–299.

k. Aspergillus flavus with 60ml of Sargassum wightii

l. Aspergillus flavus with 80ml of Sargassum wightii

iSee© category: Research article “Algal decontamination of aflatoxin” by Banu et al.

Indian Society for Education and Environment

View publication stats

You might also like

- Abiotic Stresses in Crop PlantsFrom EverandAbiotic Stresses in Crop PlantsUsha ChakrabortyNo ratings yet

- Immunomodulating Properties of Bioactive Compounds Present in Aurora GlobostellataDocument8 pagesImmunomodulating Properties of Bioactive Compounds Present in Aurora GlobostellataSyamsir mursaliNo ratings yet

- (18469558 - Acta Pharmaceutica) Anthelmintic Activity of Praziquantel and Spilanthes Acmella Extract On An Intestinal Cestode ParasiteDocument10 pages(18469558 - Acta Pharmaceutica) Anthelmintic Activity of Praziquantel and Spilanthes Acmella Extract On An Intestinal Cestode ParasiteDiego NamucheNo ratings yet

- Co Authour.1Document7 pagesCo Authour.1TamizhazhaganNo ratings yet

- Anthelmintic, Antimicrobial, Antioxidant and Cytotoxic Activity of Caltha Palustris Var. Alba Kashmir, IndiaDocument6 pagesAnthelmintic, Antimicrobial, Antioxidant and Cytotoxic Activity of Caltha Palustris Var. Alba Kashmir, IndiaSandeep SinghNo ratings yet

- Mathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CDocument17 pagesMathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CNithin VijayakumarNo ratings yet

- Acaricidal Activity of Extracts From Different Structures of Piper Tuberculatum Against Larvae and Adults of Rhipicephalus MicroplusDocument6 pagesAcaricidal Activity of Extracts From Different Structures of Piper Tuberculatum Against Larvae and Adults of Rhipicephalus MicroplusLaura Estefania Niño MNo ratings yet

- Phytochemical and Antimicrobial Activity of Acmella Paniculata Plant ExtractsDocument7 pagesPhytochemical and Antimicrobial Activity of Acmella Paniculata Plant ExtractsWinda AlzamoriNo ratings yet

- 1 PBDocument10 pages1 PBAmina BelguendouzNo ratings yet

- Inflamasi ScopusDocument5 pagesInflamasi ScopustridewantiwNo ratings yet

- Production of Monosex Nile Tilapia, Oreochromis Niloticus Using Seed of Mucuna PruriensDocument6 pagesProduction of Monosex Nile Tilapia, Oreochromis Niloticus Using Seed of Mucuna PruriensermianusNo ratings yet

- Antioxidant potential of Solanum spiraleDocument9 pagesAntioxidant potential of Solanum spiraleJulian RodriguezNo ratings yet

- 2012-Eichornia Crasiper-CulexDocument7 pages2012-Eichornia Crasiper-CulexDwiNo ratings yet

- MainDocument13 pagesMainMiy AichNo ratings yet

- PharmacognJ 12 4 835 - 0Document9 pagesPharmacognJ 12 4 835 - 0AhmadNo ratings yet

- Jurnal Falcourtia RukamDocument6 pagesJurnal Falcourtia RukamNorsarida AryaniNo ratings yet

- Evaluation of Anthelmintic and Anti-In Ammatory Activity of Amaranthus Spinosus LinnDocument5 pagesEvaluation of Anthelmintic and Anti-In Ammatory Activity of Amaranthus Spinosus LinnabirNo ratings yet

- ZLJM 16 1846862Document11 pagesZLJM 16 1846862NorlailaNo ratings yet

- Journal of Food Science - 2012 - Kumar - Inactivation of A Ochraceus Spores and Detoxification of Ochratoxin A in CoffeeDocument8 pagesJournal of Food Science - 2012 - Kumar - Inactivation of A Ochraceus Spores and Detoxification of Ochratoxin A in CoffeeAm NyctophileNo ratings yet

- Pujiastuti 2018 IOP Conf. Ser. Earth Environ. Sci. 102 012064Document9 pagesPujiastuti 2018 IOP Conf. Ser. Earth Environ. Sci. 102 012064indra maulanaNo ratings yet

- In Vitro Inhibition of Plasmodium Falciparum by Substances Isolated From Antimalarial Plants.Document7 pagesIn Vitro Inhibition of Plasmodium Falciparum by Substances Isolated From Antimalarial Plants.IJAERS JOURNALNo ratings yet

- 2018 Satish PoojariDocument4 pages2018 Satish PoojariDr Estari MamidalaNo ratings yet

- Carthamus Oxycantha Hepatoprotective EffectsDocument7 pagesCarthamus Oxycantha Hepatoprotective EffectsJavaria IkramNo ratings yet

- 2017-Justicia Adhatoda MidgutDocument11 pages2017-Justicia Adhatoda MidgutDwiNo ratings yet

- Avocado 1Document8 pagesAvocado 1Feddy Micheal FeddyNo ratings yet

- Antioxidant Acitivity of Five Seaweed Extracts: July 2018Document8 pagesAntioxidant Acitivity of Five Seaweed Extracts: July 2018rizky tsintaNo ratings yet

- Emmanuel Acha AsongalemDocument9 pagesEmmanuel Acha AsongalemPaulin NanaNo ratings yet

- Murugan Parivallal PaperDocument7 pagesMurugan Parivallal PaperRegineRojoNo ratings yet

- 02-Antispasmodic and Relaxant Effects of Thymus Algeriensis Dichloromethane Fraction On Intestinal Smooth Muscle Motility of Wistar RatsDocument5 pages02-Antispasmodic and Relaxant Effects of Thymus Algeriensis Dichloromethane Fraction On Intestinal Smooth Muscle Motility of Wistar Ratsa.karimNo ratings yet

- Article Wjpps 1451625165Document12 pagesArticle Wjpps 1451625165Arturo DíazNo ratings yet

- Anti-In Ammatory and Anti-Pyretic Activity of Aleuritis Moluccana LeavesDocument4 pagesAnti-In Ammatory and Anti-Pyretic Activity of Aleuritis Moluccana Leavesyut jombang22No ratings yet

- A Novel Combination of The Essential Oils of CinnamomumDocument5 pagesA Novel Combination of The Essential Oils of Cinnamomumasa chiNo ratings yet

- Phytochemical Analysis and Cytotoxicity Studies of Curcuma Amada Rhizomes in BHK-21 CellsDocument7 pagesPhytochemical Analysis and Cytotoxicity Studies of Curcuma Amada Rhizomes in BHK-21 CellsJessica ClarkNo ratings yet

- 31 ArticleText 34 1 10 20190102Document8 pages31 ArticleText 34 1 10 20190102febifebriantyNo ratings yet

- Asihhh 3Document8 pagesAsihhh 3Asih hendrina HendrinaNo ratings yet

- Green Tea Extract's Anti-Allergic EffectsDocument6 pagesGreen Tea Extract's Anti-Allergic EffectsCristover FernandoNo ratings yet

- Jas T 102161384633800Document9 pagesJas T 102161384633800Oki ArdiyansahNo ratings yet

- Nutrition Vol9 No2 P 450-464Document15 pagesNutrition Vol9 No2 P 450-464Subhasish DashNo ratings yet

- Ajol File Journals - 452 - Articles - 130901 - Submission - Proof - 130901 5365 353594 1 10 20160223 2Document11 pagesAjol File Journals - 452 - Articles - 130901 - Submission - Proof - 130901 5365 353594 1 10 20160223 2tameneestifanos0No ratings yet

- 12892+NBHA+Farooq+2022 12 06Document14 pages12892+NBHA+Farooq+2022 12 06Aqsa khanNo ratings yet

- Chemical Profiling of Tylophora indica Shoot CulturesDocument7 pagesChemical Profiling of Tylophora indica Shoot CulturesAtrimed F & DNo ratings yet

- 1 OnlineDocument10 pages1 OnlineHannihNo ratings yet

- Bharucha2013 Article OptimizationOfIndoleAceticAcidDocument7 pagesBharucha2013 Article OptimizationOfIndoleAceticAcidyasinNo ratings yet

- Volume: 04 Issue: 03 - May-Jun 2023Document9 pagesVolume: 04 Issue: 03 - May-Jun 2023Central Asian StudiesNo ratings yet

- Uji Daya Hambat Larutan Daun Sukun (Artocarpus Altilis) TERHADAP PERTUMBUHAN BAKTERIDocument10 pagesUji Daya Hambat Larutan Daun Sukun (Artocarpus Altilis) TERHADAP PERTUMBUHAN BAKTERIJr SparkNo ratings yet

- Isolation and Identification of Cytrid From Mangrove AreaDocument4 pagesIsolation and Identification of Cytrid From Mangrove AreaFaiqNo ratings yet

- Evaluation of Hepatocurative Effect of AqueousDocument4 pagesEvaluation of Hepatocurative Effect of AqueousInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Antioxidant Activity of Astaxanthin Isolated From Charybdis Edwardsii (Leene and Buitendijk, 1949) From Pazhayar, Southeast Coast of IndiaDocument5 pagesAntioxidant Activity of Astaxanthin Isolated From Charybdis Edwardsii (Leene and Buitendijk, 1949) From Pazhayar, Southeast Coast of IndiaEditor IJTSRDNo ratings yet

- Anti-In Ammatory Effect of Ampelocissus Indica (L.) Planch (Chembravalli) in Wistar RatsDocument19 pagesAnti-In Ammatory Effect of Ampelocissus Indica (L.) Planch (Chembravalli) in Wistar RatsAnil DasNo ratings yet

- Paranagama Et Al-2003-Letters in Applied Microbiology PDFDocument5 pagesParanagama Et Al-2003-Letters in Applied Microbiology PDFAndré Luiz Graf JuniorNo ratings yet

- tmpA3C2 TMPDocument11 pagestmpA3C2 TMPFrontiersNo ratings yet

- 2012-Jatropha Curcas-Anopheles Dan AedesDocument11 pages2012-Jatropha Curcas-Anopheles Dan AedesDwi AnggrainiNo ratings yet

- Insecticidal Activity of Castanospermum Australe Against Stored Grain Pest Callosobruchus AnalisDocument3 pagesInsecticidal Activity of Castanospermum Australe Against Stored Grain Pest Callosobruchus AnalisIOSR Journal of PharmacyNo ratings yet

- Document 4Document6 pagesDocument 4Dessy Erlyani Mugita SariNo ratings yet

- Arijit PaperDocument10 pagesArijit PaperAngel Eduardo Moreno AlboresNo ratings yet

- Solid State Fermentation Effects On Pistachio Hulls Antioxidant ActivitiesDocument7 pagesSolid State Fermentation Effects On Pistachio Hulls Antioxidant ActivitiesEhsan OskoueianNo ratings yet

- Comparative Studies On Antioxidant and Anti-InflamDocument8 pagesComparative Studies On Antioxidant and Anti-Inflaml100% (1)

- 2017 UHADROSAEAktivitas Antibakteri Ekstrak Etanol Kulit Batangdan Daun BerenukDocument15 pages2017 UHADROSAEAktivitas Antibakteri Ekstrak Etanol Kulit Batangdan Daun BerenukDe'Uma Beiby SwettyNo ratings yet

- Brine Shrimp Lethality Assay of Three Philippine Medicinal PlantsDocument4 pagesBrine Shrimp Lethality Assay of Three Philippine Medicinal PlantsMustafizur Rahman AviNo ratings yet

- HTM 2015 Conference on Herbal and Traditional MedicineDocument8 pagesHTM 2015 Conference on Herbal and Traditional Medicineden mNo ratings yet

- Concise SEO-Optimized Title for Research Article Covering LetterDocument7 pagesConcise SEO-Optimized Title for Research Article Covering LetterBimo HariokusumoNo ratings yet

- DAFTAR PUSTAKA Kadek Proposal Bu KustiDocument5 pagesDAFTAR PUSTAKA Kadek Proposal Bu Kustikadek siwiNo ratings yet

- Mendeley CiteDocument1 pageMendeley Citekadek siwiNo ratings yet

- C3501211008 - OLGA GALIH R S - Tugas PPT SurimiDocument33 pagesC3501211008 - OLGA GALIH R S - Tugas PPT Surimikadek siwiNo ratings yet

- Purolene Solvent Degreaser - MSDSDocument9 pagesPurolene Solvent Degreaser - MSDSAsadNo ratings yet

- Namma Kalvi 12th Chemistry Important Questions English Medium 221525Document6 pagesNamma Kalvi 12th Chemistry Important Questions English Medium 2215255318819.sreejithNo ratings yet

- Us 8653174Document21 pagesUs 8653174subramanian.sNo ratings yet

- Acid-base equilibria and titrationsDocument5 pagesAcid-base equilibria and titrationsblahNo ratings yet

- Chapter 1Document50 pagesChapter 1Matthewzki Ferreras100% (1)

- Movento An Innovative Ambimobile Insecticide For Sucking Insect Pest Control in Agriculture - Biological Profile and Field Performance.Document7 pagesMovento An Innovative Ambimobile Insecticide For Sucking Insect Pest Control in Agriculture - Biological Profile and Field Performance.Victor Lauro Perez GarciaNo ratings yet

- Unit 11Document3 pagesUnit 11Bharath GowdaNo ratings yet

- Basic terms in biochemistry explainedDocument41 pagesBasic terms in biochemistry explainedkumarklNo ratings yet

- Catalytic Reforming PDFDocument3 pagesCatalytic Reforming PDFAbey SamuelNo ratings yet

- Cosmetics Lectures 1,2,3Document72 pagesCosmetics Lectures 1,2,3معلومة كيميائيةNo ratings yet

- Results and Discussion of Lipid Solubility, Identification, and AnalysisDocument5 pagesResults and Discussion of Lipid Solubility, Identification, and AnalysisStarrrNo ratings yet

- Mass Relationships in Chemical ReactionsDocument28 pagesMass Relationships in Chemical ReactionsAries MalicdemNo ratings yet

- Schwald, W. Dan Bobleter, O. Hydrothermolysis of Cellulose Under Static and Dynamic Conditions at High TemperaturesDocument15 pagesSchwald, W. Dan Bobleter, O. Hydrothermolysis of Cellulose Under Static and Dynamic Conditions at High TemperaturesAdhan AkbarNo ratings yet

- Bodycare Soap Base Shower GelDocument2 pagesBodycare Soap Base Shower GelAsep Syaefun NazmiNo ratings yet

- Mi41001 - Uric - Acid-Lq - 2017Document4 pagesMi41001 - Uric - Acid-Lq - 2017Dafne Manrique JerezNo ratings yet

- Power Plant Fuels ModuleDocument18 pagesPower Plant Fuels ModuleCllyan ReyesNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- GHS MSDS R200P enDocument7 pagesGHS MSDS R200P enUsman AmjadNo ratings yet

- Agar-Agar Extraction, Structural Properties and Applications: A ReviewDocument7 pagesAgar-Agar Extraction, Structural Properties and Applications: A ReviewKarthikeyan SivashanmugamNo ratings yet

- General Biology (Biol. 1012) : Course Instructor: Kabeta LegeseDocument48 pagesGeneral Biology (Biol. 1012) : Course Instructor: Kabeta LegeseKena MegersaNo ratings yet

- Desmet Ballestra Biodiesel Technologies PDFDocument8 pagesDesmet Ballestra Biodiesel Technologies PDFRabindranath Hendy TagoreNo ratings yet

- STEM Biology Module on ATP-ADP Cycle and PhotosynthesisDocument10 pagesSTEM Biology Module on ATP-ADP Cycle and PhotosynthesisTheworld Magic100% (1)

- Standard Parameters and Values For Drinking Water Quality Philippine National Standards For Drinking Water: Code On Sanitation of The PhilippinesDocument9 pagesStandard Parameters and Values For Drinking Water Quality Philippine National Standards For Drinking Water: Code On Sanitation of The PhilippinescilovNo ratings yet

- Shinetsu FC-312 Sealant Black Catalyst-Aus GHSDocument7 pagesShinetsu FC-312 Sealant Black Catalyst-Aus GHSAreIf Cron BmxStreetNo ratings yet

- Soil Biological PropertiesDocument27 pagesSoil Biological PropertiesFitri Abdul AzizNo ratings yet

- Aldehyde and KetoneDocument72 pagesAldehyde and KetoneDalbir ToorNo ratings yet

- Ru Du PhosDocument6 pagesRu Du Phossiti emeliaNo ratings yet

- Common Coating FormulationsDocument13 pagesCommon Coating FormulationsLong An Đỗ100% (2)

- Comparing The Use of A Two-Stage MBBR System With A Methanogenic MBBRDocument8 pagesComparing The Use of A Two-Stage MBBR System With A Methanogenic MBBRVijaya GosuNo ratings yet

- Gfps 6219 Brochure Ecofit All You Need in Pe enDocument12 pagesGfps 6219 Brochure Ecofit All You Need in Pe endfdfdNo ratings yet